When using dry film PCB manufacturer need to improve what method

by:Rocket PCB

2020-07-31

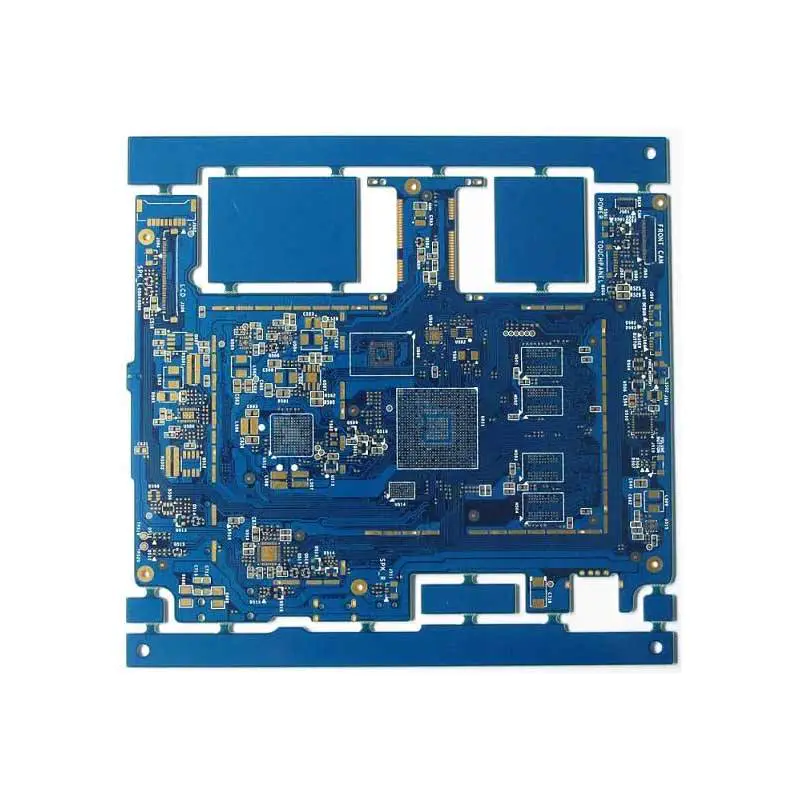

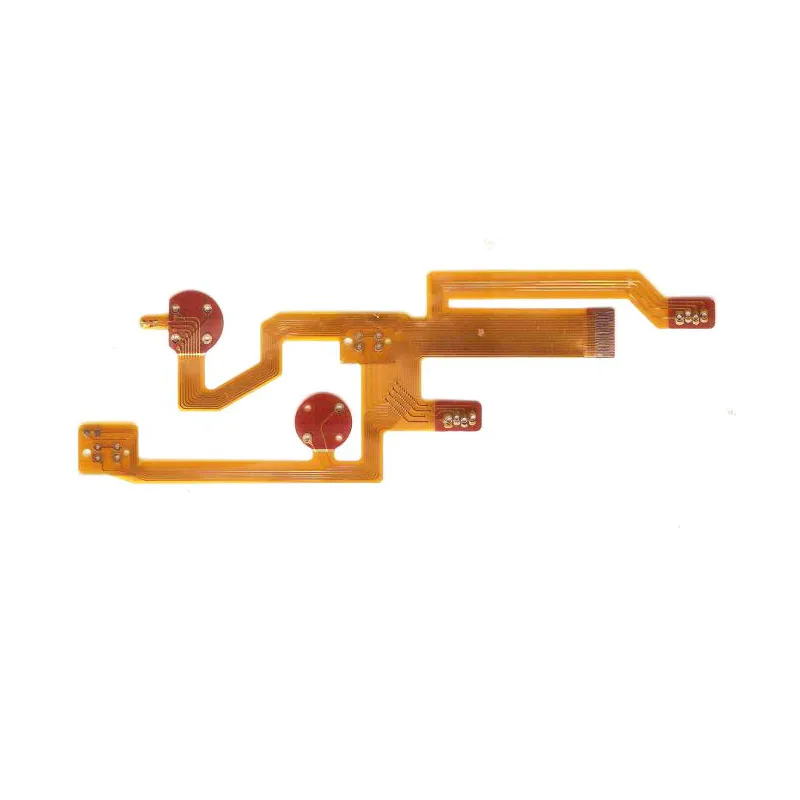

With the rapid development of electronic industry, PCB wiring is becoming more and more sophisticated, many PCB manufacturers are using dry film graphics to complete the transfer, the use of the dry film is becoming more and more popular, but I am in the process of after-sales service, still have a lot of clients in many pitfalls when using the dry film, are summed up, in order to draw lessons from.

A hole, PCB board in the dry film covering a broken hole many clients think, after a broken hole, should increase film temperature and pressure, and to enhance their binding force, actually this kind of view is incorrect, because after high temperature and pressure, corrosion resistant layer of excessive solvent volatilization, make the dry film brittle thin and vulnerable to break through the hole when developing, we always want to keep dry film toughness, so, after a broken hole, we can do to improve from the following points: 1.

Reduce the film temperature and pressure;

2.

Improve drilling phi front;

3.

To improve the exposure energy;

4.

Reduce development pressure;

5.

The paster dry film is not a too tight;

6.

Sticker after parking time cannot too long, lest cause semi-fluid corner part of yao membrane under the action of pressure spread thin.

Second, PCB plating during dry film plating plating, dry film and copper-clad plate bonding not firm, the plating solution, and cause the negative phase section plating thickening, most PCB plating factory happen is caused by the following points: 1.

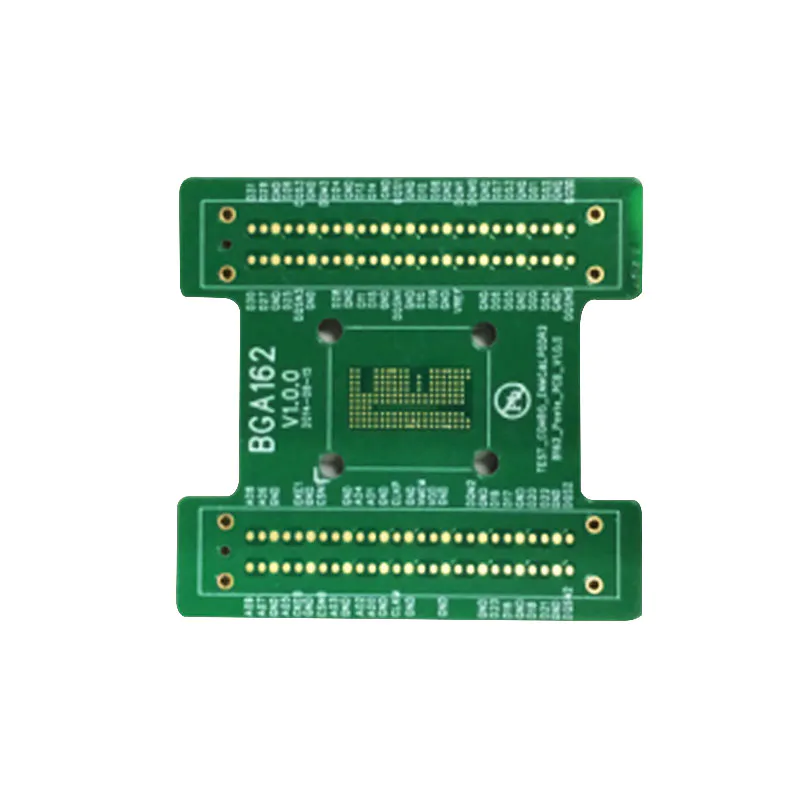

High or low exposure energy under uv irradiation, absorbed the light energy of light into a free radical initiator decomposition cause monomer polymerization, light the size of the formation of insoluble in dilute alkali solution.

Underexposure when, due to inadequate aggregate, in the process of development, the film swelling soft, line is not clear or even film layer falls off, causing membrane combined with copper bad;

If overexposed, will cause the development difficulty, also can produce case become warped in the process of electroplating, plating.

So it's very important to control the exposure energy.

2.

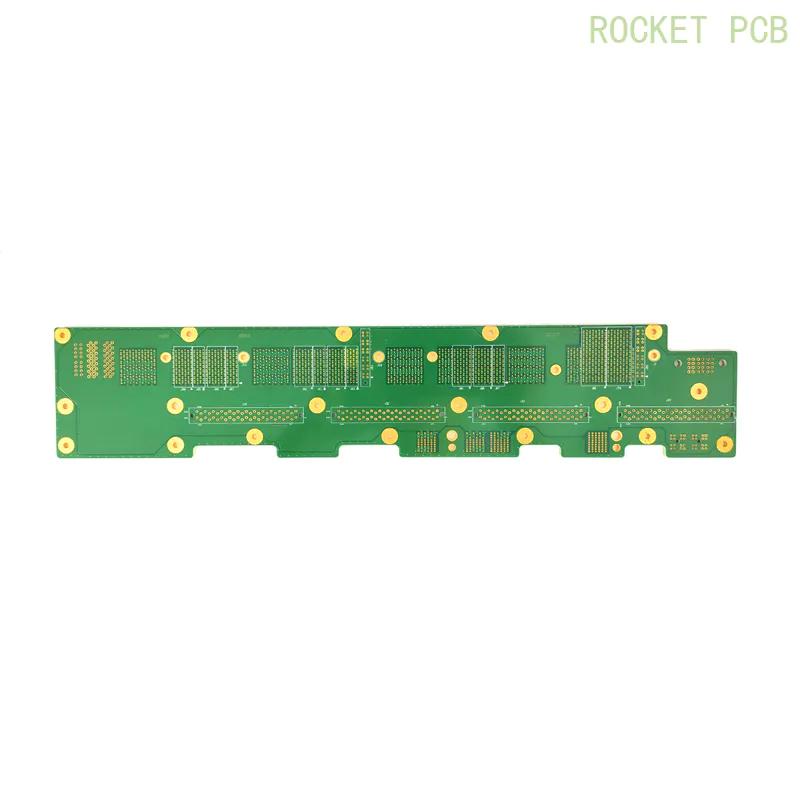

Films at low pressure is high or low the paster, may cause the paster surface uneven or dry film with clearance and could not reach the requirements of bonding strength between copper plate;

Film pressure if too high, too much corrosion resistant layer of solvent and volatiles volatile, causing dry film brittle, plating after the shock will be case become warped.

3.

Sticker is high or low temperature such as film temperature is too low, due to the corrosion film is not sufficient to soften and appropriate flow, causing dry film with copper-clad laminate surface adhesion is poor;

If the temperature is too high due to resist the solvents and other volatile substances volatilizes quickly and produce bubbles, and the dry film brittle, formed in the electroplating electric case become warped, plating.

There are many issues that affect pcb manufacturing services, which has led to the need of getting specialists trained in certain areas so as to handle all issues that may arise as well as pcb making service products that can solve pcb manufacturing services problems.

For many years, Rocket PCB Solution Ltd. has searched for and found a number of secrets to help you pcb manufacturing services. Go to Rocket PCB to learn about some of those secrets.

give you an additional pcb manufacturing services option for your pcb manufacturing services, whether it being a pcb manufacturing services, pcb manufacturing services or pcb manufacturing services. Go and get more info at Rocket PCB .

Rocket PCB Solution Ltd. agreed, noting that successful social marketing will become an even more important component of overall marketing strategies, and that marketers will have to think longer, harder and more creatively if they want to be able to fulfill the newly created potential of pcb manufacturing services.

There are many issues that affect pcb manufacturing services, which has led to the need of getting specialists trained in certain areas so as to handle all issues that may arise as well as pcb making service products that can solve pcb manufacturing services problems.

For many years, Rocket PCB Solution Ltd. has searched for and found a number of secrets to help you pcb manufacturing services. Go to Rocket PCB to learn about some of those secrets.

give you an additional pcb manufacturing services option for your pcb manufacturing services, whether it being a pcb manufacturing services, pcb manufacturing services or pcb manufacturing services. Go and get more info at Rocket PCB .

Rocket PCB Solution Ltd. agreed, noting that successful social marketing will become an even more important component of overall marketing strategies, and that marketers will have to think longer, harder and more creatively if they want to be able to fulfill the newly created potential of pcb manufacturing services.

Custom message