Reasons for the Complexity of Double-sided PCB Manufacturing and How to Choose a Cost-effective Double-sided Printed Circuit Board

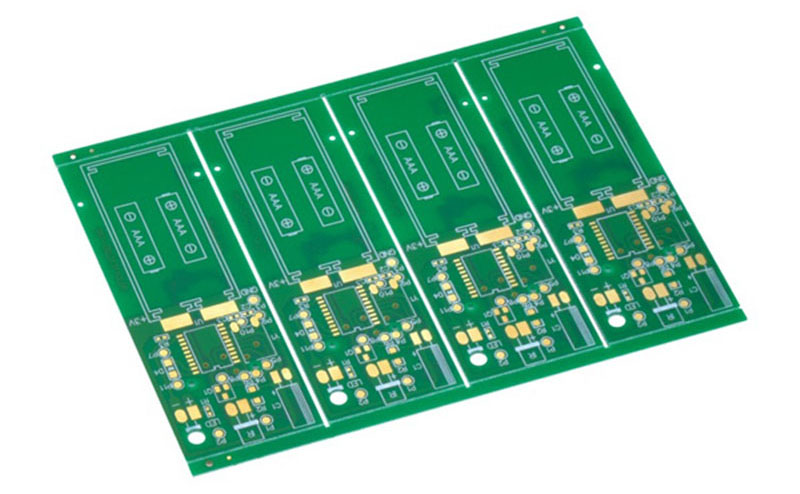

Double-sided PCB (Printed Circuit Board) refer to circuit boards where both sides feature wiring and component mounting. Compared to single-sided PCBs, double-sided PCBs are designed to accommodate more components and wiring within a limited space, thereby enhancing the reliability and performance of the circuit board.

The advantages of double-sided PCBs include not only increased integration, density, reliability, and performance of the circuit board, but also the ability to achieve more complex circuit designs, catering to various application needs. However, the drawbacks of double-sided PCBs lie in the higher difficulty in design and manufacturing, which demands more cost and time. Additionally, the manufacturing technology and equipment for certain specialized processes of double-sided PCBs are relatively scarce, limiting their range of applications.

Double-sided PCBs are widely used in various electronic products, computers, aerospace, communication devices, medical equipment, instruments, and other fields. In many high-end products, double-sided PCBs are almost indispensable as core components, enabling more complex circuit designs and more precise component installations, resulting in products with higher performance, stability, and reliability. It can be said that double-sided PCBs have become a crucial support and driving force for the development of modern electronic technology.

Benefits of Double Sided PCBs:

More flexibility for designers

Increased circuit density

Relatively lower costs

Intermediate level of circuit complexity

Reduced board size (which can reduce costs)

horizontalApplications of Double Sided PCBs

There are near limitless applications for old and new designs. Fine line surface mount, ultra high copper build, high and low temperature, Solder coated, Silver, and Gold finishes are just a few examples of double sided printed circuit board applications.

THE FOLLOWING ARE APPLICATIONS IN WHICH DOUBLE SIDED PCBS CAN BE USED:

Industrial controls

Power supplies

Converters

Control relays

Instrumentation

Regulators

UPS systems

Power conversion

HVAC

LED lighting

Hard drives

Printers

Phone systems

Power monitoring

Automotive dashboards

Line reactors

Test equipment

Amplifiers

Traffic systems

Vending machines

Rocket can produce double-sided PCBs, which allow for higher component density and make the process of layering tracks easier. Unlike multilayer PCBs, double-sided PCBs do not require lamination, but they do require plating to enable the functionality of through-holes. If you are looking for custom PCB boards, Rocket can provide you with cost-effective double-sided printed circuit boards.

Rocket PCB has an abundance of industry experience of small batch PCB manufacturing, after a period of industry development and customer build up, has built good relations of cooperation with world-famous enterprises, continues to be identified by customers with regards to product quality stability, technical level and technical service, and it has formed a larger brand awareness on the industry.

At the moment, the company has offered a large variety of clients, including terminal clients, EMS businesses, PCB traders, and so on. Its downstream applications cover industrial control, medical electronic communication equipment, communication equipment 5G, automotive electronics, intelligent house, led and a lot of other fields.

At Rocket PCB,we've been using A-class FR4 materials, never scrimp, our technique is small profits but quick turnover, so within the premise of quality assurance, our PCB cost is extremely competitive.

We passed ISO 9001 quality system, TS16949, UL standard, ROHS standard and SGS lead-free certification and related industry certifications.