On the circuit board factory: SMT processing tin don't round the sake of what

by:Rocket PCB

2020-06-17

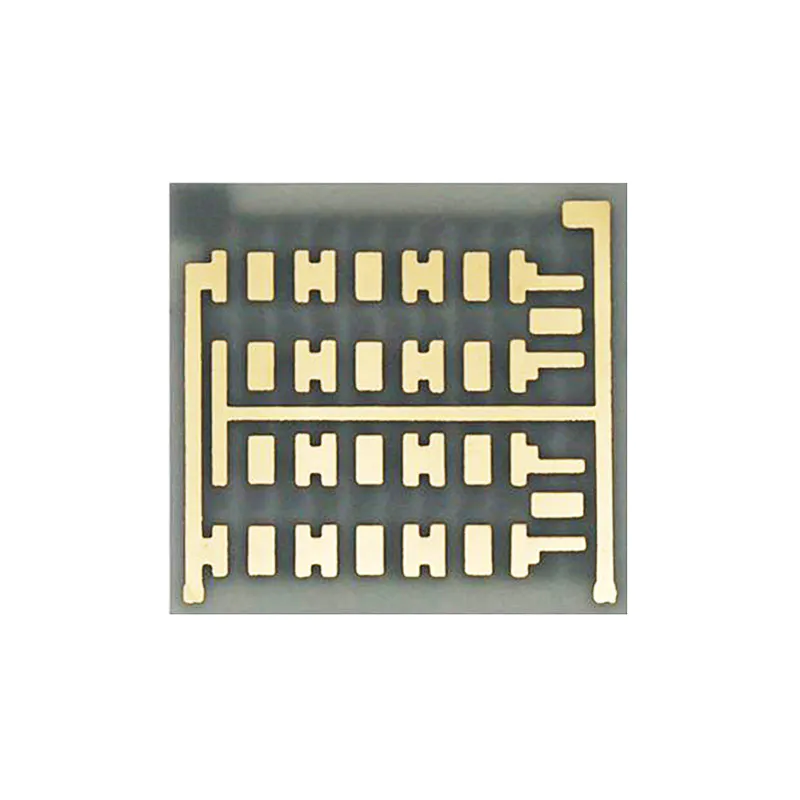

On the PCB in SMT processing, welding welding tin is a key stage, associated with the performance of the circuit board design and elegant appearance, in the concrete production can cause poor tin on because some conditions, such as common on the spot welding of tin is not round, will immediately endangering SMTSMT patch processing quality.

Dongguan Rocket PCB factory below small make up for the guys in detail on the circuit board factory SMT processing of spot welding of tin is not round.

SMT processing of spot welding circuit board factory tin not round key reason: 1, the welding position enough solder paste, tin not fruity, appeared gap;

2, help in the solder paste soldering fluid help soldering fluid expansion rate is too high, very easy to crack;

3, help help soldering fluid wettability of solder paste can not so good, can not exceed the provisions of the tin the very good;

4, PCB circuit boards welding plate or SMD welding welding has a serious air oxidation condition, harm on tin actual effect;

5, the specificity of the run-off water in solder paste is insufficient, can't remove PCB solder or SMD welding welding air oxidation of chemicals;

6, if appear on the part of the spot welding tin not round, because will be the red glue before the application can't sufficient mixing, helps the soldering fluid and tin powder can be not enough;

7, when a reflow furnace heating time is too long, or heating temperature is exorbitant, led to the solder paste in help soldering fluid specificity is invalid.

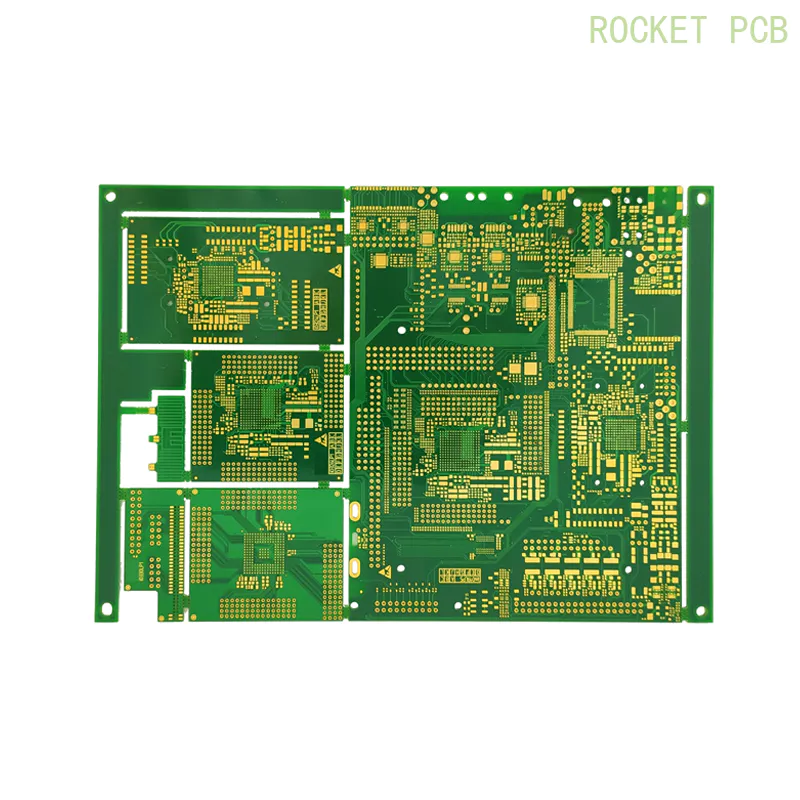

PCBA processing/SMT

are an important part of the society and they come in handy in any place where there are pcb manufacturing services in need of pcb manufacturing services.

Being a performance leader means Rocket PCB Solution Ltd. will achieve operational excellence, industry-leading customer satisfaction and superior financial performance.

Rocket PCB Solution Ltd. knew the only way to remain competitive was to ensure quality of service and customer satisfaction above all.

are an important part of the society and they come in handy in any place where there are pcb manufacturing services in need of pcb manufacturing services.

Being a performance leader means Rocket PCB Solution Ltd. will achieve operational excellence, industry-leading customer satisfaction and superior financial performance.

Rocket PCB Solution Ltd. knew the only way to remain competitive was to ensure quality of service and customer satisfaction above all.

Custom message