electronic products through quality pcb\'s ensure quality

by:Rocket PCB

2019-09-25

We find it harder and harder to earn income now, so when they buy anything from the market, they always want to get their money.

They always look for quality, especially when they need to pay a lot.

No one wants to deal with unqualified products, whether it\'s outdoor equipment or electronic equipment.

Companies or manufacturers must then ensure that their quality control departments remain vigilant at all times.

They can\'t give people anything that doesn\'t meet the standards at all.

Otherwise, these businesses will not only lose sales.

They also lost to their competitors, who are in a more difficult situation given the current global economic crisis.

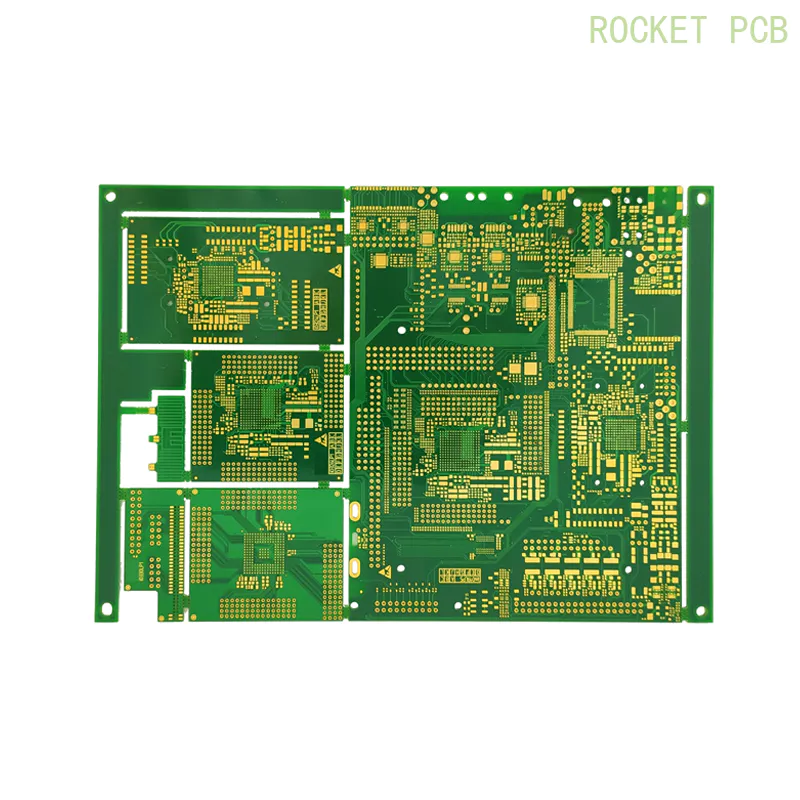

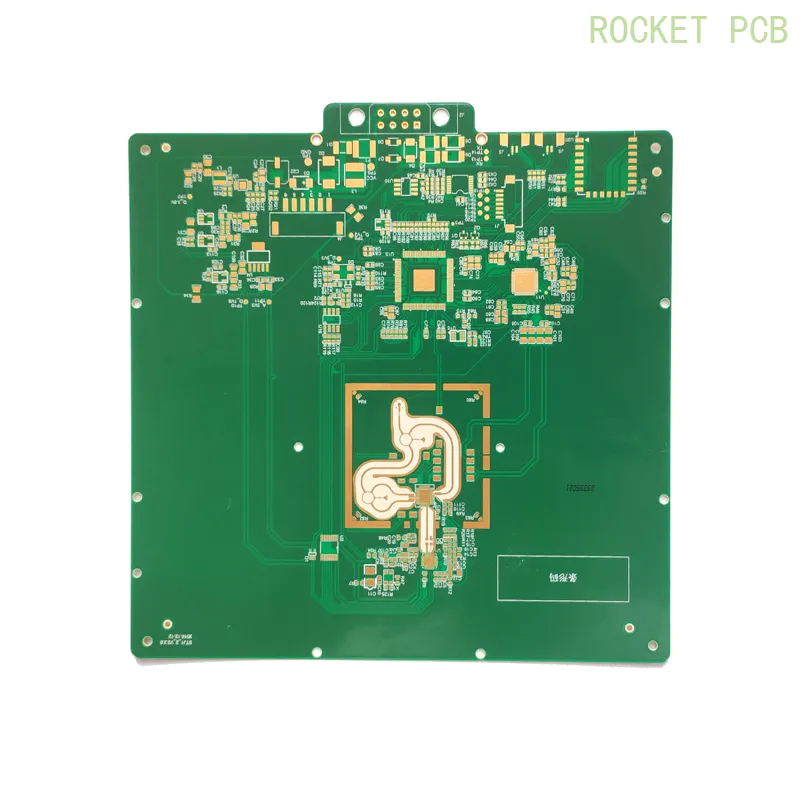

For companies that produce electronic products, it is essential to ensure the high quality of their PCB or printed circuit boards.

