What Challenges and Innovations Are Shaping the Future of Flex PCBs in Wearable Electronics?

I.Introduction

The Role of Flex PCBs in Wearable Electronics

Wearable technology has emerged as a transformative force in today's digital world. Wearables have rapidly evolved from smartwatches to health monitoring devices, becoming integral to our daily lives. At the heart of these innovative gadgets lies a critical component - the Flexible Printed Circuit Board (Flex PCB). In this article, we will explore the growing significance of Flex PCBs in wearable electronics, shedding light on the challenges faced by both manufacturers and designers and the innovations shaping this dynamic field's future.

Flex PCBs: A Fundamental Enabler

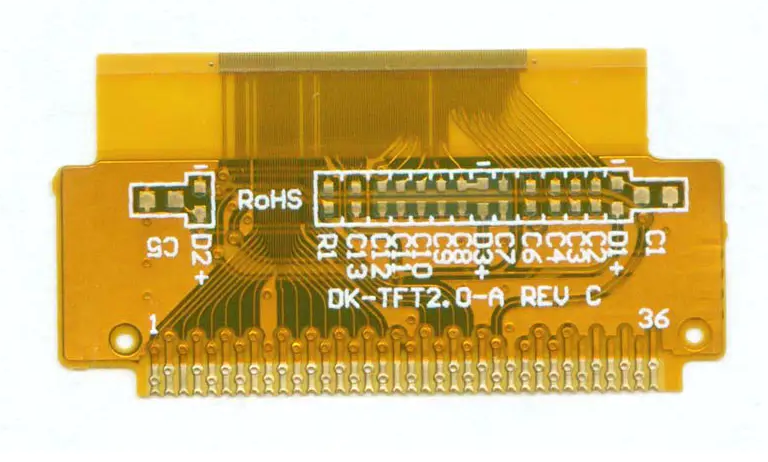

Flex PCBs, also known as flex circuits or flexible printed wiring boards, are printed circuit boards designed to be exceptionally flexible and lightweight. Unlike traditional rigid PCBs, Flex PCBs can bend, twist, and conform to the contours of a device or wearable, making them a fundamental enabler of wearable electronics.

Their ability to adapt to irregular shapes and fit into compact spaces has opened up new horizons for design creativity, allowing for the development of sleek and unobtrusive wearables. In essence, Flex PCBs serve as the backbone that connects the various electronic components within these devices, facilitating seamless functionality.

Challenges and Innovations: A Glimpse

The adoption of Flex PCBs in wearables has its challenges. Manufacturers and designers encounter durability, flexibility, and design constraints hurdles. These challenges include ensuring that the flexible boards can withstand repeated bending, are comfortable to wear, and align with the specific requirements of different applications.

This article will delve into these challenges, providing insights into the critical areas that require attention in developing Flex PCBs for wearable electronics. Additionally, we will explore the exciting innovations that are making headway in addressing these challenges, ensuring that Flex PCBs remain a driving force behind the wearable revolution.

II.The Significance of Flex PCBs in Wearable Electronics

Wearable technology has grown by leaps and bounds, infiltrating various aspects of our daily lives. These innovative devices have transformed how we monitor our health, interact with our surroundings, and express our personal style. At the heart of this wearable revolution lies a key component - Flexible Printed Circuit Boards (Flex PCBs). In this section, we will delve into the critical role of Flex PCBs in wearable electronics, highlighting why they are indispensable and offering insights into real-world applications.

Why Flex PCBs Are Crucial

1. Flexibility and Form Factor

Flex PCBs derive their name from their exceptional flexibility. Unlike rigid boards, Flex PCBs are designed to be pliable and adaptable, which makes them an ideal choice for wearables. Wearable devices often require unconventional shapes and sizes to fit comfortably on the body or seamlessly integrate into clothing. Flex PCBs can conform to these unique design requirements, making them crucial for achieving the desired form factor.

2. Weight and Space Efficiency

Wearables are meant to be lightweight and unobtrusive; this is where Flex PCBs shine. Their lightweight construction and ability to occupy minimal space are essential for wearables to be comfortable and convenient for users. Without Flex PCBs, achieving wearables' lightweight and slim profiles would be a considerable challenge.

