Conventional technology of making PCB cavity

Low-flow PP + controlled depth milling process or inner filling silica gel materials are usually used. However, there are many control points and complex operation process in the manufacturing process of this kind of stepped/cavity board, which has the following problems.

1. Deviation

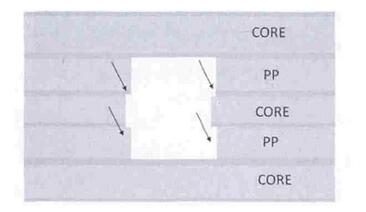

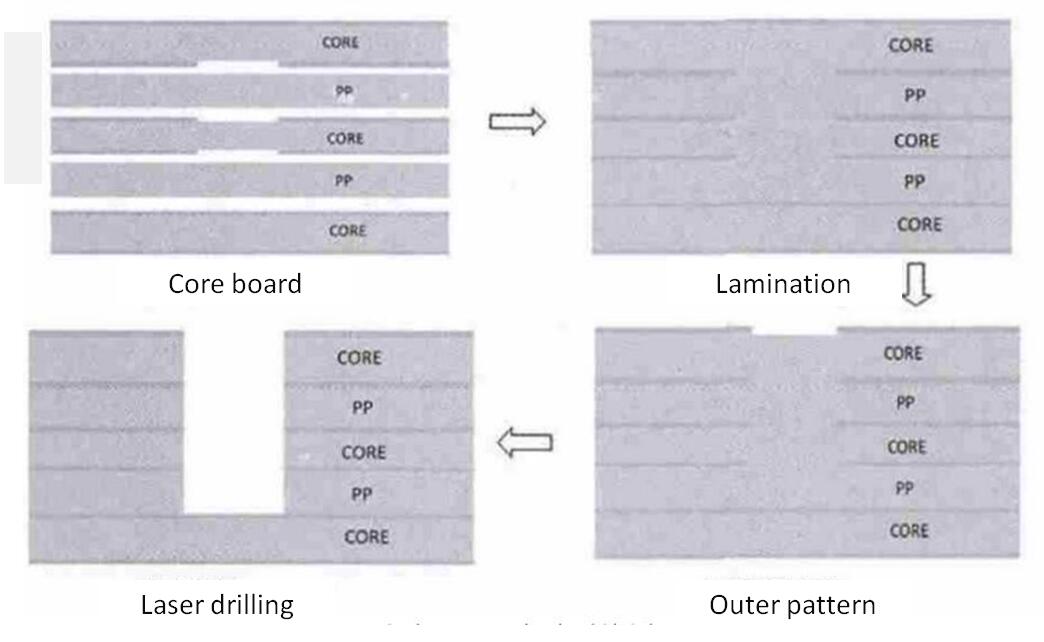

Core board and PP need to be slotted first, then pressed. Laminating is prone to offset and the size of cavity is deformed.

2. Gum flow

Usually, the slotting size of PP is 0.5mm larger than that of cavity. At this time, the gum flow is serious and the bottom of cavity is overflowing with gum.

Increasing the slot of PP to 1.0mm makes the cavity area prone to depression and the upper and lower core boards prone to loss of dielectric layer leading to conduction.

3. Material breakage

With the development of miniaturization of PCB board, the thickness of board and the depth of cavity tend to be miniaturized. The board is thinner and thinner, and the cavity is shallower and shallower. Using conventional technology to make step cavity, the cavity area after lamination is prone to depression or even rupture.

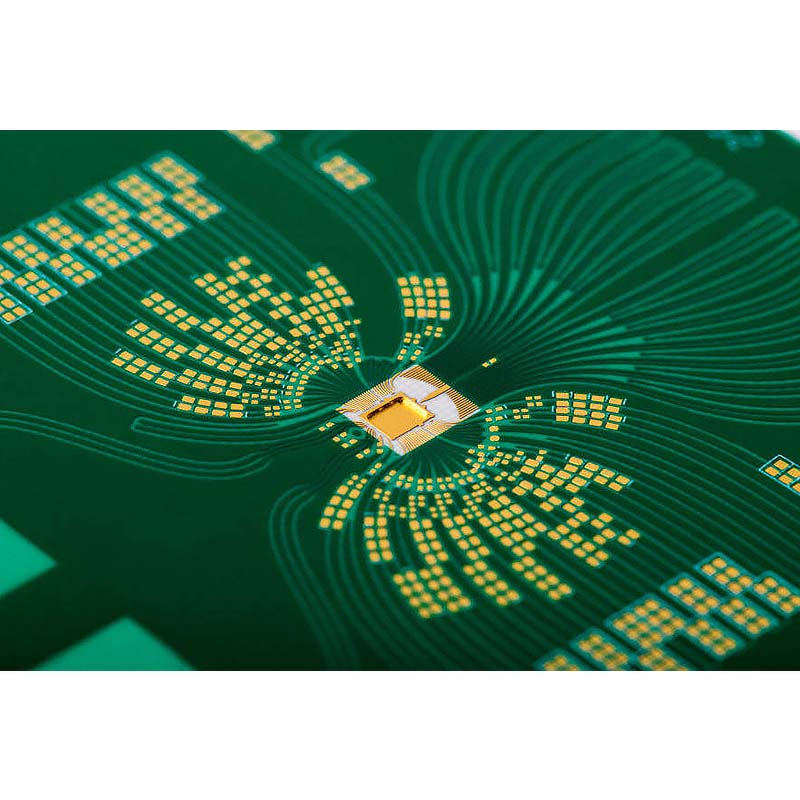

High Frequency board cavity fabrication by laser

1. Solve the problem of material damage

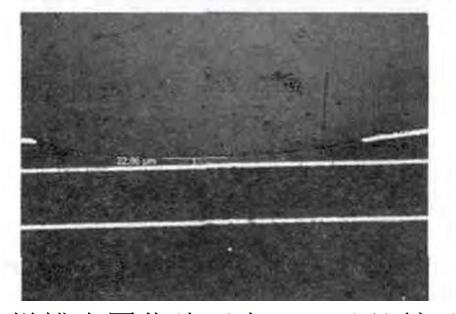

Conventionally, we use CO2 lasers to make HDI blind holes, for which we can use CO2 laser to make blind cavity. However, low-energy drilling should be used to ensure that the copper surface at the bottom of the cavity is not harmed.

2. Solution of gum flow

Conventional prepreg is low-flow, but when using high-frequency materials, PP has a certain flow gum, which cannot be solved by window opening, so it can only be solved by laser removal.

3. Solving Deviation

Because the core board is pressed directly without slotting, the copper in the cavity position is etched into a light plate, which is subsequently made by laser drilling, the problem of uneven cavity wall caused by deviation is well solved.

Difficulty Analysis

Because of the laser drilling cavity, the arrangement of the inner hole and the setting of laser energy is very important for the cavity. Through the experimental verification of different high frequency material, many practical data have been obtained on the setting of laser energy and the arrangement of laser holes, which fully realizes the machinability and reliability of the cavity.

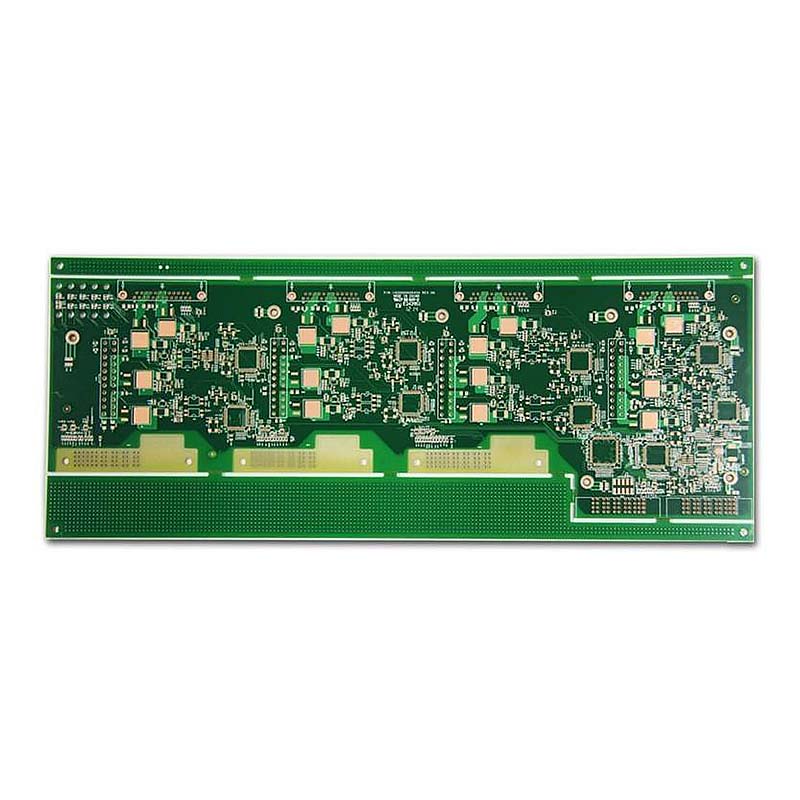

> We offer the most effective and flexible solution for you

As a Professional PCB Manufacturer in China, Rocket PCB Is able to closely integrate manufacturing, logistics and supply chain management. As a result, design, assembly and product distribution can be done faster at lower cost and without compromising our high-quality standards. We provide real-time and in-depth technical support and tailor-made application solutions, such as high speed, large capacity, high frequency, mixed pressure (hybrid structure), heat dissipation metal base solutions.

> Focus on the customer first

Excellent

customer service is a challenge for contract manufacturers, original

equipment manufacturers and design companies. Regardless of the size or

complexity of the order, Rocket PCB is committed to filling this gap in

the industry through active and continuous communication with customers.

Rocket's mission is to be a trustworthy partner of all customers.

Rocket PCB knows that the only way to achieve this is to deliver

products with the highest quality at the most competitive prices. We

always put the best interests first when providing innovative solutions

for manufacturing customers’ products. Finally, Rocket provides

industry-leading support to our customers so that we can help them grow.

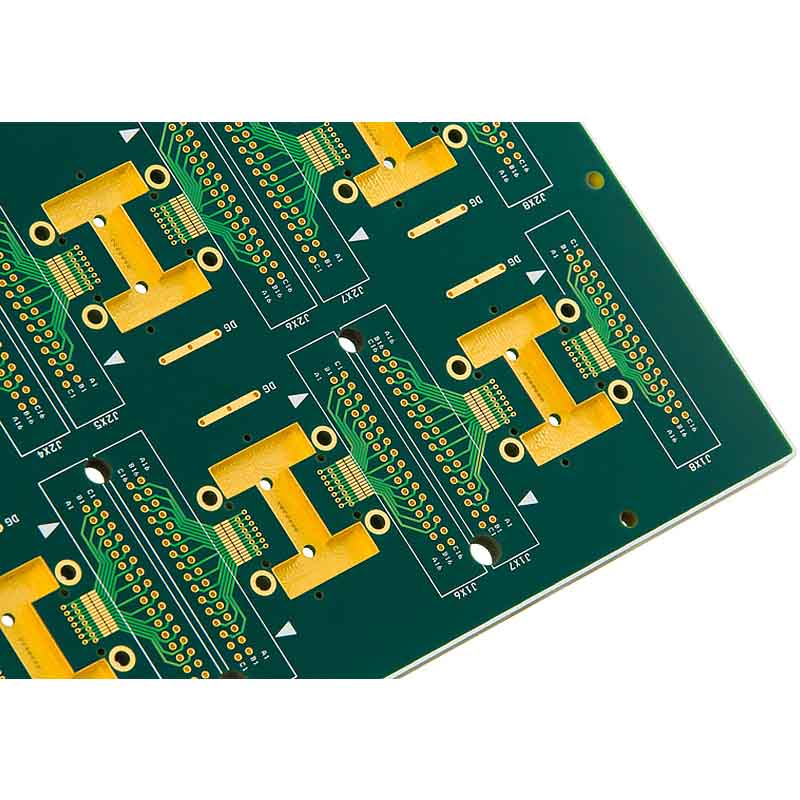

> Unlimited PCB capabilities

You don’t need to find a new and uncome-at-able supplier due to our unparalleled strength. We provide various and state-of-the-art PCB including rigid, FPC, rigid-flex, metal base, microwave, HDI, any layer, large-size, embedded, RF, LED, backplane, ceramic substrate, IC substrate, high-frequency, high-density and high-performance PCB.

> Comprehensive Engineering solutions

Elite engineers with years of industry experience provide you with free and comprehensive engineering review and support to ensure the Gerber file is completely correct before fabrication. Strong cooperation of you makes it easier for us to provide real-time and in-depth support to realize great cost efficiency for you and to turn your PCB products from conceptual design to volume production.

> High-quality Assurance

"High Quality" is always the soul in Rocket PCB production and to provide satisfying products and service is the goal we're pursuing. Our superb quality and leading market position are guaranteed under the ISO9001, ISO14001, ISO/TS16949, OHSAS18001, ISO/IEC27001 system with our strong technical development drive. We also insist on adopting 5S methods, Lean and Six Sigma quality systems.

> Reduce Your Costs

We can save your costs for PCB through our comprehensive solution that is specifically adapted to your needs. Besides obtaining cost savings from the PCB fabrication process, ROCKET also can save your costs via our design and pre-engineering services. Most of our clients tell us that this benefit is the most important reason for maintaining a long term relationship with us.

> Material Stock Advantage

We maintain a large inventory of PCB materials like Rogers, Teflon(PTFE), Nelco so that we can realize a fast service to a wide range of PCB applications. The material shortage is not a problem for us.

> Shorten Time to Market

Whether your business focuses on research, development, innovation or business development, your decision to work with Rocket PCB allows you to focus on what you do best by allowing us to do the PCB manufacturing, component procurement, programming, testing and final assembly for you. Quotation for standard projects within 2 hours, quick 24-hour prototype making, 24-hour online tech support and on-time delivery make your PCB procurement worry-less. Industry-leading fast turnaround is the foundation of our strong competitiveness.

Copyright © 2026 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink