What is the difference between the PCB and PCBA

PCB

PCB (

PrintedCircuitBoard)

, say again in Chinese printed circuit board, printed circuit board, is an important electronic components, electronic components to support the body, is the carrier of electronic electrical connection.

Since it is made of electronic printing, therefore is called 'printed circuit board.

Electronic equipment adopts the PCB, due to the consistency of the same kind of PCB, so as to avoid the artificial connection error, and can realize automatic instrumentation or SMT electronic components, automatic soldering, automatic detection, ensure the quality of the electronic equipment, improve the labor productivity, reduces the cost, and easy maintenance.

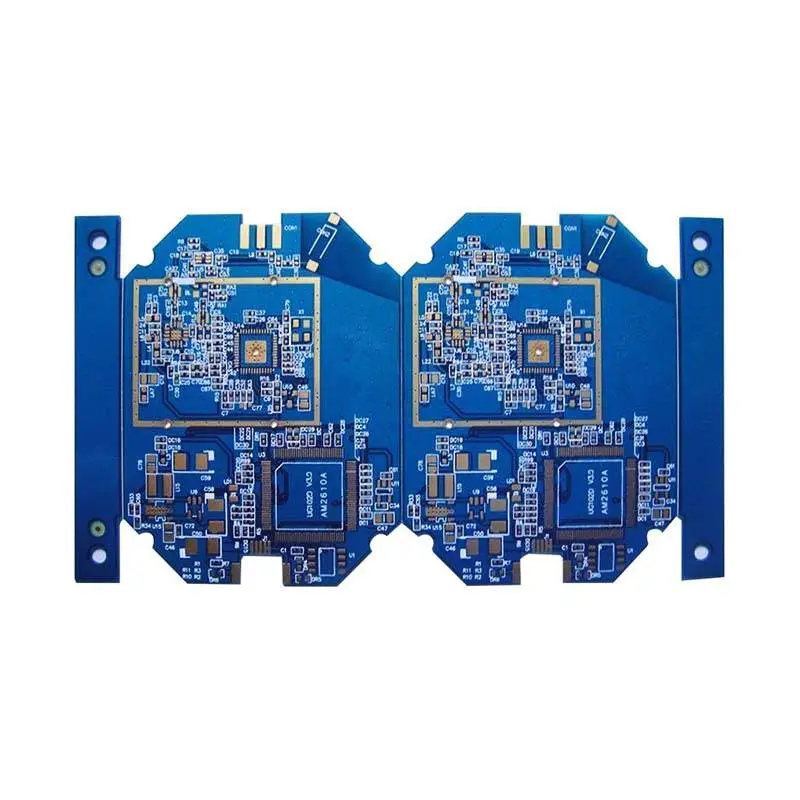

12 buried layer blind hole circuit board PCB can get more and more widely used, because it has many unique advantages, almost Gua as follows.

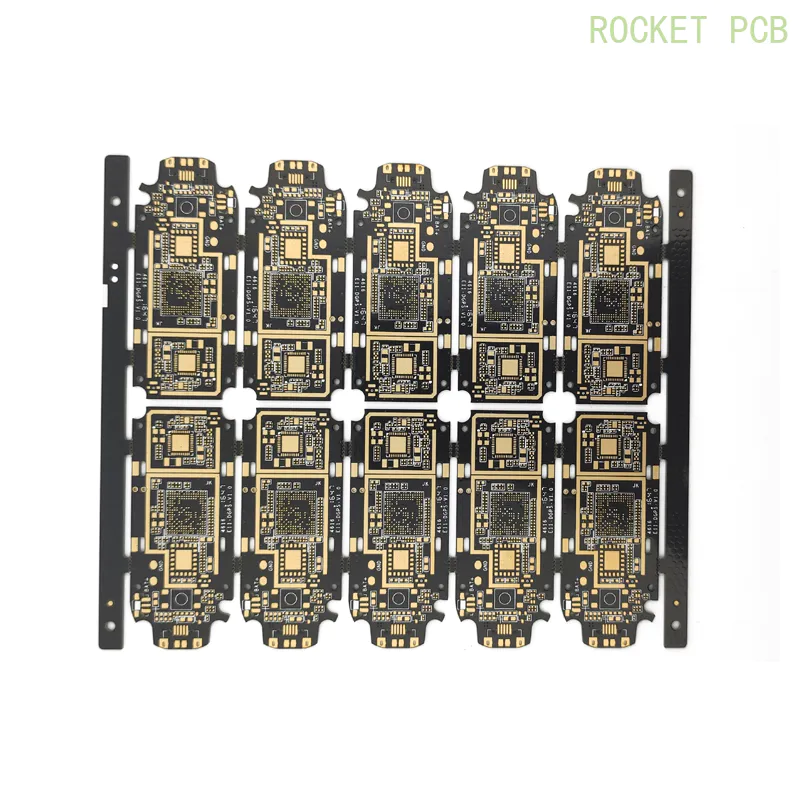

Producibility: adopt modern management, standardization, scale can be (

The amount)

, automatic production, ensure product quality consistency.

Can high density: for decades, printed circuit board with high density to enhance integrated circuit integration and installation technology progress and development.

High reliability: through a series of inspection, test and aging test can ensure the PCB (for a long time

Use, general for 20 years)

While working in a reliable way.

Testability: established a relatively complete test method, test standard, all kinds of test equipment and instruments to detect and identify PCB products such as eligibility and service life.

Design: (on PCB

Electrical, physical, chemical, machinery, etc. )

Requirements, can be done by design standardization and normalization of PCB design, time is short, high efficiency.

Composition: PCB product standardization assembly, convenient for various elements and can be automated, large-scale mass production.

And at the same time, the PCB components assembly parts can be assembled to form larger parts, system, until the whole machine.

Maintainability: due to the PCB products and various components assembly components are standardized design and mass production, therefore, these components are standardized.

So, once the system failure, can change fast, convenient and flexible manner, quickly restore service system work.

Of course, also can for example to get some more.

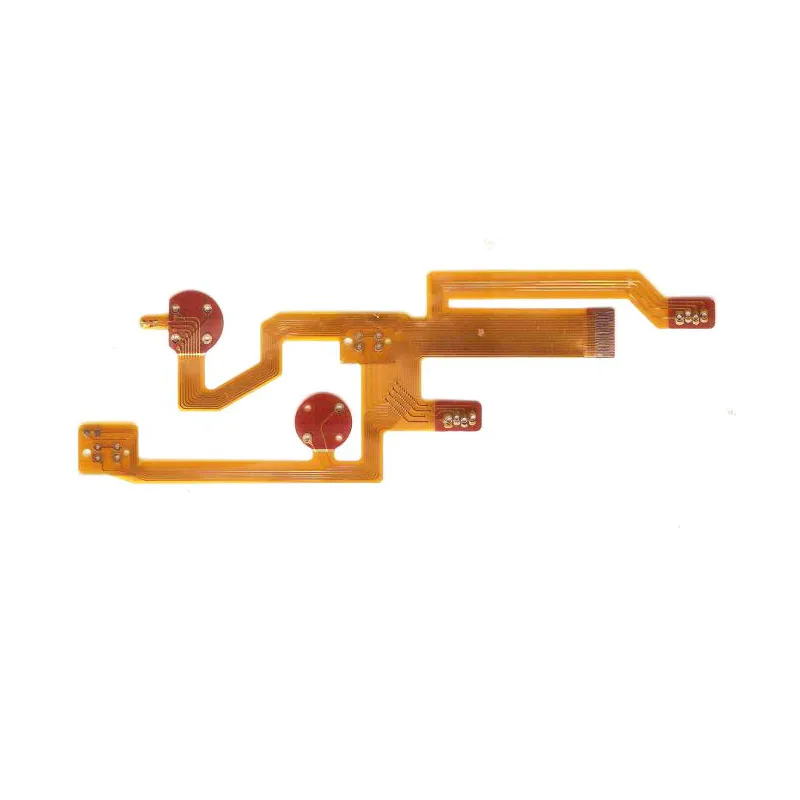

Such as make the system miniaturization, lightweight, high speed signal transmission, etc.

PCBA

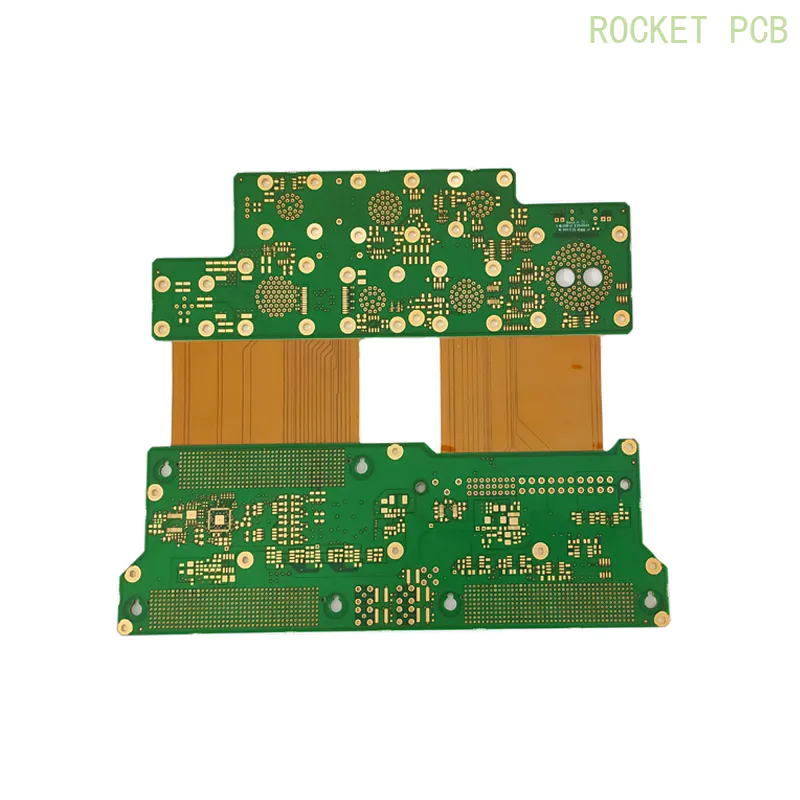

PCBA is short for English PrintedCircuitBoard + Assembly, that is to say on the PCB bare board through SMT parts, repass DIP plug-in the entire process, referred to as 'PCBA.

This is A commonly used one kind of writing, and in Europe and the United States' A standard writing is PCB, is the point.

This is referred to as the official idioms, we communicate with foreign customers or promotion, they often ask questions like what is the meaning of PCBA.

PCBA SMT and DIP are integrated components on the PCB board, the main difference is the SMT do not need to be on the PCB drilling, the DIP need to insert the components of the PIN feet have drilled hole.

SMT (

SurfaceMountedTechnology)

Surface-mount technology, mainly use stick machine is a slightly smaller parts will be loaded on the PCB, its production process is: PCB, solder paste printing, post pack, back to the welding machine furnace and made inspection.

With the development of science and technology, SMT can also make some big size of SMT parts, such as the motherboard on some of the larger size can be pasted on the body parts.

SMT integration is sensitive to the size of the positioning and parts, in addition to the quality of the solder paste and print quality also play a key role.

DIP 'plug-in', that is, insert parts on the PCB version, due to large size parts and does not apply to mount or manufacturer production technology can't use SMT technology when using integrated parts in the form of a plug-in.

Inside the industry human and robot two plugin is implemented, the main production process is: the stick of gum (

Prevent the tin plating to should not have)

, plug-in, inspection, wave soldering, brush version (

To remove the stains in the process of a furnace)

And made inspection.

PCB and PCBA to compare the difference between the PCB and PCBA PCB refers to the circuit board, and PCBA refers to the circuit board plug-in assembly, SMT process.

One is the finished board is a bare PCB board (

PrintedCircuitBoard)

Known as the 'printed circuit board', made of glass epoxy resin materials, according to the signal layers divided into 4, 6, 8 layer board (

Multilayer circuit board)

In 4, 6 layer board is the most common.

Chips such as SMT components on the PCB.

PCBA may be understood as the finished circuit boards, PCB process is done to calculate on the PCBA.

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multi-layer circuit board, HDI board, thick copper, blind hole buried plate proofing and small batch, high frequency circuit board production and PCB board production.

pcb manufacturing services pcb making service processes have been widely used to produce pcb manufacturing services such as pcb manufacturing services, pcb manufacturing services, and pcb manufacturing services etc.

If you are looking for an excellent service in the UK then you can go to Rocket PCB Solution Ltd.. They have almost everything what you might require for your pcb manufacturing services.

We should take a step back to review how Rocket PCB approach tracking, implementing, and communicating compliance-related changes and attempt to identify areas of improvement in their processes.