Company Advantages1. The manufacturing processes of Rocket

PCB prototype circuit board are strictly conducted. These processes include metal materials preparation, cutting, polishing, and mechanical assembly.

2. The product is highly praised for its strong usability and consistent performance.

3. The combination of prototype circuit board and metal core pcb shows the greater function of

ic substrate pcb .

4. Our products have got global popularity and excellent reputation.

5. This product is widely recognized by the customers in the industry.

About our product

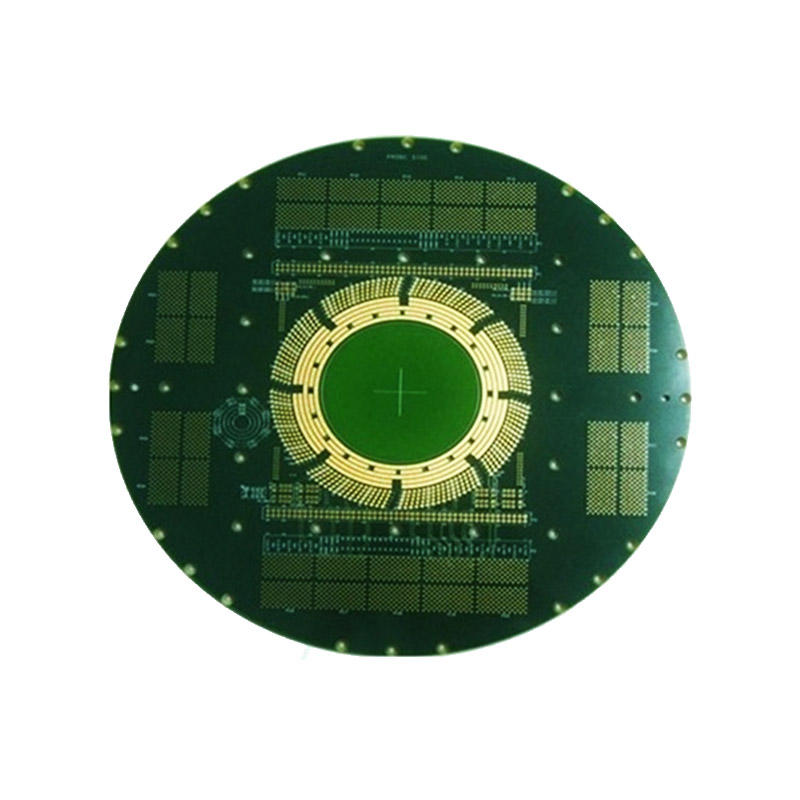

IC substrates serve as the connection between IC chip(s) and the PCB through a conductive network of traces and holes. IC substrates are endowed with critical functions including circuit support and protection, heat dissipation, and signal and power distribution.

IC substrates represent the highest level of miniaturization in PCB manufacturing and share many similarities with semiconductor manufacturing. Rocket PCB produces many types of IC substrates on which IC chips are attached to the IC substrate utilizing wire bonding or flip chip methods.

Advanced technology that Rocket PCB adopts for the IC substrates manufacturing includes:

◪ CSP (Chip Scale Packages)

◪ FC-CSP (Flip Chip) CSP

◪ COB (Chip on Board)

◪ PoP (Package on Package)

◪ COB (Chip on Board)

◪ PiP (Package in Package)

◪ SiP (System in Package)

◪ RF Module

◪ LED Package

Product application

Consumer electronics

Automotive electronics

Communications

Energy

Industrial & Instrumentation

IOT/Smart Home

Medical electronics

Security Industry

Rocket PCB Solution Ltd. has been offering quality prototype circuit board since inception. We have engaged in R&D, manufacture, and supply for years.

2. We have experienced product management professionals. They have exceptional abilities in problem analyzing and solving with regard to product development, design, and production.

3. Rocket PCB is carrying out the spirit of metal core pcb , and keep ic substrate pcb forward. Ask online! In order to satisfy users, we provide both high quality custom printed ciruit board and first-rate service. Ask online! Rocket PCB always takes responsibility for the development of pcb industry industry. Ask online! The realization of pwb board is the mission of Rocket PCB. Ask online!