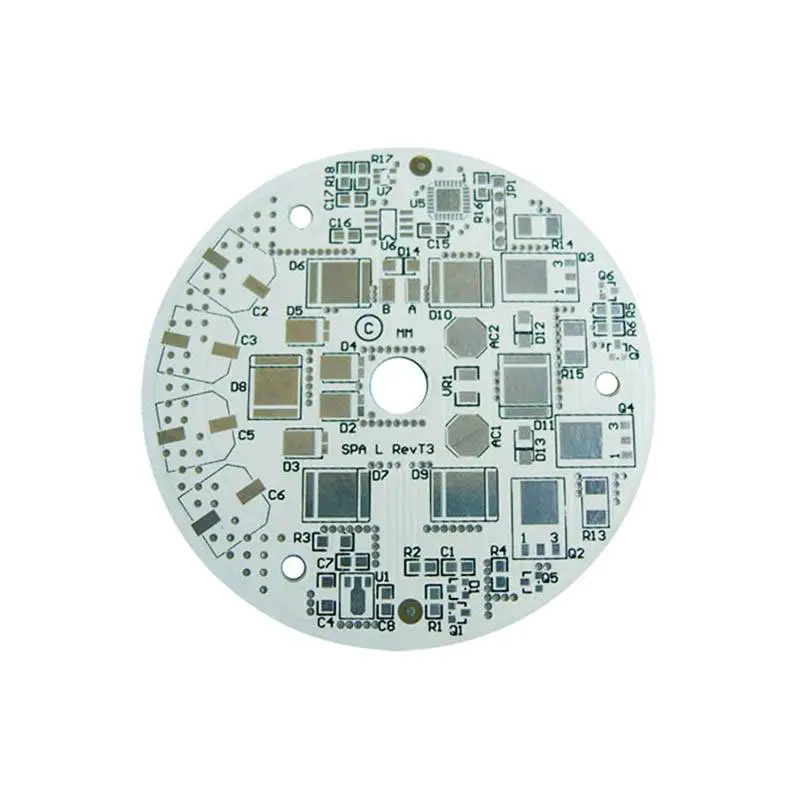

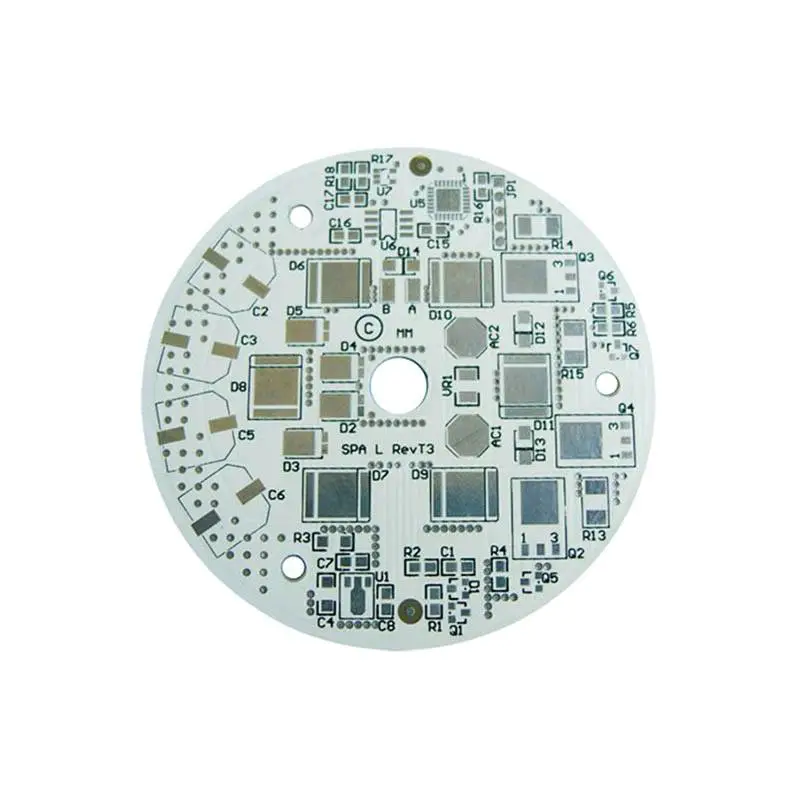

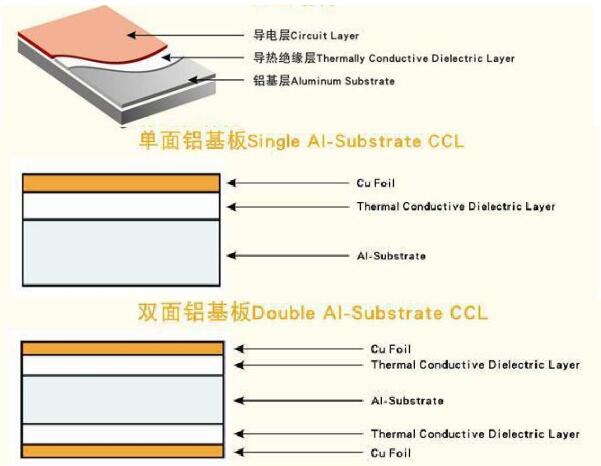

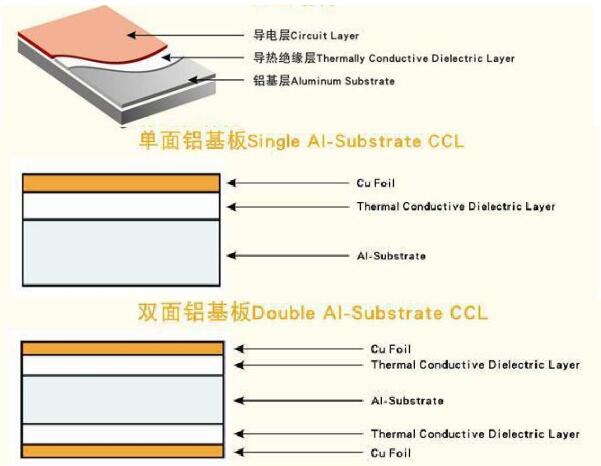

Aluminum PCB Structure

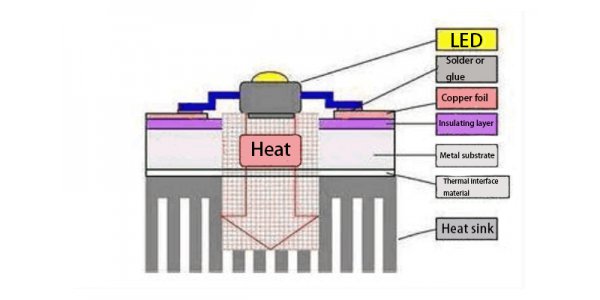

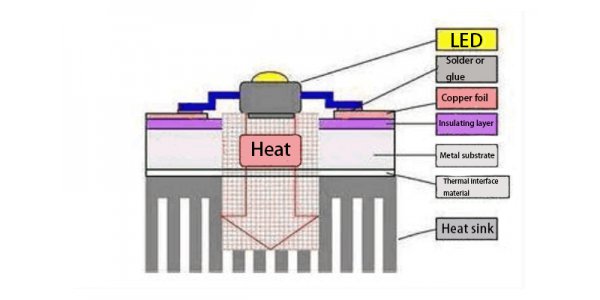

Aluminum-based copper-clad laminate is a kind of metal PCB material, which is composed of copper foil, thermal insulation layer, and metal substrate

Circuit layer: equivalent to common PCB copper clad laminate, circuit copper foil thickness from 1oz to 10oz.

Dielectric layer: insulation layer is a layer of low thermal resistance thermal insulation material. Thickness: 0. 003 "to 0. 006" inch, which is the core technology of aluminum-based copper clad laminate, and has obtained UL certification.

Base layer: it is a metal substrate, usually aluminum or copper. Aluminum-based copper-clad laminates and traditional epoxy glass cloth laminates

Aluminum base PCB (Metal core PCB including aluminum baseboard, copper baseboard, and iron baseboard) is a low alloy Al-Mg-Si system high plastic alloy plate, which has good thermal conductivity, electrical insulation, and mechanical processing performance. Aluminum compared with traditional FR-4, with the same thickness and line width, the aluminum substrate can carry higher current, the withstand voltage of aluminum substrate can reach 4500V, and the thermal conductivity is greater than 2. 0 kW/(m.h.℃)

Aluminum PCB advantages

Aluminum substrate PCB has the following unique advantages:

Meet ROHS requirements;

Surface mount technology (SMT);

In the circuit design scheme, the thermal diffusion is treated effectively;

Reduce the operating temperature of the product, improve the power density and reliability of the product, and extend the service life of the product;

Reduce product volume and hardware and assembly costs;

Replace fragile ceramic substrate for better mechanical durability.

Application of aluminum substrate PCB

Power hybrid IC (HIC)

Audio equipment: input, output amplifier, balanced amplifier, audio amplifier, preamplifier, power amplifier, etc.

Power supply equipment: Switch regulator ` DC / AC converter ` SW regulator, etc.

Communication electronic equipment: High-frequency amplifier 'filter electrical' transmitting circuit.

Office automation equipment: Motor driver, etc.

Automobile: Electronic regulator, igniter, power controller, etc.

Computer: CPU board, floppy disk drive, power supply device, etc.

Power: module Converter, solid-state relay, rectifier bridge, etc.

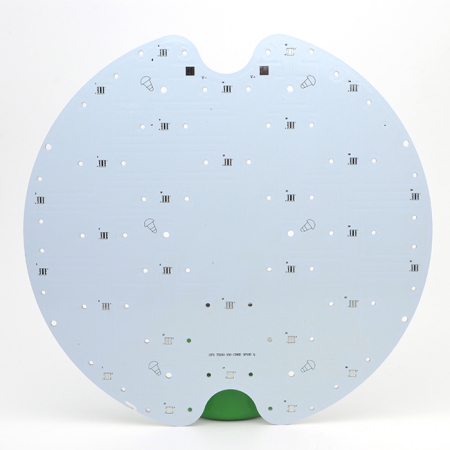

Lamps lighting: With the promotion of energy-saving lamps, all kinds of energy-saving and gorgeous LED lamps are very popular in the market, and the aluminum substrate used in LED lamps has also begun to be applied on a large scale.

Aluminum PCB material

The commonly used metal aluminum baseboards for aluminum substrate mainly include 1000 series, 5000 Series, and 6000 series. The basic characteristics of these three series aluminum materials are as follows:

①� 1000 series represents 1050, 1060, 10701000 series aluminum plate, also known as a pure aluminum plate. In all series, 1000 series has the most aluminum content, and the purity can reach more than 99. 00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is the most commonly used series in conventional industries. Most of the 1050 and 1060 series are in circulation on the market. 1000 series aluminum plate is based on the last two digits to determine the minimum aluminum content of this series. For example, the last two digits of the 1050 series are 50. According to the international brand naming principle, its aluminum content must reach 99. 5% and the top is the qualified product. In China's aluminum alloy technical standard (GB / t3880-2006), the aluminum content of 1050 is 99. 5%. In the same way, the aluminum content of the 1060 series aluminum plate must reach more than 99. 6%.

② 5000 series represents 5052, 5005, 5083, 5A05 series. 5000 series aluminum plate belongs to the common alloy aluminum plate series, the main element is magnesium, the magnesium content is between 3-5%, which is also known as an aluminum-magnesium alloy. Its main characteristics are low density, high tensile strength, and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series, so it is often used in aviation, such as aircraft fuel tanks. In addition, it is widely used in conventional industry. Its processing technology is continuous casting and rolling, belonging to the hot rolling aluminum plate series, so it can do oxidation deep processing. In China, the 5000 series aluminum plate is one of the more mature aluminum plate series.

③ The 6000 series represents 6061, which mainly contains magnesium and silicon. Therefore, it concentrates the advantages of the 4000 series and 5000 series. 6061 is a cold-treated aluminum forging product, which is suitable for applications requiring high corrosion resistance and oxidation resistance. Good usability, excellent interface characteristics, easy coating, and good processability.

6061General characteristics of excellent interface characteristics, easy coating, high strength, good usability, strong corrosion resistance. Typical uses of 6061 aluminum: aircraft parts, camera parts, couplers, ship accessories and hardware, electronic accessories, and joints. Considering the material's texture, hardness, elongation, chemical properties, and price, 5052 aluminum plate is commonly used in 5000 series aluminum materials.

The withstand voltage of aluminum PCB

The withstand voltage of aluminum PCB is a problem that many customers pay attention to. Generally, the withstand voltage value of aluminum base PCB is closely related to the insulation layer, which is normally about 500V. The aluminum substrate is used for different products, the requirements of withstand voltage are different, and some customers require that the withstand voltage should reach 3500-4000v. The treatment method is to thicken the insulation layer of the aluminum substrate. Now let’s learn how to test the withstand voltage of aluminum substrate.

1 First clean the workbench and wear anti-static gloves.

2 Connect the power switch of the voltage tester and set the voltage and circuit for the test.

3 Before connecting the aluminum substrate to be tested, make sure that the voltmeter indicates whether the "0" test lamp is off, and then connect the ground wire.

4 When pressing the start key, make sure that the red probe must be in the direction of no one, and then touch the test key.

5 During the test, if the pressure tester does not sound, the aluminum substrate is not punctured, scorched, and discolored, it is qualified and unqualified

6 After the test, the button must be reset when the aluminum base plate is removed. When the high-voltage input is "0", the product should be removed.

Classification of aluminum substrates

Universal aluminum-based CCL: The insulation layer is composed of epoxy glass cloth adhesive sheet;

High heat dissipation aluminum-based CCL: The insulation layer is composed of epoxy resin or other resins with high thermal conductivity;

Aluminum-based copper-clad laminate is used for high-frequency circuits: The insulating layer is composed of polyolefin resin or polyimide resin glass cloth adhesive sheet.

The biggest difference between Al-based CCL and conventional FR-4 CCL lies in heat dissipation. Compared with Al-based CCL, the thermal resistance of FR-4 CCL with 1. 5mm thickness is 20-22 ℃ and 1. 0-2. 0 ℃ respectively, and the latter is much smaller.

Technical requirements of aluminum substrate

The main technical requirements are as follows:

Dimensional requirements

Including plate size and deviation, thickness and deviation, perpendicularity and warpage;

Appearance

Including crack, scratch, burr and delamination, aluminum oxide film;

Performance

Including peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

Key points of fabricating aluminum PCB

(1) Machining

No burr is allowed in the hole edge after drilling on the aluminum substrate, which will affect the pressure test. It is difficult to mill the shape. And stamping shape, need to use an advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate.

After the shape is punched, the edge is required to be very neat without any burr and the solder mask on the edge of the plate is not damaged. Usually, the operation die is used, the hole is punched from the circuit, the shape is punched from the aluminum surface, the circuit board is up shear and down pull, and so on. After punching, the warpage of the board should be less than 0. 5%.

(2) The whole production process is not allowed to scratch the aluminum base surface: the aluminum base surface will change color and blacken when it is touched by hand or by some chemicals, which is absolutely unacceptable. Some customers do not accept the re-grinding of the aluminum base surface. Therefore, it is one of the difficulties to produce an aluminum base plate without touching the aluminum base surface in the whole process. Some enterprises adopt a passivation process, others stick protective film before and after hot air leveling (tin spraying).

(3) Overvoltage test: 100% high voltage test is required for the aluminum base plate of communication power supply. Some customers require direct current, some require alternating current, voltage requirements are 1500V, 1600V, time is 5 seconds, 10 seconds, 100% printed board is tested. At any point on the board surface, such as dirt, holes, burr on the edge of the aluminum base, line sawtooth, bruise, etc., the insulation layer will lead to fire, leakage, and breakdown of high voltage resistance test. Pressure test board delamination, bubble, are rejected.

Specification for aluminum base PCB fabrication

1. Aluminum substrate is often used in power devices with high power density, so the copper foil is relatively thick. If more than 3oz copper foil is used, the etching process of thick copper foil needs engineering design line width compensation, otherwise, the linewidth will be out of tolerance after etching.

2. The aluminum base surface of the aluminum substrate must be protected with protective film in advance during PCB processing, otherwise, some chemicals will erode the aluminum base surface, resulting in appearance damage. And the protective film is easy to be damaged, resulting in a gap, which requires the entire PCB processing process must be inserted into the rack.

3. The hardness of the milling cutter used in the glass fiberboard Gong board is smaller than that in the aluminum substrate. The speed of production of fiberglass milling cutters is fast during processing, while the production of aluminum substrates is at least two-thirds slower.

4. Computer milling glass fiberboard can only use the cooling system of the machine itself, but the processing of aluminum substrate must be separately targeted at Gong head and alcohol heat dissipation.

Thermal conductivity of aluminum PCB

The thermal conductivity of aluminum substrate refers to the heat dissipation performance parameter of the aluminum substrate, which is one of the three criteria to evaluate the quality of aluminum substrate (thermal resistance and pressure resistance are the other two properties).

The thermal conductivity of the aluminum substrate can be measured by the tester after the plate is pressed. At present, the high thermal conductivity values are generally ceramic and copper. However, considering the cost, the aluminum substrate is recognized by most customers in the market. The thermal conductivity of aluminum substrate is also the most concerned parameter. The higher the thermal conductivity is, the better the performance is. The aluminum substrate is a unique metal-based copper clad laminate aluminum substrate, which has good thermal conductivity, electrical insulation, and machining performance.

Thermal conductivity, also known as thermal conductivity, refers to the physical quantity of a material's thermal conductivity. It refers to the heat (kcal) passing through 1 SQM area within 1H due to heat conduction when the vertical distance of isothermal surface is 1m and the temperature difference is 1 ℃. It is expressed in kW / M. H. ℃.

If the substrate material is required to bear greater heat dissipation efficiency, the substrate material used should have high thermal conductivity (thermal conductivity). If the substrate material is required to be able to achieve the effect of thermal insulation, the lower the thermal conductivity of the substrate material used, the better.

How to check the quality of aluminum PCB is good?

1. Use tools to measure the size, dimensions, and specifications of aluminum substrates, the thickness, size, and shape of the board will directly affect the assembly of the finished product.

2. Make sure to check the thermal conductivity of the aluminum substrate, copper foil, plate thickness, and pressure resistance, which directly affect the performance of finished products and the cost of procurement.

3. The brightness and solder resistance oil of aluminum substrate. Usually, the surface of the aluminum substrate will be covered with a layer of ink, which is mainly used for insulation. If it is found that the surface of the aluminum substrate is not smooth, it is usually covered with less oil, which will lead to poor insulation effect of aluminum substrate.

4. The pad size of the aluminum substrate will directly affect the subsequent patch and line conductivity.

5. If the circuit is close to the edge of the board, we must pay attention to the withstand voltage problem of the aluminum substrate, especially for the purchasers who have requirements on the withstand voltage.

6. Substrate, this is very important. When purchasing, we must select regular and large-scale manufacturers. The incoming materials from these manufacturers are strictly inspected before they are put into production. Its product quality assurance. The aluminum substrate is not just a circuit, it is like a human blood vessel, determines the life of the product.

7. In the production process, regular aluminum substrate manufacturers should ensure the process quality of each process, especially in etching, whether the aluminum substrate is corroded by etching water determines how long the aluminum substrate you purchase can be used.

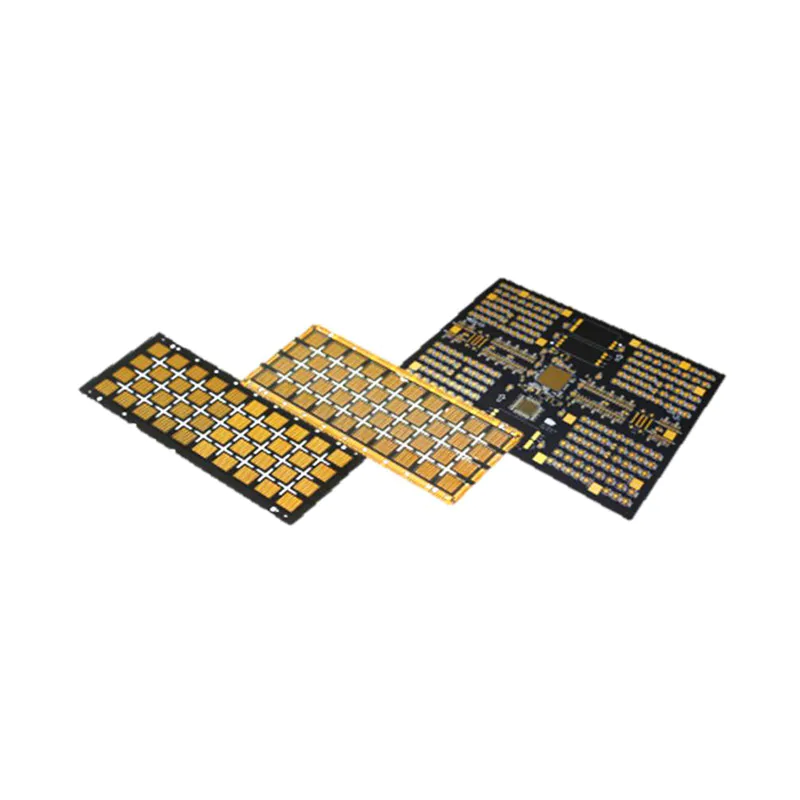

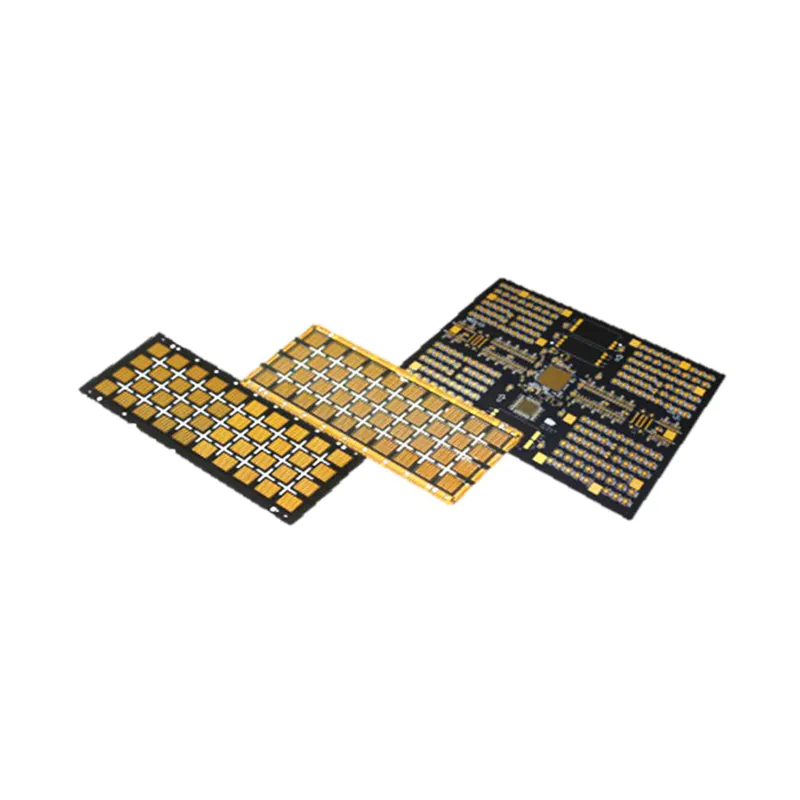

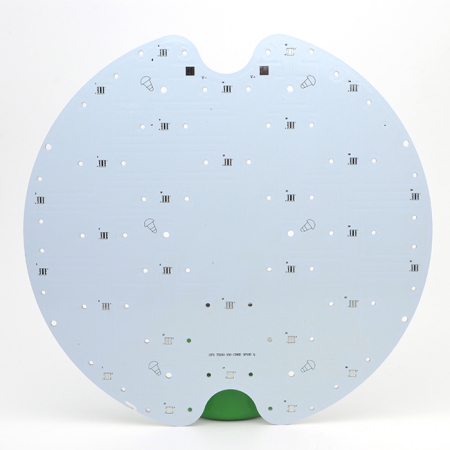

Aluminum PCB from Rocket PCB

Rocket PCB is located in the professional manufacturing of LED aluminum substrate PCB, copper substrate PCB (thermoelectric separation), copper-aluminum composite base PCB, and other metal PCBs with high performance and high thermal conductivity. The company has a complete set of automatic production equipment and precision detection equipment for the production of metal PCBs (aluminum base PCB, copper base PCB). It has been focusing on the research and development and manufacturing of metal circuit boards for many years, which enables us to achieve the first breakthrough in mass production in China: bendable aluminum substrate, ultra-high thermal conductivity (122W) ALC aluminum substrate, copper substrate (thermoelectric separation), etc.

The products are widely used in LED lighting, high-power power supply, automobile lamp lighting, new energy battery, charging pile, 5G communication equipment, etc. The company has professional technology, the quality experience of the professional team (more than 10 years of experience), committed to solving the problem of metal base PCB for customers is our responsibility. The whole production process of the company is self-sufficient, with a monthly output of 30000 square meters.