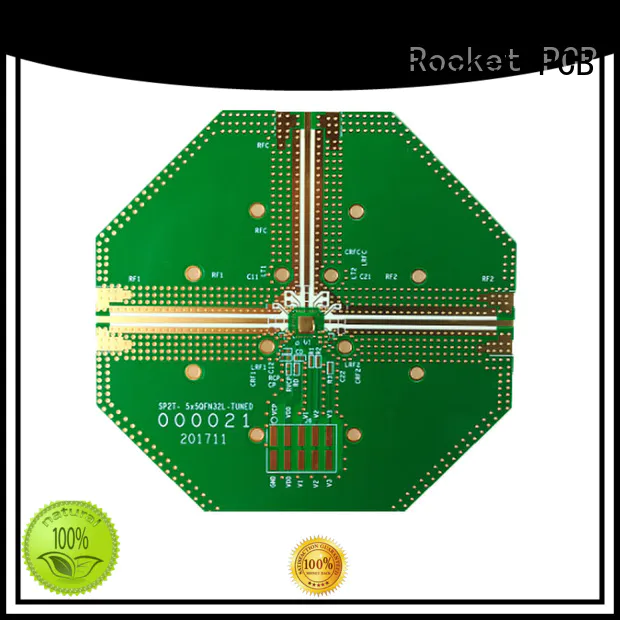

Rocket PCB deeply engaged in radio frequency field for many years, has very good experience in high frequency material characteristics, processing performance, process control, copper plating, lamination scheme, RF line tolerance, impedance parameter control, etc. Rocket PCB is your first choice for your RF PCB manufacturing.

Experience with the physical properties and equipment performance of laminates is critically important when producing printed circuit boards with different materials

Based on the CTE values of all material layers (e.g. FR4, PTFE and copper), each material grows at different rates under the thermal exposure during lamination, this can lead to significant registration problems. Because one material shrinks and the other expands, it can lead to the delamination of the interface between copper and the substrate.

As a result, not all materials can be used in hybrid applications Working with PCB manufacturers in the early stages of the design process will provide you with the best results, as they know best which materials can work together optimally For example, Rogers 5880 is an excellent RF material for high-reliability applications.

The biggest challenge for this material is that it will shrink after you etch the copper, so manufacturers need to understand how their technology work in the process to make up for the problem Hybrid structures typically include low-loss materials, such as Nelco or Rogers combined with core material such as FR-4 Common hybrid material types are also available, such as RO4350B+IT180A/370HR/NP175FR/TU768, F35/FR35A+FR4, TU-872+FR4, R-5775(M6)/R-5777/ R-5778 +FR4, RO3006/RO4360G2 +FR4, M4/M6 Nelco+IT180A etc.

One of the most difficult challenges in the stack-up of the hybrid board is consistently achieve overall thickness requirements for different products. Due to there are different material types, more than one prepreg (adhesive system) type can also be used to laminate the design together In many cases, non-flow FR-4 prepreg will be the best solution to maintain uniform thickness. Not all PCB manufacturers have exactly the same process, which is another important reason for early involvement in collaborative design with a high quality PCB manufacturer.

Usually the hybrid board also has several unique mechanical properties, which are difficult to be used in cost-effective manufacturing practices, include,

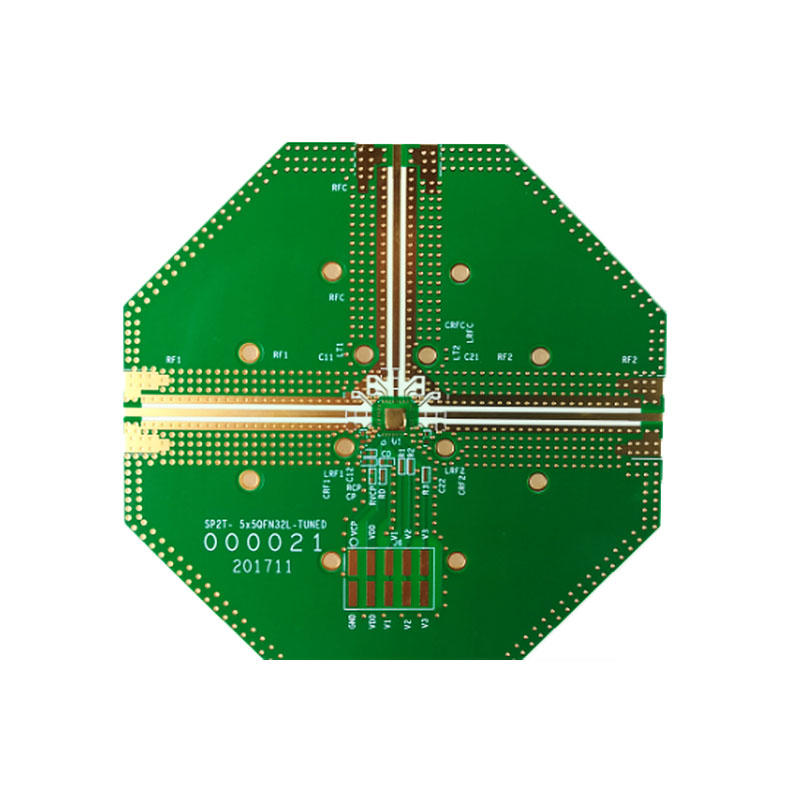

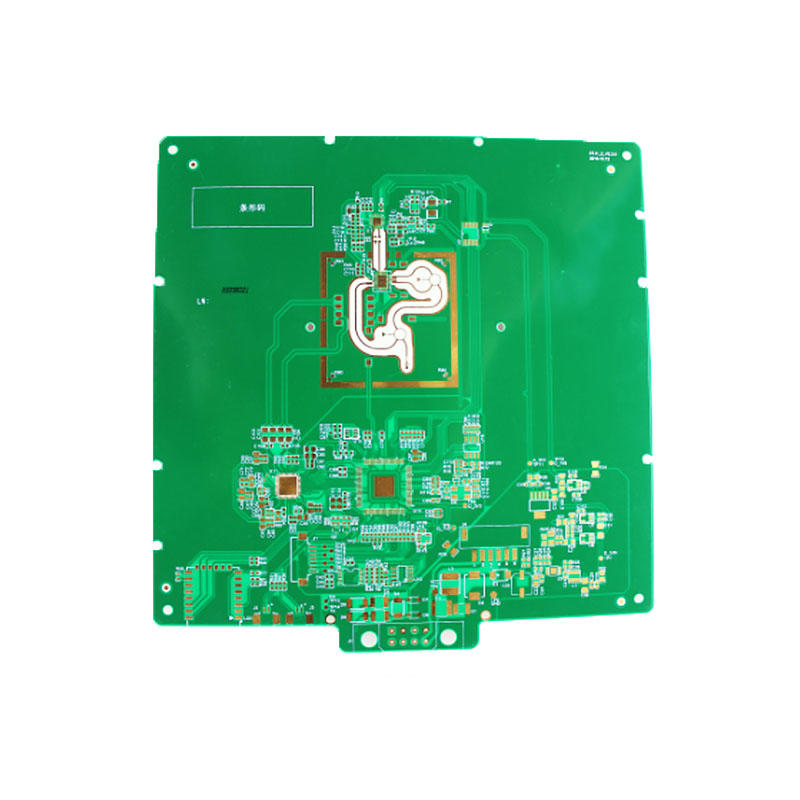

Strange Shape Board

Usually the RF PCB profile has many different twists and turns. This is a very sensitive process when dealing with hybrid designs. And some PTFE materials are very soft must slow down the feed speed.

Controll depth or internal cavity

Some of these features can be manufactured using multiple lamination,, while others must be done using a controlled depth routing process, usually a router bit or laser cutter. These challenges all increase the cost and complexity of high-speed/ hybrid PCB.

Through hole consistency

The traditional hole preparation before PTFE plating is different from that of FR4. Manufacturers must understand how processes affect hole wall quality. Because all materials have different densities and other characteristics, it is necessary to have a good experience in the control of hole copper quality, electroplating smoothness, cavity tolerances, hole wall cleanliness.

Now that you know how to make a decision, send us an RFQ. Rocket PCB has years of experience in RF field will help you get unparalleled quality printed circuit board.

Copyright © 2026 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink