The Role of PCB Prototyping in the Evolution of IoT Devices

Introduction

Please give a brief introduction to the subject of PCB prototyping and its significance in the creation of IoT devices.

The need for specialized and cutting-edge electrical devices has grown dramatically as the Internet of Things (IoT) continues transforming numerous industries. The development of IoT devices is significantly influenced by PCB prototyping, a fundamental step in the electronic manufacturing process. This article will examine the several facets of PCB prototyping, how it affects the creation of IoT devices, its definition, advantages, and effects on the electronic manufacturing sector. We'll also review people's often-asked queries about PCB prototyping and offer advice on picking the best PCB prototyping service provider.

PCB Prototyping Benefits

1. First, Design optimization

1.1. Describe how testing and iteration are made possible via PCB prototyping, which helps to optimize the design process.

1.2. Describe how this results in better-finished products with fewer mistakes.

2. Saving time

2.1. Describe the time savings that PCB prototyping brings to the development process.

2.2. Discuss the time commitment and inefficiency of traditional methods.

2.3. Give a case where PCB prototyping has shortened the time needed for development.

3. Cost-Efficient

3.1. Describe how PCB prototyping can result in long-term cost savings.

3.2. Describe how spotting mistakes early in the design process helps prevent expensive redesigns.

3.3. Illustrate a company's financial savings from PCB prototyping.

4. Enhanced Quality Assurance

4.1. Describe how PCB prototyping enhances quality assurance during the production process.

4.2. Describe how prototyping can help create better final products through testing and iteration.

4.3. Give an illustration of how PCB prototyping has helped manufacturing processes' quality control.

Why IoT Device Development Needs PCB Prototyping?

1. Customization for Needs of IoT Devices

l Circuit board designs can be modified via PCB prototyping to accommodate the particular requirements of IoT devices.

l PCB prototyping can fulfil the unique requirements of IoT devices, such as their size, power consumption, and connectivity options.

2. A shorter time to market.

l PCB prototyping helps hasten the development of IoT devices by enabling rapid design iteration and decreasing the time needed for troubleshooting.

l In the fiercely competitive IoT sector, quick time-to-market is essential.

3. Cost savings, or C

l By identifying design defects early in the process and decreasing the need for costly design revisions, PCB prototyping can help save development costs.

l Additionally, PCB prototyping can assist in locating and resolving manufacturing difficulties before production, preventing expensive delays and recalls.

4.Assuring dependability and quality

l PCB prototyping, which enables circuit board design testing prior to final production, can help ensure the quality and dependability of IoT devices.

l testing during the prototyping phase can find design and production problems that could affect the device's functionality.

5. Promoting innovation

l By permitting experimenting with novel designs and technology, PCB prototyping can facilitate the development of creative IoT devices.

l The capacity to iterate and test new ideas quickly is essential in the rapidly changing IoT sector.

6.The Value of PCB Material Choice

l The cost, performance, and reliability of IoT devices can all be significantly impacted by choosing suitable PCB materials.

l The endurance and durability of IoT devices can be increased by using high-quality materials.

7.IoT Device Security PCB Design

l PCB prototyping can play a significant role in designing secure IoT devices by enabling testing and optimizing security features.

l During the prototyping stage, security considerations like encryption and authentication can be incorporated into the circuit board design.

When creating IoT devices, PCB prototyping is crucial. It has benefits, including customization, a shorter time to market, lower costs, assurance of quality and dependability, innovation, and security. Additionally, essential elements to consider during the prototyping phase include the appropriate selection of PCB materials and the implementation of security features.

Summary

PCB prototyping is essential for creating IoT devices because it enables rapid idea testing and iteration. With the help of PCB prototyping's benefits, such as affordability, adaptability, and customization, product developers may easily design and test their products, resulting in a shorter time to market and higher-quality goods. It is impossible to emphasize the value of PCB prototypes in creating IoT devices because it is crucial to ensure that the end products fulfil user demands and perform as planned.

PCB prototyping is essential to developing IoT devices because it allows developers to swiftly and effectively realize their ideas. Developers may be confident in the calibre and dependability of their products thanks to Rocket PCB's knowledge and expertise in providing cutting-edge electronic manufacturing services, including PCB prototyping. PCB prototype will remain an essential tool in ensuring that gadgets suit user expectations and keep up with the rapid pace of technological advancement as IoT technology develops.

Rocket PCB information

Leading PCB prototype and production services are offered by Rocket PCB. Here are some details regarding the business:

With more than 100 technical employees, Rocket PCB has established itself as a leader in the provision of cutting-edge services for electronic production.

The business is dedicated to providing for the demands of consumers and assuring the excellence and dependability of its products.

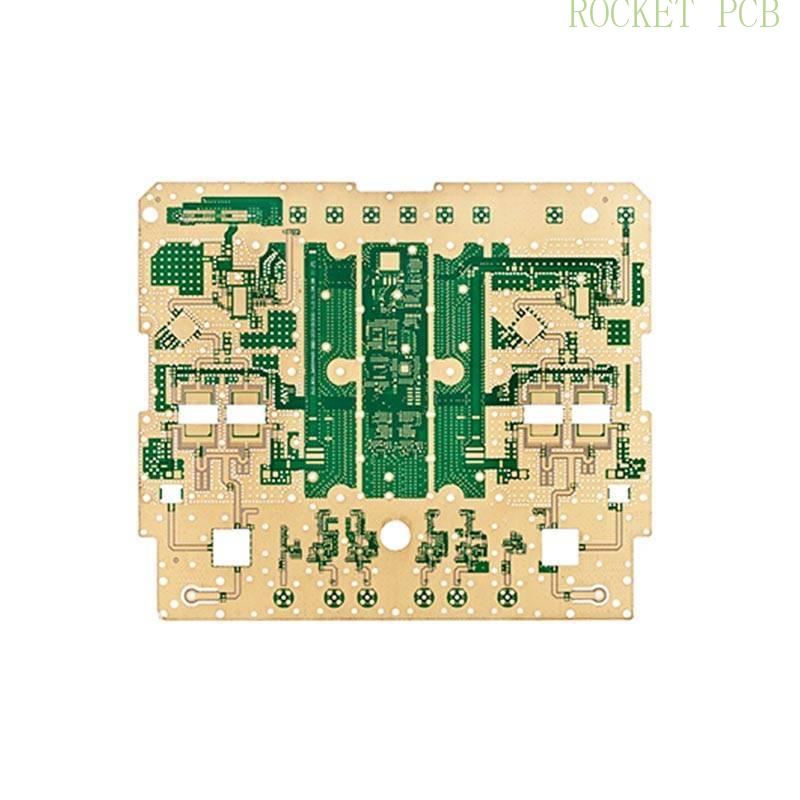

Principal Items

High-speed server boards, large data memory circuit boards, high-frequency hybrid boards, multi-stage HDI boards, IOT modules, security circuit boards, etc., are just a few of the electronic items covered by Rocket-PCB's core products.

These items are frequently utilized in communication, medicine, military security, industry, and automobiles.

Global Coverage

Products from Rocket PCB are widely distributed in North America, Europe, Asia Pacific, and other foreign markets.

The business has established a solid reputation for quality and innovation in the electronics sector, and many top companies see it as a reliable partner.

Rocket PCB is an excellent option if you're looking for a trustworthy and knowledgeable partner for your PCB prototype and manufacturing requirements. With its dedication to quality, innovation, and client satisfaction, Rocket PCB has established itself as a reliable partner for numerous global industry titans.