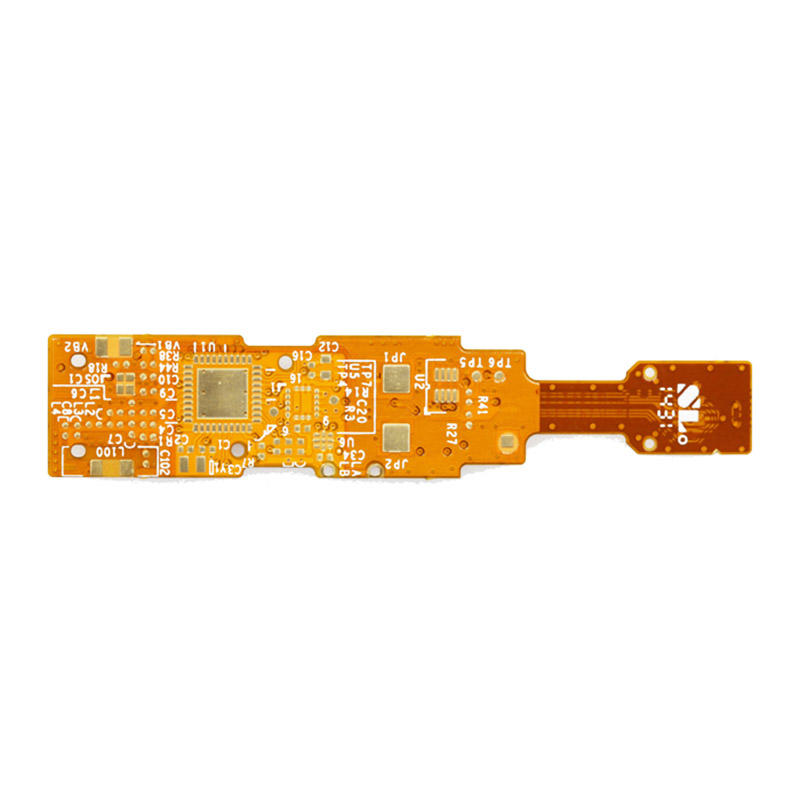

With the growing market of electronic products, the upgrading and updating of electronic products, "light, thin, short, small" and three-dimensional assembly have become the mainstream of the development of electronic products. As the carrier board of electronic components, FPC meets the more and more elaborate development needs of electronic products, and has obvious advantages and potential capabilities. As a result, its position in the production and market of printed circuit boards has attracted more and more attention. At present, FPC is growing at a rate of over 20% annual plant value, and it plays an important role in the PCB market share.

Flexible PCBs have some very amazing benefits including:

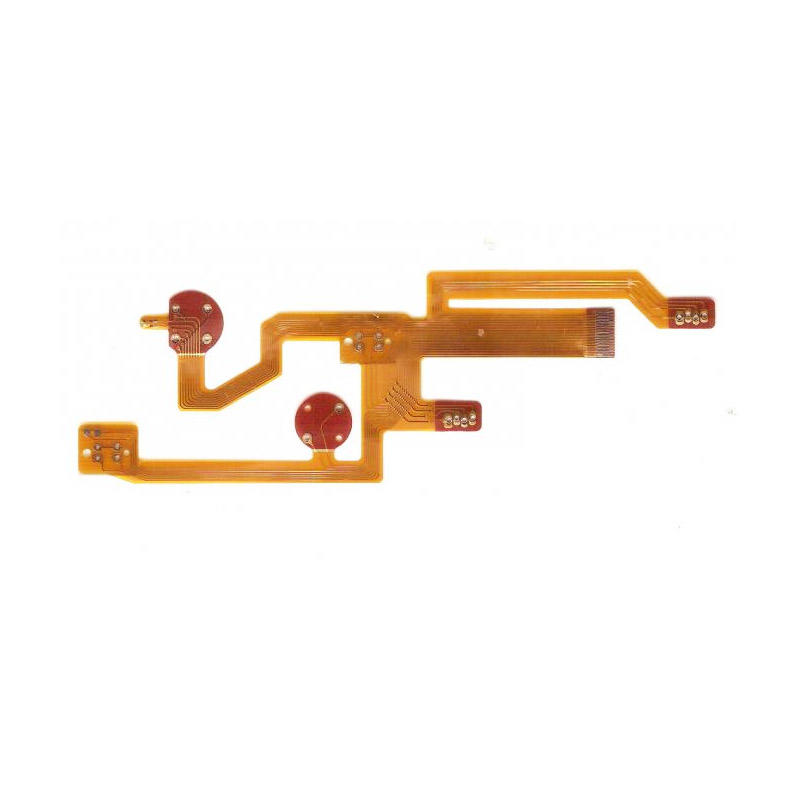

1. Flexibility

This is the most significant advantage of FPC. FPC can conveniently wiring or stereoscopic installation in three-dimensional space by flexing and folding.

2. Small size

Because of the different design, the conductor section of FPC is thinner and flatter than that of cable conductor in assembly, which reduces the size of conductor. Moreover, the lightness and flexibility of conductor medium make the overall structure of the equipment equipped with FPC more compact and reasonable. Compared with rigid board, space can be saved by more than 60%.

3. Light weight

The material of FPC determines the light weight of the product. In the same volume, compared with the cable conductor, the weight of the cable conductor can be reduced by about 70% at the same current carrying capacity, and about 90% compared with the rigid PCB.

4. Eliminate installation errors

Using cable conductor to install wiring is easy to make mistakes in the process of installation or maintenance, resulting in frequent rework or waste of time to find out the cause of the problem. FPC does not have this problem, as long as the design drawings are proofread, the products produced are consistent, no connection errors, the use of FPC also eliminates cable conductors, to provide a clear appearance of the equipment.

5. Increase reliability

Using FPC to connect can wiring on X, Y and Z planes, which reduces switching interconnection, increases the reliability of the whole system, and provides convenience for fault detection.

6. Controllable electrical parameters

Compared with cable conductors, FPC can control electrical characteristics such as capacitance, inductance, characteristic impedance, delay and attenuation by designing parameters such as line width, line spacing, line thickness, dielectric thickness and dielectric constant, which are difficult for cable conductors to achieve.

7. Reducing total cost

The use of low-cost FPC can reduce the overall cost of equipment. FPC can avoid the use of multiple rigid boards and a large number of cable conductor combinations at the same time, often only need to process a flexible board or rigid-flexible combination board can be replaced; FPC can be integrated, can be transferred to the components, reducing the cost of clamping and fixing parts.

◪ 24 hour real-time technical support. Fast turn around with 24 hours and fast quote in 2 hours. For high frequency board, the lead time will be based on the parameters and specifications.

◪ Effective and flexible PCB engineering solutions save your cost. We always focus on customer first when providing innovative solutions for manufacturing clients' products,we are more than pleased to help customers grow.

◪ Rapid suggestions on the layout, build-up, panels, impedance, material selection, design rules, manufacturability, costs of different solutions, use of micro vias, gold plating, special laminates, etc.

◪ Strong partnerships with different reputed A-class material suppliers such as Rogers, Arlon, Nelco and Taconic can realize a fast service to a wide range of high frequency PCB applications.

◪ Dozens of tests such as open/short circuit testing( ET test), AOI, X-ray, impedance testing, solderability testing, thermal shock testing, metallographic micro-slicing analysis, halogen-free testing, etc. 100% OQC inspection.

◪ Complete services like free Design Rule Check (DRC), free DFM, traceable manufacturing to complete after-sales service, on time delivery 99%.

◪ We will keep secret for customer sale area, design ideas, drawing and all other private information.

◪ Flexible payment terms. Samples for 100%TT, mass production payment: 50% advance payment 50% balance should be paid off before loading or accept monthly statement based on the order volumes.

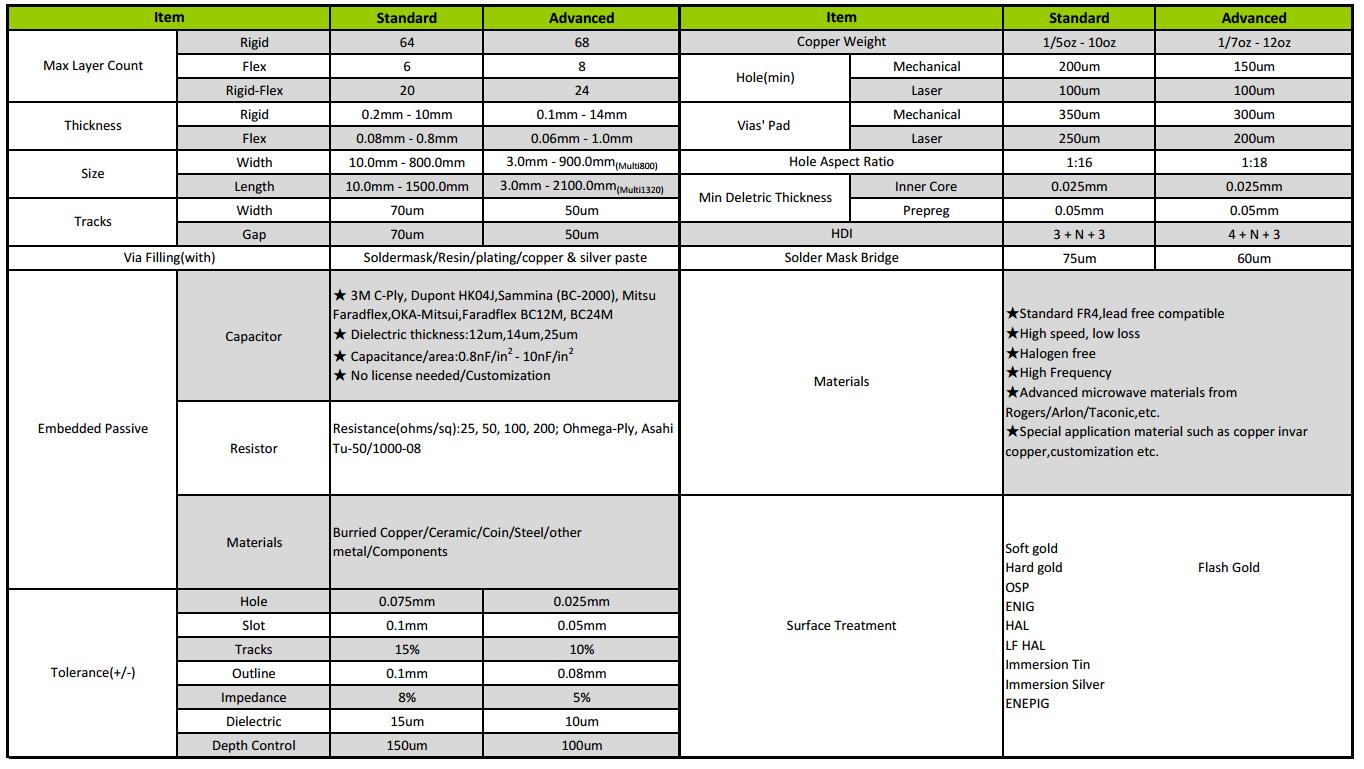

Capability List

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink