Small batch more varieties quick delivery customized PCB making

Rocket PCB has an abundance of industry experience of small batch PCB manufacturing, after a period of industry development and customer build up, has built good relations of cooperation with world-famous enterprises, continues to be identified by customers with regards to product quality stability, technical level and technical service, and it has formed a larger brand awareness on the industry.

Two layers PCB boards are broadly used and comparatively easy, every PCB manufacturer can perform it, therefore the levels of competition are always around the cost.

Part of PCB manufacturers use poor quality CCL, soldermask can also be relatively cheap, the surface treatment is thin,resulting in cost variations.

At Rocket PCB,we've been using A-class FR4 materials, never scrimp, our technique is small profits but quick turnover, so within the premise of quality assurance, our PCB cost is extremely competitive.

Strong fabrication strength, can meet the bulk needs of different clients

> Well-known cooperative suppliers import advanced equipment and production technology from Germany, Japan, Taiwan and other regions, with a monthly output of up to 250,000 square meters.

> Our suppliers have formed a complete production process, which is becoming more specialized, modern and large-scale.

> We passed ISO 9001 quality system, TS16949, UL standard, ROHS standard and SGS lead-free certification and related industry certifications.

Technical Advantages

> We provide real-time and in-depth technical support to shift your PCB products from conceptual design to mass production. Tailor-made application solutions, like high speed, high capacity and high frequency, press-fit, heat-sink solutions

> In general, customers provide gerber files and Rocket senior R&D engineers team audit and optimize them free of charge (Free DRC and DFM)

> For customers with special requirements, we can provide personalized solutions, design drawings, develop new products, and provide relevant technical support according to their needs and combined with our practical experience.

Service Advantages

> Multiple production lines meet the requirements of mass production and quick turnover of small batches and various prototype PCBs

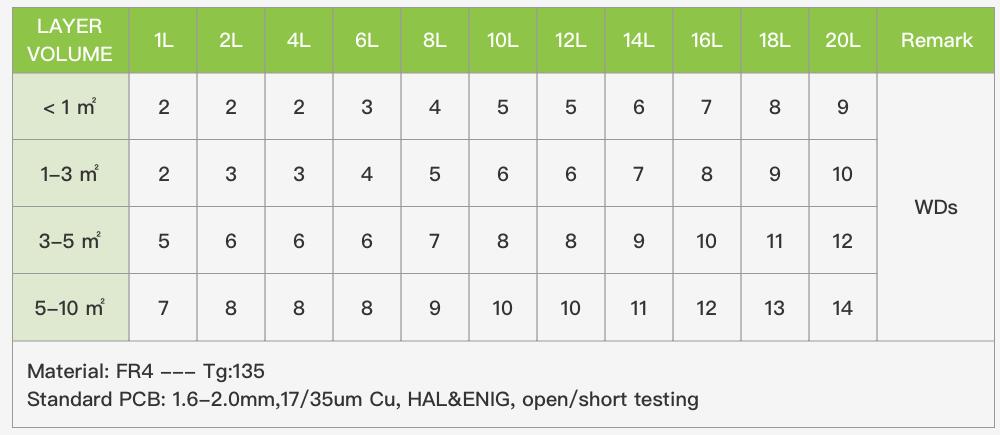

> Expedited production line for prototyping double-sided up to 24 hours, 4 layers 48 hours, 6 layers 72 hours etc.

> Mass production of double-sided board 5-6 days lead time, multi-layer board 7-9 days.

> DHL, Fedex, TNT, UPS Express Direct, fully meet the customer's time requirements.

