About our product

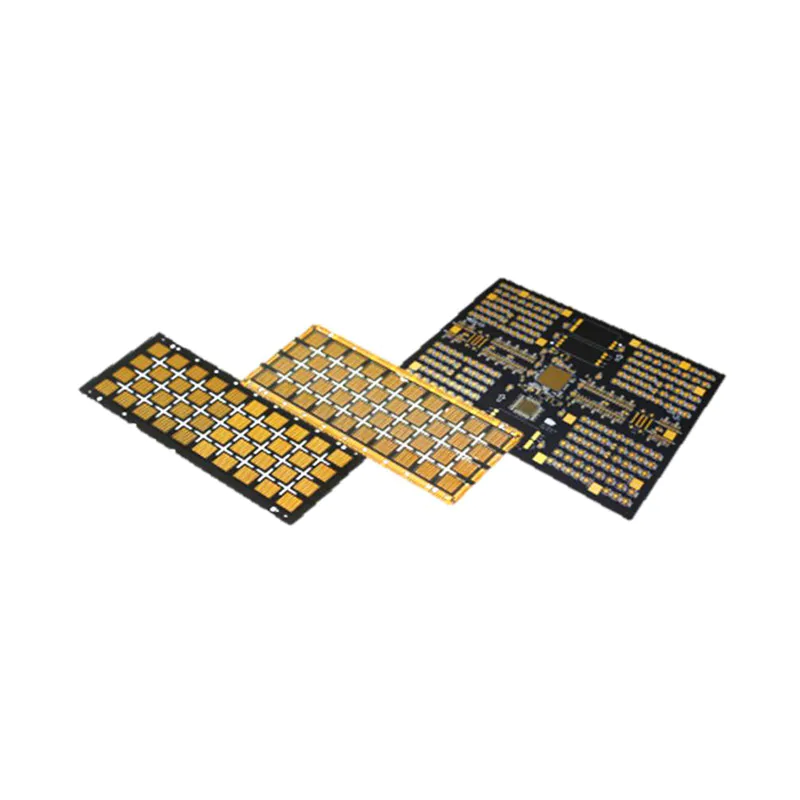

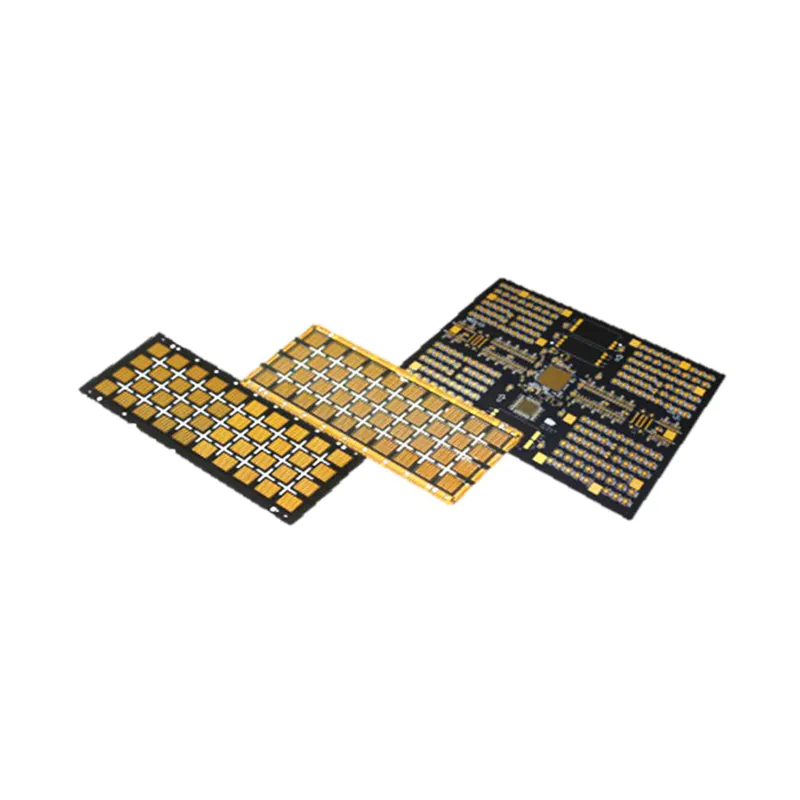

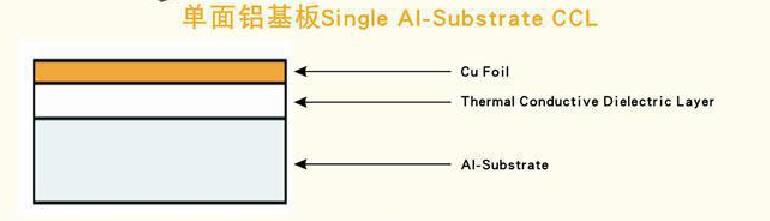

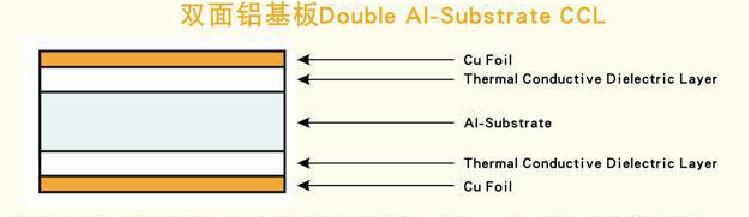

Rocket PCB

uses the industry's excellent Bergquist materials, with high thermal

conductivity insulation layer, to ensure the lowest operating

temperature, brightest brightness and longest service life of LED. In

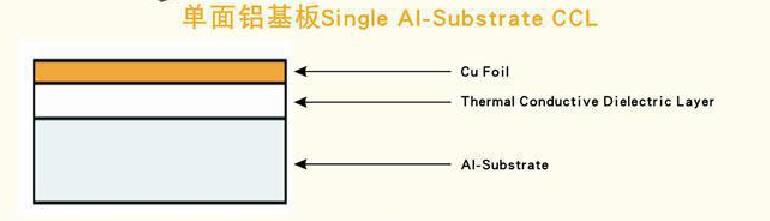

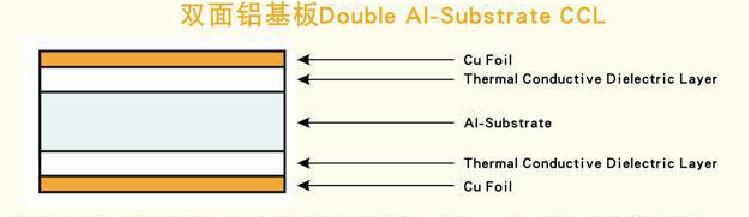

fact, aluminium substrates with high thermal conductivity can be used in

any LED application area.

However,

most of the insulating layers of aluminium substrates on the market are

made of commercialized FR-4 semi-cured sheets. These insulating layers

are all made of epoxy resin. Although these insulating layers have good

bonding properties, they have high thermal resistance (thermal

conductivity is only the 0.3w/m·k) because they are not filled with high

thermal conductivity and high insulation ceramic fillers.

If

the aluminum substrate is used, the heat generated by the high power

density module can hardly be transmitted to the metal substrate, so the

thermal accumulation will accelerate the aging of the power module and

eventually lead to the failure of the module. And the insulation

strength of this kind of aluminium substrates is limited (<2ΣKVAC),

it is difficult to meet the requirements of security testing, and can

only be used in low power density situations. For high power density

modules, it is difficult to be competent, and there are great hidden

dangers.

Bergquist

conducts 12 to 18 months of certification tests before each product is

put on the market. Bergquist' comprehensive quality verification

includes mechanical performance, bonding strength, electrical insulation

performance and thermal conductivity performance tests. In order to

verify the reliability of long-term use, a test cycle of 2000 hours is

usually selected. The main results are as follows:

500 cycles lasting 350 hours in the range of 40℃~150℃

2000 hours thermal aging test at 175 ℃

1 minute at 300 ℃ and 72 hours thermal shock test at 200 ℃

It is these rigorous validation tests that ensure the supremacy of the bergquist thermal Clad in the industry.

There are also the following unique advantages,

Compliance with RoHs requirements

In the design of electric circuit, thermal diffusion can be treated effectively.

Reducing the operating temperature of the module, prolonging the service life, increasing the power density and reliability

Reduce

the assembly of radiator and other hardware (including thermal

interface materials), reduce module size, and reduce hardware and

assembly costs;

Replacing fragile ceramic substrates for better mechanical durability

VS

> Our factories have invested heavily in importing advanced production facilities from abroad. Such as Burkle laminator, Mitsubishi laser drill, Hitachi mechanical drill, Japan screen automatic exposure machine, LDI, AOI etc, highly automated manufacturing. With a monthly output of up to 250,000 square meters.

> Our suppliers have formed a complete production process, become more professional, modern and large-scale, and signed long-term strategic cooperation agreements with well-known enterprises at home and abroad.

> Under the system of ISO 9001, ISO 14001, ISO/TS16949, OHSAS 18001, ISO/IEC27001, UL, SGS and RoHS, we have guaranteed our excellent quality and leading market position with strong technical development momentum. We also adhere to the 5S method, lean and Six Sigma quality system.

> We provide real-time and in-depth technical support and tailor-made application solutions, such as high speed, large capacity, high frequency, mixed pressure (hybrid structure), heat dissipation metal base solutions.

> Free DRC and DFM. Elite engineers with years of experience provide you with free and comprehensive engineering review and support.

> Rapid feedback on the layout, build-up, panels, impedance, material selection, design rules, manufacturability, costs of different solutions, use of micro vias, gold plating, special laminates and other engineering questions. When providing innovative solutions for our customers'products, we always consider maximizing the benefits for our customers.

> Rocket provides industry-leading support to our customers,we are more willing to help customers grow.

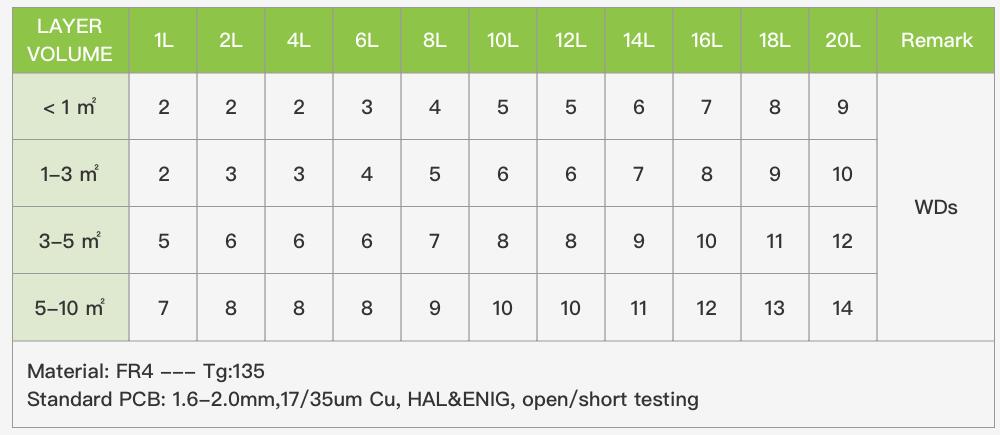

> Quotation for standard projects within 2 hours, quick 24 hours PCB prototype making.

> Multiple different product lines meet the requests of fast delivery of small batches and multi-variety prototyping and mass production.

> Expedited production line for prototyping double-sided PCB up to 24 hours, 4 layers 48 hours, 6 layers 72 hours etc.

> Mass production of double-sided PCB 5-6 days lead time, multi-layer PCB 7-9 days for standard boards.

> DHL, FedEx, TNT, UPS Express, fully meet the customer's rapid turnover requirements, punctual delivery rate of more than 99%.

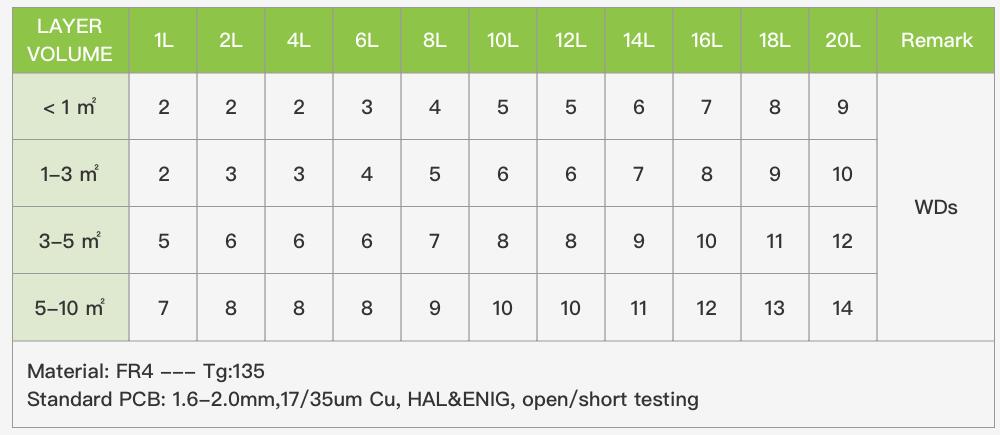

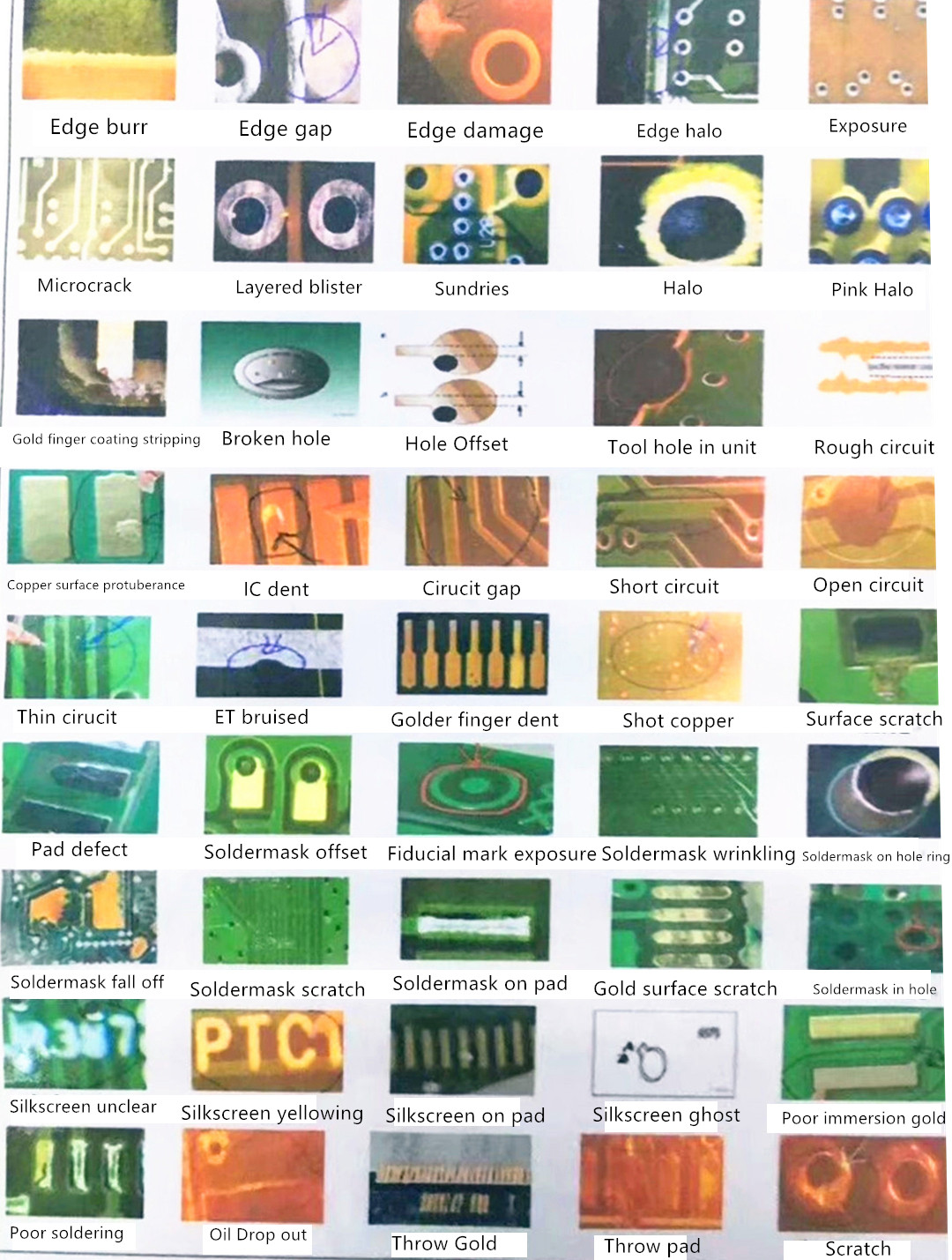

> Dozens of tests such as open/short

circuit testing( ET test), AOI, X-ray, impedance testing, solderability

testing, thermal shock testing, metallographic micro-slicing analysis,

halogen-free testing, etc. 100% outgoing pass rate.

>

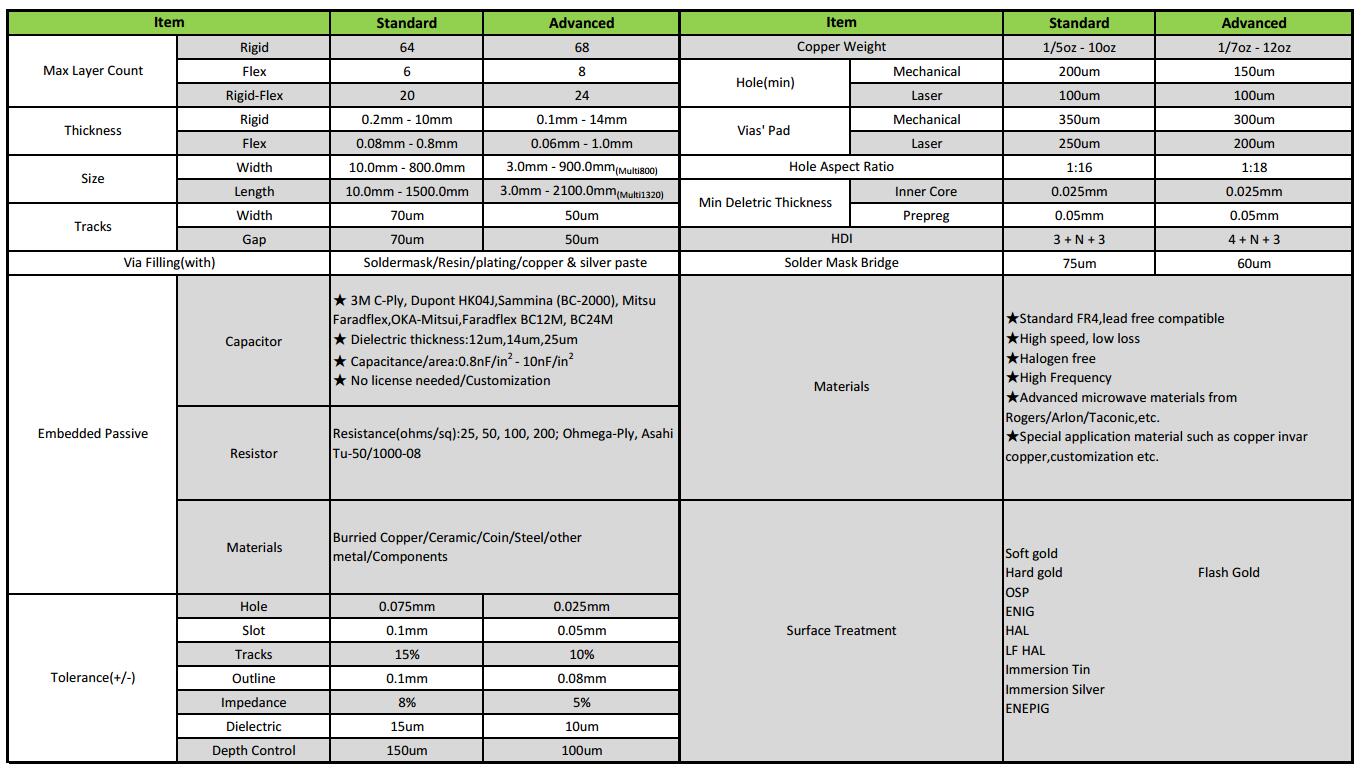

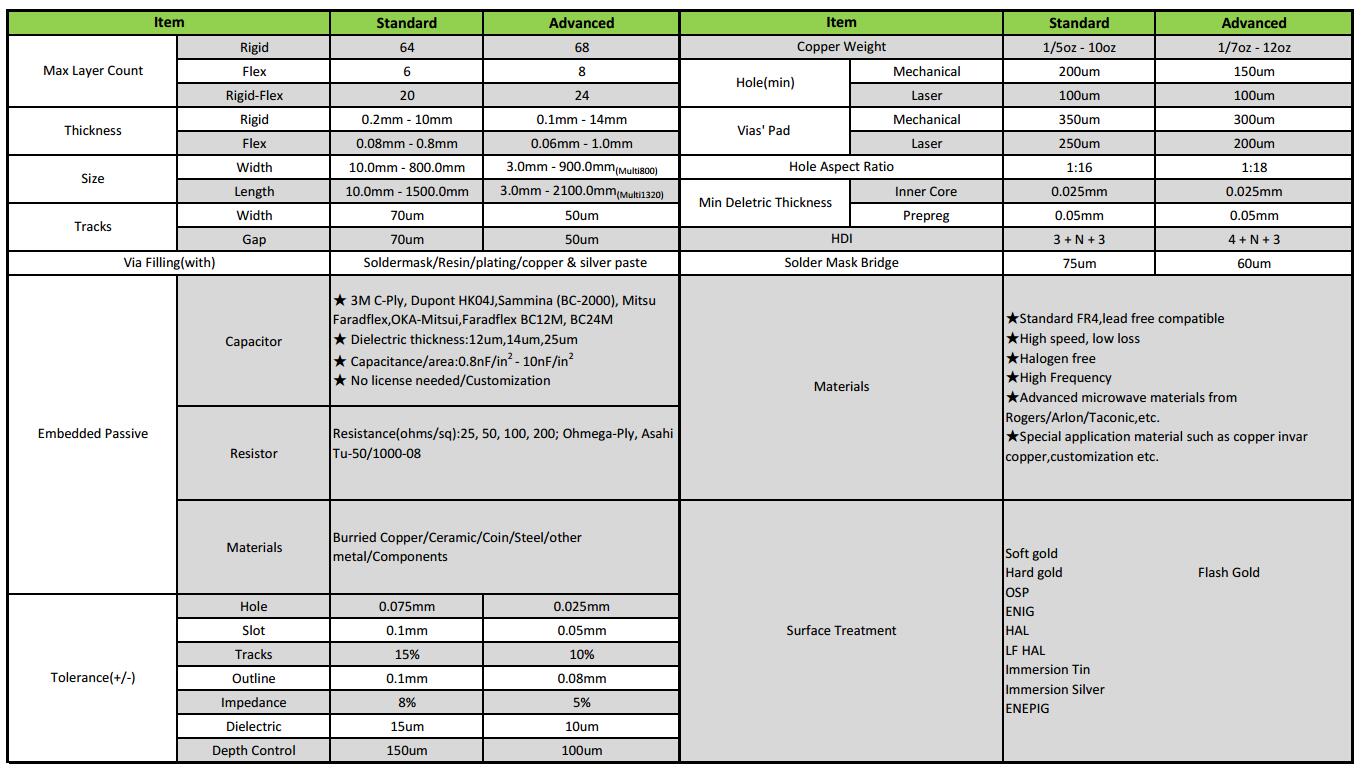

Provide 1-64 layers of different thickness, different materials,

different processes of product customization, of which the CCL using

A-class raw materials, high quality assurance.

> Unlimited

PCB capabilities,we provide various and advanced technology PCBs

include rigid, FPC,

rigid-flex, metal core, microwave/RF, HDI, any layer, heavy copper,

large-size, embedded, LED, backplane, ceramic substrate, IC substrate,

high-frequency,

high-density and high-performance PCB.

> Eight major surface treatment technology and high-quality ink printing, beautiful and reliable.

R&D is a key factor in developing new

competitive advantage in the electronic manufacturing industry. Rocket

PCB Solution Ltd in particular has devoted to R&D and as a result,

we constantly soar ahead of competition. We have continued to absorb the

talents from all directions to constitute the strong R&D team.

An innovative and creative R&D team is a key competitive advantage

for Rocket PCB. Without this team, we could not have become a

competitive manufacturer in the electronic manufacturing industry. The

team focuses on midterm proactive development and long-term research,

which includes quality improvement, operational efficiency, analysis of

every stage of production, and new and existing PCB solutions. In order

to maintain and improve R&D strength, our R&D team regularly

participate in high-level seminar in the electronic manufacturing

industry, keep close to the industry dynamics and frequently update

their industry expertise. The long-standing commitment to R&D has

brought our business results to the highest level.

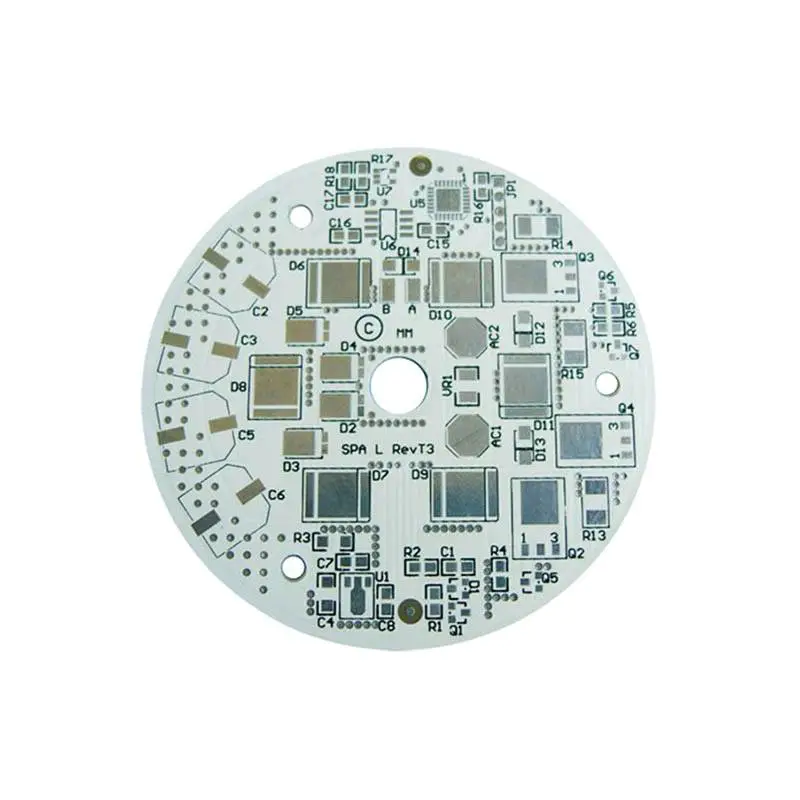

To show our

improving R&D capability in the market, we successfully developed

Aluminum PCB. The distinctive characters are High quality and

quick turn.

Rocket PCB is established as a provider of aluminum PCB with tailored service at affordable price. Aiming to

become an international high-quality supplier in the electronic

manufacturing industry, we will carry forward the outstanding spirit of

'Focus on customer first' and keep making progress in technology

innovation, constantly challenge ourselves and provide better and better

services for customers. Contact us today at https://www.rocket-pcb.com to learn more about what we can offer to your business.

SPECIALIZED MANUFACTURING

Conductive materials and core-to-core bonding

Embedded components

RF connector attachment

Laser direct imaging (LDI)

Laser etching

Laser forming

Multi-level cavity construction

Plated cavities and edges

Composite/hybrid Structures

N+N dual press-fit

Dual-drill

Bonding on metal core

Bulid-up HDI

Long-short and staged gold finger

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF control

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF control

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF contro

CAPABILITIES

3mil line and space

4mil laser defined vias

6mil chip-on-board

6mil mechanically drilled vias

Conductive and non-conductive via fill

Dual backdrilling

Sequential lamination

Mixed dielectric

Heatsink Bonding

Heavy copper/thermal vias

Blind/buried vias

Stacked and staggerd microvias

EXTENSIVE ANALYTICAL TESTING![product-Rocket PCB-Aluminum Base Printed Circuit Board LED Light PCB Control Board-img-2]()

Design Rules Check(DRC)

Electrical Testing

Automated Optical Inspection(AOI)

X-Ray

Plating thickness testing

Metalized vias inspection

Thermal shock testing

Surface peelability testing

Impedance control testing

100% visual inspection

Solderability testing

Ionic cleanliness testing

Metallographic microscopic analysis

High voltage testing

Insulating resistance testing

FEATURES

PTFE

High speed/low loss

High temperature

Low CTE

Lead-free, HASL, ENIG, EPENIG, Immersion Silver, Tin, Gold finger

Combination surface finished

Copper-filled microvias

Consumer electronics

Automotive electronics

Communications

Energy

Industrial & Instrumentation

IOT/Smart Home

Medical electronics

Security Industry