PCB applications and uses

From mobile phones to house appliances, electronics perform a huge aspect in the daily routine. In the heart of every electronic is actually a printed circuit board. It actually may be the foundation of a majority of electronic solutions presently. These components are offered in a vast array of configurations, producing it feasible for them to serve many different functions. As electronics expand and produce across industries, PCB applications proceed to expand also. At present, the usage of PCBs spans just about every industry. PCBs will be the crucial functional centers of all electronics in contemporary society. Printed circuit boards connect components to one another through a range of relevant circuits.PCBs are the significant functional centers of most electronics within the contemporary world. Most of the people will recognize Printed circuit boards after they see them. You will uncover these compact green chips in the hearts of electronics. PCBs are obtainable in an infinite quantity of configurations and created utilizing a wide assortment of supplies. This type of flexibility tends to make it achievable for PCBs to perform in a selection of applications and capacities.

We've explored a number of those applications in much more detail below.

Health-related Devices

Electronics contributes considerably towards the health-care industry, functioning as diagnostic, monitoring and therapy device. The health care applications of these electronic goods continue to expand as electronics evolve to develop to be much more successful, major to endless new possibilities. In the center of these medical appliances are PCBs. printed circuit boards inside the health-related market are extremely specialized to be able to fit the special guidelines of healthcare appliances. In most healthcare systems, a tiny package is necessary to match the size requirements for an implant or e. r. monitor. For that reason, health-related PCBs are normally unique high-density interconnect PCBs, also known as HDI PCBs. Healthcare PCBs could also be manufactured with flexible base supplies, allowing PCB to bend throughout perform, which could possibly be needed for both internal and external healthcare devices. Because of overall health implications involved with them, health-related Printed circuit boards are presented to higher standards than most other PCB sorts. Repeatability and stability are two required qualities medical-related PCB companies have to achieve, as well as compliance with stringent health-related guidelines.

Most typical medical PCB applications

Medical PCB applications improve as speedily since the healthcare product field itself. A couple of the most common healthcare PCB applications incorporate the following:

Monitors: Customized and healthcare monitors which consist of heart rate and blood tension monitors, blood glucose monitors, and significantly much more.

Scanning Technologies: ultrasonic technologies and CT scanners usually use PCB founded electronics.

Control system: The device controlling liquid infusion, move rate and dispensation is electronically handled.

Internal Goods: Heart pacemakers and connected inner health-related devices sustain patient overall health, run by tiny PCBs inside their centers.

Scientific Instrumentation: Healthcare exploration utilizes different scientific instruments to examine sickness and test patient outcomes. These consist of electronic microscopes, photometers and manage systems for power generators and compressors.

Consumer Electronics

Consumer electronics could be the devices we use each day, like smartphones or private computers. Even the newest versions of refrigerators often include electronic parts. Inside each one of those devices is a Printed Circuit Board. Since the substantial volume where these consumer electronics are made, the quantity of PCBs produced to manage them has to be equal in quantity. These higher number PCBs have a low unit price tag, holding the cost of the final goods relatively little. The challenge is keeping the consistency and good quality of those Printed circuit boards, and that's the purpose Printed circuit board suppliers need to have to in accordance with tough business specifications and quality-control recommendations to guarantee that each consumer electronic functions as you expected.

Most typical consumer electronics PCB applications

The applications of PCBs in consumer electronics are comprehensive. The following are only a handful of on the well-liked utilizes of PCBs in Consumer electronics:

Personal laptop Electronics: Personal computer systems and portable computers both have PCBs at their cores, as will the screens and peripheral goods involved with them.

Mobile Devices: Smartphones and tablets are at the core of our every day, operating as everything from our alarm clocks to our Gps devices.

Entertainment Systems: Almost everything in your house entertainment method, from the DVD and gaming console to the tv and stereo equipment.

Recording product: Camcorders, cameras, microphones and also other recording goods all depend on their internal PCBs to perform.

Home Appliances: Practically each and every modern equipment runs use of electronic components: Alarm clocks, microwaves, fridge, coffeemakers, etc.

Industrial Applications

High-powered industrial applications for Printed circuit boards are frequent too. These electronic components handle the mechanisms applied in plants and producing facilities, as well as must survive the cruel conditions normally witnessed in industrial installations.

This can incorporate anything, which includes harsh chemical compounds, vibrating machinery and rough dealing with. Industrial PCBs need to survive the harsh circumstances usually viewed in industrial installations. In this sort of speedy difficult conditions, professional standards can also be strict. At the moment, heavy copper PCBs (greatly heavier than common ounce PCBs) are frequently discovered in numerous applications. this kind of PCB assists in massive present industrial applications as well as rechargers.

Industrial Machines: A lot of electrical drills and presses utilized inside the processing operate utilizing PCB industrial controlled electronics.

Measuring Items: Products applied to measure and handle pressure, temperature and other variables in the industrial producing.

Electrical power Device: DC-to-AC electrical power inverters, solar energy cogeneration tools and also other energy units.

Automotive Applications

Cars far more and much more depend on electronic components during the present-day era. Even though within the previous, electronic circuits happen to be only actually utilized to windshield wipers and headlight switches, modern-day automobiles use electronics to get a lot much more functions.

Today's automobiles reap the benefits of the ever-advancing electronic circuit engineering by incorporating PCBs into some new usages. PCBs doing work with high-frequency signals like microwave, RF or millimeter-wave frequencies are typically utilized in sensor applications which are now frequent in vehicles. Truly, radar engineering once relegated to military cars is now prevalent in modern automobiles to assist autos to stay away from collisions, verify blind spots and adapt to traffic conditions when the car is under cruise manage.

These innovative tactics carry enhanced security to roads as well as concurrently supplying an enhanced driving experience, that is why they've developed to be so well-known in today's motor vehicles. The suppliers of these systems, consequently, have to supply and use an assortment of advanced high-frequency PCBs and related materials.

Most typical car PCB applications

Just several on the widespread applications of PCBs inside automobiles involve the following:

Manage Systems: Motor car manage systems, including engine management applications, fuel regulators and energy supplies, use PCB-based electronics to watch and deal with resources. Some management techniques even drive the car for that driver in certain circumstances. Such as some automobiles on the market at this time give automated parallel-parking functions.

Surrounding Monitors: Newer car models tend to be produced with substantial security systems to help the driver check blind spots and significantly a lot more accurately judge distances. A number of cars now function full-perimeter verify systems, employing radar or cameras to measure distances and alert the driver to close-proximity objects. These programs demand high-quality PCBs in an effort to function effectively.

Navigation Devices: Navigation equipment is now prevalent in vehicles, making use of GPS computers to aid drivers find their way across an unfamiliar territory or recognize the quickest route to their place.

Audio and Video devices: A lot of automobiles over the market today have superior dashboards that connect the car towards the radio or music device. In addition, a lot of vehicles make use of passenger film screens to occupy passengers all through longer rides. All these units are controlled by applying PCB-based electronics.

Within any of these car PCB applications, individual style, and design need to be taken into consideration. As an example, the high-vibration setting of a vehicle might possibly put a substantial amount of strain around the normal rigid PCB. In lieu of a rigid PCB, consequently, a great deal of motor vehicle electronics makers use flexible PCBs, which might be a lot more resistant to vibration also to being little and light-weight. The challenge, then, would be to produce ample of those high-frequency, flexible PCBs to meet the requirements with all the large automobile businesses.

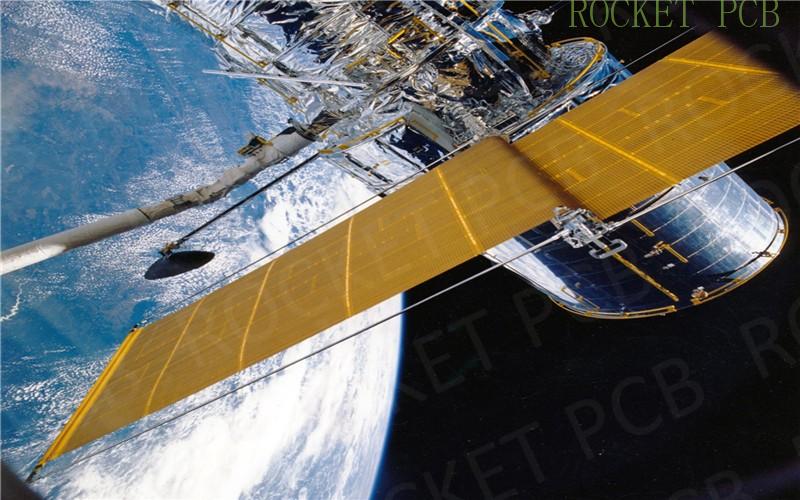

Aerospace Applications

Like automotive applications, aerospace applications of PCBs demand a terrific deal of precision and sturdiness. Jets and rockets normally undergo huge amounts of turbulence inside their atmospheric journeys, which signifies that an ordinary rigid PCB could endure sufficient strain to turn out to become broken through the process. To solve this, most aerospace producers use flexible PCBs, that are light and tiny on prime of that to remaining resistant to vibration injury.

On top of that to becoming durable, aerospace PCBs need to be exceptionally precise and high-functioning, created for optimal carry out in order to stay away from technical troubles. Because electronics utilized in aerospace technological innovation are so important around the safety around the automobile and its crew, it is essential they function perfectly.

Most typically aerospace PCB applications

Monitoring equipment: Instrumentation, like accelerometers, strain sensors, microphones and torque and force sensors all use PCBsPCBs. These goods are employed inside the engines and cockpits of airplanes, both to monitor the function of the car and to talk with ground management.

Testing Equipment: In addition to realizing the function of an aircraft, PCBs are concerned about the improvement and testing of air vehicles. Testing equipment of which collects information in the course of structural, vibrations and flight testing processes utilizes PCBs at its core. This data can then be made to make a much more efficient and safer aircraft.

Lighting Applications

Printed circuit boards provide a base for any wide range of high-output LED applications. LED lighting solutions are speedily gaining steam inside quite a few industries, valued for their low electrical power consumption, greater efficiency and light output. When integrated by using a PCB, these LEDs achieve far more versatility. PCBs assist in expanded uses for LED lighting solutions, specifically displays and indicators.

Most typical lighting PCB applications

A couple of the most common applications of PCB inside of the lighting field involve the following:

The Telecommunications Sector: Telecommunications equipment generally tends to make use of PCBs to regulate their LED indicators and displays. Inside this field, lightweight and lengthy-lasting PCBs typically be favorable, largely on account of the density of machinery within the field. Because aluminum PCB tends to have better heat transfer performance than the FR4 model, it's generally situated inside of telecommunications lighting applications.

The Automotive Sector: LED displays are normally found in the automotive field, especially on dashboard indicators, headlights, brake lights and sophisticated panel displays. This sector particularly favors PCB LEDs for their reduced manufacturing price and impressive durability, which improve the value and longevity of one's automobile.

The Laptop Technology Sector: PCB-based LEDs are acquiring to become increasingly well-known within the PC technological industry, commonly seen in desktop and laptop displays and indicators. Due to the heat-sensitive nature of the computer system, aluminum PCBs are specifically favored for lighting applications within computers.

The Healthcare Industry: Lighting devices are of huge relevance in health care applications, particularly in surgical and emergency applications, where lighting can help strengthen a physician's visibility. Inside of these applications, LED tends to acquire the lighting approach to option for its energy and tiny size. PCBs are often utilized because the base for these applications, specifically aluminum PCBs, which sustain longer and provide greater heat-transfer capabilities than other PCB designs. By undertaking this, PCB LEDs guarantee long-lasting health-related products that could repeatedly be utilized inside a choice of health-related settings.

Residential and Storefront Applications: In addition that towards the uses listed above, PCB LEDs are acquiring enhanced acceptance inside of houses and businesses in the form of signs and displays. Great LED lighting can be a cheap way for house-owners to light their residences effectively, while customizable LED displays can direct market to storefronts.

Even though practical in the assortment of applications, LEDs tend to become temperature-sensitive, with the longevity of a LED bulb lowering because of the common temperature within the light fixture increases. Even though many common PCBs present wonderful performance, not all are suited for LED applications. When paired with a LED, some PCBs may not transfer heat speedily adequate to supply a secure temperature organic environment for your LED to operate at the highest efficiency. To function very best inside a lighting application, PCBs intended for LEDs need to be intended to maximize heat transfer skills.

For this purpose, aluminum-based PCBs will probably be the top remedy. Most high-lumen-output LED applications use aluminum PCBs, mainly used for higher levels of heat transfer aluminum PCB can be realized. This way, the PCB doesn't require an extra heat sink in the design, The integration of the heatsink into the PCB base itself provides additional compact products for manufacturers and end consumers to reduce costs.

Other PCB Applications

PCB-based goods are utilized in many applications across quite a number of industries beyond those listed above. A handful of examples just like the following:

Gun application

Both military and civilian gun manufacturers use PCB in their test equipment.Before putting these products on the market, manufacturers usually use such equipment to ensure the safety and function of explosives, guns, and ammunition. Some of the equipment used includes penetration impact recorders and impact test equipment.

Marine Applications

Both underwater and sailing applications are common areas to seek out PCBs. PCBs typically manage the navigation, engine management and energy distribution applications used on sailing vessels. The fluctuating amounts of strain and vibration lead to an assortment of issues that designers need to make to ensure right, steady function.

Safety Applications

Safety systems in and all-around homes and businesses use PCBs to coordinate the numerous components and signals employed to detect the presence of an intruder. fire and burglar, smoke alarms all use PCBs, as do electronic door locks.

Broadcasting and Telecommunications Applications

As mentioned earlier, PCB based LED lighting displays are well-liked in the telecommunications and broadcasting marketplace. PCB can also be used for many other functions in this industry. High-frequency amplifier and filter equipment usually use PCB, booster station, receiver, frequency board, mixer, and microphone also use PCB.

The applications of PCBs extend far beyond the above listed, broad and varied. Wherever electronics are utilized in society, you could possibly be certain to uncover applications for PCBs of all varieties.

Discover a Maker for Your PCB Application

PCB is a flexible and adaptable choice for many applications across a collection of industries. Skilled and professional PCB maker can produce a cost-effective and effortlessly manufacturable PCB solution for your any application. If you are searching for an excellent top quality PCB supplier, Rocket PCB might help.

We provide premier PCB manufacturing solutions to corporations across the globe. We function with our customers to produce PCBs that go beyond their expectations, meeting every single requirement at the same time providing complete expertise, unrivaled high-quality assurance, and cost-effective manufacturing processes. After you decide on to do the job with Rocket PCB, you are partnering with a supplier which is committed to your satisfaction and the highest quality assurance needs. Our PCB board manufacturing and assembly observe IPC Class 3, RoHS and ISO 9001:2008-certification, and continue to find the newest certifications to be sure that we are offering the best businesses. Our principal objective is to help you save money and time so you can quit worrying about PCB manufacturing and pay attention to PCB designs and product improvement.

No matter what kinds of PCB your firm demands, we are able to manage it. Double-sided, HDI PCB, RF& microwave, SMT or mixed assembly, we can achieve it in the most cost-effective way. Browse our site or attain us for a lot more information about PCB applications, or contact us online to get a speedy quote!