Company Advantages1. To be more vibrant and competitive in pwb board industry, Rocket PCB has superb team to help the improvement of the design technology.

2. Through a thorough quality inspection, the product is guaranteed to be defect-free.

3. With the performance of metal core pcb and

pcb products, pwb board is a product which can represent excellence of Rocket PCB.

4. The product is made to last for a long time. It will not easily show signs of wear and tear with constant use.

5. 'I was delighted to find out that this product could provide me with purified water without requiring too much energy consumption. It saved much cost for me.' - Said one of our customers.

About our product

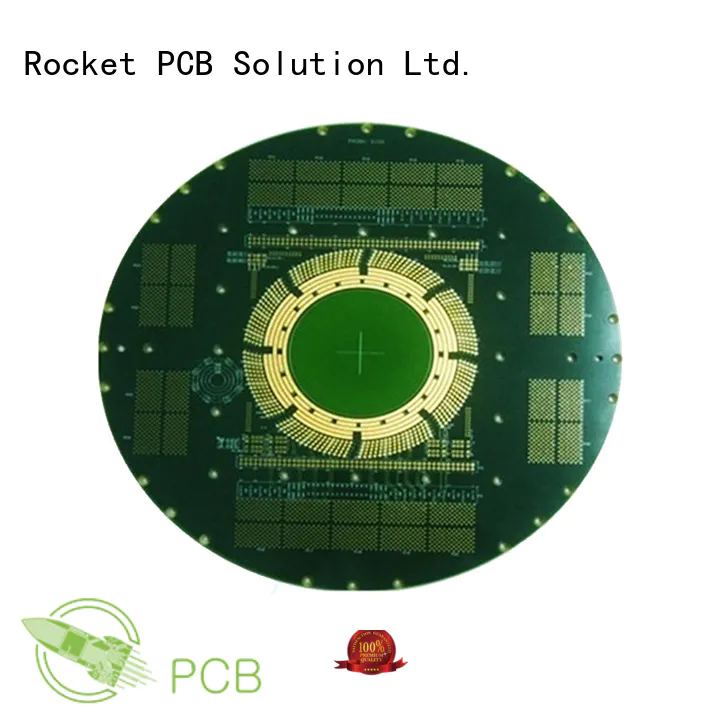

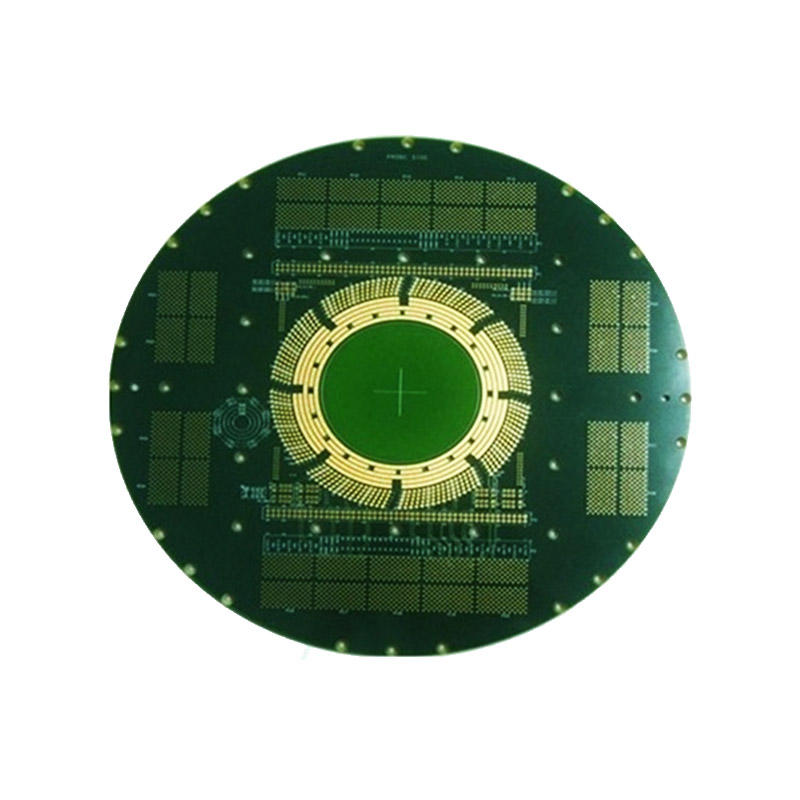

IC substrates serve as the connection between IC chip(s) and the PCB through a conductive network of traces and holes. IC substrates are endowed with critical functions including circuit support and protection, heat dissipation, and signal and power distribution.

IC substrates represent the highest level of miniaturization in PCB manufacturing and share many similarities with semiconductor manufacturing. Rocket PCB produces many types of IC substrates on which IC chips are attached to the IC substrate utilizing wire bonding or flip chip methods.

Advanced technology that Rocket PCB adopts for the IC substrates manufacturing includes:

◪ CSP (Chip Scale Packages)

◪ FC-CSP (Flip Chip) CSP

◪ COB (Chip on Board)

◪ PoP (Package on Package)

◪ COB (Chip on Board)

◪ PiP (Package in Package)

◪ SiP (System in Package)

◪ RF Module

◪ LED Package

Product application

Consumer electronics

Automotive electronics

Communications

Energy

Industrial & Instrumentation

IOT/Smart Home

Medical electronics

Security Industry

With years of development, Rocket PCB Solution Ltd. has built a significant capacity to deliver high-quality products like pwb board . We take great pride in our sound reputation.

2. We have a plant that has great manufacturing capacity. It allows us to produce a huge range of different batch sizes, depending on the requirements.

3. Rocket PCB Solution Ltd. always pays attention to the quality and service. Call now! The raw materials used in the metal core pcb are subject to strict raw material inspection. Our goal is to provide clients with the best product solution and help their businesses grow. We attach importance to clients' problems and requirements and develop a strong and effective solution that works perfectly in their markets. Call now!