by:Rocket PCB

2019-10-19

Vincent Graff update: at 08: 48 on March 2, 2011, the tricky business to predict in the future.

Tech enthusiasts are still laughing at the memory of Thomas Watson, general manager of the computer giant IBM, who stared into his crystal ball in 1943 and wisely predicted: he said, I think there may be five computers in the world.

So what do we think about the statement by American entrepreneur petpettis about his latest invention?

A device called Makerbot. o-

We have been told that matric can change the way we live and shop and completely change the manufacturing industry in the process? The Thing-o-

Marty is three.

3D space.

A traditional printer is connected to your computer to print out a flat image on the screen;

The 3D printer converts computer images to real solid objects.

In other words, it sees a picture of a project and then builds it.

On the table next to you, one quarter at a time.

The arrival of 3D printers heralds a revolution.

Some commentators say this could mean the death of traditional factory production lines once the technology is improved.

Is the computer salesman talking? Some pie-in-the-

Sky futurist?

No, economists.

Traditionally, magazines as sober as the Archbishop of Canterbury was in the state funeral.

A few days ago, the magazine declared: \"Just as no one can predict the impact of the steam engine by 1750 --

Or a 1450 printing machine, or a transistor in 1950 --

It is impossible to foresee.

Long-term impact of 3D printing.

Its title is \"print me a stradivari\" and imagine an era in which something as complex as a violin can be produced.

There is no doubt that insiders are very excited. Pettis, co-

The inventor of this thingo-Matic, is a 38-year-

Old teacher, sharp hair, side corner, big glasses.

\"We see the future and we know it will come,\" he said.

We are about one to four years away from a machine like this in almost everyone\'s house.

What is he talking about?

Let\'s start with where we are today.

You dropped a button on your coat? The Thing-o-

Matic will \"print\" a new one for you.

Lost the plug in the bathtub? Need a shoe-

Horn or toiletroll holder?

If you can find or create one or three

Size Chart of items, things-o-

Marty will create it for you.

You no longer have to throw something away just because the manufacturer stops producing spare parts.

You don\'t need to fill dozens of different tool boxes anymore.

Dimensions of nuts, bolts and screws.

A man will use a 3D printer to fix things at home and become a superhero for his wife, Pettis said.

The technology of converting graphics into objects has been in theory for several years and has been used by professional manufacturers.

But the price of these machines is between 20,000 and 100,000.

The new thing is that the 3D printer can be in contact with the normal hand-in-hand for the first time. The Thing-o-

Marty\'s price is about 890.

No price, but not expensive.

And only a little cheaper.

Keep this in mind: 25 years ago, the cost of a laser printer was about £ 1,000;

Now you can buy it for £ 50.

The remarkable thing about 3D printers is that the cost of creating a single project is the same as the cost of producing thousands of projects

A complete reversal of the \"economies of scale\" rule (

Production costs decrease as production increases)

This is excessive.

The riding principle of manufacturing.

That\'s why The Economist says 3D printing \"may have as far-reaching an impact on the world as the arrival of factories \".

However, when a revolution started, I didn\'t feel like a person --o-

Marty came to my office.

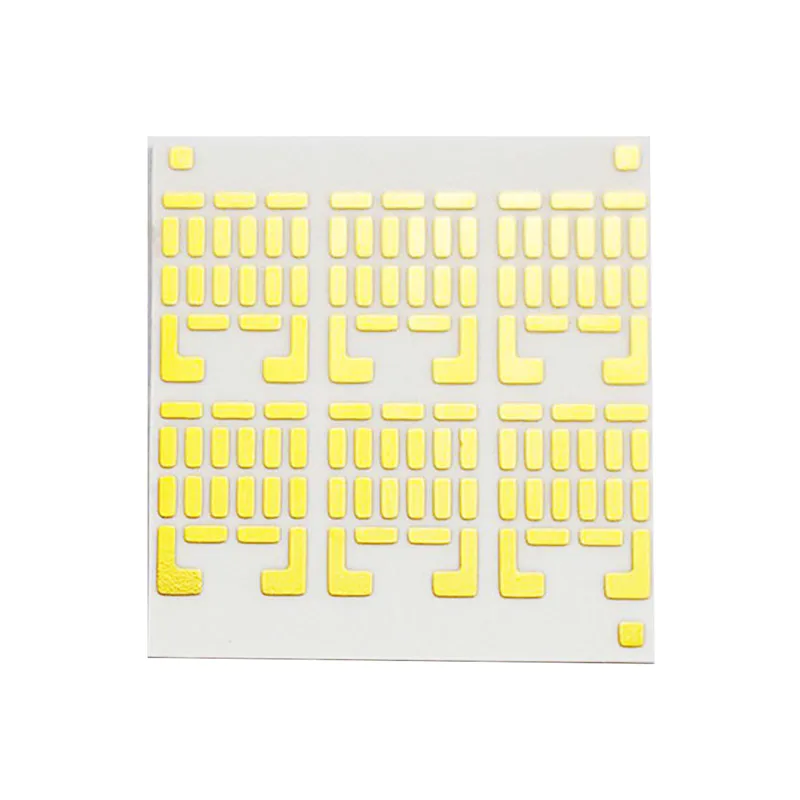

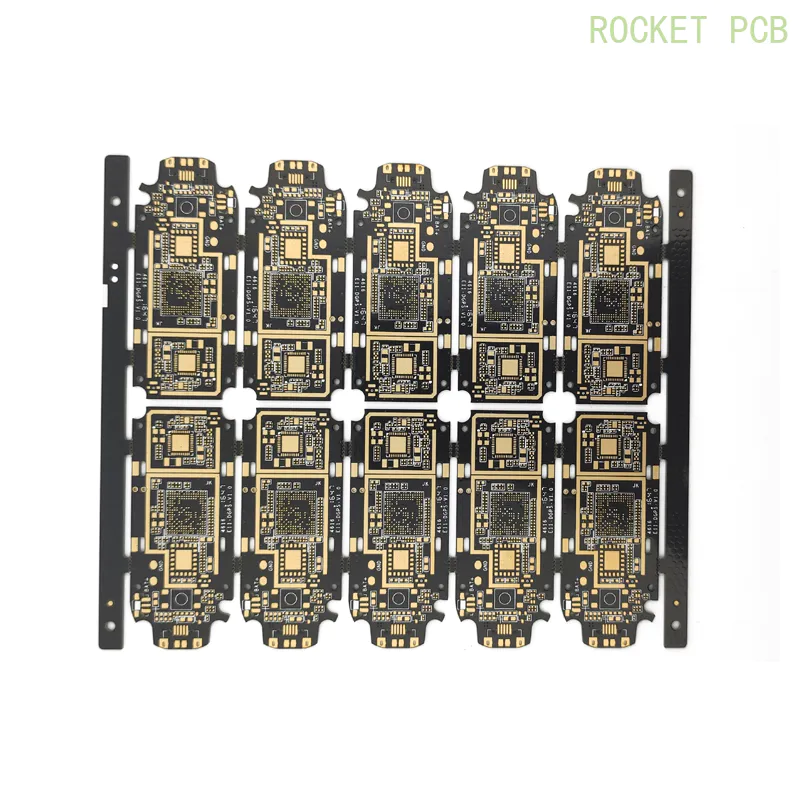

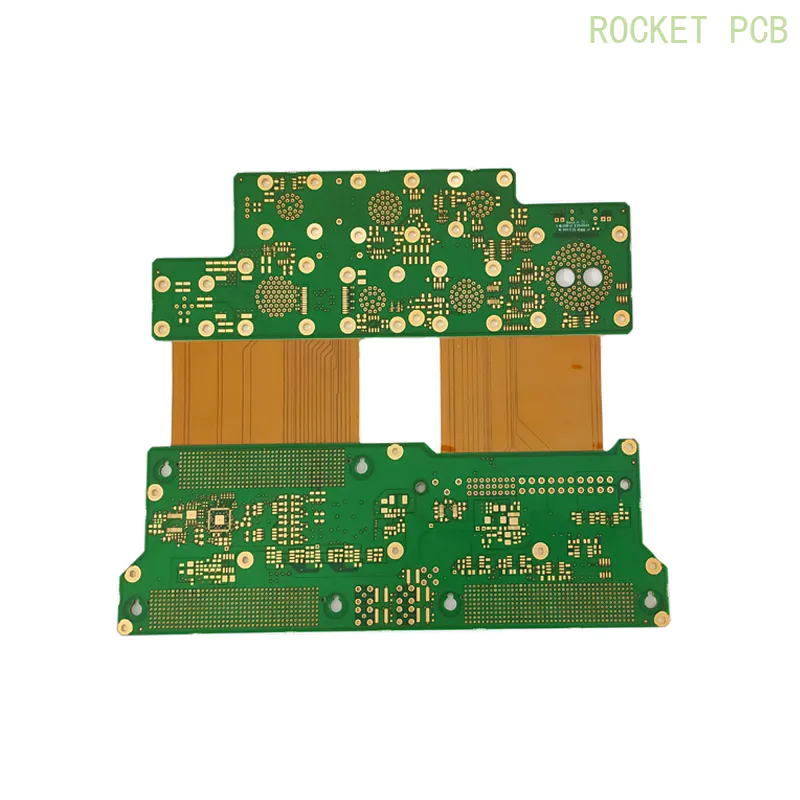

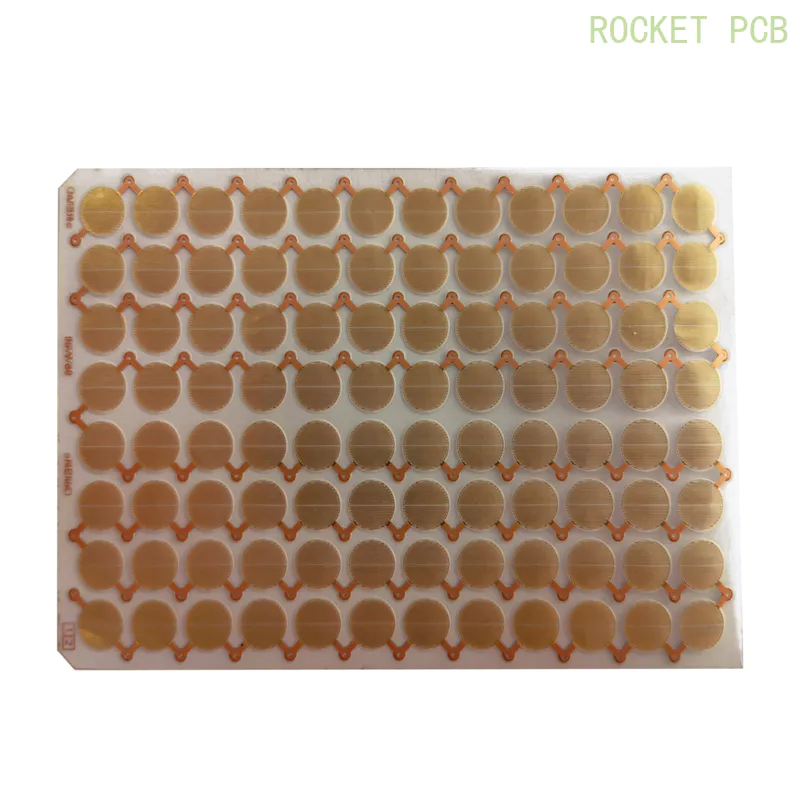

It is in the form of a kit, placed in a large carton with wires, dozens of pieces of plastic, a few pieces of printed circuit boards --

If you count every widget and screw, there may be 1,000 small parts. ‘We’ve had ten-year-

\"The old people put them together,\" Pettis said . \"

\"You can do this if you can assemble a family-friendly apartment --pack.

It takes about 12 hours.

I\'m sorry to say this is nonsense.

The task is far beyond my ability.

So I found a friend Matthew Walker, a computer programmer and someone who designed and built robots.

Matthew needed-

Experts in such things-

It takes 16 hours to assemble it.

He said the instructions were very good before qualifying in the following ways: \"But it was very tedious and very challenging.

However, the final result was impressive.

A wooden cube of 30 cm x 40 cm x 30 cm, similar to a tea box that has been hollowed out and plugged into the power supply.

At the center is a small metal platform that sits under a device that absorbs thin worms of plastic

About 2mm in diameter, as long as you need-

Then melt it under 220c and slowly drop it from a tiny molten stream onto the platform below.

Once programmed, the platform will fly in this and that way so that it is in the right place for the molten plastic

Drop down from above

Gradually build, a small layer at a time, into the desired shape.

This is the theory.

But what happens in practice?

Of course, you need a computer drawing for the 3D printer to start working.

There are about 5,000 designs on this thing. o-Matic website —

Everything from the door to the cupboard

All of this was released by colleagues. o-Matic owners.

Or, if you have this skill and time, you can draw a design yourself (

Google offers some free software to do this).

If you have an item in your home that you want to recreate, you can use a 3D scanner to scan the exact shape of it into your computer.

Once you connect your computer to this thingo-

Through the USB cable, the information needed to create a 3D shape is transferred to the machine, and then the machine starts to create a 3D shape.

This printer can only make plastic objects, but it is more expensive to use a printer of resin or metal.

Matthew and I chose something simple at first.

There is a picture of a hexagon nut on the website --

The kind of thing that can fix the bicycle lights.

After several wrong starts, the machine is working.

When the platform performs a charming little dance, it mumbles and screams quietly, always making sure it is in the right place for the next tiny layer of molten plastic.

14 minutes later, I had a perfectly formed hexagon nut made of bright red plastic with a spiral inside that looked like a nut in my toolbox.

It may be spare parts that I don\'t need, but it\'s an amazing sight.

Who knows that the process will get faster as the machine improves and improves?

Matthew tried a few more: vases and golf balls.

Some are working for the first time, some are not.

None of this reduced his enthusiasm for the project.

But he\'s not an ordinary fighter.

The real question is whether this thingo-

Marty will escape the field of technicians and continue to work with the rest of us.

Matthew said: \"Unless they are able to offer fully assembled products at a price that people can afford, it will never become mainstream.

Pettis believes that 3D printers will soon be as popular as mp3 players.

\"My grandfather saw the radio coming out,\" Pettis said.

\"My dad witnessed the appearance of TV.

Then, in my lifetime, we have computers, the Internet, and more, says Bre.

Technology is taking off.

Who knows what\'s possible?

Tech enthusiasts are still laughing at the memory of Thomas Watson, general manager of the computer giant IBM, who stared into his crystal ball in 1943 and wisely predicted: he said, I think there may be five computers in the world.

So what do we think about the statement by American entrepreneur petpettis about his latest invention?

A device called Makerbot. o-

We have been told that matric can change the way we live and shop and completely change the manufacturing industry in the process? The Thing-o-

Marty is three.

3D space.

A traditional printer is connected to your computer to print out a flat image on the screen;

The 3D printer converts computer images to real solid objects.

In other words, it sees a picture of a project and then builds it.

On the table next to you, one quarter at a time.

The arrival of 3D printers heralds a revolution.

Some commentators say this could mean the death of traditional factory production lines once the technology is improved.

Is the computer salesman talking? Some pie-in-the-

Sky futurist?

No, economists.

Traditionally, magazines as sober as the Archbishop of Canterbury was in the state funeral.

A few days ago, the magazine declared: \"Just as no one can predict the impact of the steam engine by 1750 --

Or a 1450 printing machine, or a transistor in 1950 --

It is impossible to foresee.

Long-term impact of 3D printing.

Its title is \"print me a stradivari\" and imagine an era in which something as complex as a violin can be produced.

There is no doubt that insiders are very excited. Pettis, co-

The inventor of this thingo-Matic, is a 38-year-

Old teacher, sharp hair, side corner, big glasses.

\"We see the future and we know it will come,\" he said.

We are about one to four years away from a machine like this in almost everyone\'s house.

What is he talking about?

Let\'s start with where we are today.

You dropped a button on your coat? The Thing-o-

Matic will \"print\" a new one for you.

Lost the plug in the bathtub? Need a shoe-

Horn or toiletroll holder?

If you can find or create one or three

Size Chart of items, things-o-

Marty will create it for you.

You no longer have to throw something away just because the manufacturer stops producing spare parts.

You don\'t need to fill dozens of different tool boxes anymore.

Dimensions of nuts, bolts and screws.

A man will use a 3D printer to fix things at home and become a superhero for his wife, Pettis said.

The technology of converting graphics into objects has been in theory for several years and has been used by professional manufacturers.

But the price of these machines is between 20,000 and 100,000.

The new thing is that the 3D printer can be in contact with the normal hand-in-hand for the first time. The Thing-o-

Marty\'s price is about 890.

No price, but not expensive.

And only a little cheaper.

Keep this in mind: 25 years ago, the cost of a laser printer was about £ 1,000;

Now you can buy it for £ 50.

The remarkable thing about 3D printers is that the cost of creating a single project is the same as the cost of producing thousands of projects

A complete reversal of the \"economies of scale\" rule (

Production costs decrease as production increases)

This is excessive.

The riding principle of manufacturing.

That\'s why The Economist says 3D printing \"may have as far-reaching an impact on the world as the arrival of factories \".

However, when a revolution started, I didn\'t feel like a person --o-

Marty came to my office.

It is in the form of a kit, placed in a large carton with wires, dozens of pieces of plastic, a few pieces of printed circuit boards --

If you count every widget and screw, there may be 1,000 small parts. ‘We’ve had ten-year-

\"The old people put them together,\" Pettis said . \"

\"You can do this if you can assemble a family-friendly apartment --pack.

It takes about 12 hours.

I\'m sorry to say this is nonsense.

The task is far beyond my ability.

So I found a friend Matthew Walker, a computer programmer and someone who designed and built robots.

Matthew needed-

Experts in such things-

It takes 16 hours to assemble it.

He said the instructions were very good before qualifying in the following ways: \"But it was very tedious and very challenging.

However, the final result was impressive.

A wooden cube of 30 cm x 40 cm x 30 cm, similar to a tea box that has been hollowed out and plugged into the power supply.

At the center is a small metal platform that sits under a device that absorbs thin worms of plastic

About 2mm in diameter, as long as you need-

Then melt it under 220c and slowly drop it from a tiny molten stream onto the platform below.

Once programmed, the platform will fly in this and that way so that it is in the right place for the molten plastic

Drop down from above

Gradually build, a small layer at a time, into the desired shape.

This is the theory.

But what happens in practice?

Of course, you need a computer drawing for the 3D printer to start working.

There are about 5,000 designs on this thing. o-Matic website —

Everything from the door to the cupboard

All of this was released by colleagues. o-Matic owners.

Or, if you have this skill and time, you can draw a design yourself (

Google offers some free software to do this).

If you have an item in your home that you want to recreate, you can use a 3D scanner to scan the exact shape of it into your computer.

Once you connect your computer to this thingo-

Through the USB cable, the information needed to create a 3D shape is transferred to the machine, and then the machine starts to create a 3D shape.

This printer can only make plastic objects, but it is more expensive to use a printer of resin or metal.

Matthew and I chose something simple at first.

There is a picture of a hexagon nut on the website --

The kind of thing that can fix the bicycle lights.

After several wrong starts, the machine is working.

When the platform performs a charming little dance, it mumbles and screams quietly, always making sure it is in the right place for the next tiny layer of molten plastic.

14 minutes later, I had a perfectly formed hexagon nut made of bright red plastic with a spiral inside that looked like a nut in my toolbox.

It may be spare parts that I don\'t need, but it\'s an amazing sight.

Who knows that the process will get faster as the machine improves and improves?

Matthew tried a few more: vases and golf balls.

Some are working for the first time, some are not.

None of this reduced his enthusiasm for the project.

But he\'s not an ordinary fighter.

The real question is whether this thingo-

Marty will escape the field of technicians and continue to work with the rest of us.

Matthew said: \"Unless they are able to offer fully assembled products at a price that people can afford, it will never become mainstream.

Pettis believes that 3D printers will soon be as popular as mp3 players.

\"My grandfather saw the radio coming out,\" Pettis said.

\"My dad witnessed the appearance of TV.

Then, in my lifetime, we have computers, the Internet, and more, says Bre.

Technology is taking off.

Who knows what\'s possible?

Custom message