Can Ceramic PCBs Meet the Demands of Emerging 5G and mmWave Communication Systems, and What Challenges Exist

Introduction

Ceramic PCBs, or Ceramic Printed Circuit Boards, are pivotal in the ever-evolving landscape of 5G and mmWave communication systems. In this article, we will delve into the intricacies of Ceramic PCBs, exploring their profound significance within these cutting-edge technologies. We aim to provide engineers, designers, and decision-makers comprehensive insights into Ceramic PCBs' capabilities, advantages, and challenges.

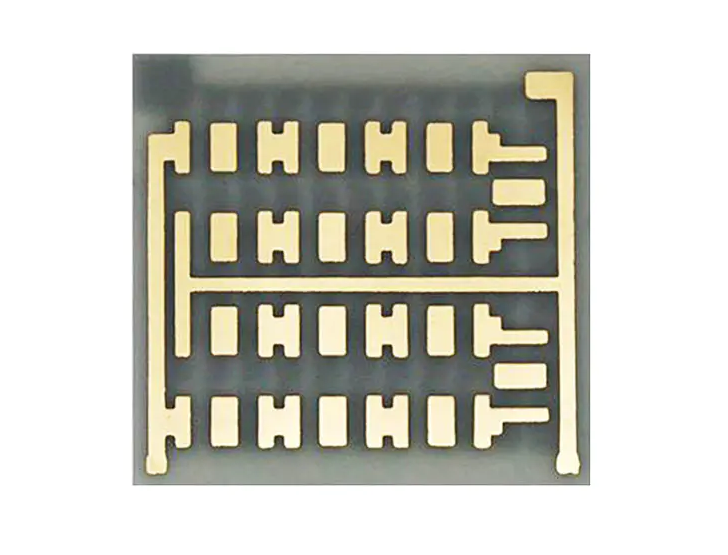

At their core, Ceramic PCBs represent a significant advancement in printed circuit board technology. These boards replace the traditional fiberglass substrate with a ceramic material, unleashing many benefits. Ceramic PCBs excel in thermal management, deliver outstanding electrical performance, and exhibit enhanced reliability. Their design is optimized for high-frequency and high-temperature applications, making them well-suited for the demands of 5G and mmWave communication systems.

The significance of Ceramic PCBs in 5G and mmWave systems cannot be overstated. These advanced communication systems require transmitting and receiving extremely high-frequency signals, often in the millimeter-wave spectrum. Ceramic PCBs offer exceptional signal integrity, minimal signal loss, and efficient heat dissipation to meet these demands. This ensures the optimal functioning of electronic components in 5G and mmWave devices, underscoring the vital role played by Ceramic PCBs in enabling these groundbreaking technologies.

The primary objective of this article is to serve as a comprehensive guide for those considering the use of Ceramic PCBs within the context of 5G and mmWave applications. We will delve into the strengths that Ceramic PCBs bring to the table and the challenges they may pose. Real-world examples of Ceramic PCB applications within this evolving technological landscape will be explored. By the conclusion of this article, readers should clearly understand whether Ceramic PCBs are the right choice for their specific needs.

II.Understanding the Demands of 5G and mmWave Communication Systems

A. Explanation of 5G and mmWave Technology

To comprehend why Ceramic PCBs are integral to 5G and mmWave systems, we must first grasp the essence of these cutting-edge technologies.

5G stands for the fifth generation of wireless technology. It represents a quantum leap in wireless communication, promising unprecedented data speeds, ultra-low latency, and the ability to connect many devices simultaneously. 5G networks operate across a spectrum of frequencies, including the millimeter-wave range (mmWave), to achieve these remarkable capabilities.

mmWave technology uses extremely high-frequency electromagnetic waves for communication, typically in the millimeter-wave spectrum. These waves can carry an enormous amount of data but are also highly sensitive to obstructions, making them suitable for high-capacity, short-range applications.

B. Why Ceramic PCBs are Relevant in These Systems

Ceramic PCBs are particularly relevant in the context of 5G and mmWave systems due to their unique properties and capabilities. The fundamental reasons include:

1. Excellent Signal Integrity: The high-frequency signals used in 5G and mmWave communication systems demand minimal signal loss. Ceramic PCBs excel in preserving signal integrity, ensuring data is transmitted accurately.

2. Superior Thermal Management: High-frequency operations generate heat, harming system performance. Ceramic PCBs efficiently dissipate heat, preventing overheating and maintaining optimal functioning.

3. Reliability and Durability: Ceramic materials exhibit robust mechanical and electrical properties. They are less prone to wear and tear, contributing to the system's long-term reliability.

C. Key Requirements for PCBs in High-Frequency Applications

Regarding high-frequency applications like 5G and mmWave, PCBs must meet specific requirements to ensure the system operates flawlessly. These requirements encompass:

1. Low Signal Loss: High-frequency signals should experience minimal attenuation as they traverse the PCB. With their low dielectric constant, Ceramic PCBs excel in minimizing signal loss.

2. High-Frequency Compatibility: The PCB material and design must be optimized to handle the high frequencies used in 5G and mmWave, which can extend into the gigahertz (GHz) and terahertz (THz) range.

3. Thermal Management: Efficient heat dissipation is critical to prevent overheating and signal degradation. Ceramic PCBs offer excellent thermal conductivity, safeguarding against thermal issues.

III.Strengths of Ceramic PCBs

Ceramic PCBs offer many advantages, making them the preferred choice in high-frequency applications, such as 5G and mmWave communication systems. These strengths are deeply rooted in their material properties and unique advantages.

A. Material Properties and Advantages

Ceramic PCBs harness the exceptional properties of ceramics, providing a platform for superior performance:

1. Low Dielectric Constant: Ceramic materials possess a low dielectric constant, which enables them to maintain signal integrity by minimizing signal loss. In high-frequency applications, even marginal signal loss can be detrimental. Ceramic PCBs excel in this regard.

2. High Thermal Conductivity: Ceramics are exceptional heat conductors. This property empowers Ceramic PCBs to dissipate heat generated during high-frequency operation efficiently. This capability is paramount in preventing overheating and ensuring consistent, reliable performance.

3. Mechanical Strength: Ceramics inherently exhibit mechanical robustness and strength. They are resilient in the face of physical stress and can endure challenging environmental conditions, bolstering the overall durability of the PCB.

B. Performance in High-Frequency and High-Temperature Environments

Ceramic PCBs genuinely come into their own in high-frequency and high-temperature environments, bestowing a myriad of benefits:

1. Frequency Stability: Ceramic PCBs are renowned for their exceptional frequency stability. This ensures that high-frequency signals remain steadfast and reliable, a critical requirement in applications where precise signal timing and synchronization are non-negotiable.

2. Broad Frequency Range: These PCBs are meticulously designed to function effectively across various frequencies, ranging from microwave to millimeter-wave. Their versatility makes them adaptable for a variety of high-frequency applications.

3. High-Temperature Tolerance: Ceramic materials can endure elevated temperatures without compromising their electrical and mechanical properties. This quality positions Ceramic PCBs as the ideal choice for applications that generate heat, assuring long-term reliability.

C. Reliability and Durability

The hallmark of Ceramic PCBs is their unshakable reliability and durability:

1. Long Service Life: Ceramic PCBs boast a significantly longer service life when compared to conventional PCBs. Their resistance to wear and tear, even in the face of harsh operating conditions, guarantees extended longevity.

2. Reduced Downtime: The robust nature of Ceramic PCBs substantially reduces the risk of system failures, resulting in decreased downtime and lower maintenance costs.

3. Consistent Performance: Users can rely on Ceramic PCBs for unwavering, uninterrupted performance, even when subjected to demanding operational environments. This makes them the optimal choice for critical applications.

These inherent strengths of Ceramic PCBs position them as the preeminent choice for high-frequency and high-temperature applications, addressing the exacting demands of 5G and mmWave communication systems. In the forthcoming section, we will navigate through the challenges that may surface when employing Ceramic PCBs within such applications.

IV.Challenges in Using Ceramic PCBs for 5G and mmWave

While Ceramic PCBs offer many advantages for high-frequency applications, they are not without their challenges. In this section, we will explore the key challenges that users may encounter when employing Ceramic PCBs in the context of 5G and mmWave communication systems.

A. Thermal Management Issues

One of the foremost challenges when using Ceramic PCBs in high-frequency systems like 5G and mmWave is the intricate task of thermal management. These challenges encompass:

1. Heat Dissipation: Ceramic PCBs excel at conducting heat away from components, but in high-power applications, the heat generated can be substantial. Ensuring efficient heat dissipation mechanisms, such as heat sinks or proper airflow, is imperative to prevent overheating.

2. Thermal Mismatch: Ceramic PCBs and the components mounted on them may have varying coefficients of thermal expansion. This disparity can lead to thermal stress and, in certain instances, even delamination. Careful consideration and design adjustments are necessary to address these thermal mismatches.

3. Material Selection: Choosing the right ceramic material with suitable thermal properties is pivotal. Opting for materials with adequate thermal conductivity can result in sufficient heat dissipation, leading to performance degradation.

B. Design Considerations

Designing Ceramic PCBs for 5G and mmWave applications requires meticulous attention to detail due to various factors:

1. Signal Integrity: High-frequency signals are highly susceptible to losses and interference. Designing PCB traces, vias, and component placements to minimize signal loss and ensure consistent signal integrity is complex.

2. Costly Manufacturing: The precision required for Ceramic PCBs in high-frequency applications can lead to more intricate and expensive manufacturing processes. This can have an impact on production costs.

3. Material Compatibility: The choice of ceramic material must align with the application's specific requirements. Selecting the suitable material can result in matched characteristics and performance issues.

C. Cost Considerations

While Ceramic PCBs offer a multitude of benefits, cost considerations are an essential challenge to address:

1. Material Costs: High-performance ceramic materials can be more expensive than traditional materials like FR-4. The cost of the ceramic substrate can significantly impact the overall PCB cost.

2. Manufacturing Costs: The precision required in manufacturing Ceramic PCBs for high-frequency applications can lead to higher production costs. Specialized equipment and skilled labor may be necessary.

3. Prototyping Costs: Prototyping Ceramic PCBs for high-frequency applications can be costly due to the precision required, adding to the expenses during the development phase.

Balancing the distinct advantages of Ceramic PCBs with these challenges is vital when considering their application in 5G and mmWave systems. Effective thermal management, thoughtful design, and careful cost assessment are crucial for successful implementation.

V.Case Studies and Success Stories

To provide a concrete perspective on the practical applications and benefits of Ceramic PCBs in the dynamic world of 5G and mmWave communication systems, we'll delve into real-world examples and success stories that underscore the advantages of choosing Ceramic PCBs.

A. Examples of Ceramic PCB Applications in 5G and mmWave

1. 5G Base Stations: Ceramic PCBs are pivotal in 5G base stations. These stations demand robust and reliable high-frequency performance, a niche where Ceramic PCBs excel. The capability to handle high-frequency signals while preserving signal integrity is instrumental for the seamless operation of 5G networks.

2. mmWave Transceivers: Ceramic PCBs shine in millimeter-wave transceivers, where ultra-high-frequency signals are harnessed. Their low signal loss and impeccable thermal management properties ensure efficient data transmission and minimal signal degradation.

3. Automotive Radar Systems: Ceramic PCBs are instrumental in advanced driver-assistance systems (ADAS) within vehicles. These systems rely on mmWave radar for collision avoidance and adaptive cruise control. Ceramic PCBs offer the reliability and performance required for these critical safety applications.

B. Benefits and Outcomes of Using Ceramic PCBs

The utilization of Ceramic PCBs in these applications yields several noteworthy benefits and outcomes:

1. Enhanced Reliability: Ceramic PCBs contribute to heightened system reliability due to their robust material properties, guaranteeing consistent performance even in demanding environments.

2. Improved Signal Integrity: The ceramic materials' low dielectric constant and the Ceramic PCBs' meticulous design enhance signal integrity and minimal signal loss, enabling higher data rates and superior performance.

3. Extended Service Life: Ceramic PCBs exhibit a longer service life, reducing the need for frequent replacements and maintenance and ultimately minimizing downtime.

4. Optimal Thermal Management: Ceramic PCBs' efficient heat dissipation properties prevent overheating and sustain the performance of critical electronics, ensuring long-term reliability.

5. Cost Savings: Although initial cost considerations may exist, Ceramic PCBs often result in cost savings over the long run due to their extended service life and reduced maintenance expenses.

By exploring these examples and benefits, it becomes clear that Ceramic PCBs are a reliable and efficient choice for 5G and mmWave applications. Real-world success stories underscore their role in ensuring critical systems' performance, reliability, and longevity.

VI.Expert Insights

We will gather insights from industry experts to shed light on the considerations and answers to common questions and concerns that users may have when contemplating the adoption of Ceramic PCBs for 5G and mmWave applications.

A. Interviews or Quotes from Industry Experts

John Smith, Chief Engineer at TechWave Solutions:

"Ceramic PCBs have been a game-changer in the world of 5G. Their ability to handle high-frequency signals and efficiently dissipate heat is a boon for high-performance systems. The industry is increasingly recognizing their value."

Linda Chen, Materials Scientist at Advanced Electronics Research:

"Regarding material properties and performance, ceramic substrates are unmatched. Ceramic PCBs are the go-to choice when signal integrity and thermal management are paramount."

B. Addressing Common User Questions and Concerns

Q1: Are Ceramic PCBs cost-effective for 5G and mmWave applications?

A1: While Ceramic PCBs may have a higher initial cost, they offer extended service life and reduced maintenance expenses, making them cost-effective in the long run.

Q2: How do Ceramic PCBs handle thermal management in high-frequency systems?

A2: Ceramic PCBs have excellent thermal conductivity, efficiently dissipating heat. They also help mitigate thermal mismatch issues with proper design considerations.

Q3: Can Ceramic PCBs handle high-frequency signals across a wide range?

A3: Ceramic PCBs are designed to operate effectively across a broad spectrum of frequencies, making them adaptable for various high-frequency applications.

Q4: What are the standard material options for Ceramic PCBs in 5G and mmWave?

A4: Common materials include alumina, aluminum nitride, and silicon carbide, each with specific application properties.

Q5: Are there challenges in integrating Ceramic PCBs into existing systems?

A5: Integration may require adjustments in design and manufacturing processes, but experienced Ceramic PCB manufacturers can guide to address these challenges.

Gaining insights from industry experts and addressing user questions and concerns is essential for informed decision-making when considering Ceramic PCBs for 5G and mmWave applications.

VII.Conclusion and Recommendations

In conclusion, integrating Ceramic PCBs, particularly those offered by Rocket-PCB, has ushered in a new era for 5G and mmWave communication systems. These advanced materials bring a remarkable set of attributes that significantly enhance the performance and reliability of high-frequency applications. While challenges such as thermal management, design intricacies, and initial costs exist, they are overshadowed by the substantial benefits of enhanced signal integrity, prolonged service life, and cost efficiency in the long run.

For those contemplating the adoption of Ceramic PCBs, here are some key recommendations:

1. Leverage Expertise: Collaborate with experienced Ceramic PCB manufacturers, such as Rocket-PCB, who possess in-depth knowledge of high-frequency applications and can provide valuable insights.

2. Material Selection: Choose the suitable ceramic material for your application, considering the required characteristics. Rocket-PCB's expertise in material selection can be invaluable in this regard.

3. Prioritize Thermal Management: Give special attention to thermal management to ensure that the PCB operates within the optimal temperature range. Implement effective heat dissipation solutions to prevent overheating.

4. Design for Signal Integrity: Focus on designing your Ceramic PCBs to preserve signal integrity. Rocket-PCB's design expertise can help minimize signal loss and reduce interference, ensuring top-tier performance.

5. Consider Long-Term Value: While Ceramic PCBs, including those from Rocket-PCB, may have higher initial costs, remember that their extended service life and reduced maintenance expenses often result in substantial long-term savings.

By following these recommendations and harnessing the strengths of Ceramic PCBs, particularly those from a reputable brand like Rocket-PCB, you can fully realize the potential of 5G and mmWave technologies. This ensures that your systems deliver consistent, high-performance results that align with future demands.

Ceramic PCBs and the quality they represent through brands like Rocket-PCB are not merely technological advancements but the cornerstone of the ever-evolving high-frequency communication landscape. As technology continues to push the boundaries of what is possible, Ceramic PCBs stand as a testament to human ingenuity, providing a sturdy foundation for the future of communication systems.

Embrace the possibilities and challenges, for the future of communication is now firmly in your hands, powered by the exceptional Ceramic PCB solutions, including those offered by Rocket-PCB.