Small white must know the PCB PCB SMT production process by hand

by:Rocket PCB

2020-07-30

Time flies, unconsciously small make up have been dealing with the electronic industry for 3 years, from one for small white electronic components are basically don't understand, to now can separate circuit board design, over the years by the road, I personally feel good bumpy and bitterness!

I remember at the beginning just contact PCB welding (

PCB SMT/SMT processing)

, a lot of PCB circuit boards welding is broken, especially the small patch exclusion, welding a few times more, pads are almost all of me can't use, plug-in electronic components, etc. , have also been I lost the many welding welding plate.

All in all, I like other industries small white, with ugly past.

But when the number of circuit boards welding began more and more, gradually, and now almost never drop welding plate.

PCB PCB/PCB real knowledge comes from practice, perhaps really is such a life.

Apply at least on my body!

But I guess there are many new to circuit board design colleagues should be followed many years ago, I the same, the welding is really is a hard to chew bones,

Words can't say never, of course, a great god will still be some)

。

But today this novice is not coming with big welding technology level, but want to talk to big guy simple introduces a relatively fast and economical and practical PCB welding technology, PCB SMT is largely this workflow: 1.

2 open the steel net.

Brush solder paste 3.

Stick element 4.

A welding machine 5.

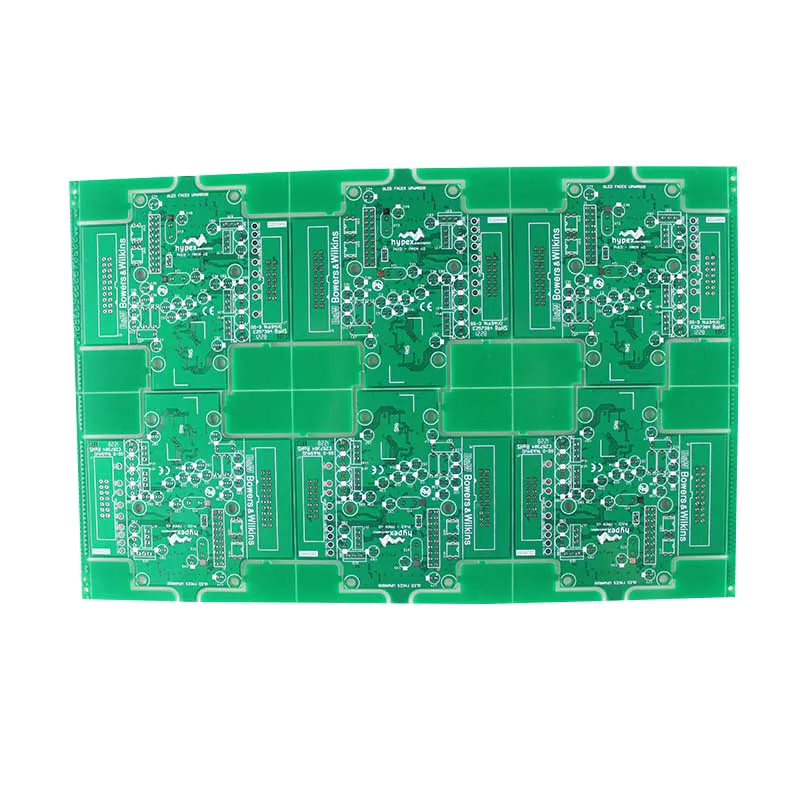

To test the methods introduced above steps is mainly suitable for SMT PCB more PCB circuit boards, electronic components welding mainstream plug-in components friends do not use the above method.

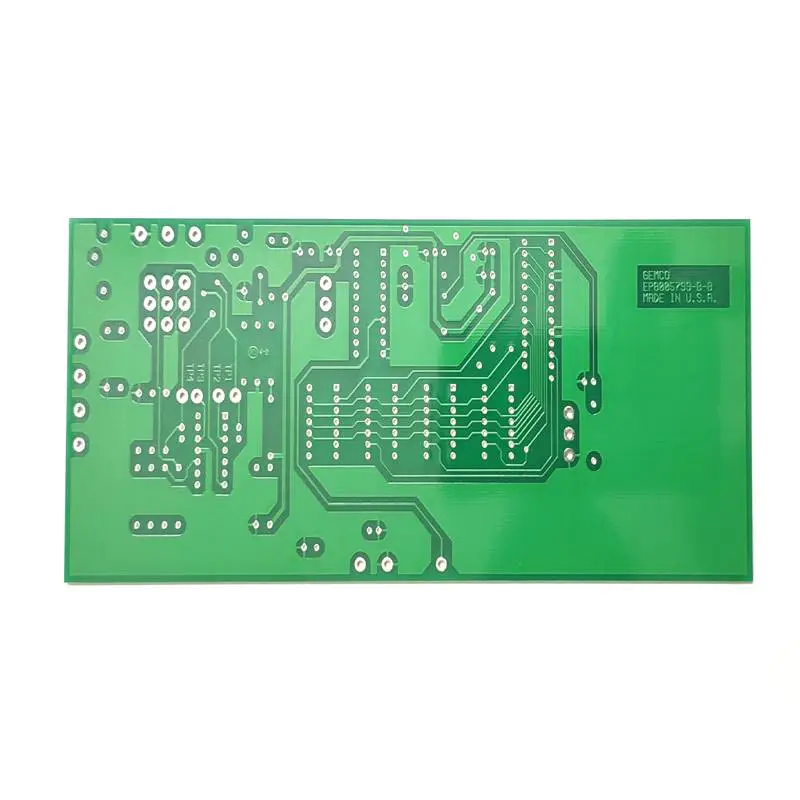

Do step 1, circuit boards, there is no doubt to open 1 zhang gang network.

When it comes to the stencil, as far as I know there are different price.

Such as ordinary corrosion of the steel net and laser.

Considering the price factor, laser, of course, many of the more expensive.

For example, I double steel net is only around 70 1, but the laser steel between profile around 200.

I have not used the laser, yet couldn't say what are the advantages, however, the corrosion effect also seems to be quite good.

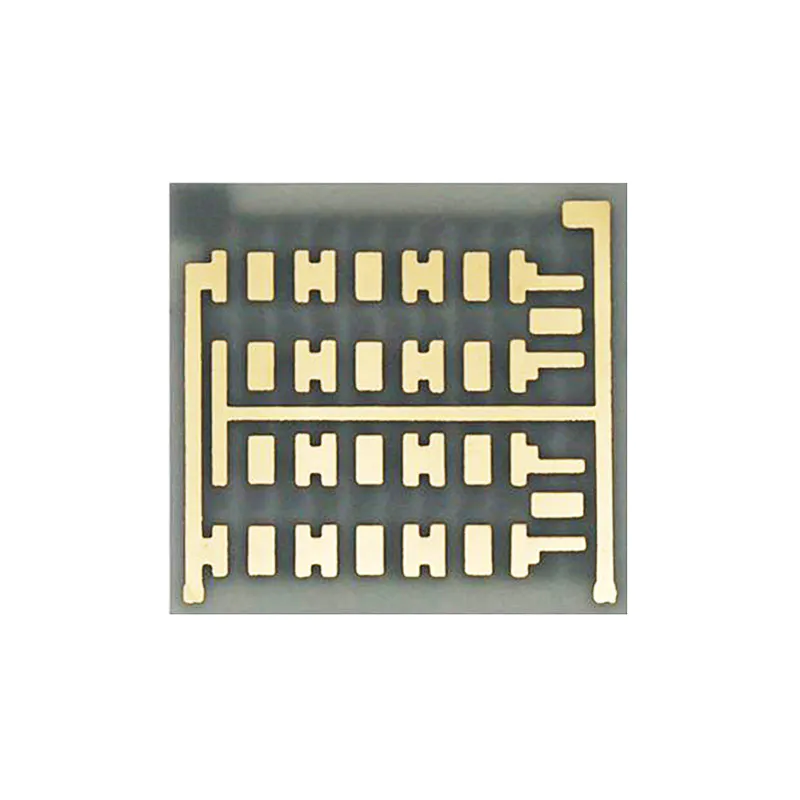

PCB circuit board strips in addition to the stencil, that placed the steel mesh of stainless steel shelves is also indispensable.

This is a small white side of a stainless steel shelves: next, steel rack fixed after the location of the stencil steel net is placed correctly, then put the circuit board.

After we will pay attention to adjust the location of the circuit board, artificial make welding plate on the steel net hole position, aim the position of the hole, the next step should be to brush the solder paste.

Pour solder paste in the steel net, using a relatively flat shovel knife will brush of solder paste evenly distributed on the welding plate aperture (

Observe whether there is no brush to part)

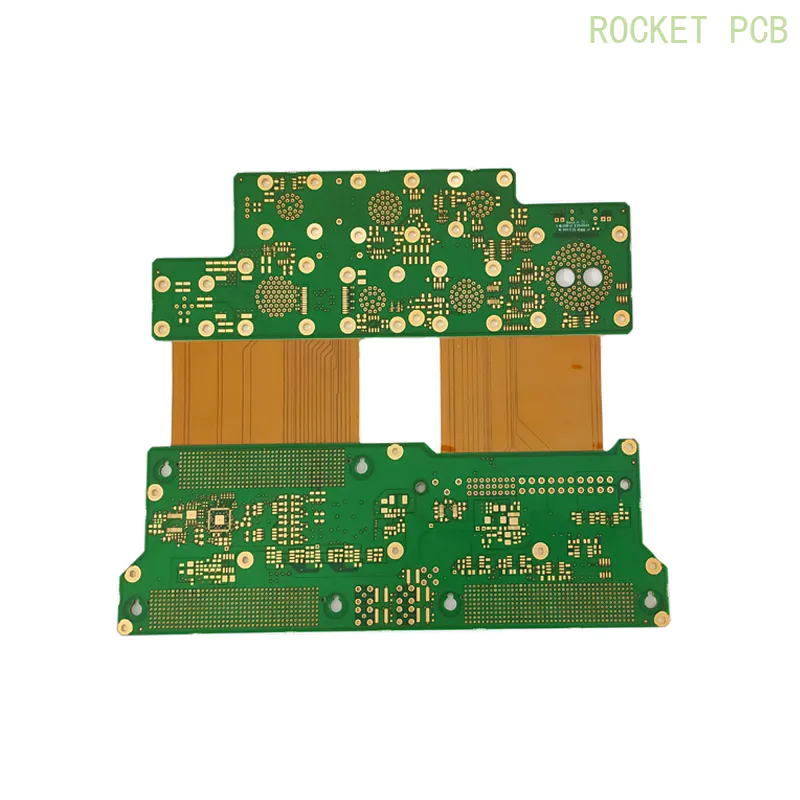

Brush with the solder paste, at this time we need to use electronic components taken carefully put up one by one, after being stick electronic components are all good place, we will be able to place the circuit board in reflow welding machine for welding in it.

Circuit board under the effect of reflow welding machine makes the electronic components on the circuit board and all welded to the board.

Such as listed as shown in figure, the effect how?

At least than hand welding is much beautiful.

In addition also need artificially to quality inspection, testing instrument, it is really over.

Above are some of my comments, general steps about PCB SMT simply say to this, has the thought practice friends can have a try.

I personally think that this way is more beautiful than hand welding and convenient.

There is a problem can leave a message below, we discuss together to learn together.

In the office, various are considered essential since they are used to achieve particular tasks in the office. Among these , pcb making service, pcb manufacturing services, and pcb manufacturing services are widely used.

More about the most suitable , visit Rocket PCB to get your offer!

With wide range of [分类关键词] products of top quality in offer, Rocket PCB Solution Ltd. will definitely be your best option for pcb making service solution. Do feel free to contact us at Rocket PCB .

In the office, various are considered essential since they are used to achieve particular tasks in the office. Among these , pcb making service, pcb manufacturing services, and pcb manufacturing services are widely used.

More about the most suitable , visit Rocket PCB to get your offer!

With wide range of [分类关键词] products of top quality in offer, Rocket PCB Solution Ltd. will definitely be your best option for pcb making service solution. Do feel free to contact us at Rocket PCB .

Custom message