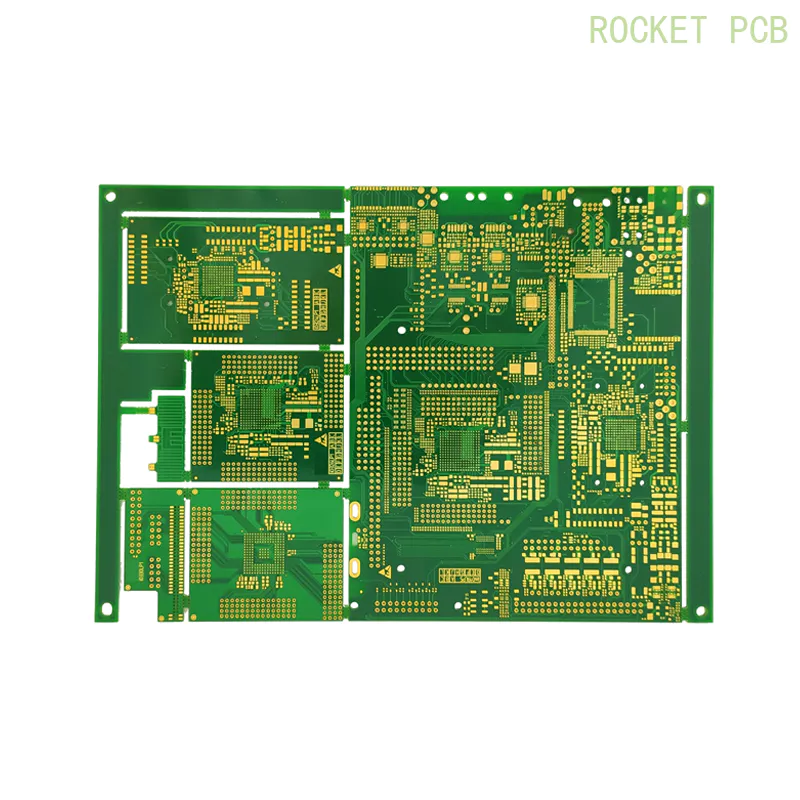

On the circuit board factory: PCB tin adverse factors and prevention programs

by:Rocket PCB

2020-05-28

Circuit board in the SMT production patch will appear not very good on tin, tin on general present bad and PCB bare board surface cleanliness, without dirt tin basically won't have bad, the second is, the tin itself when the flux, temperature, etc.

Then the circuit board production and processing of common electric tin bad concrete main performance?

After present this problem how to solve?

1.

Substrate or parts of tin surface oxidation and copper surface dull situation is serious.

2.

Circuit board face has a sheet of tin, electricity board face coating with particle impurities.

3.

High potential coating roughness, plate burning phenomenon, board face sheet electricity is not on the tin.

4.

Circuit board face with oil and impurities such as groceries, or there is a silicone oil residue.

5.

Low potential holes have obvious bright while phenomenon, high potential coating roughness, plate burning phenomenon.

6.

Complete coating and plating, low potential have obvious bright side hole phenomenon.

7.

PCB there is no guarantee that meet in the process of welding temperature or time, or is not correct to use flux.

8.

Circuit board face coating with particle impurities, or substrates in the process of making a legacy of grinding particles on the surface the lines.

9.

Low potential area not tin plating, PCB board face slightly dark red or red, a complete coating, plating bad side.

Circuit board PCB electric tin adverse condition improvement and prevention plans: 1.

Strengthen the treatment before plating.

2.

Using flux correctly.

3.

Hector slot adjust light agent content.

4.

Don't regularly check the anode consumption reasonable adding anode.

5.

Reduce the current density, the timing of the filtering system for maintenance or weak current solution treatment.

6.

Strictly control the storage, save time and environmental conditions of the process of PCB production process strictly.

7.

During the welding process temperature control PCB in 55 -

In order to 80 ℃ and ensure preheat time.

8.

Potion ingredients assay analysis timely fill add, add the current density and electroplating time.

9.

Using solvent wash sundry, if it is a silicone oil, you will need to choose a special cleaning solvent for cleaning.

10.

Reasonable adjustment for the distribution of anode, reduce the current density, reasonable planning board wiring or makeup, adjust the light.

Rocket PCB Solution Ltd. highlighted the need to foster a human openness to technological innovation.

To know more about pcb making service, please check our website at Rocket PCB .

Rocket PCB Solution Ltd. are used to coming up with solutions while think about problems, also expressing the whole idea individually.

Rocket PCB Solution Ltd. highlighted the need to foster a human openness to technological innovation.

To know more about pcb making service, please check our website at Rocket PCB .

Rocket PCB Solution Ltd. are used to coming up with solutions while think about problems, also expressing the whole idea individually.

Custom message