What is metal core PCB

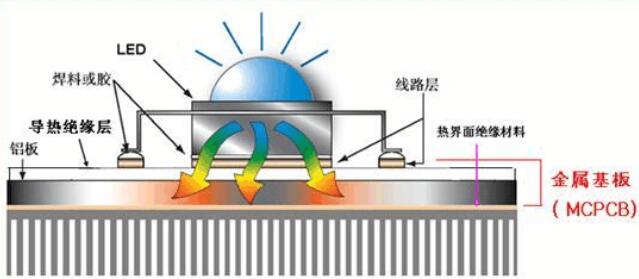

Metal core PCB is also called IMS (insulated metal substrate) PCB, metal PCB, MCPCB, Metal clad PCB. Metal core printed circuit board is a composite printed circuit board made of the metal substrate, insulating medium layer, and circuit copper layer. The metal base is usually aluminum, iron, copper, invar copper, tungsten molybdenum alloy, and so on. The insulating layer is usually modified epoxy resin, polyphenylene oxide, polyimide, and so on. The thickness of the insulating layer is 50μm-200μm. The circuit layer is composed of a copper layer. The thickness of the metal plate is 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, and 3.0 mm. Like rigid-flexible printed circuit boards, metal-based printed circuit boards can be divided into single-sided, double-sided, and multi-layered, which is a special variety of printed circuit boards.

Types of metal substrates PCB

Classification of metal-based copper-clad laminates:

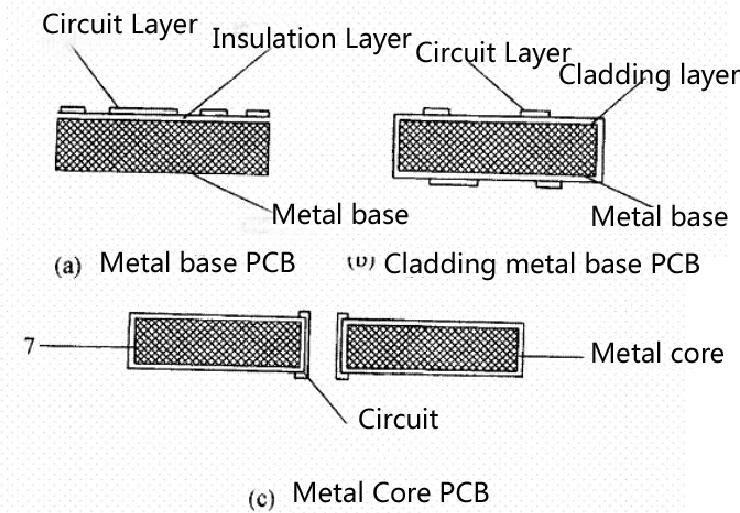

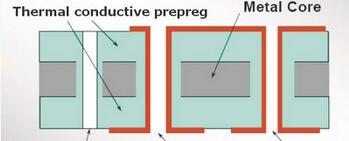

According to the structure of the metal substrate, there are three common types:

Metal substrate

Coated metal substrate

Metal core substrate

The metal substrate is based on metal (aluminum, copper, iron, molybdenum, etc. ) and covered with an insulating medium layer and conductive layer (copper foil);

The coated metal substrate is a base material which is made by coating a layer of glaze on the six sides of the metal plate and sintering, on which the conductor circuit diagram is made by silk-screen printing and sintering;

Metal core substrate generally consists of invar (iron-nickel alloy) core material, which is coated with a layer of organic polymer insulating medium, or compounded on the semi-cured sheet or PET film, and coated with conductive foil (some directly from a conductive pattern by addition method).

Among them, the metal substrate is the most common and most used one.

Metal substrates are classified according to their composition and can be divided into:

Aluminum-based copper clad laminate

Iron-based copper clad laminate

Copper-based copper clad laminate

Molybdenum-based copper clad laminate

Metal-based copper clad laminates are classified in terms of characteristics and can be divided into:

General metal-based copper-clad laminates

Flame-retardant metal-based copper-clad laminates

High heat-resistant metal-based copper-clad laminates

High thermal conductivity metal-based copper-clad laminates

Ultra-high thermal conductivity metal base copper clad laminate

High frequency, microwave type metal base copper clad laminate

Multilayer metal base copper clad laminate

Here are several common types of metal substrates:

Aluminum base PCB

Aluminum base PCB, also known as aluminum PCB, has three parts,

1. Circuit layer (copper layer) this is the printed circuit copper foil layer, from 1. 0 ounces to 8 ounces (35um-280um). Min. Trace/space 5/5mil (0.127/0.127mm)

2. Dielectric layer (insulating layer) if the raw materials have a good price and delivery time, we can choose the materials produced in China and Taiwan. We also have many customers who choose Bergquist thermal clad and larid tlam materials to strictly meet the requirements of customers to produce Al-PCB.

3. There are four kinds of aluminum in the substrate layer (metal layer), 1001, 3001, 5052, 6063. If not, we use 5052 for high thermal conductivity (2.0w /MK or higher), al1001, al3001 for 1.0w /MK to 1.5w /MK.

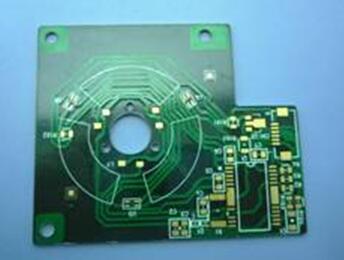

Aluminum clad PCB

It can be used as one layer of non plated through-hole (single layer) and 2 + layer of through-hole. the ideal application of power solutions and LED lighting.

The advantages of aluminum cladding include:

Reduce the working temperature.

Reduce PCB size.

Improve power density.

Extend the life of the chip.

Reduce the number of interconnects.

Improve the thermal and mechanical properties of products.

Combine power and control. Improve product durability.

Better use of surface mount technology.

Speed up heat sink and other installation hardware.

Replacement of fragile ceramic substrate, with higher mechanical durability

About price:

The price is based on the requirements of LED PCB

1. PCB thickness: 0.6 - 3.0mm, more total thickness, higher price

2. Thermal conductivity: 1.0 - 10W / m. k, higher thermal conductivity, higher price

3. Material factory: Bergquist, Laird, etc, made in the USA, more expensive than China.

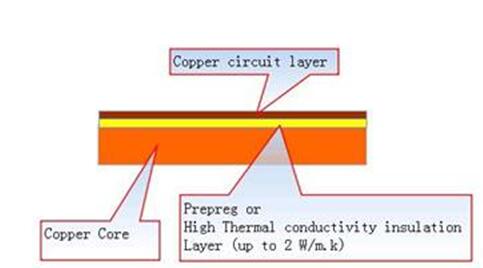

Copper core PCB

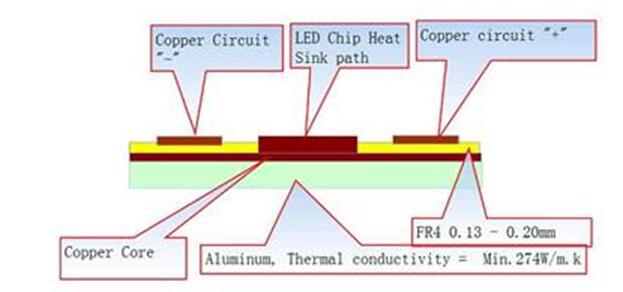

Copper core PCB is copper substrate + insulation layer + copper circuit layer PCB, also known as copper substrate PCB, copper-based PCB, copper clad PCB.

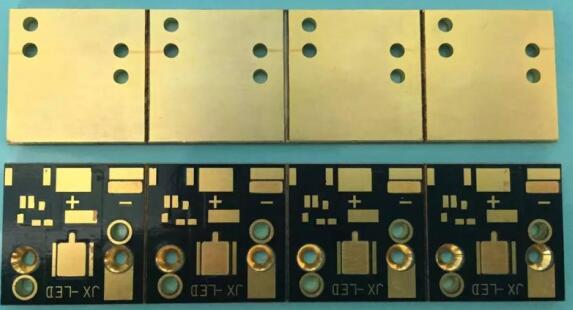

As a manufacturer of MCPCB, Rocket PCB manufactures various copper core PCBs for high-power LED lighters (1000W +).

In the field of LED, there are four types of copper-based circuit boards.

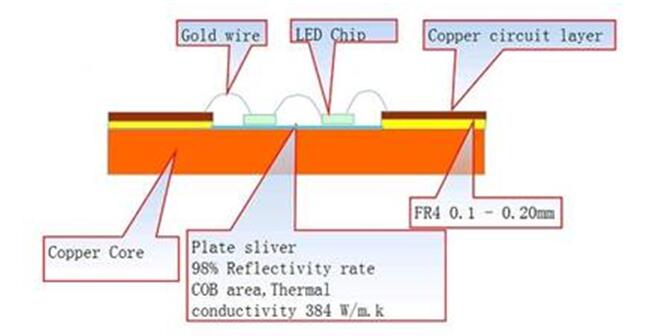

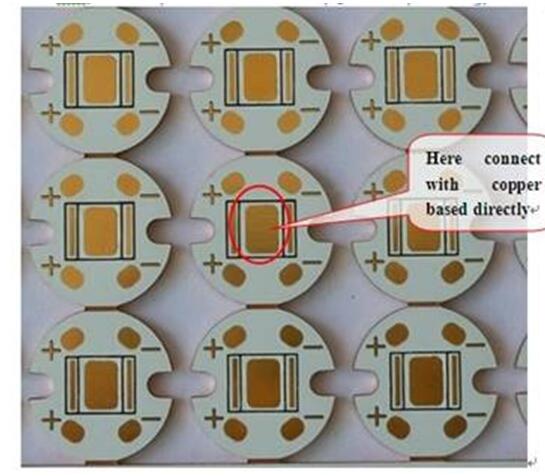

COB copper PCB (copper PCB on board) led chip directly radiates heat to the copper substrate

Copper-based COB PCB

Direct thermal path. There is no dielectric layer under the thermal path pad.

Aluminum-copper PCB

Direct thermal path, no dielectric layer, aluminum copper PCB.

Iron Based PCB

The PCB material based on iron for the base comes from FR4 or cem1 supports such as special steel and silicon steel, which can dissipate heat from keyboard components and to less important areas, such as metalcore or metal radiator backing.

Chinese PCB manufacturers are becoming more and more specialized in iron-based PCB.

Iron-Based PCB has all the functions of metal materials and has the following characteristics:

① Occupied area to facilitate further machinery, procurement, and fixed base;

② High mechanical strength, suitable for assembling electronic parts of paradise;

③ Silicon steel is ferromagnetic and can be used in VTR, FDD, and other micromotors.

Characteristics of various metal substrates

Iron based copper-clad laminate and silicon steel copper-clad laminate have excellent electrical properties, magnetic conductivity, voltage resistance, and high substrate strength. It is mainly used for brushless DC motor, recorder, recorder spindle motor, and intelligent driver. But the magnetism of silicon steel CCL is better than that of iron-based CCL;

Copper-based copper clad laminate has the basic performance of aluminum-based copper clad laminate, and its heat dissipation is better than aluminum-based copper clad laminate. This kind of substrate can carry a large current and is used to manufacture PCBs for high-power circuits such as power electronics and automotive electronics. However, due to its high density, high value, and easy oxidation, its application is limited, and its consumption is far lower than aluminum-based copper clad laminate.

Aluminum based copper clad laminate has excellent electrical performance, heat dissipation, electromagnetic shielding, high voltage resistance and bending performance. It is mainly used in automobiles, motorcycles, computers, home appliances, communication electronic products, and power electronic products.

Comparison of common metal substrates

Copper base: good thermal conductivity, used for heat conduction and electromagnetic shielding, but heavy, expensive.

Iron-based: anti-electromagnetic interference, shielding performance is the best, but the heat dissipation is slightly poor, the price is cheap

Aluminum base: good heat conduction, not too heavy, lightweight, electromagnetic shielding is also good.

