Transparent PCB-PET FCCL

Cr-Free Sputtering & Plating Type PET FCCL

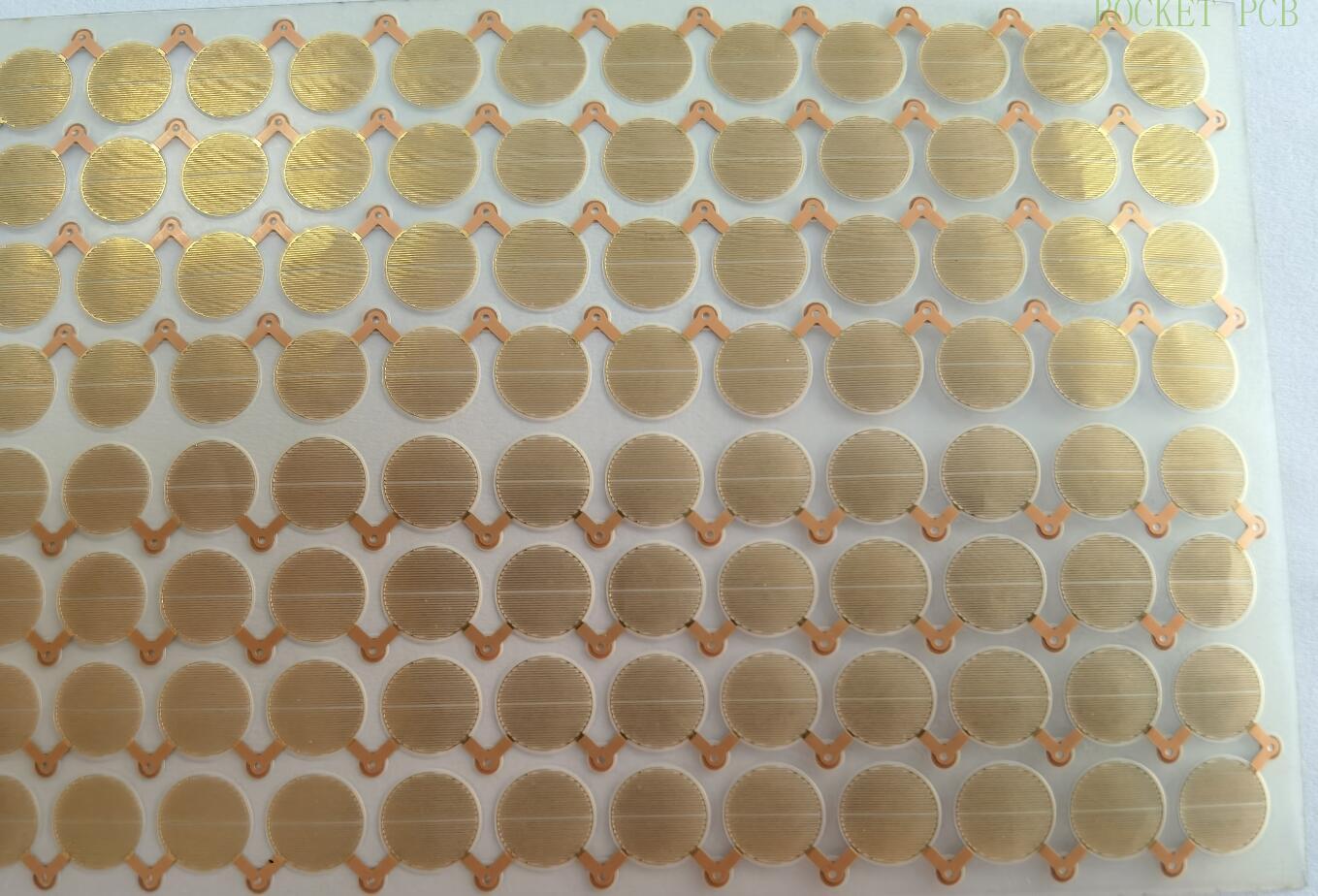

PET FCCL, Cu/PET/Cu film is an adhesiveless double-sided (D/S) copper clad laminate, using PET film and sputtering with electroplating Cu Plating on both sides.

Coated PET transparent film, coated PET substrate glue, and cured to form PET-FCCL, which is different from the traditional PI-FCCL substrate in the type of coated substrate.

Cu/PET/Cu films are designed for a wide variety of flexible cables and LED packaging substrates applications which require advanced material performance, temperature resistance, fine pitch, and high reliability.

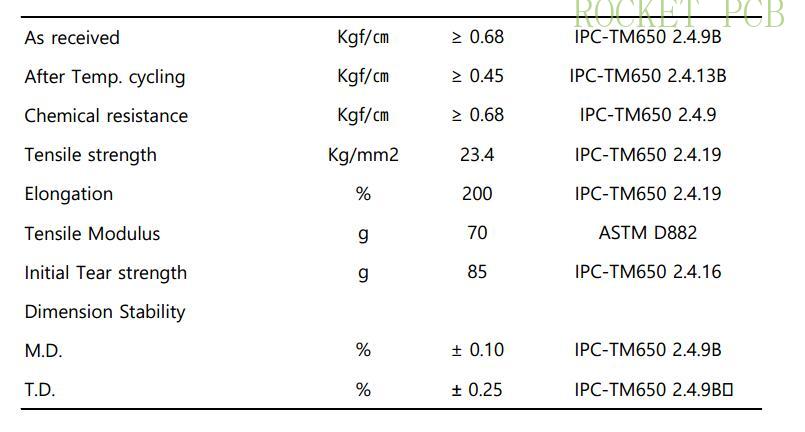

Excellent dimensional stability

Excellent flexibility

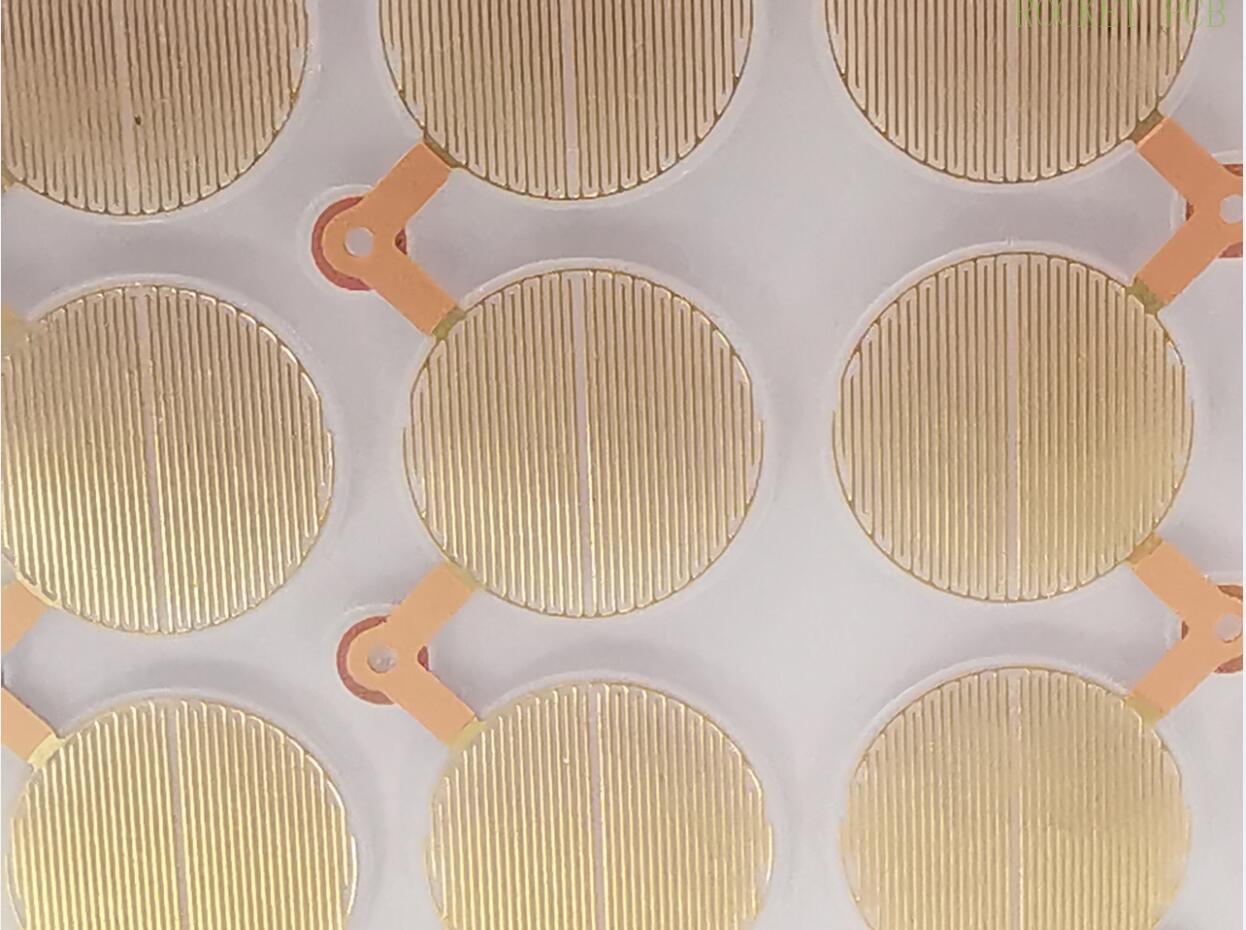

Finer line etching capability

High Peel Strength after thermal and chemical treatment

Excellent chemical durability

Manufacturing Process

1) Sputtering

Pretreatment & tie coat layer is the chief process for improving the adhesion between PET film & Cu plating layer.

2) Plating

It’s the electroplating process which is important to control the Cu plating thickness.

Structure

Properties

Storage

Cu/PET/Cu film should be stored in the original packaging at temperatures of 4–29°C (40–85°F) and below 70% humidity. The product should not be frozen and should be kept dry, clean and well protected.

Application

LED flexible light bar, radio, smart home, smart car and other fields.

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink