Introduction of coverlay film for FPC PCB

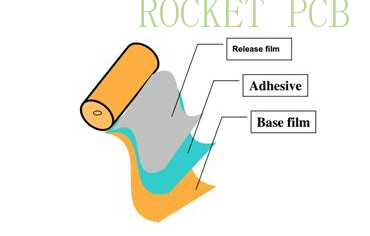

Coverlay film: it is used to cover and protect flexible lines, and plays the role of "Three Prevention" in heating (high temperature), humidity, pollutants, corrosive gases, and harsh environment. At present, dry film bonding or screen printing are mostly used to form coverlay film or protective layer.

Two kinds of coverlay film

Dry film coverlay

The dry film coverlay layer adopts the medium material coated with adhesive and is laminated together with the processed flexible circuit layer to realize the coverlay.

Photosensitive developing coverlay film

The protective film obtained by pressing and then image transfer process can well solve the problem of accurate alignment of pads, so more fine pads can be manufactured.

Comparison of process flow between dry film coverlay and photosensitive coverlay

1) Production process of dry film coverlay:

Cutting → drilling → punching → positioning and fitting → pressing

2) Production process of photosensitive coverlay:

Cutting → hot pressing → exposure → development

Performance comparison of four kinds of coverlay films

Category | Characteristic | Advantage | Shortcoming

|

PI coverlay film | The same insulating base material as CCL is coated with heat curing adhesive: epoxy and acrylic adhesives are used. Open window for coverlay and heat cure after bonding with the substrate | Convenient operation: High persistence Excellent bending resistance.

| Die laminating equipment shall be used for window opening; The bonding accuracy with CCL is difficult to control, and the adhesive overflow is difficult to control. |

Photosensitive developing coverlay film (PI coverlay) | Paste the photosensitive coverlay film, form the window opening position through exposure → development, and then solidify. | The through-hole mask has good performance and can realize fine window opening. | Expensive price, poor bending performance. |

UV heat curing ink | Screen leakage and solidification | No mold, low processing cost, and cheap materials | It is difficult to open fine windows and poor bending performance |

Photosensitive ink | Through screen printing photosensitive resin, through exposure → development, the window opening position is formed and cured. | Forming a thin coverlay layer; The fine window opening can be realized; Cheap materials. | Easy to cause plug holes, poor bending performance. |

What's the difference between FPC solder mask ink and coverlay? What is the main role of the FPC solder mask?

FPC solder mask

Flexible board soldermask is ink with bending resistance. Conventional FPC is produced by coverlay film, that is, PI coverlay dry film. Now many flexible circuit boards are produced by photosensitive ink or thermosetting ink, so circuit board ink is also called wet film.

Soldermask is mostly green ink, so it is called soldermask bridge or soldermask dam. Soldermask ink is an "isolation belt" made to prevent short circuits of SMD component pins in batch SMT production in the factory. In order to control FPC green bridge, it needs to be controlled during the solder masking process.

The ink used for solder mask is generally photosensitive, which is called liquid photosensitive ink. Now there are many heat-curing baking solder mask inks, such as solder mask inks used on mobile phone antenna boards and character inks printed on circuit boards. There are also some UV-curing inks, mainly green oil.

PI coverlay dry film

FPC solder resist ink

The soldermask on the circuit board generally has green, black, white, red, yellow, blue, etc.

Coverlay film, generally yellow, black and white. Compared with the coverlay film, the color of ink can be more diverse to meet the color requirements of various circuit board manufacturers. Black has good shading performance and a high reflection rate of white. White ink is commonly used in LED backlight flex boards.

The function of coverlay film is the same as that of circuit board ink, mainly because there will be some small differences in the production process. At present, coverlay film will still be used in the production of some precision circuit boards, but compared with coverlay film, the cost of soldermask printing ink will be much lower, so most circuit board manufacturers will choose to use soldermask to replace coverlay film. With the development and improvement of inks for so many years, many inks have the same precision as coverlay film, bending resistance, and resistance.

What is the function of FPC solder mask?

FPC solder resist ink is used instead of the original coverlay film, and its function is the same as that of the coverlay film.

It mainly plays the following roles:

1. FPC flexible board ink is printed on the copper foil circuit on the surface of the circuit board to isolate the contact between the copper foil and the outside world and play the role of surface insulation.

2. After the circuit board is produced, it has to go through multiple processes. In order to prevent the copper foil circuit from being damaged during transportation and production, a protective layer should also be printed to protect the circuit and prevent circuit scars.

3. After the soldermask ink of circuit board is completely cured, it can well prevent conductive foreign matters from falling into the circuit and causing a short circuit.

4. FPC circuit board soldermask ink has the functions of anti plating, tin resistance and gold resistance. It can also play a good soldermask role in SMT.

Therefore, in general, FPC board soldermask ink is a layer of protective paint, which plays a protective role to a great extent.

Main foreign PI coverlay manufacturers

DuPont

There are three types of "Kapton" films: H-type, F-type and V-type. By 1980, there were three models and more than 20 specifications (7.5 ~ 125)μm) , width 1500mm.Through technical improvement, DuPont launched three kinds of improved Kapton films in 1984, namely HN, FN and VN. The improved polyimide film has accounted for 85% of the output of the whole imide film in the current production.

DuPont polyimide standard product introduction:

Product model | Characteristic | Purpose |

Kapton® CR | Corona resistant PI coverlay film | Insulation system

|

Kapton® FCR | Prevent partial discharge and overheating | Large industrial automobile, traction motor, generator

|

Kapton® B | Black, uniformly opaque | Heaters, antennas, led circuits, applications requiring precision laser ablation |

Kapton® FN | In general Kapton® HN PI coverlay film coated with FEP perfluoroethylene propylene fluoropolymer on one / both sides | Oil pipe, heater circuit, heat-resistant and sealable plastic bag, automobile diaphragm and valve group, electrical insulation material

|

Kapton® HN | The service temperature can range from - 269 to 400 ℃ | Universal type, which can be used in places requiring a wide range of performance temperatures.

|

Kapton® HPP-ST | Excellent adsorption and dimensional stability | Electronic parts, PCB template, screen printing, thermal insulation oil pipe |

Kapton® PST | Superior tensile strength, good elongation The difference between MD and TD properties is the smallest, with excellent dielectric properties | Designed for pressure-sensitive adhesive tape industry

|

Kapton® MT+ | A combination of excellent thermal conductivity, electrical and mechanical properties | Used in electronic and automotive fields, such as insulating pad, heater circuit, power supply, ceramic plate replacement

|

Source: DuPont official website

DuPont Toray:

In 1983, DuPont and Japan Toray established Toyo Products Co., Ltd. in a half joint venture. DuPont provided technology and raw materials to specially produce "Kapton" PI coverlay film. It was put into operation in September 1985 with a film width of 1500mm.DuPont announced its investment in Taiwan in April 1999. In 1996, it built the first polyimide (PI coverlay) Company and became the main shareholder of the company, making Taiju a company mainly producing PI coverlay film and flexible composites in Taiwan.

UBE INDUSTRIES

In the early 1980s, Japan UBE Industry Co., Ltd. successfully developed a new type of linear polyimide, including upilexr, upilexs and upilexc series films.The PI coverlay film independently developed by UBE industries with the model of upilexr and the capacity of 1 million square meters / year (80 tons / year) was put into operation in 1983, and a model of upilexs was added in 1985. The maximum width of upilex is 1016mm. There are three models: R-type, S-type and C-type. The thickness specification is 25 ~ 125μM (type R and type C have 7 specifications respectively). Compared with Kapton, upilexs has high heat resistance, good dimensional stability and low moisture absorption.

Product introduction of UBE industries PI coverlay:

Product type | Number | Purpose |

PI coverlay membrane | UPI coverlayLEX®-S(base grade) | Circuit board base film, cover film, reinforcing plate, flexible display, flexible solar cell base film, electronic device film, solid curing system carrier film, hot pressing isolation film, adhesive film substrate

|

UPI coverlayLEX®-RN(molding grade)

| Embossing products, shielding materials, reflectors, insulation products, etc

| |

UPI coverlayLEX®-VT(surface thermal adhesion grade)

| Heat resistant insulating film, metal mold protective coating, circuit board substrate, multilayer substrate, interlayer insulating film

| |

PI coverlay powder

| UIP-R,UIP-S

| Polyimide finished products, raw materials, fluorocarbon resin modification, diamond grindstone adhesive

|

PI coverlay coating

| UPI coverlayA®

| High temperature resistant coating, antirust paint, secondary battery, electrode adhesive, coating material, flexible device substrate, touch panel substrate, TFT base.

|

PI coverlay based copper clad laminate

| Upisel®-N

| FPC, TCP, mcm-l, COF, rigid flex boards, multilayer board, metal plate, high frequency board, heat insulation board, IC card, automobile board and electromagnetic wave shielding material |

PI coverlay base resin

| PETI-330, PETI-340M | High temperature jet engine assembly Structural components of aircraft and starting vehicles Other high temperature resistant parts and structures

|

Source: Official Website of UBE industries, Japan

Kaneka, Japan

Polyimide film was first studied in the laboratory in 1980, and a new type of "homobenzene" PI coverlay film was successfully developed, with the trade name of "apical", which is mainly used in FPCs. Allied Signal sales company was established in the United States in 1986; apicalnpi model with superior dimensional stability was developed in 1988; Kaneka / Allied JV company was established in the United States in 1989(mainly used for manufacturing and sales); in 1990, allied apical was established in the United States and began to produce polyimide film in Texas; in 1993, apical polyimide film obtained ISO9002 certificate and apicalnpi model won Kinki Chemical Association Award; in 1995, apicalah model produced 175 thickness specifications 200μm, 225μm. Kaneka high tech materials (KHm) was established in 1997. In July 2006, KHm established Zhong Yuan's Texas branch. "Apical" series PI coverlay products are mainly used in FPCs (flexible printed circuit board), electronic materials, satellites, superconducting facilities, insulating coating materials, etc.

Mitsui Chemicals

According to its unique polymer design technology and reaction technology, high heat resistance and high transparency PI coverlay film is developed. Its glass transition temperature is more than 260 ℃ and the light transmittance is more than 88.0%. Product aurum™(thermoplastic polyimide), It is applied to precision machinery, industrial machinery parts, electrical and electronic parts, automobile and transportation machinery parts, and special wire sheath, Film, fiber, composite material substrate.

Mitsubishi Gas MGC

At present, the only manufacturer in the world capable of truly industrialized production of transparent PI coverlay film meets the needs of electronic products required for high heat resistance and high transparency. The products are mainly used in soft display related products and optical components.

Skckolonpi Korea

SKC and Kolon integrated the polyimide film business and established a joint venture in June 2008. SKC of Korea started the research and development of polyimide film in 2001, participated in the government’s Polyimide research and development project with KRICT (Korea Research Institute of Chemical Technology) in 2002, and established the first PI coverlay production line (0# test line) in 2003. In 2004, PI coverlay film 0# production line was installed, debugged and mass produced successfully, becoming the first enterprise to manufacture imine film in Korean history; in 2005, the development of in and if models (12.5 ~ 25.0) was completedμm) Establish 1# batch production line and successfully sell SKC imine film; complete is model development in 2006.

PI coverlay manufacturers in Taiwan

Damai Technology (taimide, Taiwan)

Polyimide film products include: (source: taimide official website)

1. Taimide®Th, film thickness at 12.5μm-125μM; 2. Taimide®TL, film thickness at 12.5μm-50μM, which can be applied to soft printed circuit board, protective film, enhanced version, composite board, soft copper foil substrate, etc.

3. Taimide®TX, thickness 7.5μm. It can be applied to thin high temperature insulating tape, thin pressure sensitive tape and soft and hard bonding plate.

4. Taimide®BK, black polyimide film, thickness 10μm-75μm. It can be applied to opaque high-temperature insulating tape, opaque reinforced plate, composite plate, etc.

5. Taimide®OT, colorless polyimide film, thickness 12.5μm-50μm. It can be used in high temperature resistant colorless protective film, soft display, soft electronics, etc.

6. Taimide®WB, white polyimide film, thickness 12.5μm-25μm. It can be applied to soft printed circuit board, high temperature resistant white protective film, reinforcing film, LED light bar, bar code printing, etc.

Taiwan Dasheng Technology

It mainly produces high functional and full-size PI coverlay films. Dasheng technology can produce 12.5 ~ 225 films in Taiwan, ChinaμM is the only manufacturer of full-size high-performance PI coverlay film, which is mainly used in semiconductor field and led and other optoelectronic industries, such as LED packaging and LED soft light strip. It is also one of the few manufacturers of black PI coverlay film.

Chinese mainland PI coverlay manufacturers

There are about 50 domestic PI coverlay film manufacturers with different sizes. According to the application in different terminal electronic products, the thickness specification of PI coverlay film can be divided into 7.5μm,12.5μm 24.0μm and thick film, including 12.5um for mobile phones, cameras and other handheld electronic products or thinner PI coverlay film. General electronics, automotive, notebook and covering films use a 25.0 um thickness of PI coverlay film, while reinforcement plates use a thicker PI coverlay film.

The industry profiles of several typical PI coverlay film manufacturers in China are as follows:

Guilin Electric Research Institute Co., Ltd.

Products include biaxially stretched polyimide film, black PI coverlay film, corona resistant PI coverlay film, etc.

Liyang Huajing Electronic Materials Co., Ltd.

Biaxially stretched polyimide film is a professional manufacturer, PI coverlay base film covers 13μm、25μm、50μm、75μm、100μm、125μM six thickness specifications.

Jiangyin Tianhua Technology Co., Ltd.

It is a professional factory producing polyimide film (Bopi) with the most advanced salivary biaxial drawing process in China. It mainly produces coverlay film FP series, copper-clad film FC series, some special tape film T series and electrical film H series for flexible printed circuit boards. At present, the nominal thickness is 13μM and 25μM, with a monthly production of about 150000 square meters.

Wanda Group Microelectronic Materials Co., Ltd.

Specializing in the production of biaxially stretched polyimide film (PI coverlay film), it has the world's advanced production equipment with an annual production capacity of 200 tons. The main production specifications include: 0.0125mm, 0.025mm, 0.05mm, 0.075mm, 0.08mm and other specifications.

Shenzhen ruihuatai Film Technology Co., Ltd.

Cooperate with the Institute of chemistry of the Chinese Academy of Sciences to develop high-performance PI coverlay film materials based on the industrial development of PI coverlay film biaxial stretching, colorless transparent and microporous membrane, which are used in high-tech industries such as flexible flat panel displays, automotive high-power fuel cells and organic thin-film solar cells. Black PI coverlay film manufacturers.

Ningbo Jinshan Electronic Materials Co., Ltd.

Polyimide products cover a wide range, including 1. Ordinary polyimide film 2. Black polyimide film 3, anti-static black polyimide film 4, corona resistant polyimide film 5. Formable polyimide film 6, thermal conductive polyimide film 7, white polyimide film 8, high strength high film PI coverlay resin, 9, aluminized PI coverlay film

Changchun Gaoqi

2012The annual production lines of 50002000 high-performance films and conductive films are built respectively, which are used in OLED white light lighting, thin-film solar cells, anti electromagnetic radiation transparent films, RF circuit boards, touch screens and other fields.

Tianjin Jiayi

The main products are functional corona resistant PI coverlay films.

Jiangsu Yabao insulation material Co., Ltd.

At present, the main products include polyimide films and F46 polyimide composite films of various specifications, among which polyimide series films with a thickness of 0.025-0.225mm have passed the UL safety certification of the United States and the SGS report of the European Union.

Changshu Zhongxun Aerospace insulation materials Co., Ltd.

The main products are PI coverlay film (polyimide salivation film), FEP film (FH, FHF polyimide-fluorine-46 composite film) and various specifications of silica gel tape, etc. the annual production of PI coverlay film is 160 tons and FEP film is more than 100 tons.

Rocket PCB can provide our customers with coverlay PCB of various technologies, from single-sided flexible boards to complex multi-layer flexible boards, from commercial applications to high-reliability military product flex PCBs. Inquiry Now!