The customer will not be able to use this electronic device, which will not only lead to his own frustration when buying a PCB defective product.

This can lead to frustration from the manufacturer as the company has just discovered dissatisfied customers who are sure to make bad comments about products that are not delivered as expected.

This will definitely bring disaster to any brand.

As we all know, PCB is responsible for the electronic function of any electronic product.

For example, a PCB damaged or defective headset will not be able to produce the experience the customer expects, simply because it will not be able to do so electronically.

The defect of the headphone PCB will make it useless.

The PCB is where the signal is processed to achieve the desired output.

When it does not work as expected, the end user will not be able to use the device.

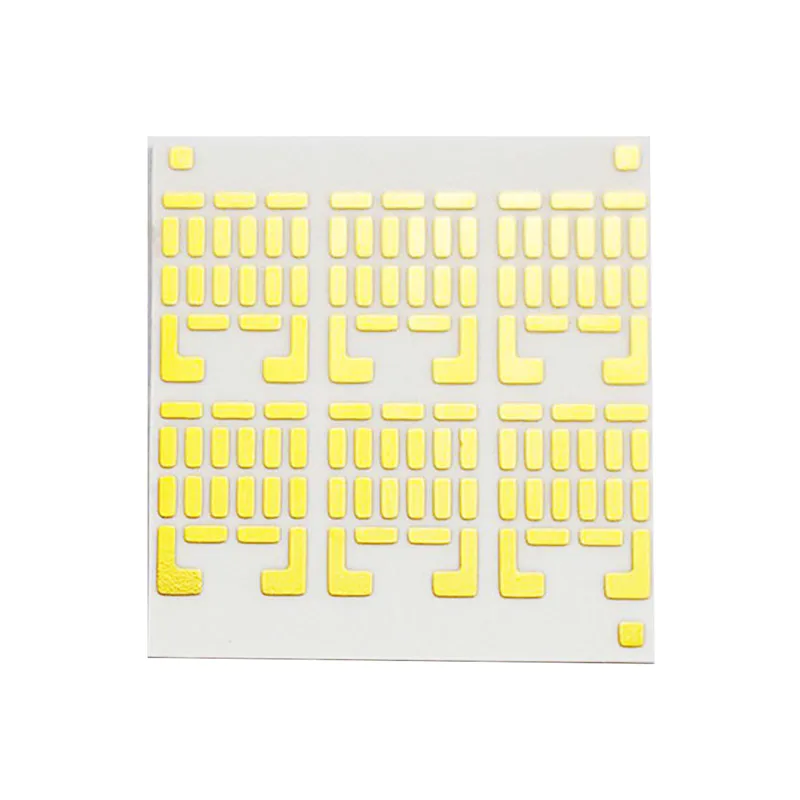

Companies that make electronic products always have to do PCB testing on their products.

This is to ensure that the PCB is actually working before it is installed into the product for marketing.

Some manufacturers have their own PCB testing department, but for smaller manufacturers, there are also companies specializing in PCB testing.

Anyway, the fact that the PCB should be tested remains.

The manufacturer therefore considers this stage of production to be critical.

In addition, it is not only the product itself that has been damaged.

Their corporate image is sure to be hit by an untested PCB.

They always look for quality, especially when they need to pay a lot.

No one wants to deal with unqualified products, whether it\'s outdoor equipment or electronic equipment.

Companies or manufacturers must then ensure that their quality control departments remain vigilant at all times.

They can\'t give people anything that doesn\'t meet the standards at all.

Otherwise, these businesses will not only lose sales.

They also lost to their competitors, who are in a more difficult situation given the current global economic crisis.

For companies that produce electronic products, it is essential to ensure the high quality of their PCB or printed circuit boards.

The customer will not be able to use this electronic device, which will not only lead to his own frustration when buying a PCB defective product.

This can lead to frustration from the manufacturer as the company has just discovered dissatisfied customers who are sure to make bad comments about products that are not delivered as expected.

This will definitely bring disaster to any brand.

As we all know, PCB is responsible for the electronic function of any electronic product.

For example, a PCB damaged or defective headset will not be able to produce the experience the customer expects, simply because it will not be able to do so electronically.

The defect of the headphone PCB will make it useless.

The PCB is where the signal is processed to achieve the desired output.

When it does not work as expected, the end user will not be able to use the device.

Companies that make electronic products always have to do PCB testing on their products.

This is to ensure that the PCB is actually working before it is installed into the product for marketing.

Some manufacturers have their own PCB testing department, but for smaller manufacturers, there are also companies specializing in PCB testing.

Anyway, the fact that the PCB should be tested remains.

The manufacturer therefore considers this stage of production to be critical.

In addition, it is not only the product itself that has been damaged.

Their corporate image is sure to be hit by an untested PCB.

Custom message