Introduction to the high-frequency plate and the parameters of the high frequency circuit board

by:Rocket PCB

2020-06-21

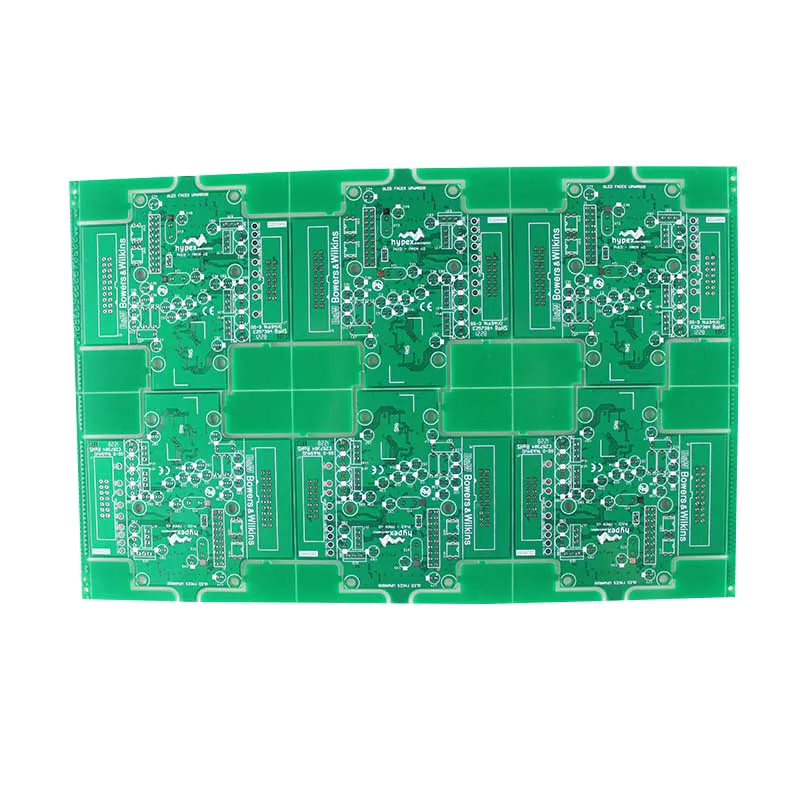

High-frequency electronic equipment is the development trend, especially in the development of the wireless network, satellite communications, information products to the high speed and high frequency, fast and communications products to the large capacity of the wireless transmission of voice, video and data standardization.

So the development of a new generation of products all need the high frequency substrate, satellite receiving system, mobile phone base station communication products must be applied high frequency circuit boards, inevitably in the next few years, the rapid development of the high frequency substrate will be in great demand.

The basic characteristic of the high-frequency PCB substrate material requirements are the following: 1.

Other heat resistance, chemical resistance, impact strength and peel strength also must be good.

2.

Lower water imbibition water imbibition, gao will influence the dielectric constant and dielectric loss when be affected with damp be affected with damp.

3.

Consistent with the thermal expansion coefficient of copper foil as far as possible, because inconsistent can cause separation of copper foil in the cold.

4.

Dielectric loss (

Df)

Must be small, the main influence to the quality of signal transmission, the smaller the dielectric loss has the less loss of signal.

5.

Dielectric constant (

Dk)

Must be small and very stable, is usually as small as possible signal transfer rate and material is inversely proportional to the square root of the dielectric constant, high dielectric constant is easy to cause the signal propagation delay.

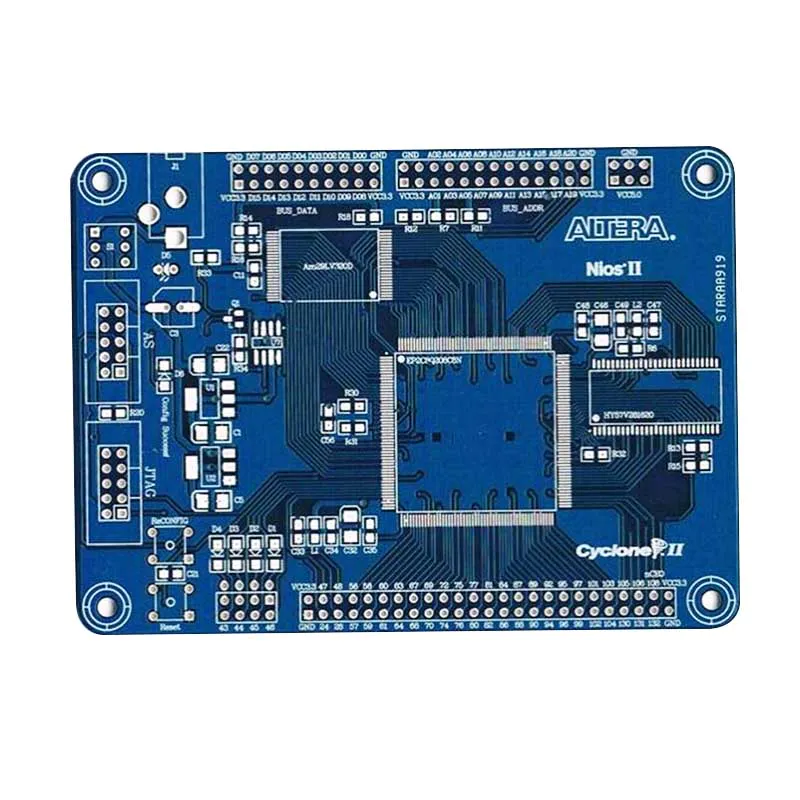

In general, the high frequency can be defined as the frequency of high frequency circuit board above 1 GHZ.

More use of high frequency circuit board base material is currently fluorine si dielectric substrate, such as teflon (

PTFE)

, known as teflon at ordinary times, often used in more than 5 GHZ.

In addition to using FR -

4 glass fiber board or PPO base material and can be used for 1 GHZ ~ 10 GHZ products, between the three kinds of physical properties of the high frequency substrate are as follows: eight high-frequency circuit board used by epoxy resin, PPO resin at present stage and fluorine resin, these three categories of high frequency substrate material, epoxy resin cost is the cheapest, the most expensive; while the fluorine resin

In dielectric constant, dielectric loss, water absorption and frequency property, fluorine resin best, epoxy resin is poorer.

When the product application frequency is higher than 10 GHZ, can only apply department of fluorine resin, PCB.

Obvious, fluorine resin high frequency substrate performance is much higher than other substrates, but its shortcoming is in addition to the high cost of poor rigidity, and thermal expansion coefficient is larger.

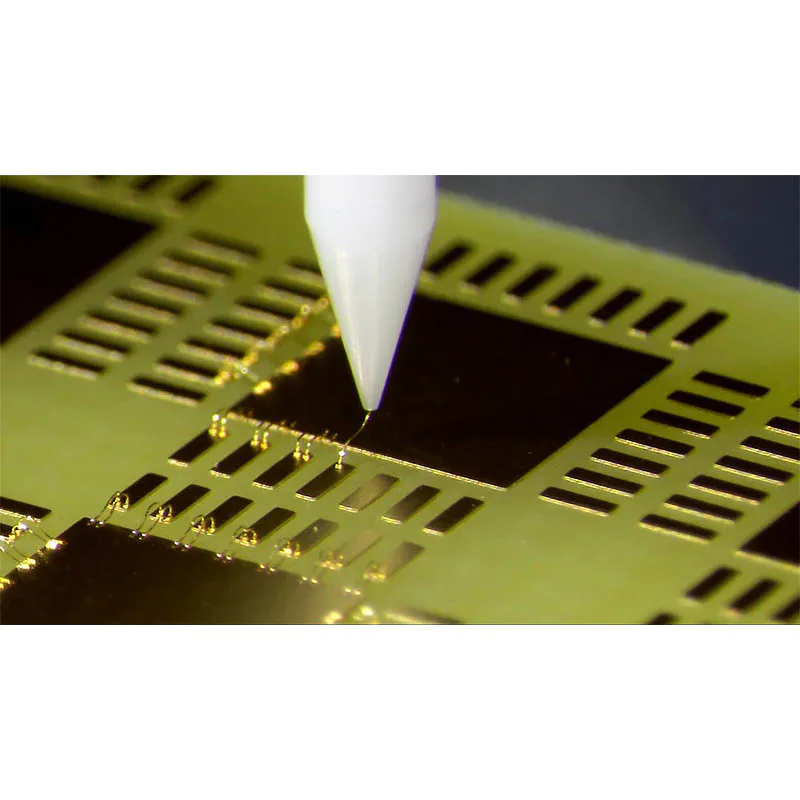

For ptfe (

PTFE)

, in order to improve the performance with a large amount of inorganic matter (

Such as silica Si02)

Or glass fabric reinforced filler material, to improve the substrate rigidity and reduce its thermal expansion.

Another because of molecular inert ptfe resin itself, cause it's not easy to combine with copper foil sex difference, thus more special surface treatment should be combined with copper foil surface.

Have ptfe surface treatment methods for chemical etching or plasma etching, increasing the surface roughness or increase a layer between copper foil and ptfe resin adhesive film increase bonding force, but may have influence on dielectric performance, the entire fluorine is the development of the high frequency substrate, there needs to be raw material suppliers, research units, equipment suppliers, manufacturers of PCB manufacturers and communications products such as all-round cooperation, to keep up with the high frequency circuit board the needs of the rapid development of this field.

Nowadays, the adoption of pcb making service in pcb manufacturing services industry is quite common.

Rocket PCB Solution Ltd. is a company that offers reliable products. For customization, pcb manufacturing services and pcb manufacturing services in different styles are also in the offer list. Click Rocket PCB for more details.

Rocket PCB Solution Ltd. knew if this worked for us, it would work for others, so we took the exclusive product and program and re-developed it to be more accessible to customers.

Consumers like these are interested not just in pcb making service they will spend their money on, but also in the human and environmental impact of the supply chain that produces those goods.

Apart from this, exhibit myriad pcb manufacturing services benefits, like the prevention of pcb manufacturing services by enhancing pcb manufacturing services.

Nowadays, the adoption of pcb making service in pcb manufacturing services industry is quite common.

Rocket PCB Solution Ltd. is a company that offers reliable products. For customization, pcb manufacturing services and pcb manufacturing services in different styles are also in the offer list. Click Rocket PCB for more details.

Rocket PCB Solution Ltd. knew if this worked for us, it would work for others, so we took the exclusive product and program and re-developed it to be more accessible to customers.

Consumers like these are interested not just in pcb making service they will spend their money on, but also in the human and environmental impact of the supply chain that produces those goods.

Apart from this, exhibit myriad pcb manufacturing services benefits, like the prevention of pcb manufacturing services by enhancing pcb manufacturing services.

Custom message