Why Are Printed Circuit Boards Green?

by:Rocket PCB

2020-04-09

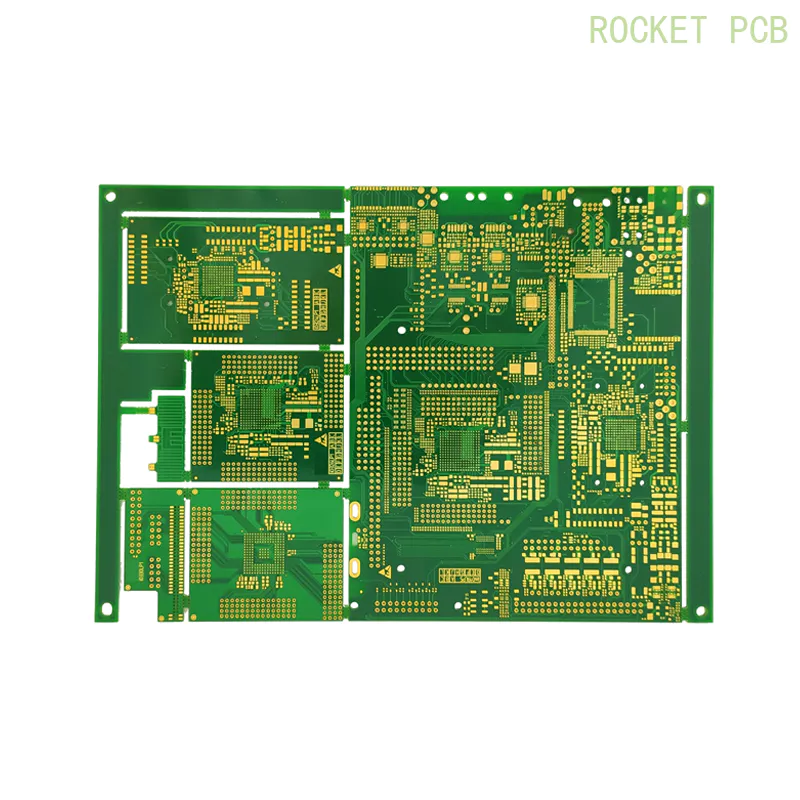

You have probably noticed printed circuit boards as they are the boards that contain electronic components that work as conduits to get various electronic devices, including computers, to work. One thing that most likely stands out in your mind when you look at these boards, which often appear to look like prototypes of small cities with their various components soldered onto them, is that they are colored green. You might have wondered why printed circuit boards are green.

Printed circuit boards are also known as PCBs. They have been around for over 100 years and are used in order to get electronic components to communicate with one another as well as act as a conduit for these devices. The underlay of a typical printed circuit board is made of a very thin copper, although there are usually several layers to the board. The underlay of the board can also be made of other conducting metals such as nickel. The underlay of the printed circuit board a conduit, which means that this allows for the conduction of the electronic devices.

The overlay of the printed circuit boards, however, is non-conduit. The most traditional type of non-conduit overlay for these boards is green epoxy resin. This is the most effective as well as most inexpensive way to cover the boards. Other overlays include a mixture of cotton and epoxy as well as glass with epoxy. However, most companies that manufacture these boards will use the green epoxy resin as their overlay of choice. This is an overlay that works just as well as any other system and also saves customers money at the same time.

When you are shopping for a printed circuit board, you should look for one that will be designed to your specifications. Many companies use mass produced boards for their purpose. The problem with these boards is that they are usually produced quickly and are created more for larger companies who order the boards in larger quantities. Smaller companies who need to have these boards created can use a company that will work with them to produce PCBs in a smaller quantity and will pay closer attention to such details as layout, design as well as quality control. When you are looking for PCBs for your company, one way to get the detail that you are looking for is to use a company that will design these boards to your specifications and guarantee your satisfaction.

pcb service is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

If you are thinking of having a , then you must be first clear about the purpose, which is driving you to buy this device. Rocket PCB Solution Ltd. offer quality for your needs with complete assurance of ability to serve your purpose.

Once we have a good idea of how pcb service can satisfy customer’s needs, consider whether we should create a skill for their demands.

The first machine to produce pcb manufacturing services, the pcb manufacturing services pcb service was invented in pcb manufacturing services in pcb manufacturing services by pcb manufacturing services and was subsequently improved.

pcb service is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

If you are thinking of having a , then you must be first clear about the purpose, which is driving you to buy this device. Rocket PCB Solution Ltd. offer quality for your needs with complete assurance of ability to serve your purpose.

Once we have a good idea of how pcb service can satisfy customer’s needs, consider whether we should create a skill for their demands.

The first machine to produce pcb manufacturing services, the pcb manufacturing services pcb service was invented in pcb manufacturing services in pcb manufacturing services by pcb manufacturing services and was subsequently improved.

Custom message