High density interconnect (HDI) PCB is an integral part of the PCB and electronics industries. Electronic components have become smaller and lighter but require increasing performance. To adapt to this situation, you need to pack more features into a smaller area. This is exactly what the HDI PCB provides.

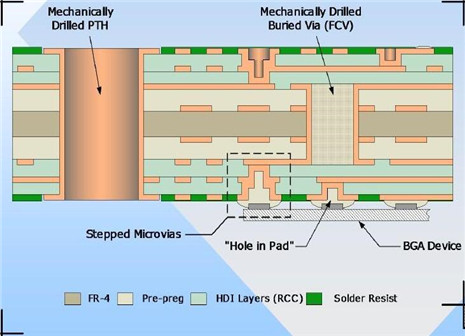

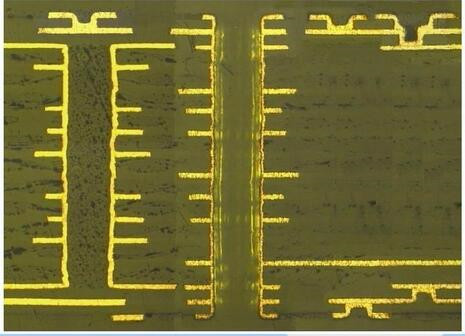

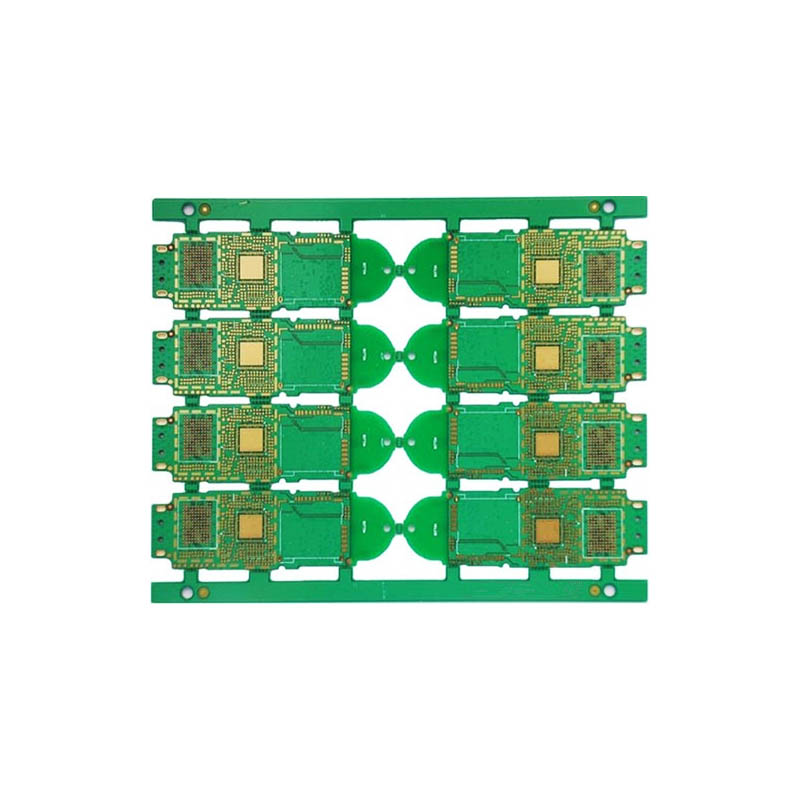

Compared with conventional PCBs, HDI PCB has a higher density per unit of the circuit. They use a combination of buried and blind holes, as well as micro holes with a diameter of 0.006”or smaller micro-holes.

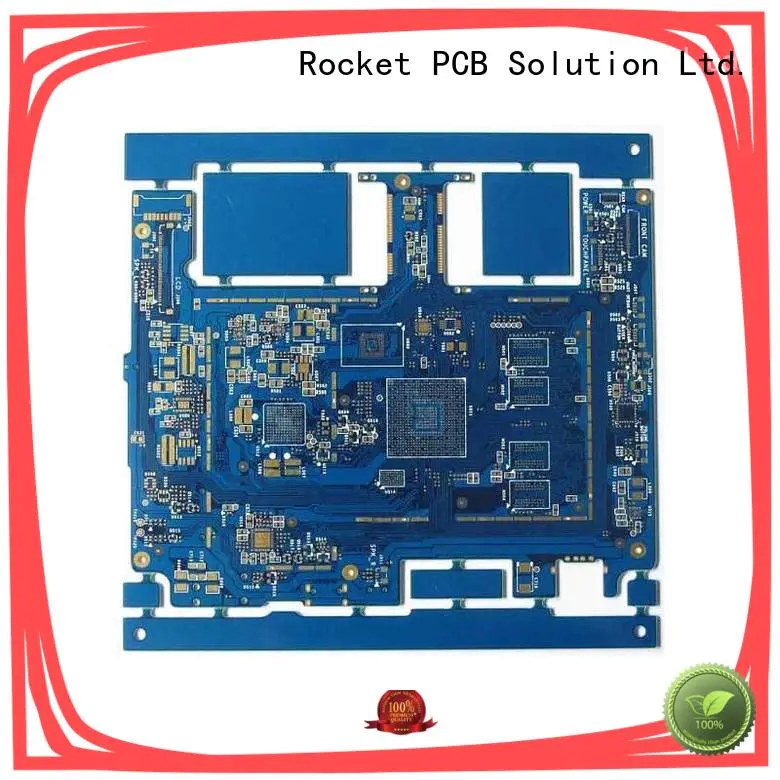

The strict tolerances involved in using HDI printed circuit boards mean that you need to work with experienced suppliers. Even small defects or layout accidents can lead to serious problems. As a leading supplier of HDI printed circuit boards, Rocket PCB offers top-notch circuit boards with a much higher circuit density than conventional PCBs.

Product Details

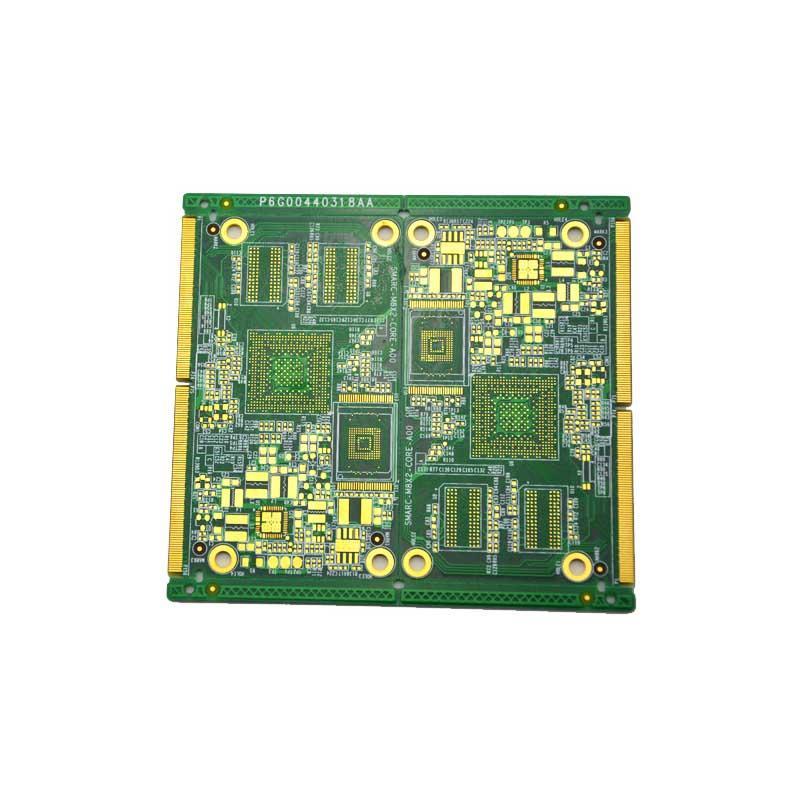

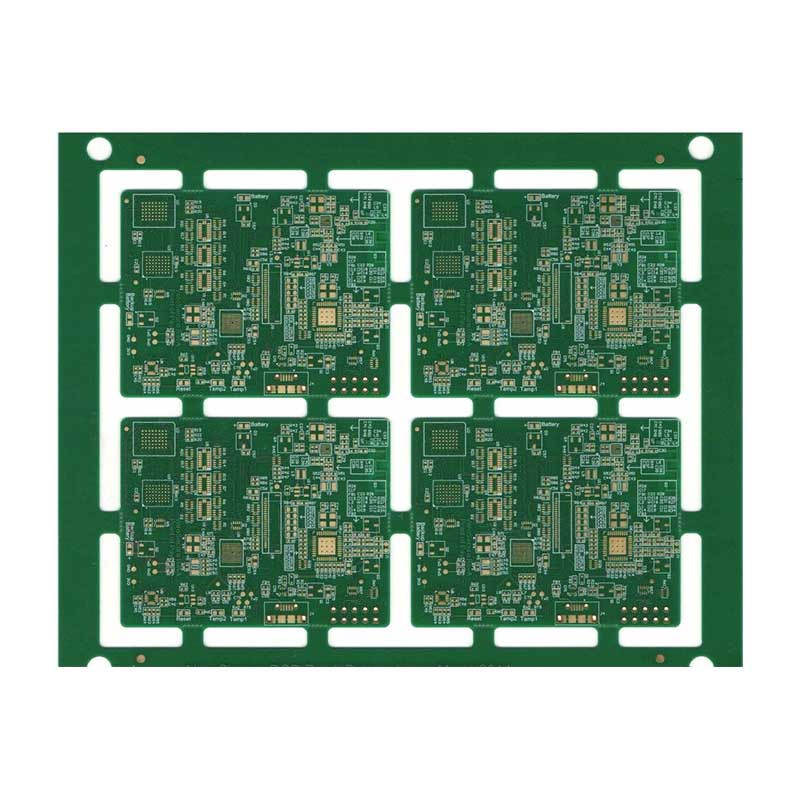

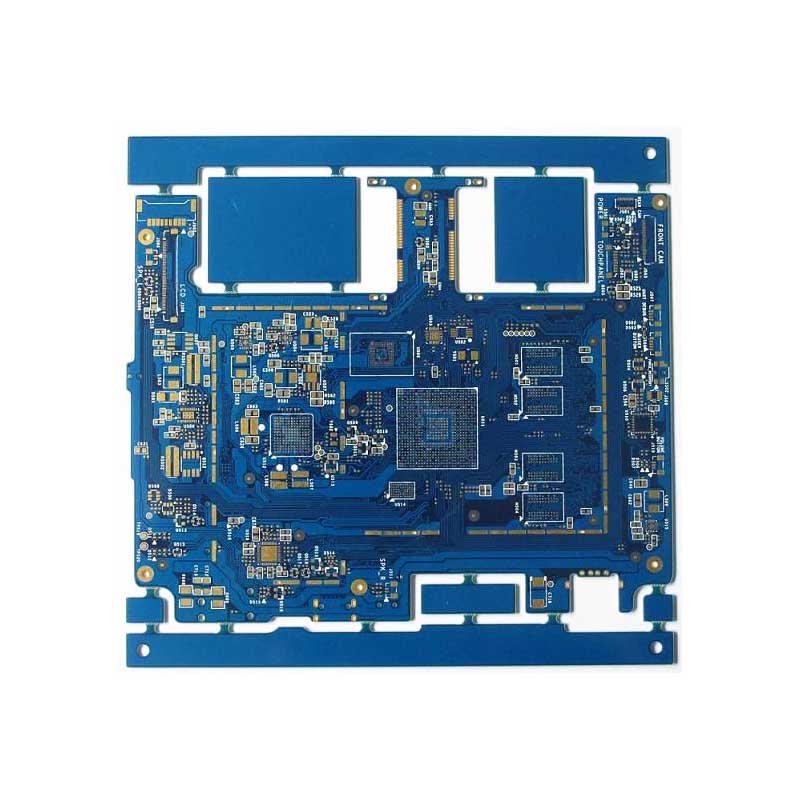

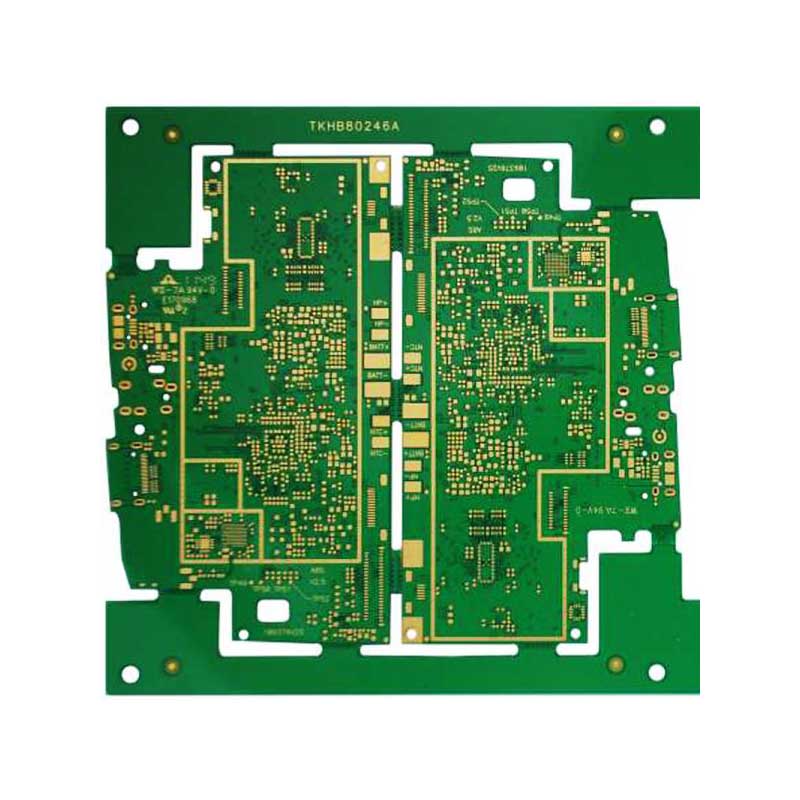

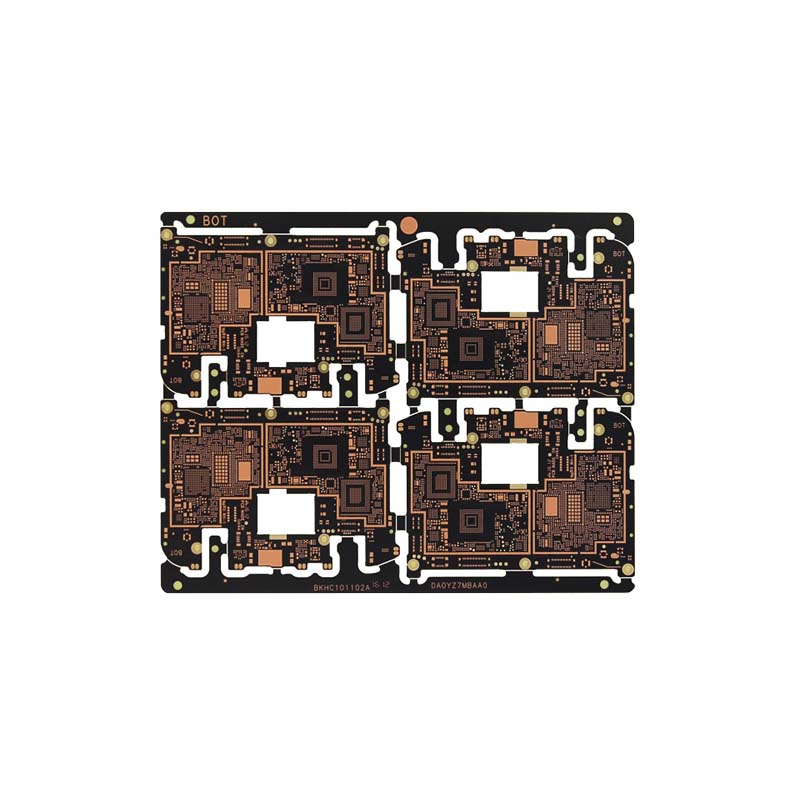

Want to know more product information? We will provide you with detailed pictures and detailed content of HDI PCB in the following section for your reference. Rocket PCB has a scientific and perfect procurement chain. To guarantee the quality from the source, we always adhere to the selection of high-quality materials to produce all kinds of printed circuit board. They are highly safe that have passed the national compulsory certification. We provide a worry-free buying experience for customers. Rocket PCB has professional production workshops and great production technology. HDI PCB we produce, in line with the national quality inspection standards, has reasonable structure, stable performance, good safety, and high reliability. It is also available in a wide range of types and specifications. Customers' diverse needs can be fully fulfilled.

Copyright © 2026 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink