If you need a prototype printed circuit board, it is important to work with a manufacturer who can complete the manufacture quickly. Before starting standard production, these boards help verify that your design is correct, thus avoiding costly errors. The sooner you get the prototype circuit board, the sooner you complete the test and enter the standard batch production process.

We provide a fast convertible prototype PCB, while still fully complying with your design specifications. The PCB prototype service is the perfect way to ensure that there are no errors in the design before entering mass production.

PCB Fast PCB conversion-Fast PCB prototyping means you can quickly test your circuit board.

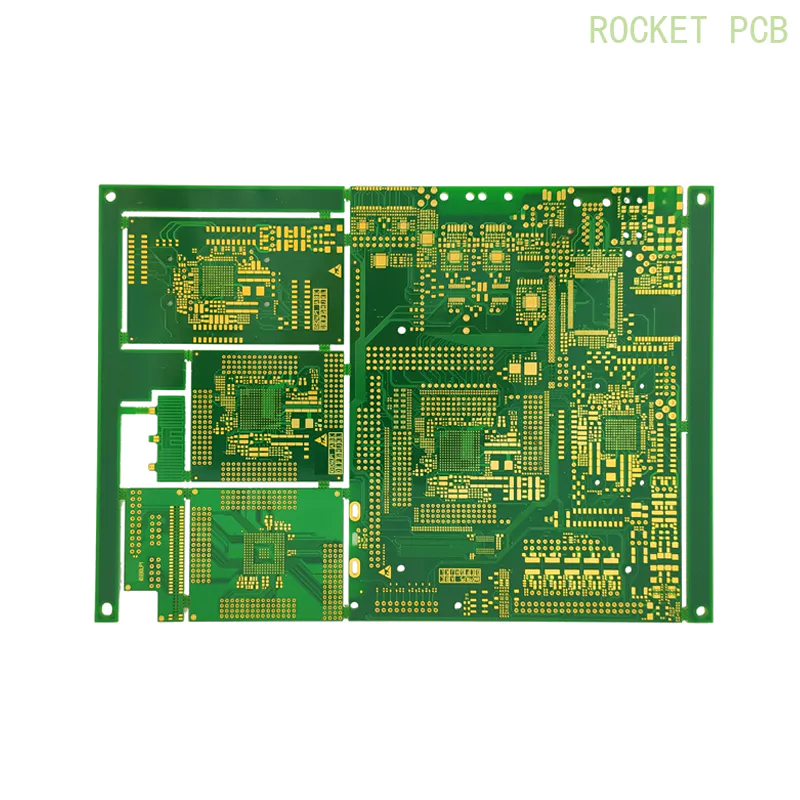

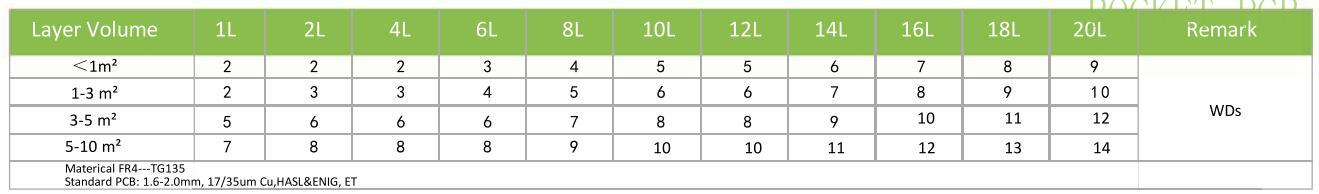

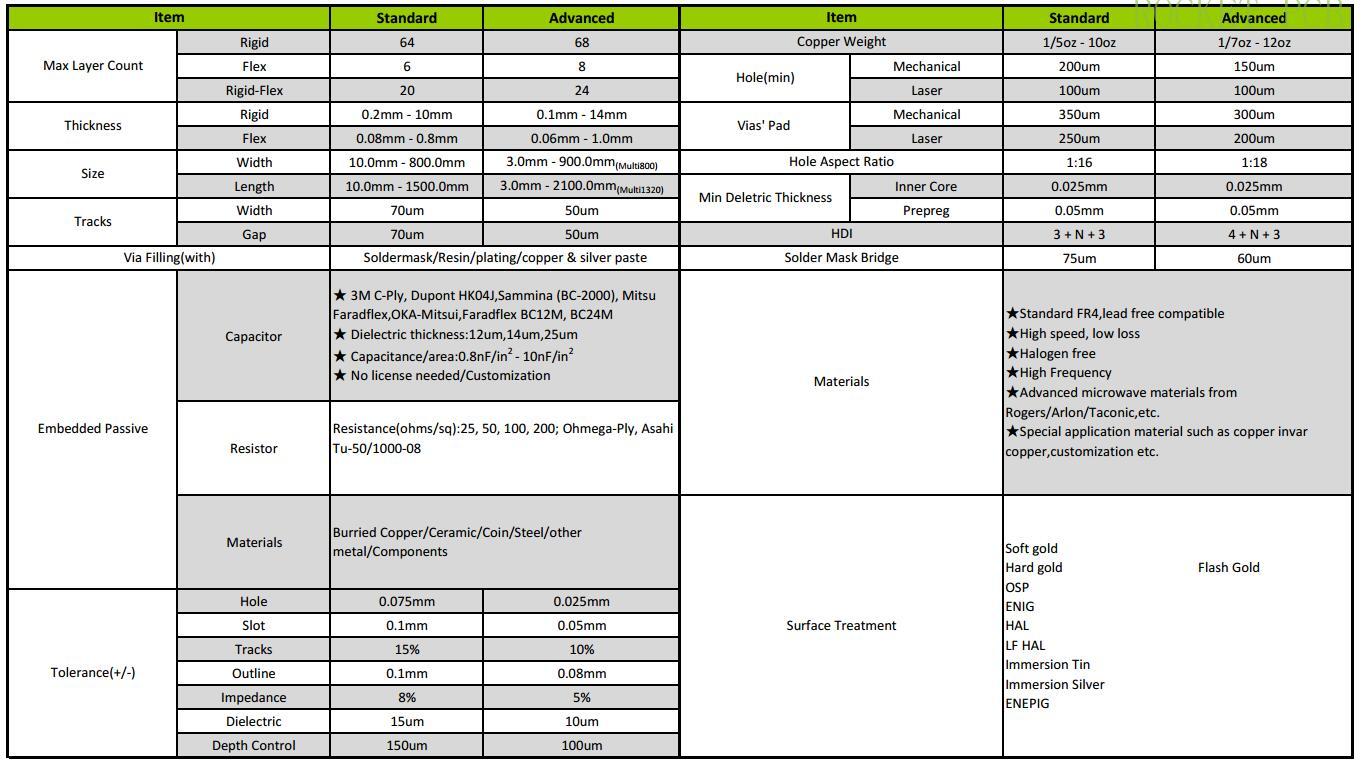

We provide rapid PCB prototyping of 2-64 layers. More than 8 layers of rapid prototyping depends on the processing technology, and it will take longer. We are still very good at prototyping high multi-layer PCB, responding quickly, and the quality standard is IPC2 or higher according to customer requirements.

Usually, customers are most concerned about the prototyping price and want to complete the design phase testing at a low cost. Rocket PCB provides PCB prototypes and standard PCB.

With prototyping services, quickly build a small number of circuit boards using basic materials and deliver them to you in a few days. You can test the circuit board to identify any design defects before making a huge investment in PCB manufacturing based on this design.

We strongly recommend that you use our PCB prototype service.You will spend very little time verifying that your design is feasible and can save a lot of time and money.

You will get a sample PCB price below the market average price from Rocket PCB without sacrificing quality. Even in the sample stage, we always adhere to meet the industry IPC-2 standards, meet the production ISO9001, in line with ROHS, advanced equipment and standard management to ensure that our sample quality is ahead of other competitors, which is the key to maintain our reputation.

Rocket PCB provides PCB engineering solutions that help optimize all stages of the manufacturing cycle, from manufacturing, assembly, testing, delivery to service. Rocket PCB adheres to the following design principles: cost-effectiveness, safety, compliance, time to market, reliability and customer satisfaction.

Our engineering support service can provide customers with the most accurate and in-depth feedback without delay, and all quality problems will be found before manufacturing. We will use our computer-aided manufacturing (CAM) to conduct a complete design review of all prototypes and unfinished circuit board products. With our rich design experience and many years of PCB manufacturing experience, we ensure that there are no defects and help our customers speed up the time to market.

Signal Checks

Solder Mask Checks

Drill Checks

Plane Checks

Silk Screen Checks

… …

Highly automated production ensures production efficiency. Multiple production lines can meet the requirements of mass production and rapid turnover of small batches and various prototypes of PCB.

The factory has invested heavily in importing advanced foreign PCB production equipment, such as Burkle laminating machine, Mitsubishi laser drill, Hitachi machine drill, Japanese screen automatic exposure machine, LDI,AOI, etc., to achieve a high degree of automation of production.

At the same time, our advanced ERP management, supply chain process optimization, forecasting management, replenishment strategy, warehousing and logistics and electronic data interchange (EDI) make production more efficient, keep track of progress in a timely manner, and Rockets are always committed to reducing production preparation time.

Rocket PCB provides 1-64 layers of customized products with different thickness, different materials and different processes, in which copper clad laminates are made of A-grade raw materials with high quality assurance.

Support various types of rigid, rigid-flexible, flexible, RF, metal core, Al-base, ceramic, HDI, backplane, IC carrier board and other advanced PCB technology.

In fact, we have a very strong manufacturing capacity to achieve any PCB process, which is not bragging.

It is our purpose to respond to customers quickly, and we know what efficiency means to customers. At the same time, we provide real-time and in-depth technical support.

Tailored application solutions, such as high speed, high capacity and high frequency, preconditioning, radiator solutions.

Quick feedback on layout, structure, panel, impedance, material selection, design rules, manufacturability, cost of different solutions, use of microholes, gold plating, special laminates, etc.

The level of production in the PCB market is usually unequal and we have an unparalleled positive side.

Low-end manufacturing plants lead to many quality problems due to outdated machines, chaotic on-site operation, unbalanced operation, poor quality management, lack of professional knowledge of engineers and lack of daily management.

High quality is our soul. If there is no quality, there will be no customers. With strong technology development and accumulation, the excellent quality of our supply chain under ISO9001,ISO14001,TS16949,OHSAS1800, UL,ROHS and other systems is guaranteed.

Every stage of the production process tests are treated strictly, from the CAM stage of engineering inspection, to the production stage of dozens of tests such as IQC,AOI,X-ray,100% ET, we always meet the IPC-A-600 quality standards, IPC-6012 control PCB performance.

Other tests include

Electroplating thickness test

Metal through hole inspection

Thermal shock test

Surface exfoliation test

Impedance control test

100% appearance inspection

Solderability test

Ion cleanliness test

Metallographic microscope analysis

High voltage test

Insulation resistance test

Product application

Rocket PCB has rich experience in small batch PCB manufacturing industry, has established a good cooperative relationship with world-famous enterprises, continues to be recognized by customers in terms of product quality stability, technical level and technical service, and has formed a large brand awareness in the industry.

At present, the company has provided services to many customers, including end customers, EMS services, PCB traders and so on. Its downstream applications include consumer electronics, industrial control, medical electronics, communication equipment, 5G communications, automotive electronics, intelligent housing, LED, telecommunications, power, computers, digital products, scientific and educational instruments, aerospace, national defense, military and many other fields.

Have the opportunity to conduct a small test of your PCB design.

Quick turnover of orders.

Quickly find any design defects.

You can change the design without wasting the entire standard production run

If you choose Rocket PCB for PCB prototyping, you will get a very cost-effective service. If you choose Rocket PCB, for PCB prototyping, you will get a very cost-effective service, which is worth your visit.

Product Message

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink