THE IMPORTANCE OF IPC STANDARDS FOR PCB CIRCUIT BOARDS

WHAT IS IPC?

IPC-Association Connecting Electronics Industries is a worldwide trade association that issues standards for the production of printed circuit boards (PCBs). IPC stands for the Institute of Printed Circuits, and they have been around since 1957. They make and ship printed circuit boards around the world and IPC standards are used to make sure that circuit boards are usable.One such widely recognized international standard that governs the design, assembly, inspection, testing, and documentation stages of PCB fabrication is the Institute for Printed Circuits (IPC). IPC is formulated with a goal of ensuring performance and reliability of PCBs and electronic products.IPC standards are essential for all companies involved in the production of PCBs and electronic products. They help ensure quality products, reduce costs, streamline communication, increase competitiveness and improve credibility. If circuit boards do not follow these standards, they will not be compatible or usable for any electronic device. These conform with ANSI standards and match their requirements. Because these circuit boards are used so widely, it is important for them to follow IPC standards.

The role of IPC standards in the printed circuit board industry

IPC standards are used to maintain the pcb fabrication around the world. They help the PCB manufacturers build PCBs that are safe, reliable and high performance. Without IPC standards, circuit boards made by different companies would be held to inconsistent standards and the resulting equipment may be faulty or not compatible with other technology. IPC standards help keep the same standards of PCBs across the globe, which keeps the products reliable, consistent, and cost effective.

THE IMPORTANCE OF IPC STANDARDS FOR PCB CIRCUIT BOARDS

Have you ever had a system in your computer break for no reasons? For example, has your Wi-Fi ever randomly disconnected, or your touch screen monitor glitched? These are things that happen when a circuit board ceases to function correctly. When circuit boards follow IPC standards, they will perform as expected for much longer than they otherwise would have. IPC standards make sure that circuit boards perform to the best of their ability by creating standards for hardware installation on assembly lines, stating clearly what constitutes acceptable soldering results and other standards for circuit board manufacture. IPC standards keep life running smoothly for a technology-based society.

IPC standards are an essential part of the creation of printed circuit boards. IPC brings together all the players of the technology industry to bring consumers the best circuit boards. The standards IPC upholds for their technology have had long lasting impacts and will continue to do so.

Circuit boards are the brains of all electronic devices. Because they are incredibly important to the functioning of society today. Everything from your Google Home to your computer to your key fob for your car has a circuit board. Because they are used in so many things, it is important that they comply with IPC standards.

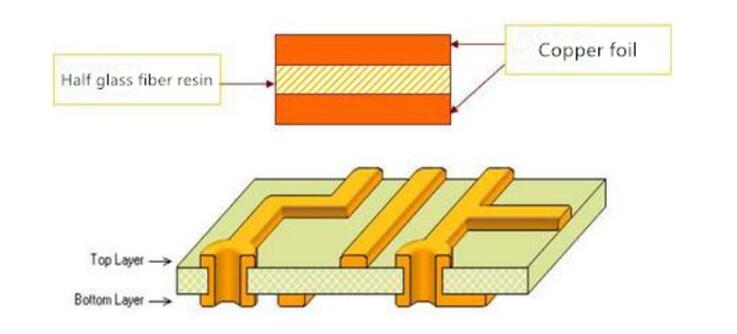

IPC standards are of great significance to the circuit board industry. First, IPC standards specify requirements for all aspects of circuit board design, manufacturing and assembly, including material selection, size specifications, welding quality, reliability testing, etc., providing a unified reference and guide for circuit board manufacturers, improving product quality and reliability.

Second, IPC standards can help circuit board manufacturers communicate and cooperate with customers. By referring to IPC standards, both parties can reach a consensus on product specifications, quality requirements, etc., reduce misunderstandings and disputes, and improve production efficiency.

In addition, IPC standards also contribute to the technological innovation and development of the circuit board manufacturing industry. By keeping pace with the international standards and understanding the latest technological trends and standard requirements, manufacturers can continuously improve production processes and equipment, improve production efficiency and product quality, and enhance competitiveness. At the same time, IPC also regularly updates and revises standards to meet changing technology and market needs.

Therefore, IPC standards play an important role in regulating and guiding the circuit board industry, helping to improve product quality and promote industry innovation and development.