3. Durability

Wearable devices are subjected to various stresses, including bending, twisting, and stretching. Flex PCBs are designed to withstand these mechanical stresses without compromising their functionality. Their durability ensures the wearables maintain performance and reliability even under harsh conditions.

4. Interconnectivity

Wearable devices often require intricate interconnections among components, sensors, and power sources. Flex PCBs provide an efficient and reliable means of interconnecting these elements. They allow for complex circuitry within a limited space, a fundamental requirement for many wearable applications.

Real-World Applications

To emphasize the significance of Flex PCBs in wearable electronics, let's consider a few real-world examples where Flex PCBs play a vital role:

1. Smartwatches

Smartwatches are a prime example of wearables that rely on Flex PCBs. Their sleek and compact design, with a range of sensors and a display, demands flexible and space-efficient circuitry. Flex PCBs enable the intricate, tight layout of components that smartwatches require.

2. Fitness Trackers

Fitness trackers are designed to be worn 24/7, which means they must be lightweight, comfortable, and durable. Flex PCBs are essential in constructing fitness trackers, enabling flexibility and toughness while accommodating the required electronic components.

3. Medical Wearables

Wearable medical devices like ECG monitors and insulin pumps rely on Flex PCBs to provide comfort and reliability. The flexibility of these boards allows for devices that can be worn discreetly under clothing, improving the quality of life for patients.

III.Challenges in Using Flex PCBs for Wearable Electronics

Adopting Flexible Printed Circuit Boards (Flex PCBs) in wearable electronics has ushered in a new era of design flexibility and innovation. However, with this newfound versatility comes a set of unique challenges that manufacturers and designers must overcome.

Durability Matters

1. Bending Fatigue

One of the foremost challenges in using Flex PCBs for wearables is ensuring their durability under constant bending and flexing. Wearable devices are intended to be worn daily, often in situations that subject them to repeated flexing, such as smartwatches on wrists or clothing-embedded sensors. Flex PCBs must be engineered to withstand thousands of bending cycles without developing cracks or deteriorating performance.

2. Environmental Resilience

Wearable devices are frequently exposed to various environmental conditions, from moisture and sweat to extreme temperatures. Flex PCBs need to be designed to resist moisture ingress and remain functional across a wide temperature range. Ensuring their resilience against these environmental factors is a significant challenge.

The Balancing Act: Flexibility and Rigidity

1. Flexibility vs. Component Rigidity

The very nature of Flex PCBs is their flexibility, which enables them to adapt to the shape of a wearable device. However, this flexibility can sometimes clash with the rigidity required for mounting specific components like sensors, microcontrollers, or batteries. Balancing the need for flexibility with the rigidity essential for component mounting is a delicate design challenge.

2. Connector Reliability

Wearable devices often include connectors to link Flex PCBs to rigid PCBs or external components. The connectors must maintain reliable electrical connections even as the Flex PCB undergoes continuous bending and flexing. Achieving this balance between flexibility and connector reliability is a significant technical hurdle.

Customization and Design Constraints

1. Application-Specific Design

Different wearables cater to various applications, each with unique design requirements. The challenge lies in creating Flex PCBs that can be tailored to the specific needs of multiple applications, from fitness trackers to medical devices.

2. Miniaturization and Component Integration

Wearable electronics demand compact, space-efficient designs. Designers must find innovative ways to integrate essential components into a limited space while maintaining the required functionality. This challenge involves carefully placing sensors, power sources, and communication modules.

In the world of Flex PCBs for wearables, addressing these challenges is paramount to ensure the reliability and functionality of these devices. Manufacturers, designers, and engineers continually push the boundaries of what Flex PCBs can achieve.

IV.Innovations Addressing Wearable Electronics Challenges

In the ever-evolving landscape of wearable electronics, the challenges posed by incorporating Flexible Printed Circuit Boards (Flex PCBs) are met with innovative solutions that redefine the possibilities of wearables.

Advanced Materials

1. High-Performance Substrates

The choice of materials is fundamental to the durability and performance of Flex PCBs in wearables. Advances in materials science have introduced high-performance substrates that offer exceptional flexibility and resilience. These materials enable Flex PCBs to withstand bending and exposure to harsh environments, ensuring longevity and reliability in wearable devices.

2. Nanomaterials and Conductive Inks

Nanomaterials and conductive inks have opened new frontiers in Flex PCB design. They offer enhanced conductivity, flexibility, and miniaturization capabilities. These innovations enable the development of intricate circuits on Flex PCBs, even in the most space-constrained wearables, while maintaining high reliability.

Design Techniques

1. 3D Printing and Additive Manufacturing

3D printing and additive manufacturing techniques have revolutionized Flex PCB design. They allow for the creating of complex, three-dimensional shapes that were previously challenging to achieve. This innovation caters to wearables that need flexible circuitry to conform to irregular surfaces while maintaining structural integrity.

2. Miniaturization and Component Integration

Advancements in design techniques have facilitated the miniaturization of components while maintaining their functionality. Wearables now house smaller yet more powerful sensors, microcontrollers, and batteries, thanks to innovative component integration methods.

Manufacturing Processes

1. Laser Direct Structuring (LDS)

Laser Direct Structuring is a manufacturing process that enables the creation of conductive traces on Flex PCBs with precision. This method allows for intricate circuit patterns, enhancing the performance of wearables.

2. Roll-to-Roll Manufacturing

Roll-to-roll manufacturing streamlines the production of Flex PCBs, making it more cost-effective and efficient. This innovative approach is essential for mass-producing wearable electronics without compromising quality.

These innovations in materials, design techniques, and manufacturing processes are revolutionizing the use of Flex PCBs in wearable electronics. They are paving the way for more durable, flexible, and versatile wearables that can meet the demands of modern consumers. As we continue to push the boundaries of wearable technology, the Flex PCB manufacturer, Flex PCB supplier, and Flex PCB factory become even more critical in making these innovations accessible to the broader industry.

V.Customization and Design Flexibility

Flex Printed Circuit Boards (Flex PCBs) are at the forefront of innovation in the field of wearable electronics, offering a level of design flexibility and customization that is reshaping the landscape of wearable technology. In this section, we will explore how Flex PCBs provide design flexibility and customization options for wearable electronics, and we will provide examples of how this adaptability can meet specific application needs.

Design Flexibility

1. Conforming to Complex Shapes

One of the hallmark features of Flex PCBs is their ability to conform to complex and irregular shapes. This unique characteristic makes them ideal for wearables that need to integrate seamlessly into various forms, such as bright clothing, wristbands, or even flexible displays. The flexibility of Flex PCBs allows designers to create comfortable and ergonomic devices for users.

2. Space-Efficient Design

Flex PCBs are also invaluable for optimizing space within wearables. As these devices become more compact, every millimeter counts. Flex PCBs can be designed to fit into tight spaces, accommodating essential components while reducing bulk. This is especially important in applications like medical wearables, where discreet and lightweight designs are paramount.

Customization Options

1. Tailored to Specific Applications

Each wearable application has unique requirements. For example, a fitness tracker may need different sensors and circuitry than a medical device. Flex PCBs can be customized to meet these specific needs. Manufacturers can create Flex PCBs tailored to the intended purpose, ensuring optimal functionality.

2. Integration of Additional Features

Flex PCBs can be designed to integrate additional features, such as antennas, touch-sensitive surfaces, or even energy-harvesting components. These added features can enhance the capabilities of wearables, making them more versatile and user-friendly.

3. Aesthetic Customization

In the world of wearables, aesthetics matter. Flex PCBs can create visually appealing designs that align with a brand's identity. For example, illuminated patterns or unique form factors can set a wearable device apart in the market, and Flex PCBs are crucial in achieving such aesthetics.

Examples of Customization

1. Medical Wearables

In the realm of medical wearables, customization is essential. Patients may require different monitoring parameters or specific sensor integration. Flex PCBs can be customized to meet these varying medical needs, resulting in devices tailored to each patient's health condition.

2. Smart Clothing

Bright clothing demands flexibility and design that aligns with the fashion industry's trends. Flex PCBs allow sensors and electronics to seamlessly integrate into garments, providing a discreet and fashionable user experience.

3. Industrial Wearables

Flex PCBs can be customized to withstand extreme conditions for industrial wearables used in rugged environments. These wearables can be built to endure high temperatures, humidity, and physical impacts, ensuring reliability in challenging work settings.

In summary, Flex PCBs offer the design flexibility and customization options necessary to meet the diverse demands of wearable electronics. Their ability to conform to shapes, optimize space, and cater to specific application needs makes them a critical component in developing innovative wearables.

VI.Reliability and Longevity

In the world of wearable electronics, the importance of reliability cannot be overstated. Wearable devices are designed to withstand the rigors of daily life, and users expect these gadgets to function flawlessly for extended periods. In this section, we will explore the critical role of reliability in wearable electronics and how Flex Printed Circuit Boards (Flex PCBs) contribute to the longevity of these devices. We will highlight key factors such as bending cycles and environmental resilience that are crucial in ensuring the reliability of wearables.

The Significance of Reliability

1. User Trust

Reliability is the bedrock upon which user trust is built. Wearable devices often play a pivotal role in health monitoring, fitness tracking, and even safety-critical applications. Users depend on these devices to provide accurate data and make informed decisions. Reliability is essential to ensure that users can trust the information and functionality of their wearables.

2. Consistent Performance

Reliability ensures consistent performance over time. Wearables need to maintain their functionality even after prolonged use. Whether it's a fitness tracker, a smartwatch, or a medical wearable, users expect these devices to deliver consistent results without degradation in performance.

Flex PCBs and Device Longevity

1. Bending Cycles

One of the unique challenges wearables face is the need for Flex PCBs to endure countless bending cycles. Wearable devices are often subjected to continuous movement and bending, mainly when worn on the body. Flex PCBs are designed to withstand these mechanical stresses, ensuring they remain intact and fully functional. This capability contributes significantly to the longevity of wearables.

2. Environmental Resilience

Wearable devices are exposed to diverse environmental conditions. They must endure it all, from sweat and moisture to extreme temperatures and physical impacts. Flex PCBs are engineered to be resilient, resisting moisture ingress and remaining functional across a wide temperature range. This environmental resilience ensures that wearables maintain their performance even under challenging conditions.

Role of Flex PCB Manufacturers

Flex PCB manufacturers play a pivotal role in ensuring the reliability and longevity of wearable electronics. Their expertise in material selection, design, and manufacturing processes directly impacts the quality of Flex PCBs. Manufacturers must adhere to rigorous quality control standards to produce Flex PCBs that can withstand the demands of wearable applications.

Reliability is a cornerstone of wearable electronics, and Flex PCBs are at the forefront of achieving this crucial aspect. Their ability to withstand bending cycles and environmental stressors makes them essential in developing long-lasting wearables.

VII.Cost Considerations

The use of Flexible Printed Circuit Boards (Flex PCBs) in wearable electronics brings many design flexibility and performance advantages. However, cost considerations play a crucial role in developing and producing wearable devices.

Cost Factors in Flex PCBs for Wearable Electronics

1. Material Costs

The choice of materials for Flex PCBs can significantly impact the overall cost. High-performance substrates and advanced nanomaterials may come at a higher price point. Material selection must balance cost-effectiveness with meeting the specific requirements of the wearable device.

2. Design Complexity

Highly intricate and customized Flex PCB designs may involve increased design and development costs. This is particularly relevant when wearables demand unique shapes, components, or features that require specialized design work.

3. Manufacturing Processes

Manufacturing Flex PCBs can involve various techniques and processes. More advanced and intricate manufacturing processes may be costlier but offer performance, durability, and miniaturization benefits.

4. Quantity and Scale

The scale of production can influence costs. Mass production often results in economies of scale, reducing unit costs. Smaller-scale exhibitions may incur higher charges per unit.

Strategies to Optimize Costs

1. Material Selection

Careful consideration of materials is crucial. By working closely with Flex PCB manufacturers and suppliers, it is possible to identify materials that meet performance requirements while keeping costs in check. Opting for materials that balance performance and affordability is a crucial strategy.

2. Standardization

Standardizing designs and components can help reduce costs. Manufacturers can achieve cost efficiencies through economies of scale and streamlined manufacturing using standard features and techniques across different wearable models.

3. Advanced Manufacturing Techniques

While advanced manufacturing processes may come at a higher initial cost, they can lead to more cost-efficient production in the long run. Processes like roll-to-roll manufacturing can increase productivity and reduce unit costs.

4. Collaboration with Suppliers

Collaborating closely with Flex PCB suppliers and manufacturers can lead to cost savings. Suppliers often have insights into cost-effective materials and processes and can provide valuable recommendations.

Balancing Cost and Quality

While cost optimization is essential, it should not come at the expense of quality and reliability. Wearable electronics must meet performance and durability standards to ensure user satisfaction and safety. Balancing cost and quality is a delicate act that requires careful consideration at every stage of development.

The Role of Flex PCB Suppliers and Factories

Flex PCB suppliers and factories play a vital role in managing cost-effectiveness. They can provide cost-effective sourcing options, recommend efficient manufacturing processes, and assist in standardizing designs to reduce costs while maintaining quality.

Cost considerations are an integral part of developing and producing wearable electronics using Flex PCBs. Manufacturers can balance affordability and quality by carefully analyzing cost factors, optimizing material selection, and implementing efficient manufacturing processes. This balance is essential to make wearables innovative and accessible to a broad range of users.

VIII.Case Studies and Success Stories

The integration of Flexible Printed Circuit Boards (Flex PCBs) in wearable electronics has led to numerous success stories, revolutionizing the capabilities and applications of these devices. In this section, we will delve into real-world case studies of wearable devices that have seamlessly integrated Flex PCBs, highlighting the benefits and outcomes of using Flex PCBs in these applications.

Case Study 1: Fitness Tracker

Device Overview: A fitness tracker designed for athletes, fitness enthusiasts, and health-conscious individuals. It monitors various health metrics, including heart rate, steps taken, and sleep quality.

Flex PCB Integration: Flex PCBs were used to create a flexible and comfortable form factor that can be worn during strenuous physical activities. The Flex PCBs allowed the device to conform to the user's wrist, providing accurate sensor readings without discomfort.

Benefits and Outcomes:

· Improved User Experience: Flex PCBs enhanced the user experience by making the fitness tracker comfortable, even during intense workouts.

· Accurate Sensor Readings: Flex PCBs contributed to the device's accuracy by ensuring that sensors maintain consistent contact with the user's skin.

· Durability: The Flex PCBs can withstand bending and flexing, ensuring the longevity of the fitness tracker under challenging conditions.

Case Study 2: Smart Clothing

Device Overview: Smart clothing designed for outdoor enthusiasts and athletes. It incorporates integrated sensors to monitor vital signs and environmental conditions.

Flex PCB Integration: Flex PCBs were used to create flexible and washable circuits integrated into the fabric of the bright clothing. These circuits allowed for continuous monitoring without compromising the garment's comfort.

Benefits and Outcomes:

· Seamless Integration: The use of Flex PCBs allowed for the seamless integration of electronics into the fabric, maintaining the natural feel of the clothing.

· Customized Design: Flex PCBs permitted customization of the sensor layout to meet specific application needs.

· Comfort and Durability: The bright clothing was comfortable to wear and could withstand the rigors of outdoor activities, thanks to Flex PCBs.

Case Study 3: Medical Wearable

Device Overview: A wearable medical device for continuous glucose monitoring, primarily for diabetic patients. The widget tracks glucose levels and sends real-time data to a mobile app for monitoring.

Flex PCB Integration: Flex PCBs created a discreet and comfortable wearable that adheres to the patient's skin. The flexibility of the PCBs ensured that the device could be worn under clothing without causing discomfort.

Benefits and Outcomes:

· Improved Quality of Life: The discreet design made it more convenient for diabetic patients to continuously monitor their glucose levels without disrupting their daily activities.

· Durability: Flex PCBs contribute to the device's durability, allowing it to withstand the rigors of everyday life.

· Accuracy: The Flex PCBs ensured that sensors remained in close contact with the skin, resulting in accurate glucose level monitoring.

These case studies illustrate the transformative power of Flex PCBs in wearable electronics. They highlight how Flex PCBs have enabled comfortable, durable, and accurate wearables in various applications, from fitness tracking to medical monitoring. The successful integration of Flex PCBs in these cases demonstrates the crucial role these circuit boards play in the wearable electronics industry, driving innovation and improving the quality of life for users. As we conclude this article, we emphasize that the journey of Flex PCBs in wearables is still evolving, with exciting possibilities and advancements on the horizon.

IX.Future Trends and Emerging Applications

Integrating Flexible Printed Circuit Boards (Flex PCBs) in wearable electronics has come a long way, and the journey is far from over. As technology advances, new trends and emerging applications are reshaping the landscape of wearable devices.

Advancements in Health Monitoring

1. Personalized Health Devices

The future of health monitoring wearables will emphasize personalization. Flex PCBs will enable devices that adapt to an individual's unique health needs, providing real-time data and insights for better healthcare management. These devices will monitor physical and mental health, creating a holistic approach to health.

2. Disease Prevention and Early Detection

Wearable devices will play a crucial role in disease prevention and early detection. Flex PCBs will be integral to developing wearables that can monitor specific biomarkers, allowing for the early identification of health issues. This will result in timely intervention and improved health outcomes.

3. Non-Invasive Medical Wearables

Flex PCBs will continue to drive the development of non-invasive medical wearables. Devices that can monitor blood glucose levels, measure vital signs, and even deliver medication will become more sophisticated, comfortable, and user-friendly, improving the quality of life for patients.

Smart Clothing Evolution

1. Beyond Fitness Monitoring

Bright clothing will extend beyond fitness monitoring. These garments will incorporate advanced sensors and flexible electronics to monitor physical activity and environmental conditions. They will provide insights into air quality, UV exposure, and more, enhancing safety and comfort.

2. Integration with Augmented Reality (AR) and Virtual Reality (VR)

Integrating AR and VR technology into bright clothing is on the horizon. Flex PCBs will enable the creation of immersive, responsive garments that can provide sensory feedback and enhance the overall AR and VR experience.

3. Sustainability and Wearable Tech

The intersection of sustainability and wearable tech will become more pronounced. Flex PCBs will create environmentally friendly wearables, incorporating recyclable materials and energy-efficient components.

Innovative Wearables

1. Biometric Wearables

Biometric wearables, such as ECG monitoring jewelry and stress-tracking accessories, will gain prominence. These wearables will integrate seamlessly into everyday life, providing valuable health and wellness insights.

2. Industrial and Safety Wearables

Industrial and safety wearables will see increased adoption, benefiting from Flex PCBs' durability and customizability. These devices will enhance workplace safety and productivity, with applications ranging from manufacturing to construction.

3. Assistive Technology

Flex PCBs will contribute to developing assistive technology wearables that aid individuals with disabilities. These wearables will offer new levels of independence and improved quality of life for users.

The future of Flex PCBs in wearable electronics is filled with exciting possibilities. As technology advances, Flex PCBs will remain at the forefront of innovation in the wearable industry. Whether improving health monitoring, evolving bright clothing, or introducing innovative wearables, Flex PCBs will continue to drive the development of devices that enhance our lives, well-being, and experiences. As we look to the future, the role of Flex PCB manufacturers, suppliers, and factories remains pivotal in turning these trends and emerging applications into reality.

X.Conclusion

As the wearable electronics industry forges ahead, the opportunities for innovation and improvement are boundless, driven by the excellence of Rocket-PCB. The future holds the promise of more comfortable, personalized, and capable wearables than ever, thanks to Rocket-PCB's Flex PCBs. The possibilities are fascinating, whether it's integrating advanced sensors, evolving bright clothing, or introducing groundbreaking assistive technology wearables.

For those contemplating a wearable electronic project, Rocket-PCB encourages you to explore the exceptional benefits of Flex PCBs. These versatile circuit boards empower your designs, allowing you to create bespoke wearables that excel in comfort, durability, and reliability. Rocket-PCB's team of experts, from manufacturers to suppliers, is your trusted partner with the knowledge and resources to bring your visionary wearable concepts to life.

In the ever-evolving world of wearable electronics, the Rocket-PCB brand represents a key to unlocking innovation, delivering enhanced user experiences, and pushing the boundaries of what wearable technology can achieve. Embrace the possibilities and embark on your journey to create the wearables of the future with Rocket-PCB as your trusted companion.