As a well-known electronic enterprise in China, relying on a strong factory background, Rocket PCB has more than 100 technical staff. Rocket PCB has become a leader in providing innovative electronic manufacturing services and has turned the dream into reality.

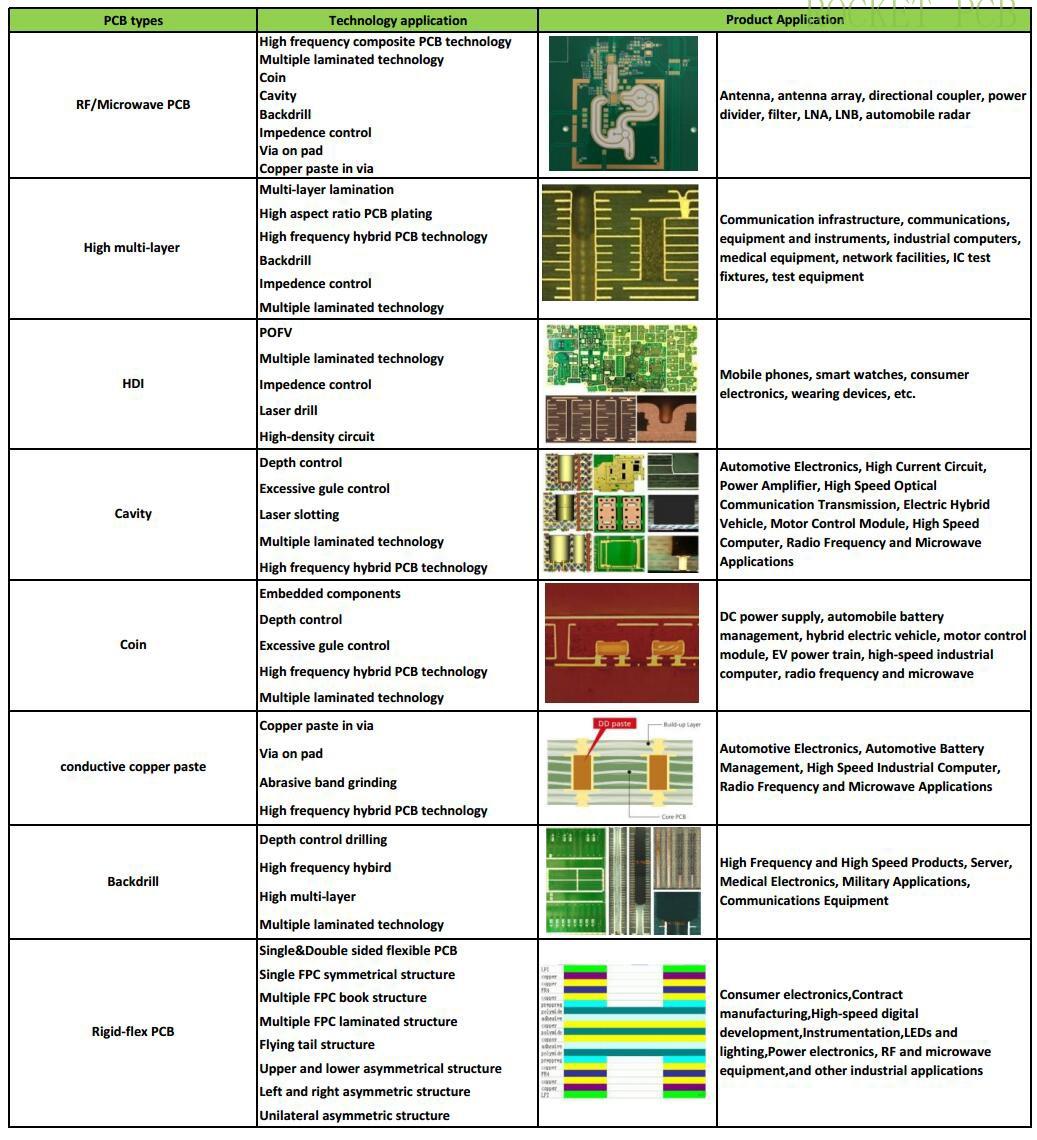

Rocket PCB was founded in 2002 and located in Shenzhen, China equipped with domestic and foreign top equipment. Our products cover a wide range including rigid, rigid-flex, HDI, any layer, Flex, large-size, embedded, RF, LED, backplane, metal substrate, ceramic substrate, IC structure, high-frequency, heavy copper and undergo strict surface treatment process. We support a full range of PCB prototypes and batch production and now we have thousands of prototypes for mass production.

At present, our main products cover high-speed server boards, large data memory circuit boards, high-frequency hybrid boards, multi-stage HDI boards, IOT modules, security circuit boards, etc. which are widely used for communication, medical, military, security, industrial, automotive fields. Products are sold far to North America, Europe, Asia Pacific and other international regions.

Rocket PCB meticulously practices all-around quality management and actively introduces and implements multi-domain system management. We have successively obtained ISO9001, ISO14001, IATF16949, OHSAS18001, ISO/IEC27001, ISO13485 and AS9100 certifications.

We always adhere to the principle of "pursuing ultimate customer satisfaction". Rocket PCB pays high attention to scientific and technological innovation and personnel training so that we have maintained a leading position in the domestic industry.

We have cooperated with many well-known customers at home and abroad including Dell, Inspur, Sugon, Panasonic, Quanta, Fineline, Honeywell, Polycom, Foxconn, etc. and have received wide market recognition.

Rocket PCB is working together with our customers to realize large PCB production. We provide strong technical support and high added value for our customers. We are able to give fast response to customer needs, think about what customers think and care about what customers care.

Our engineering services and techniques cover a wide range from 1 layer PCB to 64-layer PCB, from rigid PCB to flex PCB, from 1-step HDI to any-layer, from embedded materials to hybrid ones, from metal substrate to IC substrate, from backplanes to high speed frequency and RF, from standard materials to special materials, etc. Our technicians have rich experiences in putting forward proposals on printed circuit board prototypes, PCB design, cost factors of products and technology and provide rapid feedback on Gerber checking, modules, design rules, costs of different solutions, CAM design, build-up ,impedance simulations, material selection, manufacturability, layout, use of micro-vias, gold plating, special laminates, etc.

We can offer short lead time through rapid logistics. We can communicate technical details with you through phone, email, video meetings or site meetings. Your strong cooperation will make it easier for us and we will provide real-time and in-depth technical support to turn your PCB products from conceptual design to volume production.

During the design period, our professional engineering team will confirm the layout design, specifications and will detect potential risks for our customers. After the order is placed, we are going to prepare the tooling needed and start the pre-processing work to meet customers’ requirements. We promise that every step is strictly monitored and every problem will be solved as soon as possible and that flawless products are delivered to customers.

Rogan Luo

General Manager

With 15 years experience in the PCB industry, Rogan’s first job was a MI&CAM engineer in PCB factory. With 3 years of personal development, his own PCB trading company went into operation. After 12 years of PCB trading in China, he maintains a great relationship with many Chinese famous PCB factories and deeply knows about the advantages of each factory in the aspect of technology and operation.

Toby He

Marketing Representative

Toby worked for several famous PCB factories. With 10 years of sales and marketing experience in the PCB industry, Toby is experienced in serving overseas customers and providing the best solution for them.

Hans Hu

Sales Manager

Hans Hu is a man is full of energy and has been working as an engineering supervisor for 8 years in NCAB before joining Rocket PCB. Hans has rich knowledge about PCB technology and engineering and serves as a great counselor for customers and contributes a lot to our R&D department.

Jeff Fu

Engineering and Quality

More than 8 years PCB industry experience as CAM and QE engineer in ranking first domestic enterprises-Shennan Circuits(SCC), be good at managing and controlling engineering quality and solving technical problems. In addition, later as a sales manager, also be excellent in market development and customer service support.

PCB EQUIPMENT

Our factory invested heavily in importing foreign advanced PCB production equipment, such as Burkle laminator, Mitsubishi laser drill, Hitachi mechanical drill, Japan screen automatic exposure machine, LDI, AOI etc, highly automated production. One of the few companies in the industry equipped with complete set of surface treatment equipment (gold, silver, tin, OSP, HASL, gold plating), meeting diverse PCB needs.

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink