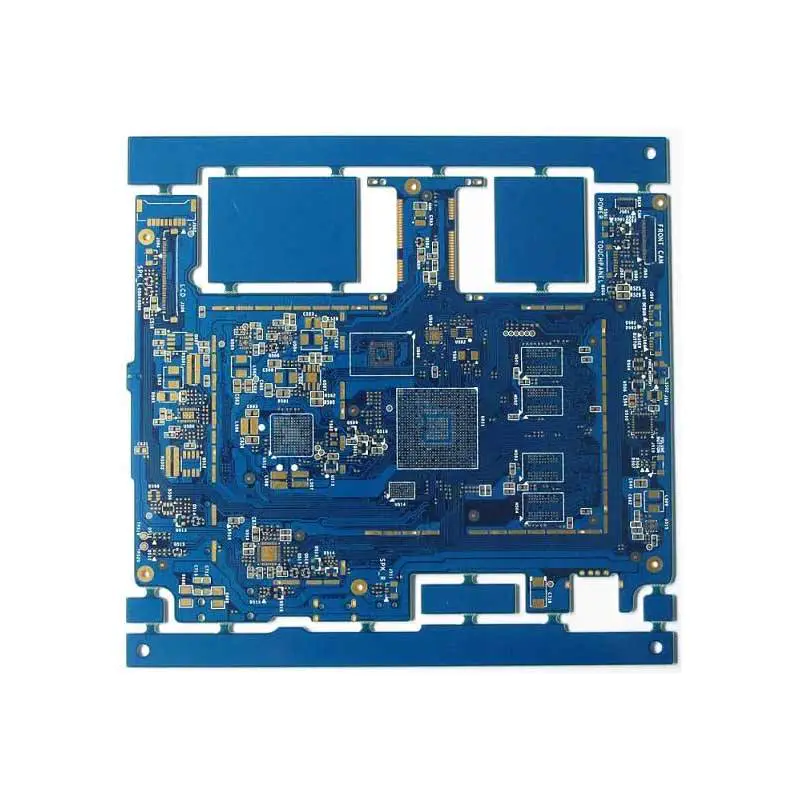

acid etching printed circuit boards

by:Rocket PCB

2019-09-27

I have been playing with the toner transfer method for producing printed circuit boards for a while and I have encountered varying degrees of success.

This is a remake of my blog post and I think I will provide it here as an Instructure.

It doesn\'t need to be expensive or difficult to make your own printed circuit board, but in the process I have learned some tips that may help you achieve greater success.

If you don\'t know the process. . .

To put it simply: acid is not a toy.

Be cautious at all times.

I don\'t take any responsibility for you beating idiots with acid.

If you are a minor, you must get help from your parents/guardians or give up now!

The paper you use in your laser printer is important.

Some people use (recycling)magazine paper.

This is usually a thin half.

Glossy paper.

Others say good quality paper is used.

I did a little experiment with a different sheet and for my money I used an A4 laser print paper of quite good quality (80gsm)is good enough.

I get consistent results using print paper than anything else.

When you put your printed image on a copper-clad board, reduce it to the right size first.

I used to tape the paper onto the board.

I did a little experiment here, and I think the easiest way is to first iron a corner and be careful not to iron your fingers when you press your fingers on the board.

Remember that copper is a good thermal conductor, so it will burn you if you keep it for too long.

Once you iron a corner, cover the entire surface of the board and paper with an iron, and press it down.

If you do the ironing board on the ironing board . . . . . . The ironing board will be your enemy.

It gives too much, the PCB will swing away from the heat with pressure.

Also, this piece of paper will come down from the board Cup and you will get a blurry transfer.

Use the ironing board anyway, but put a piece of wood under the PCB (

At least as long and wide as an iron).

This will prevent the PCB from getting uneven heat and greatly improve your transmission.

The time you take the iron is another point of contention.

Some people say 4 minutes to the iron plate, well, I\'m here to tell you that I \'ve been iron for about 2 minutes, up to 1/2 minutes.

I \'ve got the paper Coke and I start smoking if I\'m close to 4 minutes.

It\'s good to soak in water, but you should soak in hot water.

I will boil the kettle before I put the iron on the board.

When I transfer enough I put the iron aside and pour about 3 cm of boiling water into an old ice

The cream container, then put the board directly in.

When the water is cold (

It\'s almost cold)

Then I took the board out of the water and wiped the paper off.

Cook the kettle again if you need it

Soak it up and take any extra paper from the blackboard.

You can repeat the soaking process as you like. . .

It will not ruin the board or the newspaper.

However, it is better not to soak too much if your cardboard is a very cheap adhesive paper material.

Test the board to make sure.

Really, you want a fiberglass or phenol plastic base.

Look for boards for \"FR.

When you remove the paper, you may notice that there are some gaps or holes in your transfer.

Well, this happened.

To recover from this situation, the thing to do is to fill the gaps with a pen that uses an etchproof ink.

You will get a lot of money if you search the corrosion resistant pen online.

If you are not as rich as Croesus, go to your stationery store or art store and buy a Staedtler Lumocolor permanent mark.

Their thickness ranges from (

What I see, this is not a clear list)

M to F thin. . . Is there a small S?

But I haven\'t really seen the tip of it yet.

I had a medium tip and it was good for me and it only cost me $4.

05 Australian dollars in art stores (

Artery of Hobart).

I also tried to compare with a Chinagraph pencil and found that while it did lay an etchproof material, the line was sketchy and left me a pitted mark.

I think this is because of the way the pencil works on a hard surface.

I tried some free ones, too.

The hand is bent with the marker pen and the result is fine.

Of course, Staedtler is not the only manufacturer to make permanent ink marks with anti-etching properties, but this is what I tried and succeeded.

The art store also showed me some other etching-resistant materials.

One is 120 ml bottles, $44 for exposure, so I think it\'s good.

Another $22 200 ml bottle is a very thin latex for a variety of other artistic pursuits such as watercolors and screen printing.

The disadvantage of these other materials is that they are applied with a brush.

Now, I have a lot of fine brushes in my war game era, and I admit that one bottle per milliliter, or even $44, is much cheaper than the marker, but I don\'t like to paint it with a brush . . . . . . My eyesight is no longer so good.

At this stage, you should also clean up the sticky residue on the tape with some acetone (

Also from chemists).

Sticky garbage is also acidic, leaving messy copper spots on the PCB.

When it comes to acid bath, there are actually only two options.

Iron chloride or copper acid.

Iron Chloride is too painful for me and much more expensive.

On the other hand, copper acid is much cheaper and easy to get.

Simply mix 2 parts of hydrogen peroxide with 1 part of hydrochloric acid to get the base of the etching agent.

Hydrogen peroxide from chemists (

Yes, that\'s right, what people use to make hair blonde).

Hydrochloric acid comes from hardware store (

Cleaning part in brick).

The main drawback of this acid is that the peroxide evaporates quite quickly, so just make enough money for what you do today and don\'t expect it to be useful tomorrow.

Also, make sure to add the acid to the peroxide instead of the opposite.

An acid bath on your face can be frustrating.

Dispose of your waste by bringing the waste to the chemical waste site . . . . . . Instead of pouring it in the sink (

Even if you use acid in salt, it is still poison).

Copper acid takes a while to etching your board, so don\'t plan to fill your board immediately or leave it unattended.

It\'s really not a good idea to sit in the acid and go shopping, too many things can happen and it can ruin your day.

It will be a bit transparent when your board is etched properly.

You can take the cardboard out of the tub, rinse it thoroughly and dry it, then lift it to the Sun to test the gloss of the cardboard.

You should see your copper trace clearly through the board.

If you can, take out your multimeter and switch to the continuity test.

Test the circuit board by placing an anode (

Or cathode, it doesn\'t matter which one)

In one tracking and another (

Cathode or anode)

In the field of PCB . . . . . . There shouldn\'t be any copper there.

If you hear a beep, it will go back to the bathroom.

You may also want to do regular continuity testing from one end to the other of each trace to ensure that the tracking is continuous.

Sometimes you will still have gaps and the way to solve this problem is to make the welding Bridge at the break.

The image above is the 4x5 LED matrix I made (

Cheap desk lamp).

There are two points on the board (

Red border)

That\'s the gap we\'re tracking.

For these, I made the welding Bridge by building a pad at both ends of the break and then dragging the soldering iron through the gap, and the soldering tin followed the iron to form a bridge.

If you have a gap that the welding bridge will not fix, Weld with a small amount of copper core wire.

In the continuity test, check the entire board with a multimeter to ensure that all tracks are complete.

Sometimes the gap is micro, and this is the only way to find out your shortcomings.

So now your board has been completely etched, flushed and tested.

Now you want to clear the etchresistant toner/mark.

For this you need to look for some acetone for your wife/daughter\'s vanity.

Or, when you go to the pharmacy to buy hydrogen peroxide, you can buy it yourself.

Apply some acetone on cotton swab, cotton bud, tissue, thumb and \"wipe off\" the offending mark \"! Out! Damned spot! ” (

I thought Mrs. Macbeth was trying to drive her dog away. .

You may need to discard the black cloth/swab/Bud and have another one to do the job.

You should have a PCB available at this stage, waiting for drilling and filling.

Put it on with you-

Screen circuit design, since you confuse both positive and negative images, it\'s not uncommon to have your PCB back-to-back.

I know I \'ve done enough.

To be honest, you can cut your dud PCB into small pendants and earrings for your wife/girlfriend/daughter . . . . . . They will like them (sure).

For the silk shield on the PCB, this is a really cheap alternative, just print a copy of the PCB silk side and glue it to the top of the board.

I made vinyl acetate (

White Wood glue-PVA)

On the board, then put the paper on it, then I sealed it on the paper with more pva glue.

The picture above is the Arduino shield I made (

ICSP of ATTiny85).

Alternatively, you can transfer the mirror image to the front of the motherboard using the same toner transfer method.

With careful management and good luck, you will be able to make your own PCB quickly and cheaply, keeping in mind that you are making toxic waste that you need to deal.

This is a remake of my blog post and I think I will provide it here as an Instructure.

It doesn\'t need to be expensive or difficult to make your own printed circuit board, but in the process I have learned some tips that may help you achieve greater success.

If you don\'t know the process. . .

To put it simply: acid is not a toy.

Be cautious at all times.

I don\'t take any responsibility for you beating idiots with acid.

If you are a minor, you must get help from your parents/guardians or give up now!

The paper you use in your laser printer is important.

Some people use (recycling)magazine paper.

This is usually a thin half.

Glossy paper.

Others say good quality paper is used.

I did a little experiment with a different sheet and for my money I used an A4 laser print paper of quite good quality (80gsm)is good enough.

I get consistent results using print paper than anything else.

When you put your printed image on a copper-clad board, reduce it to the right size first.

I used to tape the paper onto the board.

I did a little experiment here, and I think the easiest way is to first iron a corner and be careful not to iron your fingers when you press your fingers on the board.

Remember that copper is a good thermal conductor, so it will burn you if you keep it for too long.

Once you iron a corner, cover the entire surface of the board and paper with an iron, and press it down.

If you do the ironing board on the ironing board . . . . . . The ironing board will be your enemy.

It gives too much, the PCB will swing away from the heat with pressure.

Also, this piece of paper will come down from the board Cup and you will get a blurry transfer.

Use the ironing board anyway, but put a piece of wood under the PCB (

At least as long and wide as an iron).

This will prevent the PCB from getting uneven heat and greatly improve your transmission.

The time you take the iron is another point of contention.

Some people say 4 minutes to the iron plate, well, I\'m here to tell you that I \'ve been iron for about 2 minutes, up to 1/2 minutes.

I \'ve got the paper Coke and I start smoking if I\'m close to 4 minutes.

It\'s good to soak in water, but you should soak in hot water.

I will boil the kettle before I put the iron on the board.

When I transfer enough I put the iron aside and pour about 3 cm of boiling water into an old ice

The cream container, then put the board directly in.

When the water is cold (

It\'s almost cold)

Then I took the board out of the water and wiped the paper off.

Cook the kettle again if you need it

Soak it up and take any extra paper from the blackboard.

You can repeat the soaking process as you like. . .

It will not ruin the board or the newspaper.

However, it is better not to soak too much if your cardboard is a very cheap adhesive paper material.

Test the board to make sure.

Really, you want a fiberglass or phenol plastic base.

Look for boards for \"FR.

When you remove the paper, you may notice that there are some gaps or holes in your transfer.

Well, this happened.

To recover from this situation, the thing to do is to fill the gaps with a pen that uses an etchproof ink.

You will get a lot of money if you search the corrosion resistant pen online.

If you are not as rich as Croesus, go to your stationery store or art store and buy a Staedtler Lumocolor permanent mark.

Their thickness ranges from (

What I see, this is not a clear list)

M to F thin. . . Is there a small S?

But I haven\'t really seen the tip of it yet.

I had a medium tip and it was good for me and it only cost me $4.

05 Australian dollars in art stores (

Artery of Hobart).

I also tried to compare with a Chinagraph pencil and found that while it did lay an etchproof material, the line was sketchy and left me a pitted mark.

I think this is because of the way the pencil works on a hard surface.

I tried some free ones, too.

The hand is bent with the marker pen and the result is fine.

Of course, Staedtler is not the only manufacturer to make permanent ink marks with anti-etching properties, but this is what I tried and succeeded.

The art store also showed me some other etching-resistant materials.

One is 120 ml bottles, $44 for exposure, so I think it\'s good.

Another $22 200 ml bottle is a very thin latex for a variety of other artistic pursuits such as watercolors and screen printing.

The disadvantage of these other materials is that they are applied with a brush.

Now, I have a lot of fine brushes in my war game era, and I admit that one bottle per milliliter, or even $44, is much cheaper than the marker, but I don\'t like to paint it with a brush . . . . . . My eyesight is no longer so good.

At this stage, you should also clean up the sticky residue on the tape with some acetone (

Also from chemists).

Sticky garbage is also acidic, leaving messy copper spots on the PCB.

When it comes to acid bath, there are actually only two options.

Iron chloride or copper acid.

Iron Chloride is too painful for me and much more expensive.

On the other hand, copper acid is much cheaper and easy to get.

Simply mix 2 parts of hydrogen peroxide with 1 part of hydrochloric acid to get the base of the etching agent.

Hydrogen peroxide from chemists (

Yes, that\'s right, what people use to make hair blonde).

Hydrochloric acid comes from hardware store (

Cleaning part in brick).

The main drawback of this acid is that the peroxide evaporates quite quickly, so just make enough money for what you do today and don\'t expect it to be useful tomorrow.

Also, make sure to add the acid to the peroxide instead of the opposite.

An acid bath on your face can be frustrating.

Dispose of your waste by bringing the waste to the chemical waste site . . . . . . Instead of pouring it in the sink (

Even if you use acid in salt, it is still poison).

Copper acid takes a while to etching your board, so don\'t plan to fill your board immediately or leave it unattended.

It\'s really not a good idea to sit in the acid and go shopping, too many things can happen and it can ruin your day.

It will be a bit transparent when your board is etched properly.

You can take the cardboard out of the tub, rinse it thoroughly and dry it, then lift it to the Sun to test the gloss of the cardboard.

You should see your copper trace clearly through the board.

If you can, take out your multimeter and switch to the continuity test.

Test the circuit board by placing an anode (

Or cathode, it doesn\'t matter which one)

In one tracking and another (

Cathode or anode)

In the field of PCB . . . . . . There shouldn\'t be any copper there.

If you hear a beep, it will go back to the bathroom.

You may also want to do regular continuity testing from one end to the other of each trace to ensure that the tracking is continuous.

Sometimes you will still have gaps and the way to solve this problem is to make the welding Bridge at the break.

The image above is the 4x5 LED matrix I made (

Cheap desk lamp).

There are two points on the board (

Red border)

That\'s the gap we\'re tracking.

For these, I made the welding Bridge by building a pad at both ends of the break and then dragging the soldering iron through the gap, and the soldering tin followed the iron to form a bridge.

If you have a gap that the welding bridge will not fix, Weld with a small amount of copper core wire.

In the continuity test, check the entire board with a multimeter to ensure that all tracks are complete.

Sometimes the gap is micro, and this is the only way to find out your shortcomings.

So now your board has been completely etched, flushed and tested.

Now you want to clear the etchresistant toner/mark.

For this you need to look for some acetone for your wife/daughter\'s vanity.

Or, when you go to the pharmacy to buy hydrogen peroxide, you can buy it yourself.

Apply some acetone on cotton swab, cotton bud, tissue, thumb and \"wipe off\" the offending mark \"! Out! Damned spot! ” (

I thought Mrs. Macbeth was trying to drive her dog away. .

You may need to discard the black cloth/swab/Bud and have another one to do the job.

You should have a PCB available at this stage, waiting for drilling and filling.

Put it on with you-

Screen circuit design, since you confuse both positive and negative images, it\'s not uncommon to have your PCB back-to-back.

I know I \'ve done enough.

To be honest, you can cut your dud PCB into small pendants and earrings for your wife/girlfriend/daughter . . . . . . They will like them (sure).

For the silk shield on the PCB, this is a really cheap alternative, just print a copy of the PCB silk side and glue it to the top of the board.

I made vinyl acetate (

White Wood glue-PVA)

On the board, then put the paper on it, then I sealed it on the paper with more pva glue.

The picture above is the Arduino shield I made (

ICSP of ATTiny85).

Alternatively, you can transfer the mirror image to the front of the motherboard using the same toner transfer method.

With careful management and good luck, you will be able to make your own PCB quickly and cheaply, keeping in mind that you are making toxic waste that you need to deal.

Custom message