Application fields of MCPCB

Aluminum based copper clad laminate is the most widely used metal PCB substrate in the market. Its application examples are as follows.

Automotive electronic equipment: igniter, voltage regulator, automatic safety control system, lighting conversion system, AC converter, SW power supply;

Motorcycle electronic products: power regulator, igniter, voltage regulator;

Computer: power supply device, floppy disk drive, CPU;

Power Supply;

Switch regulator, transfer switch, DC-DC converter, voltage regulator, regulator, DC-AC converter, large power supply, solar power substrate;

Communication electronic products: car phone, mobile phone high-frequency amplifier, filter circuit, transmitter circuit;

Electronic control: relay, transistor base;

Switch;

Radiator, semiconductor device insulation heat conduction plate, motor controller;

Others: IC chip carrier, air conditioner.

Thermophysical properties of metal PCB substrate

Material name | Thermal conductivity w / m ° C | relative density Kg/m℃ | specific heat J/kg-℃ | Thermal diffusivity MM²/s | Thermal resistance ℃ / W | The rising temperature of components is 5W |

Metal aluminum base plate 1.0mm | 237 | 2688 | 0. 905 | 96. 8 | 2. 8 | 14℃ |

Metal copper base plate 1.0mm | 398 | 8880 | 0. 368 | 117 | - | - |

Metal iron base plate 1.0mm | 80. 3 | 7870 | 0. 442 | 22. 7 | 4. 6 | 23℃ |

FR4 1.2mm | 0. 3 | 1850 | 1. 1 | 0. 14 | 14 | 70℃ |

Aluminum ceramic composite substrate | 36 | 3896 | 0. 779 | 11. 89 | - | - |

Market development trend of metal PCB

With the development of electronic technology, the market demand for aluminum based copper clad laminate is heating up. At the same time, the technical requirements for metal PCB substrate are also higher and higher,

A higher thermal conductivity is required for metal PCB substrate;

B. the aluminum-based copper clad laminate is required to withstand higher breakdown voltage, and the maximum breakdown voltage is required to be as high as 15 kV (DC, AC). The Research Institute of 704 plants has been able to provide aluminum based copper-clad laminates with withstand voltage of 8 kV (AC) and 10 kV (DC);

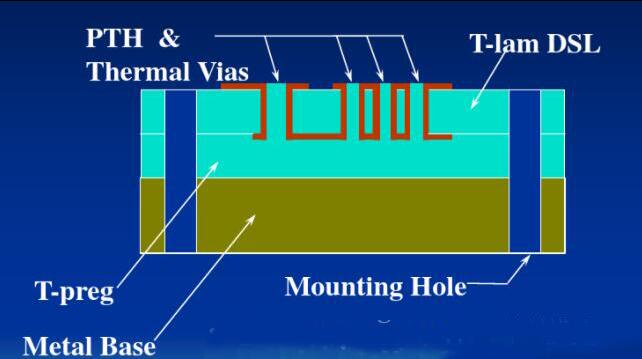

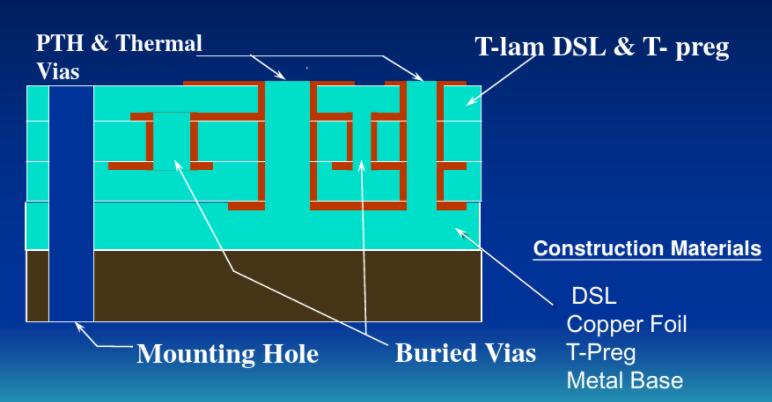

With the development of multilayer aluminum substrate, high thermal conductivity aluminum based CCL sheet and thermally conductive adhesive film are needed.

Advantages of Metal Core PCB

Metal based printed circuit board has the following characteristics,

① Excellent heat dissipation performance. Metal based copper clad laminate has excellent heat dissipation performance, which is the most prominent feature of this kind of plate. The PCB made of it can not only prevent the temperature rise of components and substrate loaded on PCB, but also rapidly dissipate the heat generated by power amplifier components, high-power components, large circuit power switches, and other components. Among the different types of metal substrates, the metal substrate with copper as the substrate has the best heat dissipation performance. However, if the copper plate and aluminum plate are used with the same volume ratio, the copper price is high and the density is high, which is not suitable for the development of lightweight substrate materials, so it is not widely used. Only when manufacturing high heat dissipation metal substrate, a small amount of copper plate is used. The aluminum plate has better heat dissipation than the iron plate.

② Good machinability. Metal-based copper-clad laminate has high mechanical strength and toughness, which is much better than rigid resin-based copper-clad laminate and ceramic substrate. Therefore, a large area of PCB can be manufactured on the metal substrate. Heavy components can be installed on this kind of substrate. In addition, the metal substrate also has good flatness, which can be used for hammering, riveting, and other assembly processing on the substrate. On the PCB made of it, the nonwiring part can also be processed by bending and twisting.

③ Excellent dimensional stability. For all kinds of CCL, there is thermal expansion (dimensional stability) problems, especially the thermal expansion in the thickness direction (Z-axis), which affects the quality of metalized holes and circuits. The coefficient of linear expansion of iron and aluminum substrate is much smaller than that of the general resin substrate and closer to that of copper, which is conducive to ensuring the quality and reliability of the printed circuit.

④ Electromagnetic shielding. In order to ensure the performance of electronic circuits, some components in electronic products must prevent electromagnetic radiation and interference. The metal substrate can act as a shielding plate to shield electromagnetic waves.

⑤ Electromagnetic characteristics. The substrate material of iron-based copper-clad laminate is an alloy of iron series elements with magnetic properties (such as silicon steel plate, low carbon steel, galvanized cold-rolled steel plate, etc. ), which is used in small precision motors such as tape recorder (VTR), floppy disk driver (FDD), servo motor, etc. The metal-based copper clad laminate not only plays the role of PCB but also plays the role of a small motor stator substrate.

Our Metal core PCB capabilities

Layer counts | Al-base, Copper-base: 1-8L coated-metal, embedded metal: 2-24L. |

PCB size (Finished) | MAX:610*610mm, MIN:5*5mm

|

PCB thickness(Finished) | 0.5-5.0mm |

Copper thickness(Finished) | 0.5-10 OZ |

Metal thickness | 0.5-4.5mm |

Metal material type | AL: 1100/1050/2124/5052/6061 Copper-base: c1100 Stainless-steel base: 202, 304, 430 |

Min finished hole size&tolerance | NPTH:0.5±0.05mm; PTH(Al-base, Cu-base):1.0±0.1mm; PTH(coated-metal sintering, Embedded metal):0.2±0.10mm; |

Dimension tolerance | ±0.05mm |

PCB partial surface treatment | HASL, LF-HASL;OSP, ENIG, ENEPIG, Plating(Ni)Soft/Hard gold, Plating Sn, immersion Sn/silver |

Material | Totking(T-110、T-111)、Ventec (VT-4A1、VT-4A2、VT-4A3);Domestic brand, customer supply |

Thermal glue thickness (dielectric layer) | 75-150μm |

Buried copper block size | 3*3mm—60*80mm |

Buried copper block drop tolerance | ±3mil |

Min gap between Buried copper block and hole wall | ≥12mil |

Thermal conductivity | 0.3-3W/m.k(copper and aluminum base) 8.33W/m.k(sintering board) 0.35-30W/m.k(embedded metal) |