guidelines for prototype circuit board outsourcing

by:Rocket PCB

2019-09-24

It\'s one thing to do exciting new designs of circuits on paper, but it\'s another thing to build a model that it will actually perform.

The best way to figure out if an idea or concept works is to make a prototype board.

This is the best way to ensure that your concept works properly when converting to a physical printed circuit board.

Whether you are planning to build a prototype before the launch of a new product line or for other reasons, you will need to get the services of a professional company that builds a PCB prototype.

Manufacturing a prototype PCB is a task that is best left to professionals as it needs to be done according to precise specifications.

Any errors in the prototype phase can have a ripple effect on the pcb and the product during the production run.

Bringing your design to a professional PCB manufacturing company that can accurately build prototypes can eliminate errors that can take precious time and money.

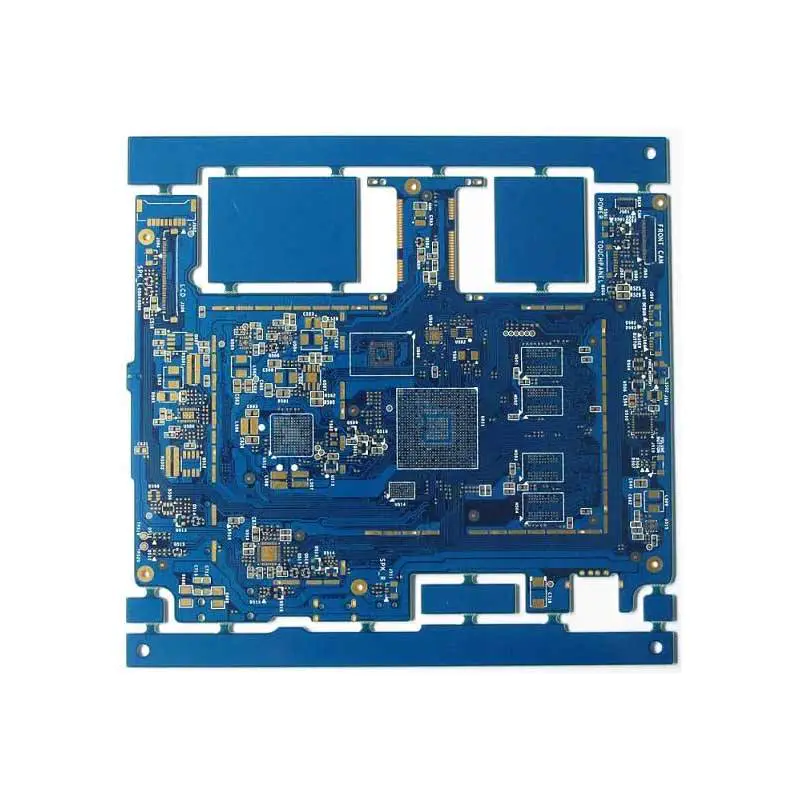

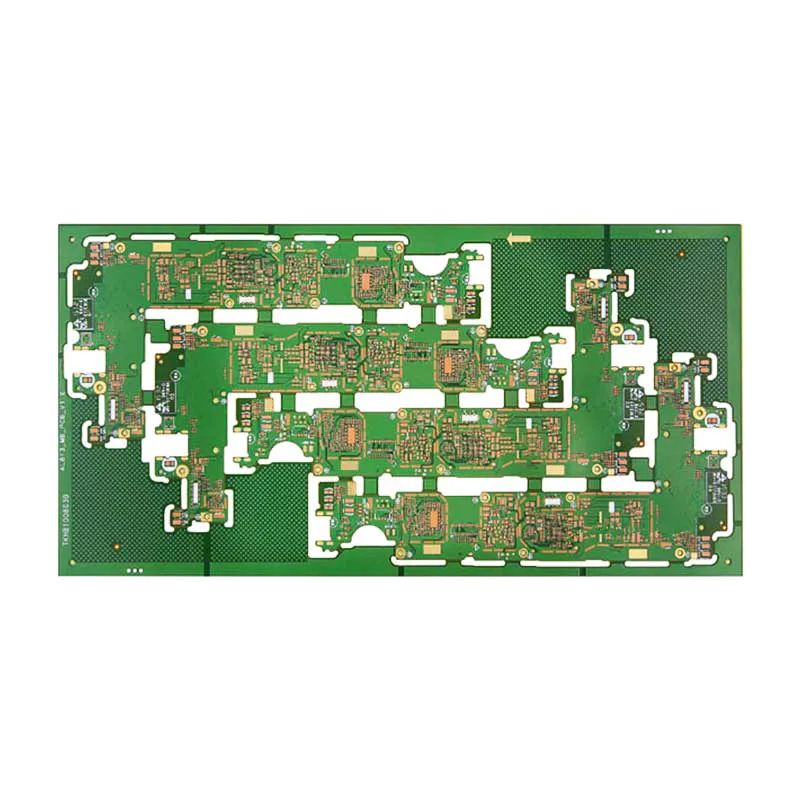

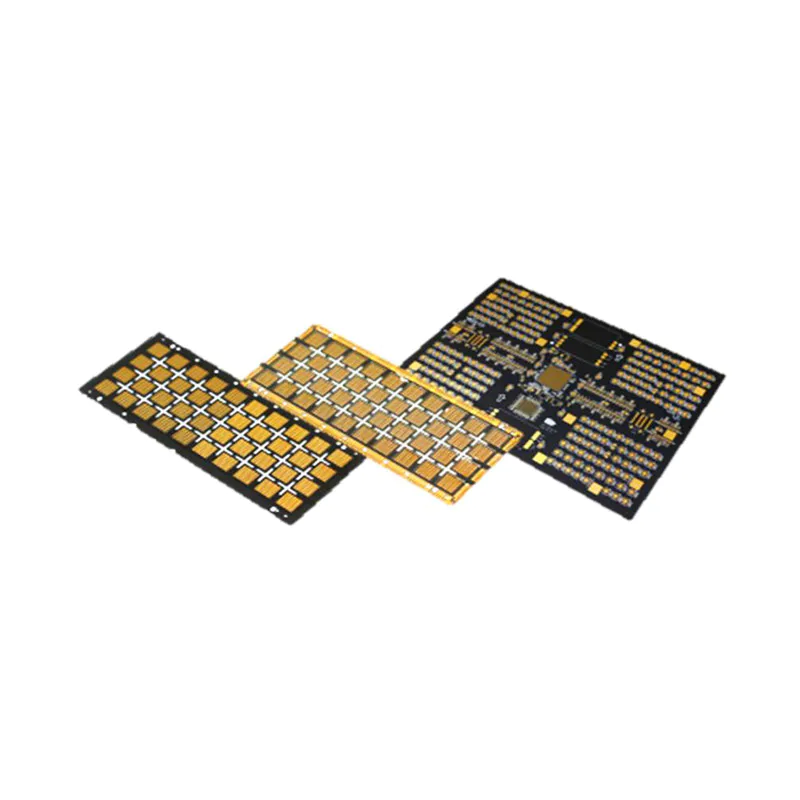

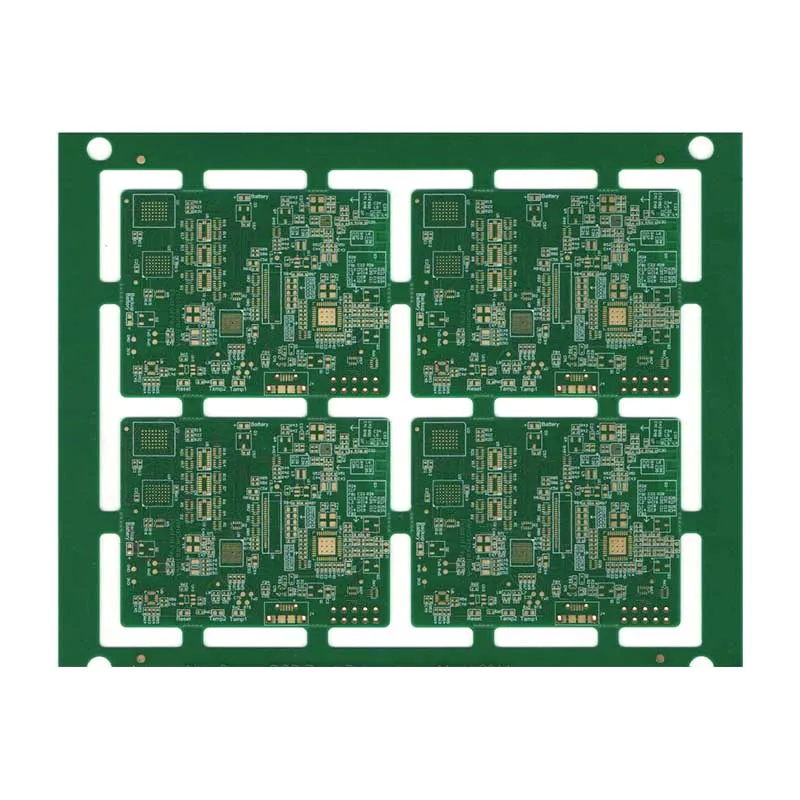

Here\'s what a well-known company that makes prototype boards should expect: PCB design and manufacturing companies serve flexible and rigid printed prototype boards.

This process is best started with a professional review of your manufacturing design documents (DFM).

This means that your products will be made more.

Able to solve various feasibility and performance problems.

Your documents will also be reviewed for high quality materials and quick turnaround.

It is not the best business practice to rush through a document review.

It is better to choose a company that ensures a thorough review, even if it takes longer to review.

Checking the problem at an early stage can ensure that no time is wasted at a critical stage.

The company you choose should also have sufficient knowledge of the product design process and related stages/deadlines.

This will make your interaction with the prototype board provider more efficient.

Most people underestimate the valuable contribution that a supplier\'s designer and engineer can make to your product.

If things don\'t go as planned, designers and engineers can suggest smart design solutions.

In this case, getting a service from a vendor with an active team can also add value to your end product.

Choosing an experienced and well-performing company is another prerequisite.

If your company has a reputation for quality, you can make sure that your prototype board is very accurate in every way.

All in all, you need a prototype board provider that can help with the resolution of the fault, redesign or production of variations of the same circuit. These value-

Additional services are the reason for distinguishing between general manufacturers and professional companies.

The best way to figure out if an idea or concept works is to make a prototype board.

This is the best way to ensure that your concept works properly when converting to a physical printed circuit board.

Whether you are planning to build a prototype before the launch of a new product line or for other reasons, you will need to get the services of a professional company that builds a PCB prototype.

Manufacturing a prototype PCB is a task that is best left to professionals as it needs to be done according to precise specifications.

Any errors in the prototype phase can have a ripple effect on the pcb and the product during the production run.

Bringing your design to a professional PCB manufacturing company that can accurately build prototypes can eliminate errors that can take precious time and money.

Here\'s what a well-known company that makes prototype boards should expect: PCB design and manufacturing companies serve flexible and rigid printed prototype boards.

This process is best started with a professional review of your manufacturing design documents (DFM).

This means that your products will be made more.

Able to solve various feasibility and performance problems.

Your documents will also be reviewed for high quality materials and quick turnaround.

It is not the best business practice to rush through a document review.

It is better to choose a company that ensures a thorough review, even if it takes longer to review.

Checking the problem at an early stage can ensure that no time is wasted at a critical stage.

The company you choose should also have sufficient knowledge of the product design process and related stages/deadlines.

This will make your interaction with the prototype board provider more efficient.

Most people underestimate the valuable contribution that a supplier\'s designer and engineer can make to your product.

If things don\'t go as planned, designers and engineers can suggest smart design solutions.

In this case, getting a service from a vendor with an active team can also add value to your end product.

Choosing an experienced and well-performing company is another prerequisite.

If your company has a reputation for quality, you can make sure that your prototype board is very accurate in every way.

All in all, you need a prototype board provider that can help with the resolution of the fault, redesign or production of variations of the same circuit. These value-

Additional services are the reason for distinguishing between general manufacturers and professional companies.

Custom message