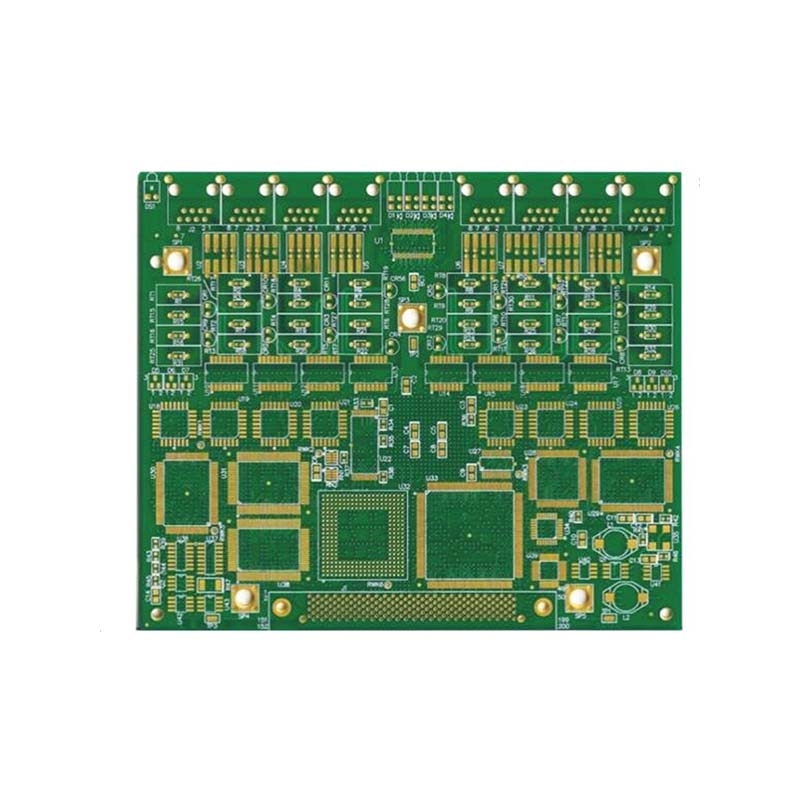

Multilayer printed circuit board, fast prototype PCB fabrication

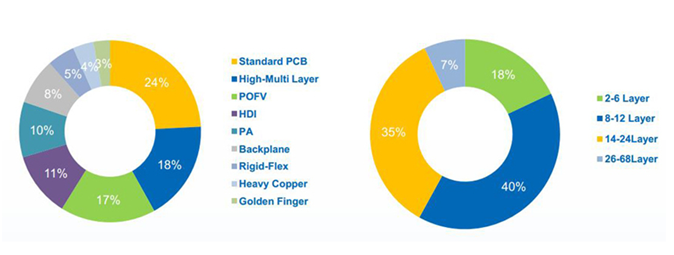

Multilayer PCB is one of the most distinguished product among those collections in Rocket PCB Solution Ltd.

It is designed by using superior and well- selected FR4. It comes with

various structures. The design of it caters to varied needs of customers

at home and abroad. Impedance control, dense circuit is adopted to

produce high-quality Multilayer PCB. With such parameters as up to 64

layers, high reliable characterize Multilayer PCB.

Rocket PCB has been producing multilayer PCBs for over 20 years. Over the years, we have seen all types of multilayer constructions from various industries, answered all types of multilayer questions, and solved all types of problems with multilayer PCBs.

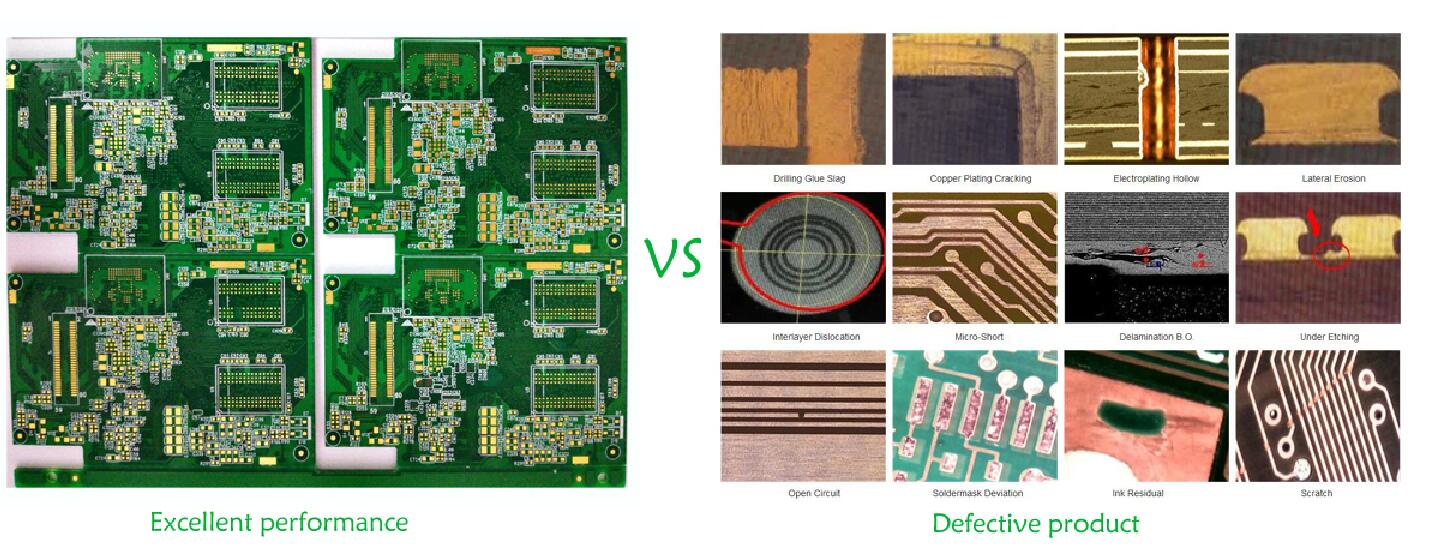

The quality of raw materials isn't as much as standard

The quality of raw materials would be the fundamental quality of circuit boards. The material itself isn't as much as standard. The circuit boards created will occur foaming, stratification, warping and uneven thickness.

Production euqipment is just not as much as standard

Together with the progress of science and technologies, the replacement of PCB production gear is quicker and quicker, as well as the cost is more and more expensive. Equipment is to assure the quality of hardware, improve funding in equipment, to ensure that equipment to attain higher efficiency, stability could be the basic method to strengthen the quality of circuit boards. Because of this, some small PCB factories aren't able to get high-priced equipment, which in the end results in the poor quality of Printed circuit board products.

Production technologies isn't as much as standard

Every approach of PCB manufacturing should be carried out depending on stringent production procedure, and every procedure has to be equipped with related inspection equipment. These procedure parameters and equipment can assure the stability of PCB quality. Since the production technologies isn't as much as the standard, several PCB factories have only low prices, resulting in the quality of the manufacturing line board isn't as much as standard.

The first point will be the circuit design

The PCB with top quality must have a reasonable circuit layout. Whether double-layer or multiplayer board, it should have correct line control and reasonable trace pattern, in order to prevent the slow response on account of redundant lines, which is, line width, line thickness, line space meet the requirements, in order to prevent line heating, circuit breakage, and short circuit.

The 2nd point is the appearance

The PCB circuit board with top quality not only has a neat and smooth surface, and also basically does not appear the occurrence of bending or irregular. The copper surface is not easy to oxidize, and there will be no cracks or scars, print ink falling off.

The 3rd point is the heat resistance

This aspect needs to be observed personally, PCB circuit boards are assembled in their own products. If they can endure the instantaneous high temperature produced by welding as well as the copper foil is difficult to fall off under high temperature, it shows that the PCB circuit boards have excellent heat resistance and high-quality.

