What will the PCB Factory be like after has 5G

Throughout history, the United States has had a strong innovation performance in the manufacturing sector. As early as 1913, Henry Ford brought a new turning point for the industrial society with the first automatic assembly line in the world. Circuit board factories have found that today, manufacturing still plays a crucial role in the economy: according to data released by the Bureau of labor statistics, the manufacturing industry supports nearly 13 million jobs in the United States.

However, with the continuous expansion of the skill gap and the increasing difficulty in finding suitable candidates for many jobs, enterprises will have to further improve the level of automation as the only way to increase profits, improve productivity and enhance competitive advantage. Research reports released by ABI research show that organizations that have not yet made digital transformation have substantially lagged behind other competitors.

At present, the coming of the global health crisis also brings great challenges and unforeseen new demands to the whole manufacturing industry. With the rapid spread of covid-19 epidemic, enterprises are facing a variety of unexpected market changes and problems. It's clear that manufacturing has to be more efficient and agile, while rapidly increasing capacity and supporting more different products. Once the core employees can't work normally, the highly automated production line becomes the only solution that the manufacturing industry can rely on. Only in this way, the whole industry can withstand the crisis pressure and continue to maintain relatively normal operating output.

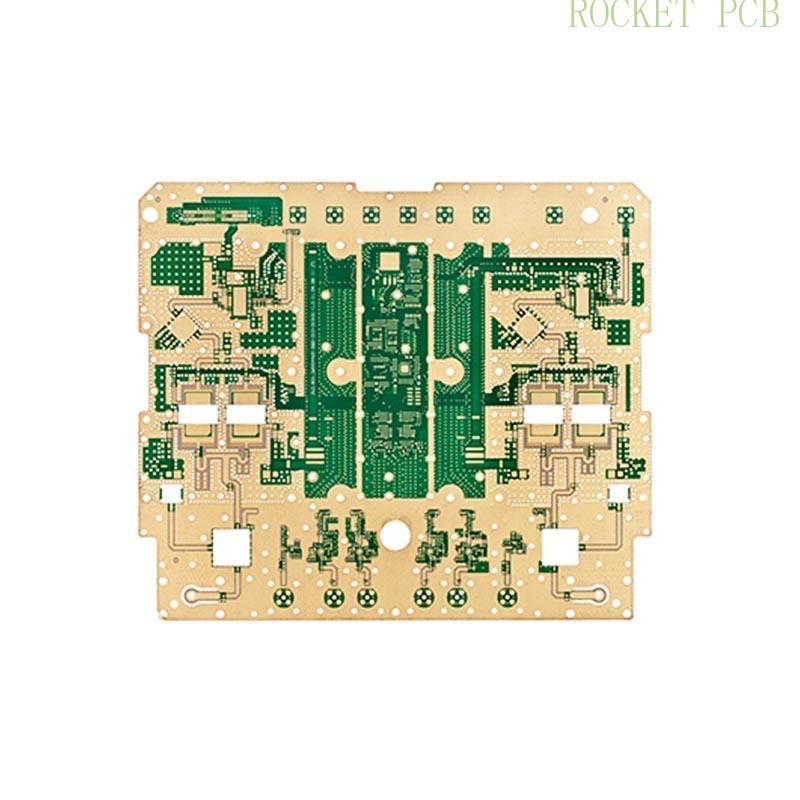

The automatic connection system established by fixed Ethernet and traditional wireless transmission system has become an inherent part of the factory environment. PCB manufacturers have learned that so far, wireless technology is not fast enough to support those machines that require instantaneous response and precise operation. However, 5G network, which has been gradually popularized, is expected to replace expensive fixed network cables, help equipment get rid of rigid wiring limitations, and finally make the overall layout and flexibility of the factory leap to a new height.

Finally, the production automation system supported by 5G connection will help manufacturing enterprises improve production efficiency, reduce operating costs and improve potential return on investment. In addition, 5G technology will also effectively improve the traceability of part quality, at the same time, bring more strict control guidance to the production process, ensure that the factory comprehensively improves production safety and product quality, and ultimately reduce the failure probability and enhance the reliability and repeatability of the business process.

How does 5G operation realize the above advantages?

The emerging 5G network can support three kinds of practical communication pcb types applicable to industrial Internet of things (IOT) scenarios, including:

Enhanced mobile broadband is similar to the familiar 4G network in nature, but with faster transmission speed. Large machine class communication (mmtc) is suitable for connecting a large number of sensors, and the bandwidth resource required by a single sensor is relatively low. Ultra reliable, low latency communication (urllc) is also the real game changer - allowing us to control all kinds of time sensitive operations with high precision remotely and automatically.

Each of these communication types may subvert or even completely change one or more core functions in the manufacturing chain.