Rocket PCB

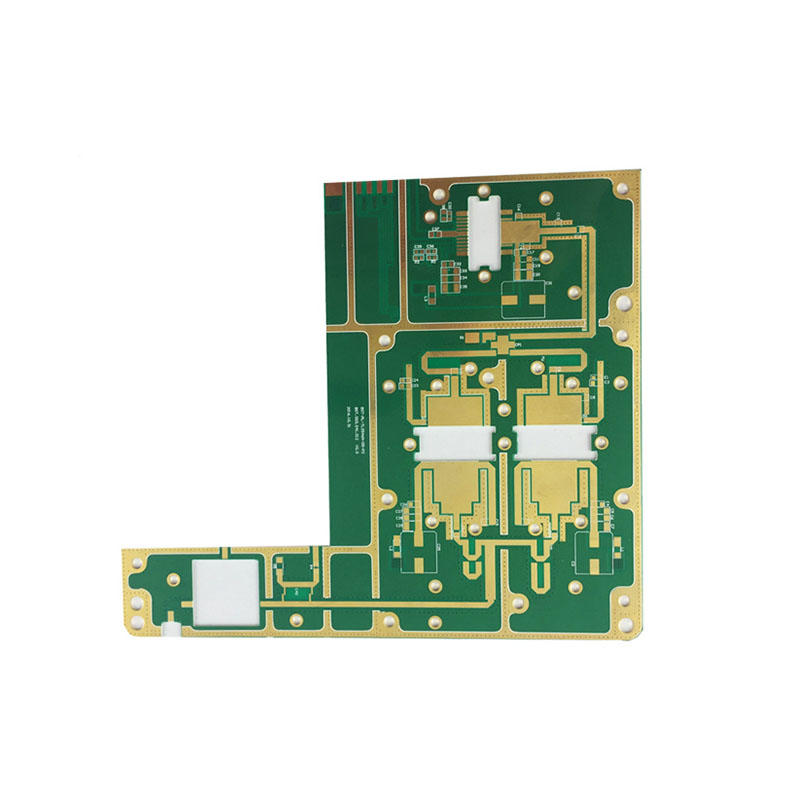

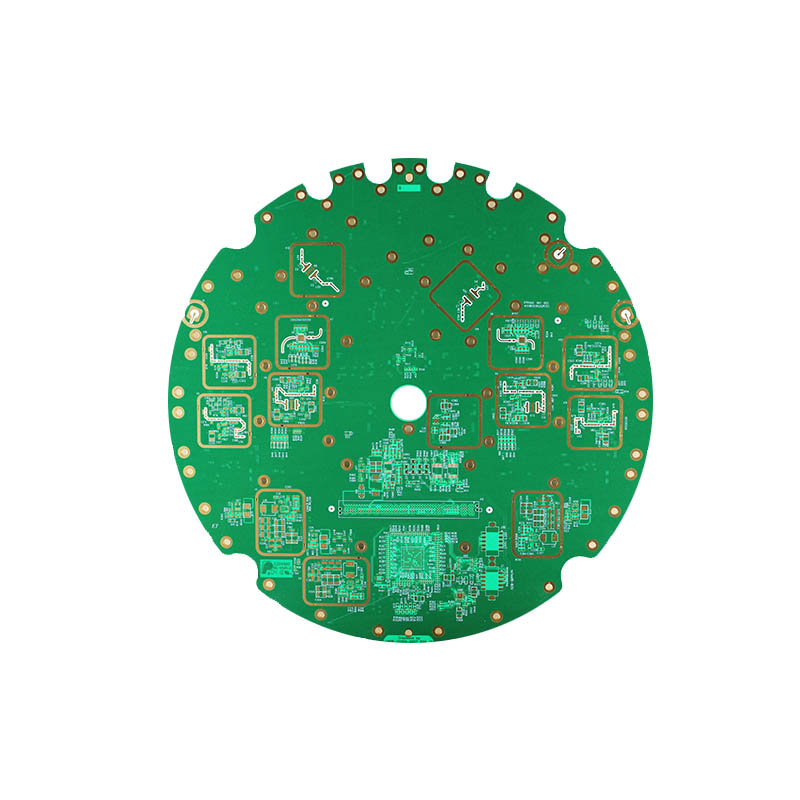

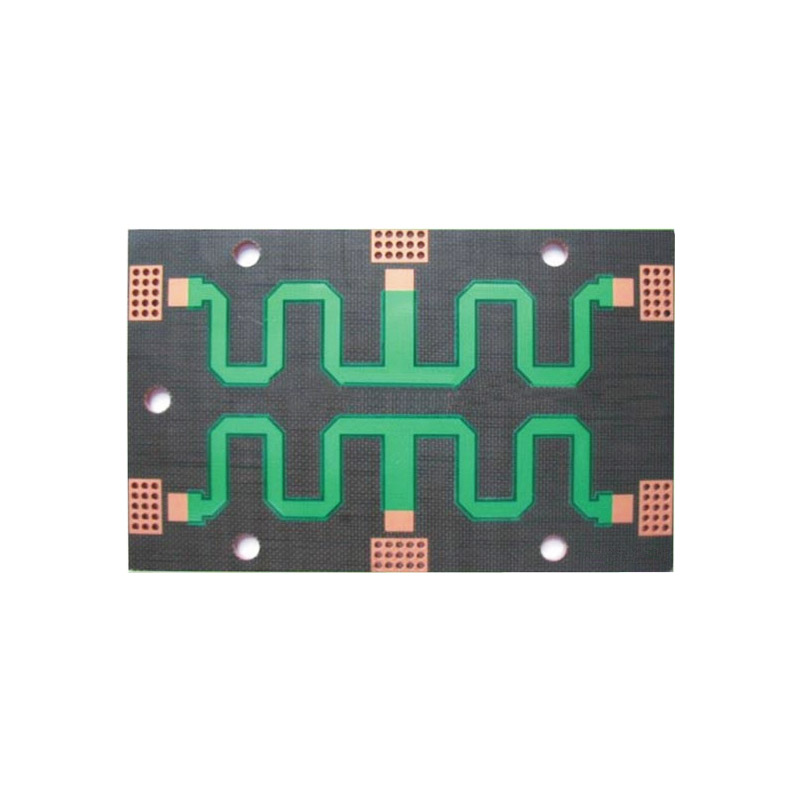

provides high-frequency high speed microwave RF printing circuit board of the fast

sample production services. Professional fabrication experience for high

frequency circuit boards used in power divider, coupling and device,

circuit builder, amplifier, dry release, base station 3G antenna.

Company year-round stocks domestic and imported high-frequency material

(F4B, Rogers, TACO, NC, ARLON, TP-2) dielectric constant 22106, etc. Can

provide fast turn around service and mass production in time to meet your

diverse, multi-variety and fast delivery needs.

We have a vibrant, professional and dedicated, experienced, high-quality team on technology, production and management.

Our

company has low cost and foreign information technology support and

other advantages, after more than 10 years of efforts and repeated

combination of resources, the company is casting its own brand with a

new face.

”Depends on professional

technology and rich experience of high-frequency microwave printed

circuit board production to become the domestic 3G/4G equipment top

manufacturer.” With high quality, fast delivery, high quality

after-sales service and high-level professional ethics win praise from

customers.

01 Top imported raw materials to protect product quality from the source

TR1: EMC, ITEQ, SYL, Isola, Rogers, Arlon, Nelco, Taconic, Hitachi, etc.

557k: Rohm& Haas(US) Atotech(Germany) Umicore(Germany)

Ink: Taiyo (Japan) Dry film: Asahi (apan), Dupont(us)

02 Top high frequency material resources, so that your products win in the fundamental

The world's top high frequency materials merchants Rogers, Taconic, Arlon, Neco, Isola's long-term strategic partner

Can

provide customers in the communications industry with the highest

quality materials and related resources, fundamentally control product

quality

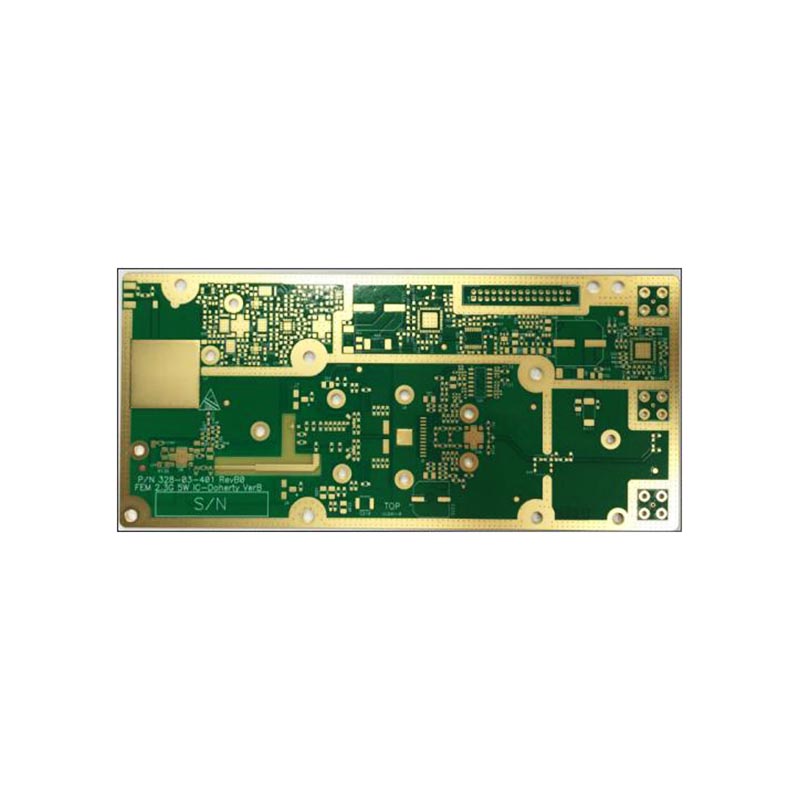

03 Full set of surface treatment equipment to meet the needs of various industries

can

completely deal with immersion gold ,immersion tin, OSP, HASL, gold

plating, thick gold, tin plating, silver plated and other related needs

04 Leading process capabilities

3mil/3mil minimum line width/space, impedance tolerance control in 8%

PTH hole+/-0.05mm, drilling precision +/-0.05mm

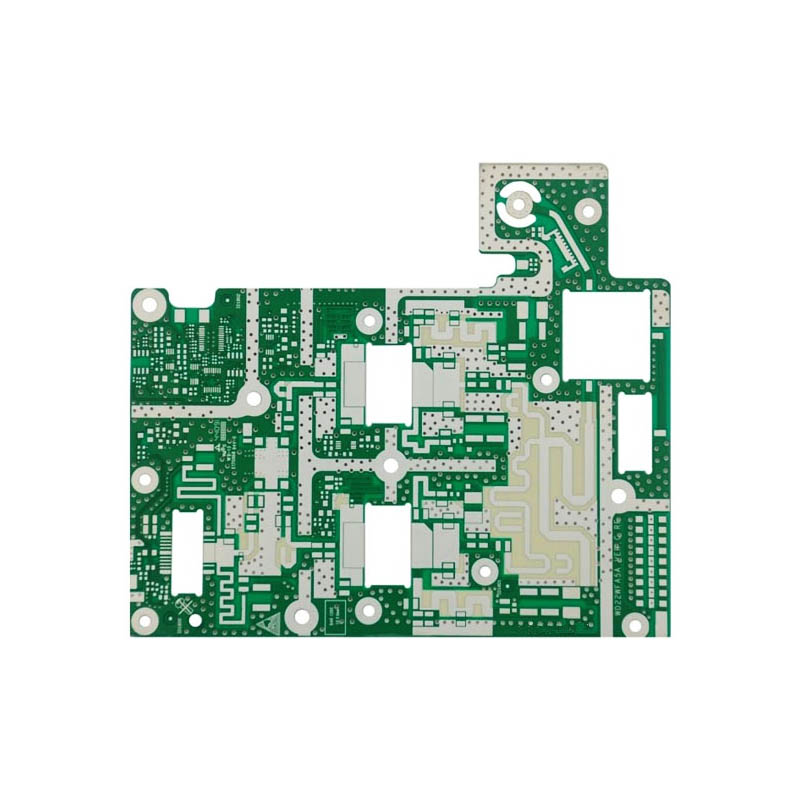

05 Process capability fully meets high frequency PCB

Mature hybrid technology:FR4+ PTFE, FR4+408HRFR4+ ROGERS

06 Rigorous quality control system to effectively ensure product performance

Strictly in accordance with | PC standard control, Guaranteed Shipment Quality Pass rate 100%

Perform quality PDCA cycle processes to continuously improve product performance

Imported

American Diane Ion chromatography Tester (D| ONEX ICS-900) and

temperature cycle inspection equipment to ensure high reliability and

stability of products

R&D is a key factor in developing new competitive advantage in the electronic manufacturing industry. Rocket PCB Solution Ltd in particular has devoted to R&D and as a result, we constantly soar ahead of competition. We have continued to absorb the talents from all directions to constitute the strong R&D team.

An innovative and creative R&D team is a key competitive advantage for Rocket PCB. Without this team, we could not have become a competitive manufacturer in the electronic manufacturing industry. The team focuses on midterm proactive development and long-term research, which includes quality improvement, operational efficiency, analysis of every stage of production, and new and existing PCB solutions. In order to maintain and improve R&D strength, our R&D team regularly participate in high-level seminar in the electronic manufacturing industry, keep close to the industry dynamics and frequently update their industry expertise. The long-standing commitment to R&D has brought our business results to the highest level.

To show our improving R&D capability in the market, we successfully developed High frequency PCB. The distinctive characters are High quality and quick turn.

Rocket PCB is established as a provider of High frequency PCB with tailored service at affordable price. Aiming to become an international high-quality supplier in the electronic manufacturing industry, we will carry forward the outstanding spirit of 'Focus on customer first' and keep making progress in technology innovation, constantly challenge ourselves and provide better and better services for customers. Contact us today at https://www.rocket-pcb.com to learn more about what we can offer to your business.

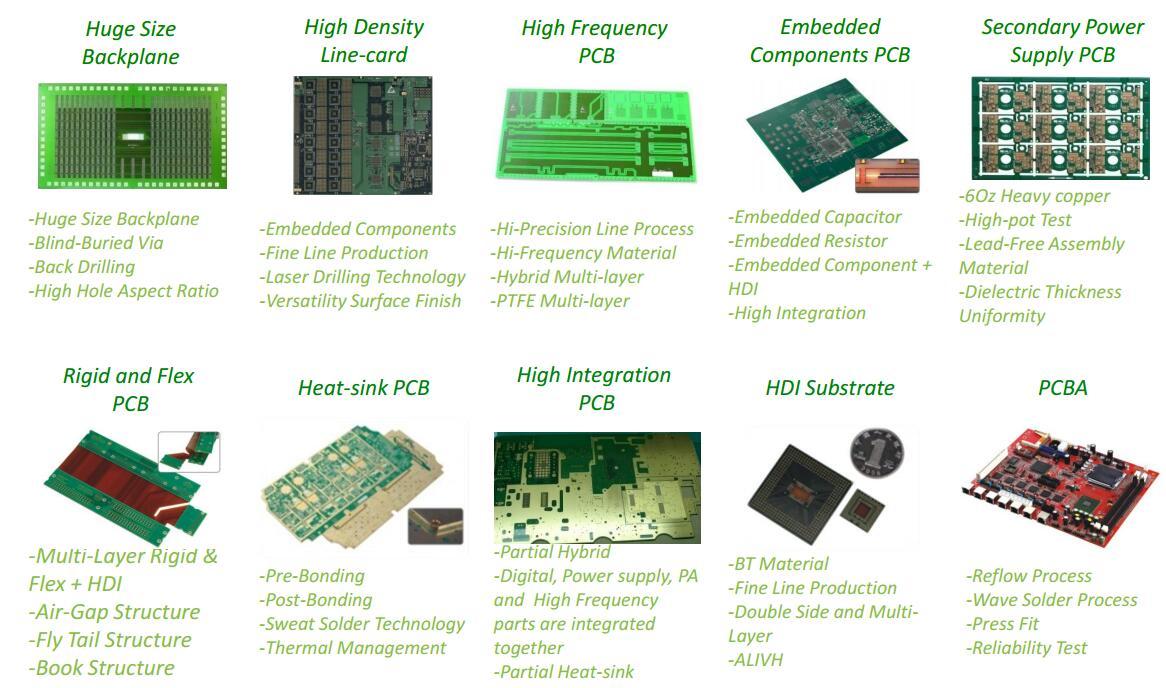

SPECIALIZED MANUFACTURING

Conductive materials and core-to-core bonding

Embedded components

RF connector attachment

Laser direct imaging (LDI)

Laser etching

Laser forming

Multi-level cavity construction

Plated cavities and edges

Composite/hybrid Structures

N+N dual press-fit

Dual-drill

Bonding on metal core

Bulid-up HDI

Long-short and staged gold finger

CAPABILITIES

3mil line and space

4mil laser defined vias

6mil chip-on-board

6mil mechanically drilled vias

Conductive and non-conductive via fill

Dual backdrilling

Sequential lamination

Mixed dielectric

Heatsink Bonding

Heavy copper/thermal vias

Blind/buried vias

Stacked and staggerd microvias

EXTENSIVE ANALYTICAL TESTING

Design Rules Check(DRC)

Electrical Testing

Automated Optical Inspection(AOI)

X-Ray

Plating thickness testing

Metalized vias inspection

Thermal shock testing

Surface peelability testing

Impedance control testing

100% visual inspection

Solderability testing

Ionic cleanliness testing

Metallographic microscopic analysis

High voltage testing

Insulating resistance testing

FEATURES

PTFE

High speed/low loss

High temperature

Low CTE

Lead-free, HASL, ENIG, EPENIG, Immersion Silver, Tin, Gold finger

Combination surface finished

Copper-filled microvias

Rocket PCB supply chain meticulously practices all-around quality management and actively introduces and implements multi-domain system management. We have successively obtained ISO9001, ISO14001, IATF16949, OHSAS18001, ISO/IEC27001, ISO13485 and AS9100 certifications.

◪24 hour real-time technical support. Fast prototype with 24 hours and instant quote in 2 hours. For RF board, the lead time will be based on the parameters and specifications.

◪ Effective and flexible PCB engineering solutions save your cost. We always put the best interests first when providing innovative solutions for manufacturing customers’ products, we are more willing to help customers grow.

◪ Rapid feedback on the layout, build-up, panels, impedance, material selection, design rules, manufacturability, costs of different solutions, use of micro vias, gold plating, special laminates, etc.

◪ Strong partnerships with different reputed A-class material suppliers such as Rogers, Arlon, Nelco and Taconic can realize a fast service to a wide range of PCB applications.

◪Dozens of tests such as open/short circuit testing( ET test), AOI, X-ray, impedance testing, solderability testing, thermal shock testing, metallographic micro-slicing analysis, halogen-free testing, etc. 100% outgoing pass rate.

◪Complete services like free Design Rule Check (DRC), free DFM, traceable manufacturing to complete after-sales service, on time delivery 99%.

◪We will keep secret for customer sale area, design ideas, drawing and all other private information.

◪Flexible payment terms. Samples for 100%TT, mass production payment: 50% advance payment 50% balance should be paid off before loading or accept monthly statement based on the order volumes.

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink