How to choose high speed and high frequency PCB material

Evaluation and selection of PCB materials for high speed and high frequency PCB

PCB substrate material plays an increasingly important role in the development of high-speed and high-frequency PCB technology and products. The development of high-speed and high-frequency PCB products will bring new business opportunities to PCB industry. From its product design, to the selection of PCB substrate materials, PCB manufacturing, PCB inspection, etc., all contain new technologies and new levels. Its application field has also been upgraded to a new high-end level. It can be considered that high-speed and high-frequency PCB industry is an industry with high added value and "knowledge economy".

The high-speed and high-frequency characteristics of PCB are mainly attributed to two technical ways: on the one hand, it is to make this kind of PCB develop into high-density wiring (micro wire and spacing, micro aperture), thin shape, high reliability of conduction and insulation. In this way, the distance of signal transmission can be further shortened to reduce its loss in transmission. On the other hand, PCB material with high speed and high frequency characteristics should be used.

The realization of the latter requires the PCB industry to carry out the research on the comparison of such PCB PCB substrate materials to find out and master the accurate control process methods, so as to achieve the purpose of reasonable matching between the selected PCB substrate materials and PCB manufacturing process, performance and cost requirements.

Low dielectric constant and low dielectric loss factor are important performance items for PCB to realize high speed and high frequency. In this paper, the dielectric constant and low dielectric loss factor of different resin PCB substrate materials are compared, and their relations with frequency, temperature, humidity, characteristic impedance control accuracy are discussed, so that the correct and reasonable selection of these PCB substrate materials can be achieved in PCB manufacturing.

Characteristics of high speed and high frequency PCB

The characteristics of high-speed and high-frequency PCB are mainly shown in three aspects:

(1) It has the characteristics of small transmission loss (α), short transmission delay time (TPD) and small signal transmission distortion.

(2) It has excellent dielectric properties, and the dielectric properties (mainly ε r, Tan δ) can maintain its stability under the environmental changes of frequency, humidity and temperature.

(3) High precision control with characteristic impedance (Zo).

In order to achieve the above characteristics, the PCB substrate materials need to have low dielectric constant (hereinafter referred to as "dielectric constant", expressed by ε), low dielectric loss factor (Tan δ). At present, the control of high-precision characteristic impedance value has also become an important characteristic requirement of high-speed and high-speed PCB. The above ε, Tan δ, together with the thickness of the insulating layer of the substrate, the circuit figure shape of the conductive layer (Mainly refers to the width of the wire), constitute three important factors for the precision control of characteristic impedance value.

For high-speed, high-frequency PCB substrate performance requirements in addition to the above dielectric properties, but also should have other main characteristics. For example, it has excellent heat resistance, processability, formability and can be used to manufacture high multi-layer PCB board (more than 30 layers).

Types and characteristics of high speed and high frequency PCB substrate materials

There are many kinds of high speed and high frequency PCB substrate materials. But they have a common characteristic, which is the resin used in the PCB substrate material whose dielectric constant and dielectric loss factor are very low or low. The magnitude of ε, Tan δ of the resin used in the PCB substrate material is mainly determined by the polarization degree of the resin structure itself. The greater the polarization, the higher the dielectric constant.

Therefore, eliminating or reducing the easily polarized chemical structure in the resin can effectively reduce the tan δ value of the PCB substrate material

---Which has become an important way for this kind of PCB substrate material to improve this property.

From this, it can be seen that the properties of a high-speed and high-frequency PCB substrate material are good or bad, the type of resin used, that is, the molecular structure of the resin used, is quite critical and important.

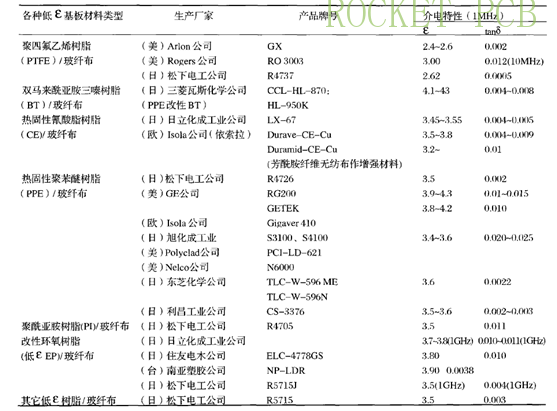

Table 1 summarizes the varieties and dielectric properties of several kinds of high-speed and high-frequency PCB substrate materials which have been put on the market in recent years or are widely used in the current market.

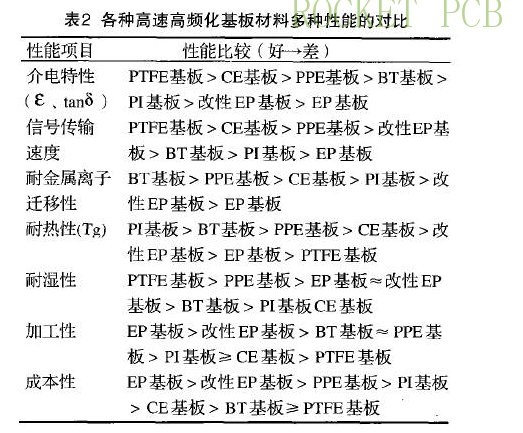

Table 2 compares the advantages and disadvantages of different high-speed and high-frequency PCB substrate materials from the seven aspects of dielectric properties (ε, Tan δ signal transmission speed, metal ion migration resistance, heat resistance (TG), moisture resistance, processability, cost, etc. (sorted by performance items from good to bad)

The high-speed and high-frequency PCB substrate materials made of different resins shown in= Table 1 have different advantages and disadvantages. Understanding their different advantages and disadvantages will help the PCB industry to have the best choice in using this kind of PCB substrate materials, and give full play to their advantages in manufacturing high-speed and high-frequency PCB, and take relevant technological measures to overcome their disadvantages.

Generally speaking, the PCB substrate materials with high-speed and high-frequency characteristics are all PCB substrate materials with low dielectric constant and low dielectric loss factor. But specifically, it also has its dielectric constant, low dielectric loss factor in the frequency, temperature, humidity changes under the performance of stable characteristics. No matter the manufacturer of this kind of board material or the PCB manufacturer using this kind of board material, should carefully study the relationship between the high-speed and high-frequency board material and the change of frequency, temperature and humidity, and what common characteristics they have.

Relationship with frequency

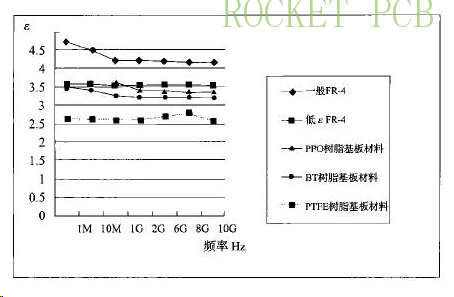

Fig. 3 and Fig. 4 respectively show the change of dielectric constant (ε) and dielectric loss factor (Tan δ) of different resin PCB substrate materials under different frequency conditions.

Fig. 3 Change of dielectric constant of different resin substrate materials at different frequencies

Fig.4 Change of dielectric loss factors of different resin substrate materials at different

1. Frequencies

Under the condition of frequency change, the general PCB substrate materials show the rule of large change of ε, Tan δ values. Especially in the frequency range of 1MHz to 1GHz, the change of ε, Tan δ is more obvious.

The dielectric loss factor, Tan δ of general PCB substrate materials is larger than that of ε due to the influence of frequency variation (especially in the high frequency range).The law of change is tend to increase.

Therefore, when evaluating the high frequency characteristics of a PCB substrate material, we should focus on the change of Tan δ value.

In terms of their changing characteristics at high frequencies, there are two distinct differences between the materials with high-speed and high-frequency characteristics, and the general substrate materials.

One is that with the change of frequency, the change of Tan δ is very small. The other is that the tan δ value of the substrate is relatively low, although it is similar to that of the general PCB substrate material.

2. Relationship with temperature

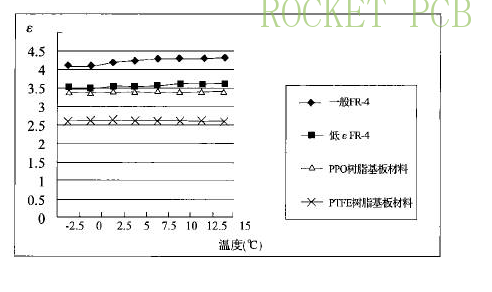

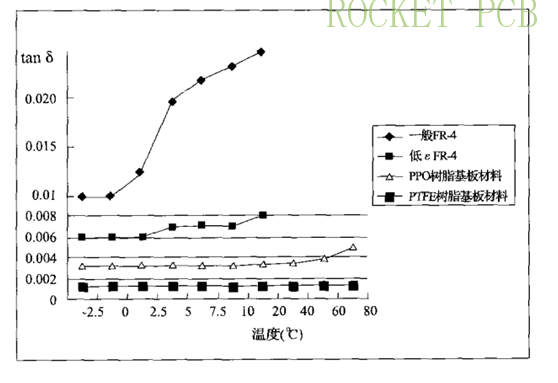

Fig. 5 and Fig. 6 respectively show the change of transmission loss of dielectric constant (ε) and dielectric loss factor (Tan δ) of different resin PCB substrate materials under the change of temperature environment.

As shown in Fig. 5 and Fig. 6, the corresponding relationship between the ε, Tan δ of the PCB substrate material and the temperature change increases with the increase of the temperature. The change of Tan δ is more "sensitive" than that of ε.

3. Relationship with hygroscopicity

The polarity in the molecular structure of the resin has a great influence on its high-speed and high-frequency properties. The higher the polarity in the molecular structure, the higher the dielectric constant. The water molecule is a high polar molecule, its ε value is as high as 70, so the residual moisture in the PCB substrate material will increase the ε, Tan δ of the PCB substrate material. Therefore, it can be seen that the size of water absorption is also a very important characteristic project of high-speed and high-frequency PCB substrate materials.

Comprehensive evaluation of its performance

Whether the PCB substrate material manufacturer is in the development and production of high-speed and high-frequency PCB substrate material, or the manufacturer of PCB is in the selection and use of high-speed and high-frequency PCB substrate material, it should make a comprehensive evaluation of its performance. Mainly to grasp its three aspects of performance inspection and evaluation. That is, basic performance, application processing performance and cost.

Basic performance

The assessment and evaluation of the basic properties of high-speed and high-frequency PCB substrate materials refer to the actual measured properties according to the items and indexes specified in the general and conventional standards (at present, most of them are based on IPC-4101A). In more than ten basic properties, special attention should be paid to the actual properties of its heat resistance (TG, acid and alkali resistance, chemical properties, water absorption, dimensional stability, etc.).

Application processing performance

The application and processing performance of high-speed and high-frequency PCB substrate material mainly refers to its lamination processability in multilayer board, hole processing characteristics and performance in various environmental experiments. These three aspects of performance are ultimately to ensure the high-speed high-frequency PCB conduction, insulation reliability requirements. It is a common and effective way to judge the melting viscosity of the semi-cured prepreg of the PCB substrate material and its change rule, which is used to evaluate the lamination processability of the PCB substrate material.

Under various environmental experimental conditions, the main way to determine the performance of various high-speed and high-frequency substrate materials, mainly through the "cold-thermal shock" cycle change, to measure the change in insulation resistance between the via holes of the substrate. As well as under the condition of continuous high humidity and high temperature treatment, the change of insulation resistance of PCB substrate material is measured continuously to check its insulation reliability.

Cost

According to the recent survey and statistics of Taiwan PCB industry, among the electronic products (or communication products) with high-speed and high-frequency characteristics, PCB manufacturing cost accounts for 8% to 12% of the total PCB component cost of the assembled electronic components. In some products, PCB manufacturing cost accounts for more than 12%. Therefore, PCB manufacturing cost is an important aspect of PCB competition in the market. Using high-speed and high-frequency PCB substrate materials is bound to increase the material cost compared with using general PCB substrate materials.

At present, if the high-speed and high-frequency PCB substrate materials are selected from the consideration of cost insurance, then the PCB substrate materials of FR-4 with low ε and PPE modified by epoxy resin are more favored by PCB industry. At present, they have a larger application market than other high-speed and high-frequency PCB substrate materials.

In the development of PCB manufacturers for the selection and application of high-speed and high-frequency PCB substrate materials, in order to solve the technical difficulties and reduce the manufacturing cost, PCB designers and manufacturers are forced to have more and more extensive understanding of this, master the characteristics of high-frequency circuit of PCB substrate materials, and master the characteristics of high-speed transmission of PCB substrate materials. At the same time, understand and master the difference between the two, and more accurately select PCB substrate materials. At present, many PCB manufacturers have learned from the theory and time that when selecting the substrate material for PCBs used in high-frequency circuits, special attention should be paid to the characteristics of the substrate material to examine how its “δ” changes at different frequencies, and when focusing on the requirements of high-speed signal transmission or on the requirements for the control of the characteristic impedance accuracy, it should focus on the characteristics of the substrate material used “ε” and other performance under frequency, humidity, temperature and other conditions.

On the basis of further understanding of this aspect, some manufacturers of PCB materials in the world have timely developed low ε and Tan δ varieties suitable for high-speed and high-frequency PCB series and put them on the market.