> Strict production and testing, 100% outgoing pass rate

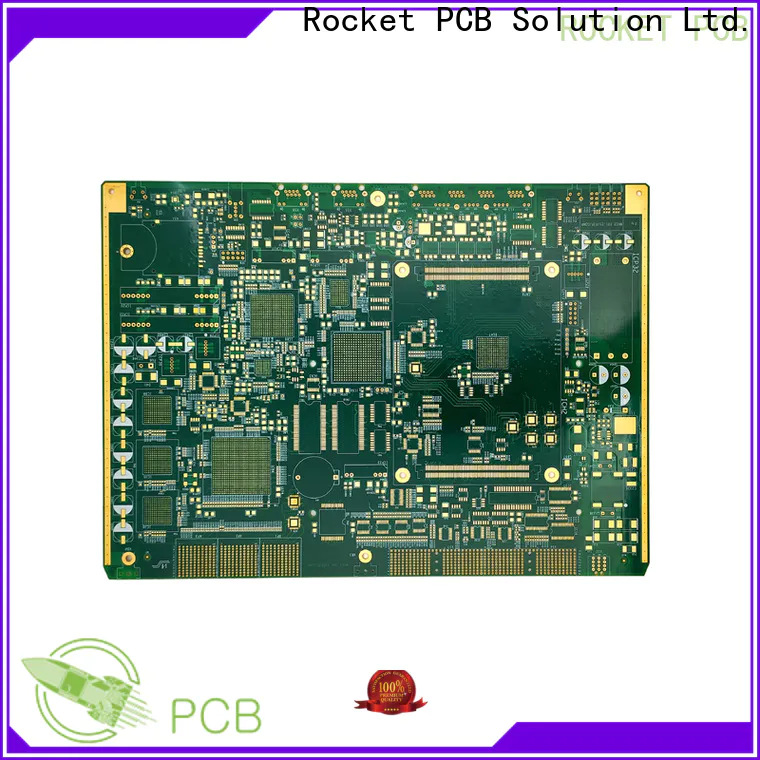

> Provide 1-64 layers of different thickness, different materials, different processes of product customization, of which the CCL using A-class raw materials, high quality assurance;

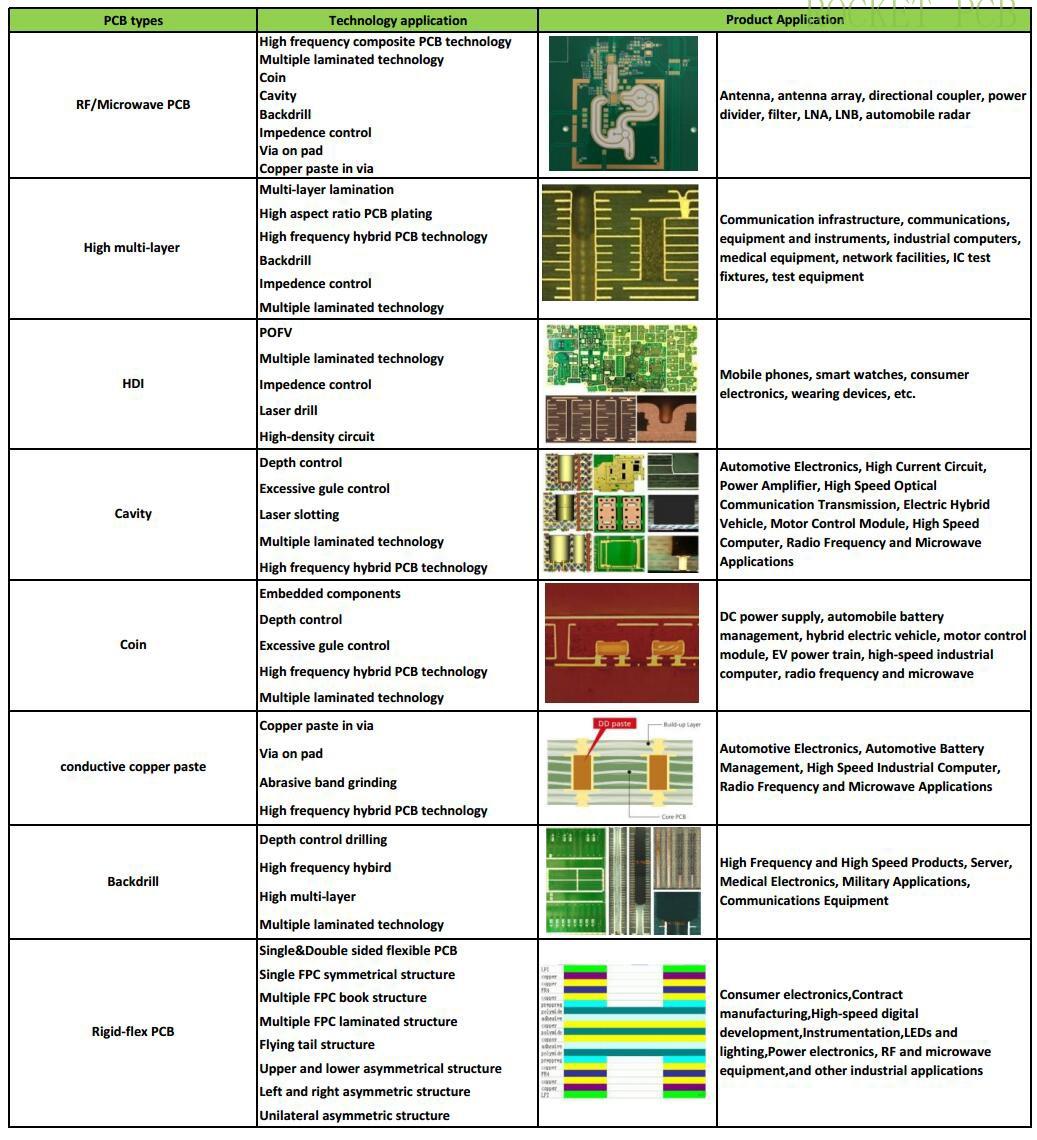

> Advanced technology for rigid, rigid-flex, flexible, RF, metal core, backplane, ceramic, HDI and so on.

> Eight major surface treatment technology and high-quality ink printing, beautiful and reliable

> Dozens of tests such as open/short circuit testing, impedance testing, solderability testing, thermal shock testing, metallographic micro-slicing analysis, halogen-free testing, etc.Rocket PCB supply chain meticulously practices all-around quality management and actively introduces and implements multi-domain system management. We have successively obtained ISO9001, ISO14001, IATF16949, OHSAS18001, ISO/IEC27001, ISO13485 and AS9100 certifications.

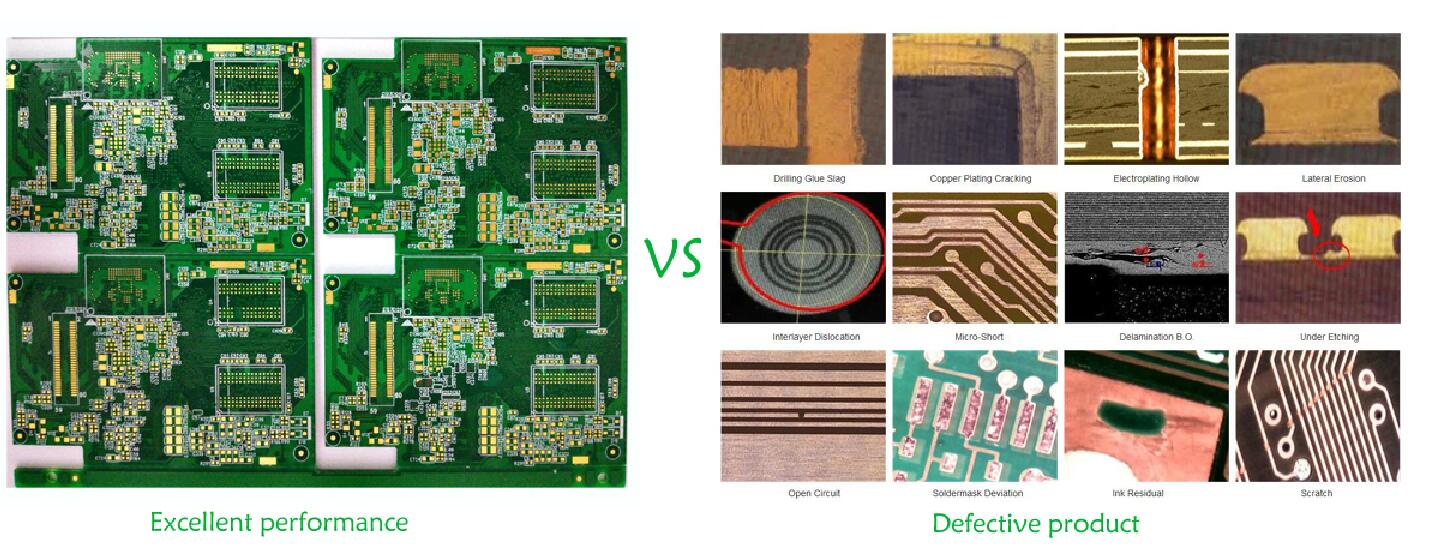

PCB market producing levels is usually unequal, in comparison with some other low-end makers, we've unmatched positive aspects. Low-end making factories are going through numerous quality problems as a result of out-of-date machines, confused spot operations, unbalanced operation, bad quality manage, not enough expertise of engineers and inadequate routine manage.

Copyright © 2026 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink