SMT processing factory in optical inspection ( AOI) The working principle of equipment - Ding circuit technology

by:Rocket PCB

2020-03-31

Optical detection in SMT processing plant (

AOI)

The working principle of the equipment by SMT processing factory today: Rocket PCB Solution Ltd, tell your brother speaking: optical detection in SMT processing plant (

AOI)

The working principle of equipment.

After SMT reflow soldering AOl, for example, there are usually: 2 d AOI, 3 d AOI two kinds.

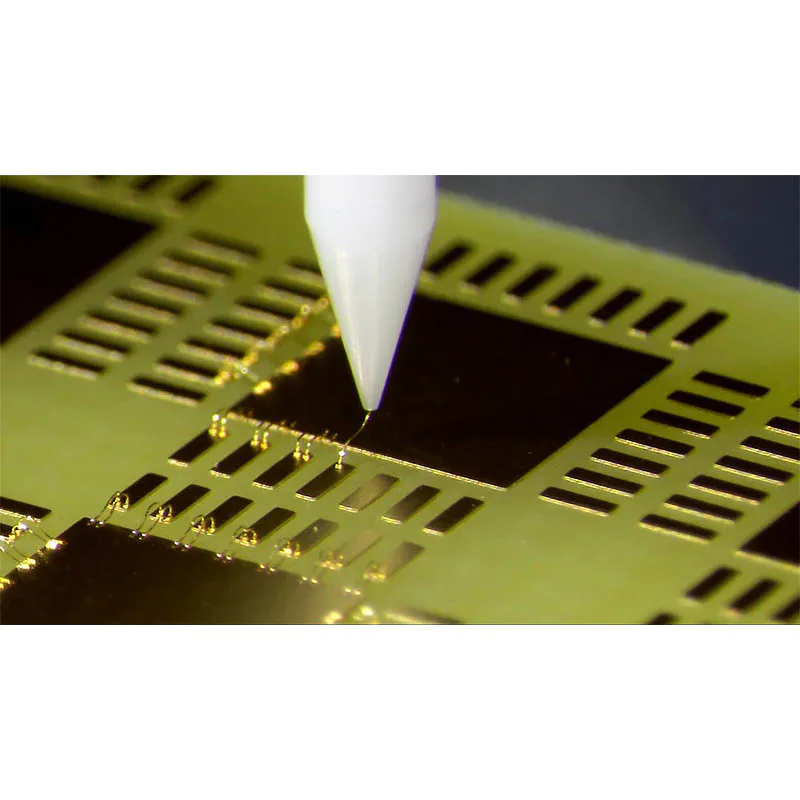

AOI detection in SMT processing is through: the basic principle of artificial lighting, LED lighting analyte, optical lens, CCD exposure, the amount of light reflected back, and have good programming standards than schools, analysis, and judgment.

Working principle of the two-dimensional AOI introduction: 2 d AOI using vertical camera, through color high brightness method for the determination of the solder joint quality, typical products are omron VT -

WN, the machine is at work, red, green, blue, 3 period of annular illumination in different height.

To have finished SMT processing PCBA board to illuminate, color video camera installed vertically in the center of the ring lighting online, extract the PCBA board picture, due to the red light is farther from the base board face than other two kinds of light in the location (

Higher position)

。

So relative to the base board face Angle of incidence is larger, exposure to the flat surface of machine direction to the upper part of the reflected light, and light to the solder surface of the light reflected from directly above.

Therefore, for the quality of the flat surface of the cameras is the red areas.

Principle is the same with the red light, green areas for the camera to the slight tilt of the surface of the solder, the blue areas for there camera zoom up to the steep slope of the surface of the solder.

Three-dimensional solder joint shape can pass color brightness model into 2 d color images, which can be further by the mathematical model of image processing and combined with certain is to realize the detection of SMT solder joint quality.

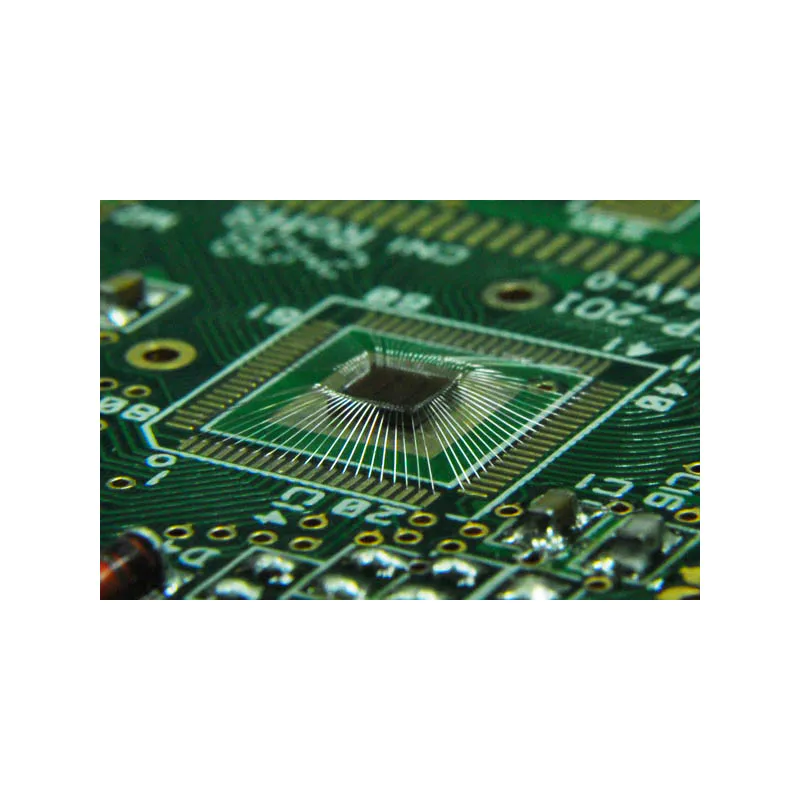

Working principle of the 3 d AOI introduction: 3 d AOI vertical camera is in use at the same time, increase the Angle of camera.

When vertical to like from the top to look down at the same time, camera Angle to observe solder joint image from the side, like artificial visual inspection, to see the local details, need to adjust the light and the viewing Angle.

It has stronger 3 d AOI, SMT processing good product for fault detection, such as when welding quality detection of PLCC device, 3 d AOI advantages can be fully revealed.

Lighting system adopted in 3 d AOI independently controllable light-emitting diode array as the light source, light emitting diodes arranged in a precision circular array, all the focus in the field of view, the closer the figure lights the closer it gets to the vertical Angle, the more close to the outer ring lights illuminate the tilt Angle.

Programming and can be used to control these diodes, texture, Angle for optimal lighting direction, density, etc.

Can adjust the lighting Angle for each test picture, direction and brightness, to meet the unique requirements of any SMT processing testing required.

As (

AOI)

In the development of optical inspection equipment, SMT processing plant for the product quality control personnel configuration will have a very large number of abate, at the same time will be more efficient would improve product percent of pass.

The above content by: (SMT plant

火箭PCB解决方案有限公司)

Provided, hope to be of help.

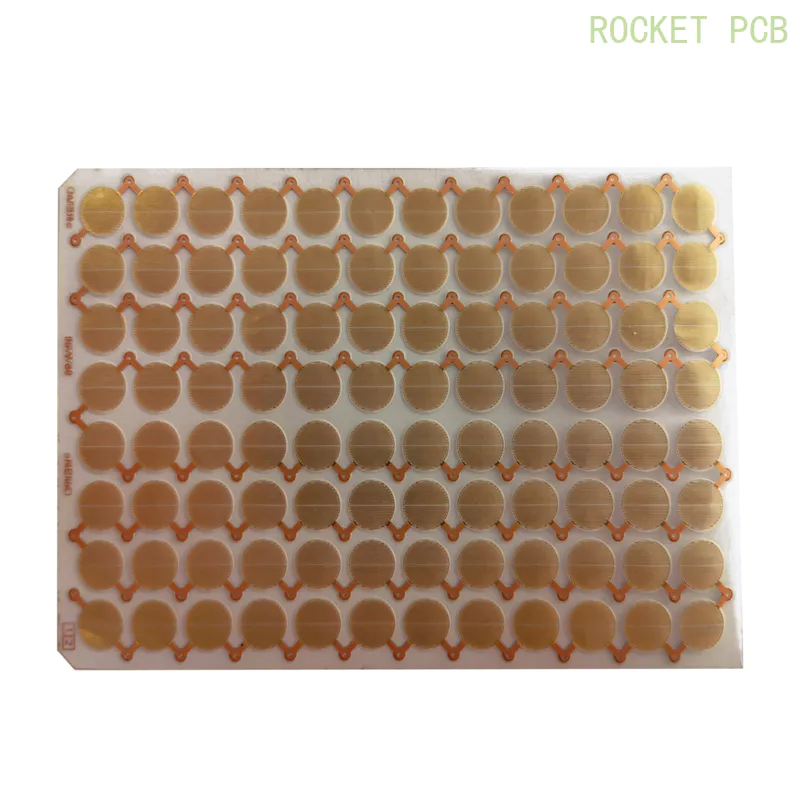

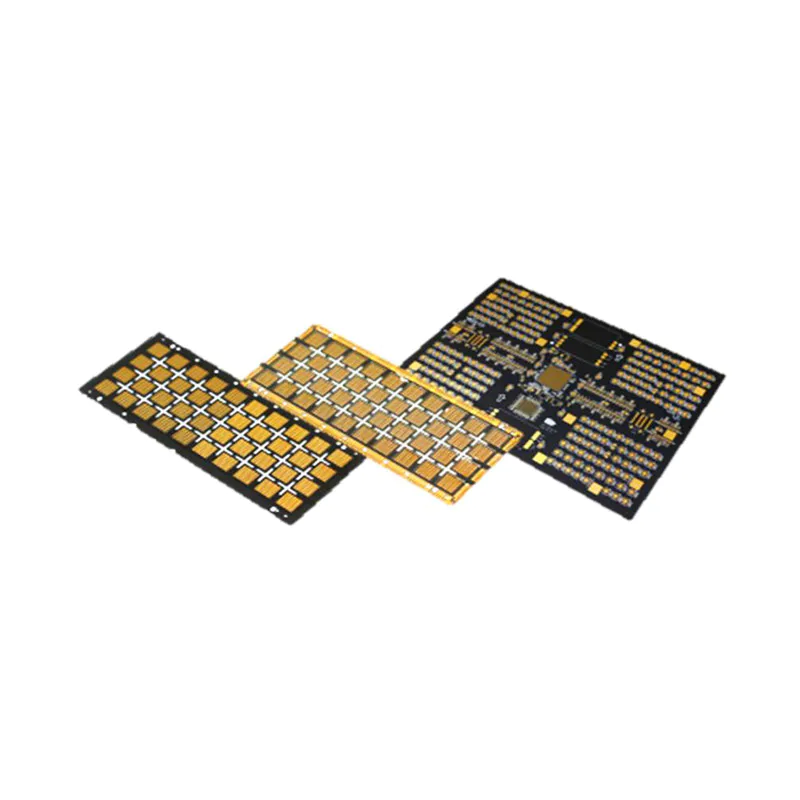

Rocket PCB Solution Ltd is one specialized is engaged in: SMT processing, engineering sample SMT proofing, dip plug-in welding, materials processing, OEM generation, any way, such as PCB SMT processing, welcome to consult customer service for more details.

Custom message