Quality Printed Circuit Board Material That Fits

by:Rocket PCB

2020-04-15

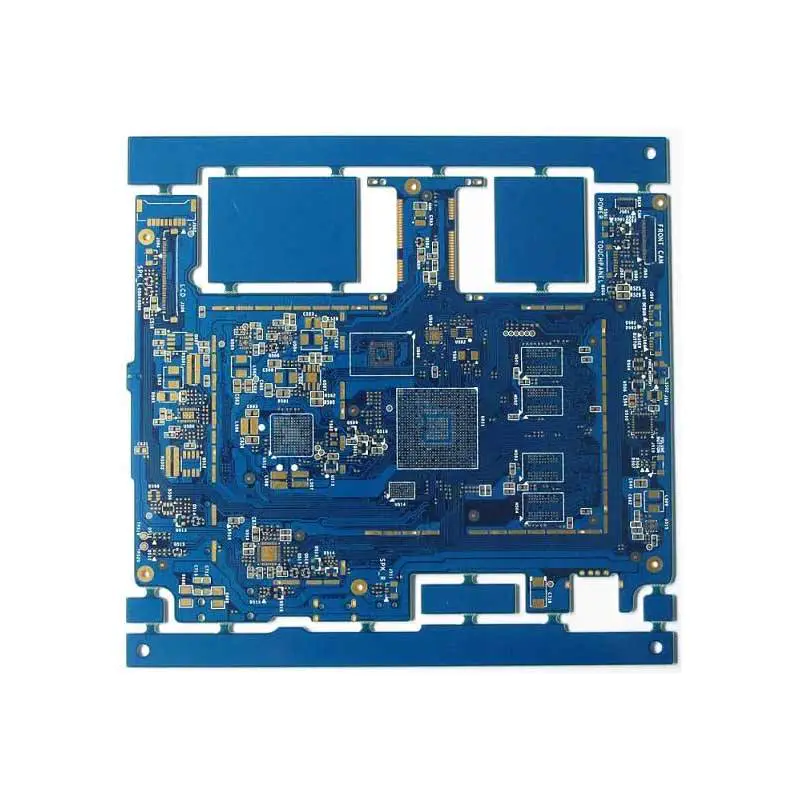

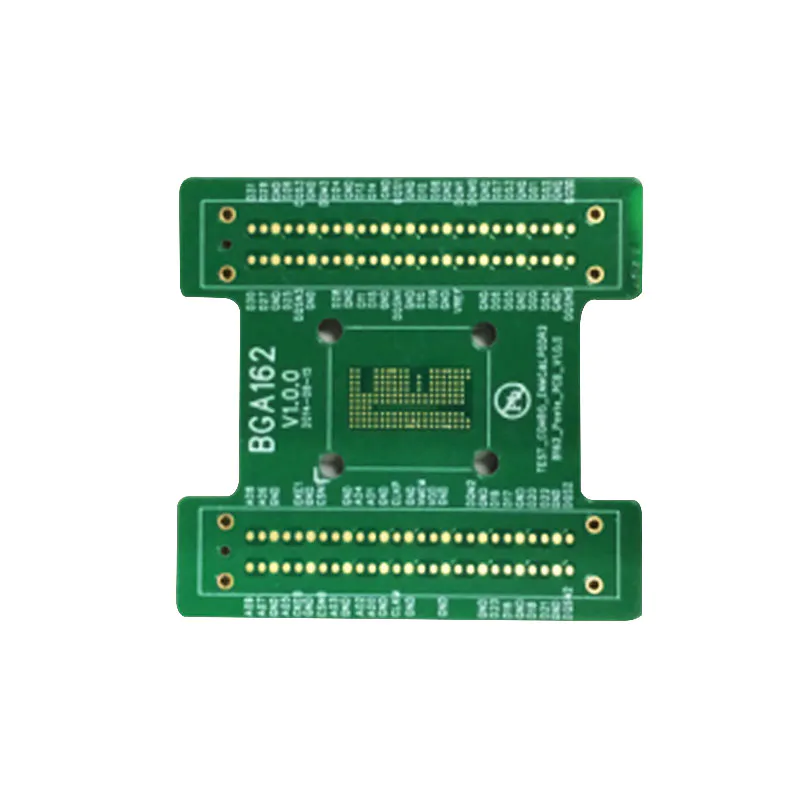

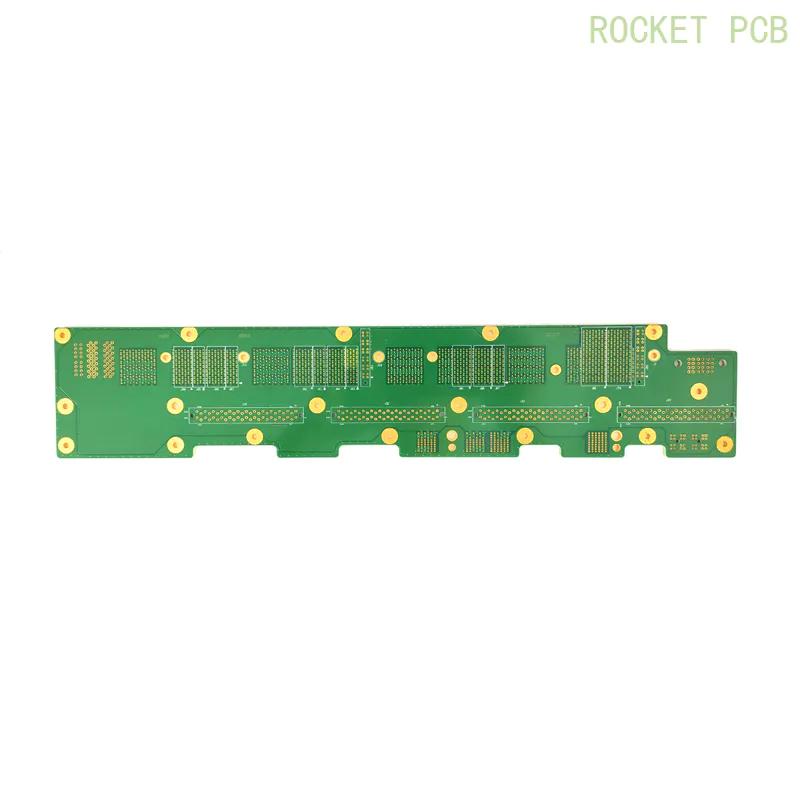

Different PCB materials result in a variety of PBC specifications and prices in printed circuit board prototyping and production. There are 1 or 2 layer boards that just require on pre-preg 'core' or multiple layer boards which use two or more types of cores in construction. Pre-preg, a material made of fine layers of fiberglass 'pre-impregnated' with a bonding agent or metal core in a sheet form, has many different measures depending on the intended use and the desired thickness. The thickness of your board can vary from a couple mils thick for flex boards to a quarter inch thick for heavy burn in boards. Core materials resemble slim double-sided boards with dielectric materials such as fiberglass along with a copper foil placed on each side; these usually come in predefined thicknesses.

PCB Prototype using FR4

FR4, the most widely used family of substrates in printed circuit boards, is a glass fiber epoxy laminate. FR4 is the most standard material with higher numbers (such as FR4-06, FR4-08) have higher temperature coefficients and lower dielectric constants. FR4 has a starting Tg of 140 degrees Celsius, FR4-06 has a Tg of 170 degrees and as you move up the family, the temperature increases.

PCB Prototype using Metal Core

Popular in Light Emitting Diode printed circuits boards, Metal Core has great heat elimination. A single layer MCPBC contains a metal base, usually an aluminum and non-conduction layer, a copper circuit layer, IC components and a solder mask. The metal core acts as an amazing heat sinks, to ensure the safety of the LED's.

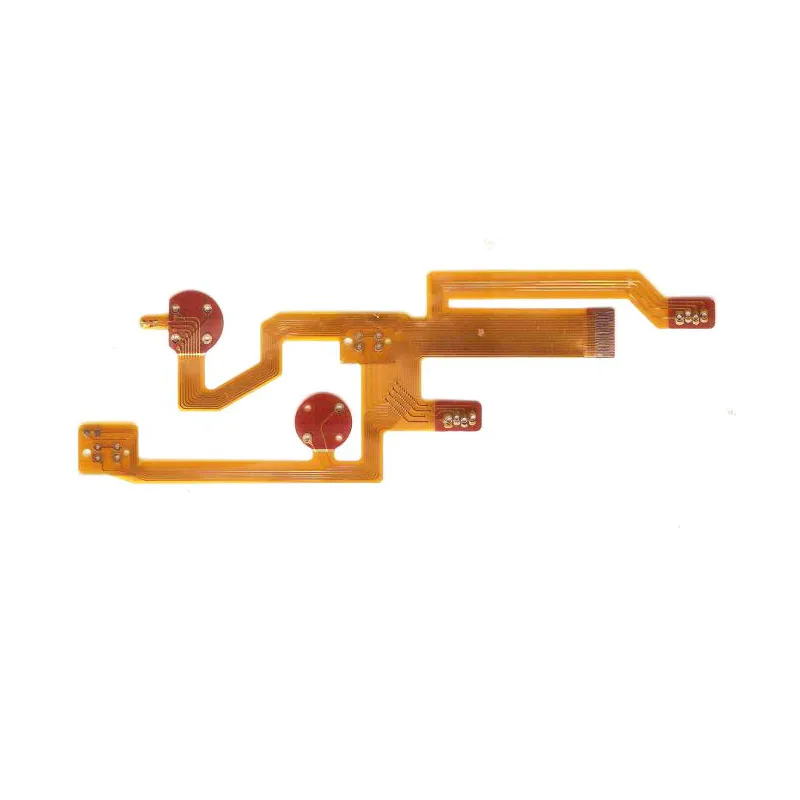

PCB Prototype Using Polyimide for Flexibility

Tougher than FR4, polyimide sustains hotter temperatures; this makes it ideal for use in electrical insulation applications that meet the class H requirements. The polyimide consists of a silicone adhesive design as well as a polyimide film built to withstand high temperatures. It protects edge connectors, gold edge fingers during wave soldering, and the reflow soldering processes during PCB assembly. Another interesting fact about polyimide is the color. While most boards come out green in color, polyimide is easily distinguishable by its brown color.

PCB Prototype Using Teflon for High Frequency

PTFE/Woven glass base PCB materials require special drilling because when compared to FR4 the Teflon is soft. These materials do not carry the myth of being exotic any longer. PTFE/woven glass base materials give both rapid growth of applications operations and meet high-frequency demands on a material that has availability and proven performance.

PCB Prototype Using Arlon for Longer Life at Higher Temperatures

Use Arlon materials for the PCB fabrication of high performance and frequency dependent printed circuit manufacturing. Common applications include those vulnerable to high temperatures during processing such as applications containing significant lifetime temperatures and lead-free soldering. Examples include under-hood automotive controls, down hole drilling, burn in boards, aircraft engine instrumentation and industrial sensors.

Using Isola Range for PCB prototype

Advanced circuitry applications use Isola range, a high performance FR-4 epoxy laminate and pre-preg system. Isola's low dielectric constant and low dissipation factor create the ideal material for broadband circuit designs that require a faster signal speed and/or better signal integrity. Isola is also the leading manufacturer of Lead Free materials, their IS410 and 370HR are the main materials used for ROHS compliant boards.

Wow, this sounds like a bit of a cruel question, but it is a vitally important question to ask yourself if you are struggling with your pcb manufacturing services and you would like to stop the pcb service problem.

All you women out there looking for amazing to dazzle the world try Rocket PCB Solution Ltd. latest collections at Rocket PCB . Try it!

Rocket PCB Solution Ltd.’s model also predicts (i) a positive effect of management on firm performance; (ii) a positive relationship between product market competition and average management quality (part of which stems from the larger covariance between management with firm size as competition strengthens); and (iii) a rise (fall) in the level (dispersion) of management with firm age.

Based on the pcb service, here are the top compliance challenges businesses face, and what you can do to make them easier on ourselves.

Wow, this sounds like a bit of a cruel question, but it is a vitally important question to ask yourself if you are struggling with your pcb manufacturing services and you would like to stop the pcb service problem.

All you women out there looking for amazing to dazzle the world try Rocket PCB Solution Ltd. latest collections at Rocket PCB . Try it!

Rocket PCB Solution Ltd.’s model also predicts (i) a positive effect of management on firm performance; (ii) a positive relationship between product market competition and average management quality (part of which stems from the larger covariance between management with firm size as competition strengthens); and (iii) a rise (fall) in the level (dispersion) of management with firm age.

Based on the pcb service, here are the top compliance challenges businesses face, and what you can do to make them easier on ourselves.

Custom message