The 4th point is the expansion coefficient

PCB circuit boards can create drastic expansion or contraction in cold and hot environments. In case the expansion coefficient is small the thermal and cold environment has small effect on PCB circuit boards, the quality of PCB circuit boards is nice and the components on PCB circuit boards will not be damaged.

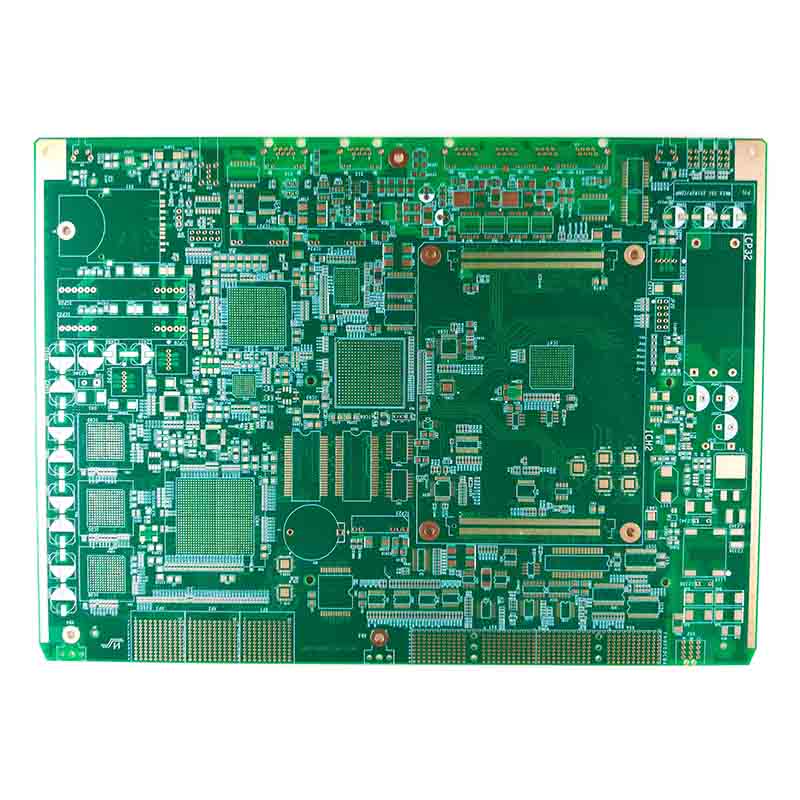

Compared with a double-layer board, the multilayer circuit board has greatly improved the electromagnetic compatibility.

For example, in a four-layer board, the middle layer is used as a power layer and a ground layer, and the benefits of doing so are as follows,

(1) The inductance of the power wire and ground wire is greatly reduced, thus reducing the noise voltage

(2) The power supply layer and ground layer form a large distributed capacitor, which provides a good high-frequency decoupling effect for the power supply, thus reducing the noise on the power cord.

(3) Independent power and ground layer can minimize the area of all signal loops

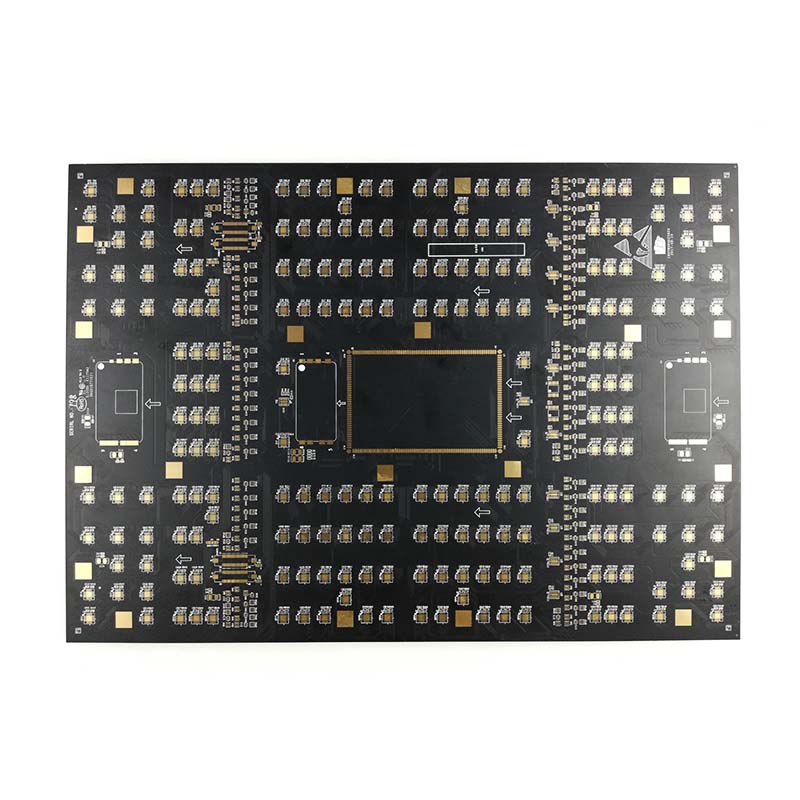

PCB multilayer board is the trend of the circuit board industry, the circuit board industry is developing toward the smaller size, the smaller the hole, the thinner the thickness, the larger the number of layers, the smaller the line width and spacing and so on.

Many high-precision high-tech electronic products are required multilayer PCB board to achieve functions, the ordinary double-sided board simply cannot replace

Strong fabrication strength, can meet the bulk needs of different clients

> The factory invested heavily in importing foreign advanced PCB production equipment, such as Burkle laminator, Mitsubishi laser drill, Hitachi mechanical drill, Japan screen automatic exposure machine, LDI, AOI etc, highly automated production.With a monthly output of up to 250,000 square meters.

> Our suppliers have formed a complete production process, which is becoming more specialized, modern and large-scale, has signed long-term strategic cooperation agreements with well-known enterprises at home and abroad.

> We passed ISO 9001 quality system, TS16949, UL standard, ROHS standard and SGS lead-free certification and related industry certification.

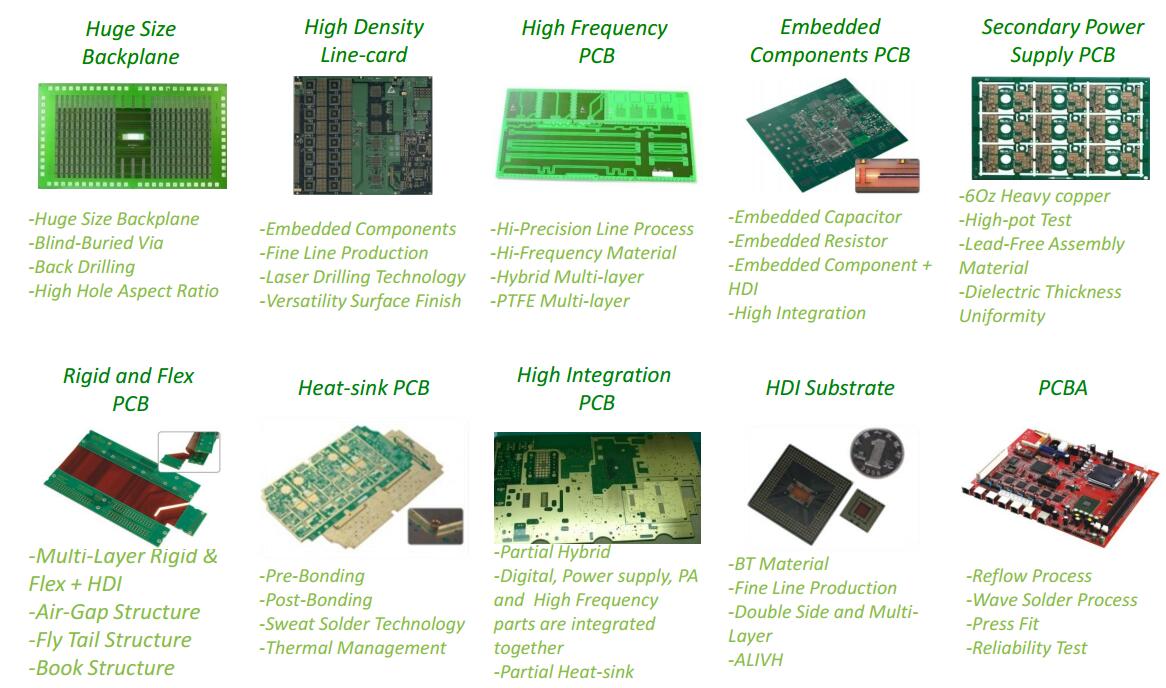

Technical Advantages

> We provide real-time and in-depth technical support. Tailor-made application solutions, like high speed, high capacity and high frequency, press-fit, heat-sink solutions.

> Free DRC and DFM.

> Rapid feedback on the layout,build-up, panels, impedance, material selection, design rules, manufacturability, costs of different solutions, use of micro vias, gold plating, special laminates, etc.

Service Advantages

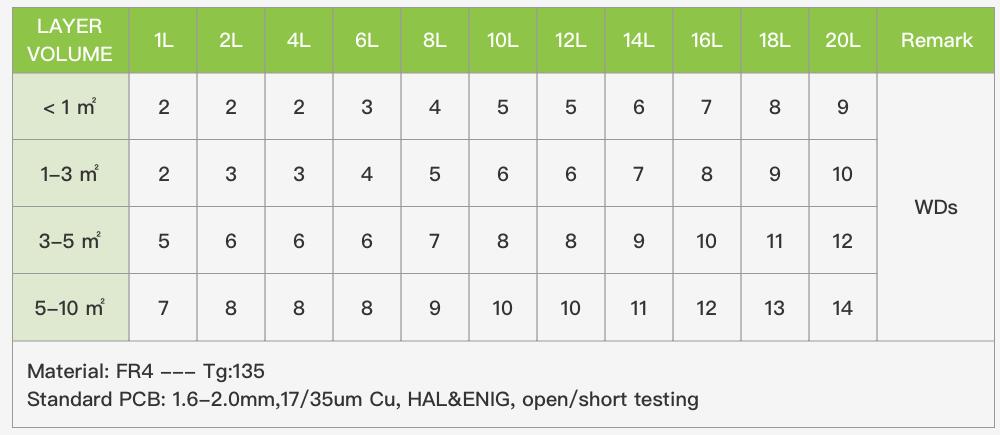

> A number of production lines meet the request of mass production and fast turn around of small batches and various prototype PCBs

> Expedited production line for prototyping double-sided up to 24 hours, 4 layers 48 hours, 6 layers 72 hours etc.

> Mass production of double-sided board 5-6 days lead time, multi-layer board 7-9 days.

> DHL, Fedex, TNT, UPS Express Direct, fully meet the customer's time requirements.

> Strict production and testing, 100% outgoing pass rate

> Provide 1-64 layers of different thickness, different materials, different processes of product customization, of which the CCL using A-class raw materials, high quality assurance;

> Advanced technology for rigid, rigid-flex, flexible, RF, metal core, backplane, ceramic, HDI and so on.

> Eight major surface treatment technology and high-quality ink printing, beautiful and reliable.

> Dozens of tests such as open/short circuit testing, impedance testing, solderability testing, thermal shock testing, metallographic micro-slicing analysis, halogen-free testing, etc.Rocket PCB supply chain meticulously practices all-around quality management and actively introduces and implements multi-domain system management. We have successively obtained ISO9001, ISO14001, IATF16949, OHSAS18001, ISO/IEC27001, ISO13485 and AS9100 certifications.

PCB industry manufacturing level is uneven, compared with other low-end manufacturers, we have unparalleled advantages. Low-end manufacturing factories are facing various quality defects due to outdated equipment, confused site management, improper operation, poor quality control, insufficient skills of engineers and inadequate process control.

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink