Glass Substrate PCBs: Unraveling the Potential Advantages for High-Frequency Applications?

Introduction

The demand for high-power applications has surged significantly in today's rapidly advancing electronics industry. As electronic devices become more sophisticated and power-hungry, robust and efficient PCB technology to support high-power circuit designs has become paramount. This article aims to explore and analyze two prominent contenders in the high-power PCB realm - Glass Hybrid PCBs and Glass Substrate PCBs.

A Growing Need for High-Power Applications

The modern world relies heavily on electronic devices with ever-increasing power requirements. From industrial machinery and automotive systems to renewable energy applications and communication infrastructure, the call for high-power electronics is ubiquitous. As electronic devices and techniques evolve, so does the necessity for PCBs capable of handling higher currents and dissipating increased heat levels.

The Significance of Choosing the Right PCB Technology

The appropriate PCB technology ensures optimal performance, reliability, and safety in high-power applications. High-power circuits pose unique challenges in heat management, signal integrity, and mechanical stability. The PCB substrate addresses these challenges and determines the circuit's effectiveness in high-power environments.

Throughout the article, we will discuss the features and benefits of both Glass Hybrid PCBs and Glass Substrate PCBs, examine their performance in high-power environments, evaluate their signal integrity capabilities, and assess their reliability under challenging conditions.

For those seeking to source high-quality Glass substrate PCBs, the article will also touch upon aspects such as reputable Glass substrate PCB manufacturers, services available, and considerations when sourcing from China, including the potential for wholesale Glass substrate PCB options.

In the subsequent sections, we delve into the specifics of each PCB technology and conduct a thorough comparative analysis to determine which holds the edge in high-power applications. With this information, readers will be equipped to make well-informed choices and ensure the success of their high-power electronic projects.

II.Understanding Glass Hybrid PCBs

A.Definition and Construction of Glass Hybrid PCBs

Glass Hybrid PCBs, also known as Composite PCBs, are printed circuit boards that combine the advantages of conventional FR-4 PCBs and specialized ceramic or metal core PCBs. The construction of Glass Hybrid PCBs involves a layered approach, wherein a high-performance glass epoxy material is utilized as the core substrate, and additional layers of ceramic or metal are bonded to it.

The core substrate, made of glass epoxy, provides good electrical insulation and mechanical support, similar to traditional FR-4 PCBs. On top of this core, ceramic or metal layers are integrated, imparting excellent thermal conductivity and mechanical reinforcement to the PCB.

The combination of these materials allows Glass Hybrid PCBs to achieve a unique balance between electrical performance, thermal management, and mechanical strength, making them well-suited for high-power applications.

B.Advantages of Glass Hybrid PCBs in High-Power Applications

1. Enhanced Thermal Conductivity and Heat Dissipation

One of the primary advantages of Glass Hybrid PCBs is their superior thermal conductivity compared to standard FR-4 PCBs. Integrating ceramic or metal layers significantly enhances the PCB's ability to dissipate heat generated by high-power components.

In high-power applications, efficient heat dissipation is crucial to prevent overheating and maintain optimal operating temperatures. Glass Hybrid PCBs efficiently channel heat away from critical components, thus contributing to enhanced system performance and overall reliability.

2. Improved Mechanical Strength and Reliability

Glass Hybrid PCBs offer substantial mechanical reinforcement, thanks to the inclusion of ceramic or metal layers. This enhanced mechanical strength ensures the PCB can withstand the stresses and strains imposed during the assembly and operation of high-power electronic systems.

Furthermore, the improved reliability of Glass Hybrid PCBs makes them suitable for applications where mechanical integrity is a priority, such as aerospace, automotive, and industrial sectors.

C.Key Considerations when Using Glass Hybrid PCBs

While Glass Hybrid PCBs offer compelling advantages for high-power applications, designers and engineers must be mindful of several key considerations:

1. Material Selection: Careful selection of the glass epoxy material and the type of ceramic or metal layers is essential to optimize the PCB's electrical, thermal, and mechanical properties.

2. Thermal Management: Although Glass Hybrid PCBs demonstrate enhanced thermal conductivity, proper thermal management strategies, such as heatsinks and thermal vias, should still be implemented to ensure efficient heat dissipation.

3. Manufacturing Complexity: The fabrication of Glass Hybrid PCBs can be more complex than traditional PCBs. Manufacturers must possess expertise in handling the combination of materials and processes involved.

4. Cost: Glass Hybrid PCBs may be relatively more expensive than standard FR-4 PCBs due to the additional materials and manufacturing complexity. Cost considerations should be balanced against the specific benefits required for the high-power application.

By carefully addressing these considerations, engineers and designers can fully leverage the advantages of Glass Hybrid PCBs, creating robust and reliable solutions for their high-power electronic projects.

III.Exploring Glass Substrate PCBs

A.Definition and Composition of Glass Substrate PCBs

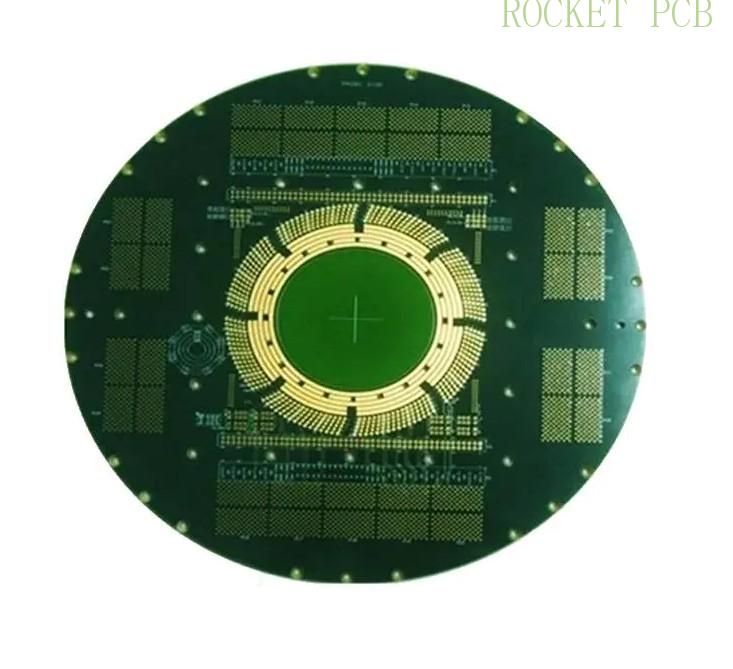

Glass Substrate PCBs are a specialized type of printed circuit board that utilizes glass as the base material for the substrate. The composition typically involves a thin layer of copper or other conductive materials etched onto the glass surface to form the circuitry.

The glass substrate provides several advantages, such as high dimensional stability, excellent flatness, and superior electrical properties. These attributes make Glass Substrate PCBs suitable for high-power applications that demand precise signal transmission and efficient electrical performance.

B.Advantages of Glass Substrate PCBs in High-Power Applications

1. Excellent Electrical Properties for High-Frequency Signals

Glass Substrate PCBs exhibit exceptional electrical characteristics, particularly for high-frequency signals. Due to glass's uniformity and low dielectric constant, these PCBs offer minimal signal loss and excellent signal integrity at high frequencies.

High-power electronic systems often involve high-frequency components and fast signal transitions. Glass Substrate PCBs effectively manage these high-frequency signals, minimizing signal distortion and ensuring reliable data transmission, making them ideal for communication and radar applications.

2. Low Dielectric Loss and Signal Attenuation

Glass Substrate PCBs possess low dielectric loss, indicating minimal energy dissipation as signals traverse the circuitry. This feature is essential for high-power applications, as it contributes to reduced signal attenuation and minimizes unwanted heat generation.

In high-power systems, minimizing signal attenuation helps maintain signal strength, reduces the risk of data corruption, and enhances overall system efficiency. Glass Substrate PCBs' low-loss characteristics make them well-suited for power amplifiers, microwave devices, and other high-frequency applications.

C.Key Considerations when Using Glass Substrate PCBs

To fully capitalize on the advantages of Glass Substrate PCBs in high-power applications, engineers should be mindful of the following considerations:

1. Glass Substrate Selection: Different glass substrates are available, each with unique properties. Selecting the appropriate glass substrate with the desired dielectric constant and thermal properties is essential for achieving optimal performance.

2. Thermal Management: While Glass Substrate PCBs demonstrate good thermal properties, effective thermal management is still vital to ensure the reliable operation of high-power components.

3. Manufacturing Complexity: The fabrication of Glass Substrate PCBs requires specialized processes, including precision drilling and glass material handling. Working with experienced manufacturers well-versed in these techniques is crucial to ensure quality and reliability.

4. Cost: Glass Substrate PCBs may have higher production costs than standard FR-4 PCBs. Therefore, cost-benefit analysis is essential to determine their suitability for specific high-power applications.

By considering these fundamental considerations, engineers can harness the advantages of Glass Substrate PCBs, optimize their electrical performance, and meet the demanding requirements of high-power applications more effectively.

IV.Comparative Analysis: Glass Hybrid PCBs vs. Glass Substrate PCBs

A.Performance in High-Power Environments

1. Thermal Management Capabilities

Glass Hybrid PCBs:

· Integrating ceramic or metal layers enhances thermal conductivity, enabling efficient heat dissipation from high-power components.

· Effective thermal vias and heatsinks can be employed to improve thermal management further.

Glass Substrate PCBs:

· Glass Substrate PCBs exhibit good thermal properties due to the uniformity and stability of the glass.

· Proper thermal vias and heatsinks are essential to optimize heat dissipation in high-power applications.

Both Glass Hybrid PCBs and Glass Substrate PCBs can effectively manage heat in high-power environments. Glass Hybrid PCBs may have a slight edge due to the additional thermal conductivity provided by the ceramic or metal layers.

2. Power Handling Capacity

Glass Hybrid PCBs:

· Incorporating ceramic or metal layers enhances mechanical strength, allowing Glass Hybrid PCBs to withstand higher power loads.

· Glass Hybrid PCBs are well-suited for power applications that involve high current and voltage requirements.

Glass Substrate PCBs:

· The low dielectric loss and signal attenuation of Glass Substrate PCBs contribute to reduced power dissipation and better power handling capabilities.

· Glass Substrate PCBs are particularly suitable for high-power applications that involve high-frequency signals.

Both Glass Hybrid PCBs and Glass Substrate PCBs demonstrate power-handling solid capabilities. Still, the choice may depend on the specific requirements of the high-power application, such as frequency range and mechanical stress tolerance.

B.Signal Integrity and High-Frequency Performance

1. Comparative Analysis of Dielectric Constant and Dissipation Factor

Glass Hybrid PCBs:

· Glass Hybrid PCBs may have a slightly higher dielectric constant due to the presence of ceramic or metal layers.

· The choice of glass epoxy material and additional layers influences the dissipation factor.

Glass Substrate PCBs:

· Glass Substrate PCBs typically exhibit a lower dielectric constant and dissipation factor due to the uniformity of glass as the base substrate.

Glass Substrate PCBs tend to have a slight advantage in terms of dielectric properties, which can positively impact signal integrity and high-frequency performance.

2. Impact on Signal Propagation and Transmission Losses

Glass Hybrid PCBs:

· The integration of ceramic or metal layers can influence signal propagation in specific frequency ranges, leading to controlled impedance and reduced transmission losses.

· Signal integrity can be further optimized through impedance matching and controlled trace routing.

Glass Substrate PCBs:

· Glass Substrate PCBs' low dielectric loss and consistent dielectric properties promote minimal signal attenuation and improved signal propagation at high frequencies.

· Proper impedance control is critical for maximizing high-frequency performance.

Both Glass Hybrid PCBs and Glass Substrate PCBs offer excellent signal integrity characteristics, but the choice depends on the specific high-frequency requirements and the need for impedance control.

C.Reliability and Durability in Harsh Conditions

1. Comparative Assessment of Mechanical and Environmental Stress Tolerance

Glass Hybrid PCBs:

· Incorporating ceramic or metal layers enhances the mechanical strength and resilience of Glass Hybrid PCBs, making them more resistant to mechanical stresses.

· Environmental factors, such as humidity and temperature fluctuations, may have a lesser impact on the overall performance.

Glass Substrate PCBs:

· Glass Substrate PCBs demonstrate good dimensional stability and mechanical resistance under various environmental conditions.

· Careful material selection is essential to ensure optimal performance in harsh environments.

Both Glass Hybrid PCBs and Glass Substrate PCBs exhibit reliability in harsh conditions. The choice may depend on specific environmental stress factors and mechanical load requirements.

2. Failure Modes and Susceptibility to High-Power Stress

Glass Hybrid PCBs:

· Failure modes in Glass Hybrid PCBs may be related to delamination between layers or thermal expansion mismatch.

· The robust construction of Glass Hybrid PCBs makes them less susceptible to high-power stress-induced failures.

Glass Substrate PCBs:

· Glass Substrate PCBs are less prone to delamination and exhibit good thermal stability under high-power conditions.

· However, mechanical stress and improper handling may pose challenges.

Glass Hybrid PCBs and Glass Substrate PCBs offer high reliability, but the specific failure modes and susceptibility to high-power stress may differ.

Glass Hybrid PCBs and Glass Substrate PCBs have unique advantages and considerations when applied in high-power environments. The decision between the two will largely depend on the specific requirements of the high-power application, including thermal management needs, signal integrity demands, and environmental robustness. Engineers must carefully evaluate the trade-offs and select the PCB technology that best aligns with their project's objectives and performance criteria.

For those seeking high-quality Glass substrate PCBs, engaging with reputable manufacturers and considering the available services, including sourcing options from China and potential opportunities for wholesale Glass substrate PCB solutions, is essential. Making an informed decision based on this comparative analysis will lead to successful high-power electronic designs.

V.Selection Criteria for High-Power Applications

Selecting the appropriate PCB technology for high-power applications requires careful consideration of various factors to ensure optimal performance, reliability, and cost-effectiveness.

A.Application-Specific Requirements

The first and most crucial step in the selection process is understanding the specific requirements of the high-power application. Considerations should include:

· Power Levels: Determine the maximum power levels the PCB needs to handle to ensure it can safely accommodate the current and voltage demands of the application.

· Frequency Range: Assess the frequency range of the signals involved in the application. If high-frequency signals are prominent, the PCB's signal integrity and impedance control become critical factors.

· Environmental Conditions: Consider the operating environment and potential exposure to harsh conditions, such as high temperatures, humidity, or vibration. This will impact the choice of PCB substrate with suitable mechanical and environmental stress tolerance.

· Mechanical Load: Evaluate the mechanical load the PCB may encounter during assembly, transportation, and operation. Robustness and mechanical strength become essential in applications with heavy mechanical stresses.

B.Cost Considerations and Budget Constraints

Cost considerations are significant when selecting the ideal PCB technology for high-power applications. Factors to keep in mind include:

· Material Costs: Compare the cost of materials used in Glass Hybrid PCBs and Glass Substrate PCBs. Glass Substrate PCBs may have a cost advantage due to the simplicity of their construction.

· Manufacturing Complexity: Assess the manufacturing complexity of each PCB type. Glass Hybrid PCBs may involve additional processes, impacting production costs.

· Lifecycle Cost: Consider each PCB technology's long-term reliability and maintenance costs. Opting for a more reliable solution may reduce overall lifecycle expenses.

· Budget Constraints: Balance the performance requirements with the available budget. While high-performance PCBs may offer superior features, they should align with the project's financial constraints.

C.Production Feasibility and Lead Time

Before finalizing the choice, evaluate the production feasibility and lead time of each PCB technology:

· Supplier Capability: Work with reputable PCB manufacturers experienced in producing both Glass Hybrid PCBs and Glass Substrate PCBs.

· Lead Time: Analyze the lead time for manufacturing and delivery of the chosen PCB technology. Time-sensitive projects may require expedited production options.

· Volume Production: Consider the production volume needed for the application. Some PCB technologies may be more suitable for small-batch production, while others excel in larger quantities.

· Prototype Availability: If the application necessitates prototyping or iterative development, ensure that prototype services are readily available for the chosen PCB technology.

Selecting the most suitable PCB technology for high-power applications involves carefully evaluating application-specific requirements, cost considerations, and production feasibility. Glass Hybrid PCBs and Glass Substrate PCBs offer distinct advantages, and the final decision should align with the project's objectives, performance demands, and budget constraints.

For those seeking to source Glass substrate PCBs, it is essential to collaborate with reputable manufacturers and explore available services, including those from manufacturers based in China. Additionally, exploring wholesale Glass substrate PCB options may prove advantageous for projects requiring larger PCBs. By adhering to these selection criteria, engineers and designers can ensure the successful implementation of high-power electronic projects, achieving optimal performance and reliability.

VI.Recommendations and Best Practices

A.Guidelines for Selecting the Appropriate PCB Technology Based on Application Requirements

Choosing the right PCB technology is crucial for achieving optimal performance and reliability in high-power applications. Here are some guidelines to help engineers and designers make informed decisions:

1. Define Application Requirements: Clearly outline the specific requirements of the high-power application, including power levels, frequency range, environmental conditions, and mechanical load.

2. Evaluate Signal Integrity Needs: If the application involves high-frequency signals, prioritize PCB technologies with excellent signal integrity characteristics, such as Glass Substrate PCBs.

3. Assess Thermal Management Demands: For applications generating significant heat, consider PCB technologies with superior thermal conductivity, such as Glass Hybrid PCBs, to ensure efficient heat dissipation.

4. Analyze Mechanical Stress Tolerance: Assess the mechanical stresses the PCB may encounter and choose a technology with appropriate mechanical strength and durability.

5. Consider Lifecycle Costs: Balance the initial cost of the PCB technology with long-term reliability and maintenance expenses to make cost-effective choices.

6. Prototype and Test Iteratively: Perform prototyping and iterative testing to verify the selected PCB technology's suitability for the application.

7. Collaborate with PCB Manufacturers: Engage with reputable PCB manufacturers with expertise in producing the chosen PCB technology and can provide valuable insights during the selection process.

B.Design Considerations to Optimize Performance and Reliability

To maximize the performance and reliability of high-power PCBs, implement the following design considerations:

1. Proper Trace Routing: Optimize trace routing to minimize signal losses, crosstalk, and interference. Follow impedance control guidelines for high-frequency applications.

2. Thermal Vias and Heatsinks: Incorporate thermal vias and heatsinks to efficiently dissipate heat and maintain the operating temperature within acceptable limits.

3. Ground Plane Design: Implement a solid ground plane to minimize noise and improve signal integrity, especially in high-frequency circuits.

4. Component Placement: Carefully position components to ensure efficient heat dissipation and minimize signal propagation delays.

5. Environmental Protection: Apply conformal coatings or encapsulation techniques to safeguard the PCB from environmental factors like moisture, dust, and chemical exposure.

6. Mechanical Reinforcement: If required, use additional automated reinforcement techniques to enhance the PCB's resistance to mechanical stresses.

7. Reliability Testing: Conduct rigorous reliability testing, including thermal cycling and vibration testing, to validate the PCB's performance under demanding conditions.

C.Supplier Selection and Quality Assurance

Ensuring the quality and reliability of PCBs starts with choosing suitable suppliers and implementing quality assurance measures:

1. Reputation and Experience: Partner with reputable PCB manufacturers with a proven record of producing high-quality Glass substrate PCBs.

2. Certifications and Standards: Verify that the supplier complies with industry standards and holds relevant certifications, such as ISO 9001 and UL certifications.

3. Quality Control Processes: Inquire about the supplier's quality control processes and inspect their manufacturing facilities to assess their commitment to quality.

4. Prototyping Services: Opt for suppliers who offer prototyping services to validate designs before mass production.

5. Batch Testing: Request batch testing reports to ensure consistency and reliability across multiple PCBs.

6. Communication and Support: Choose suppliers who provide excellent customer support and clear communication throughout manufacturing.

By adhering to these best practices and recommendations, engineers and designers can confidently select the appropriate PCB technology, optimize the design for performance and reliability, and collaborate with reliable suppliers to ensure the success of high-power electronic projects.

VII.Conclusion

Glass Hybrid PCBs and Rocket-PCB Glass Substrate PCBs

In this comprehensive analysis, we delved into the strengths of Rocket-PCB's two prominent PCB technologies for high-power applications: Rocket-PCB Glass Hybrid PCBs and Rocket-PCB Glass Substrate PCBs. Both technologies offer unique advantages tailored to specific high-power demands.

Rocket-PCB Glass Hybrid PCBs excel in thermal management, thanks to the integration of ceramic or metal layers, providing enhanced thermal conductivity and mechanical strength. They are a favorable choice for applications that require efficient heat dissipation and robust mechanical support.

By meticulously evaluating application-specific needs, considering performance trade-offs, and partnering with Rocket-PCB, a reputable and experienced PCB manufacturer, engineers can confidently make the best choices for their high-power projects. Implementing design considerations to optimize performance and reliability will further enhance the success of their electronic designs.

In the dynamic and fast-evolving electronics industry, the choice of PCB technology can be a defining factor, providing a competitive edge and elevating the overall performance of high-power electronic systems. By staying abreast of technological advancements and close collaboration with Rocket-PCB, engineers can drive innovation and excel in diverse industries with their high-power electronic designs.

Remember, each high-power application is unique, and the ideal PCB technology may vary. With Rocket-PCB's comprehensive range of Glass Hybrid PCBs and Glass Substrate PCBs, engineers have a broad spectrum of options to match the specific demands of their high-power electronic projects.

As we continue to advance in high-power electronics, Rocket-PCB remains committed to delivering cutting-edge PCB technologies and providing unmatched support to empower engineers in their pursuit of excellence. Together, we can shape a future where high-power electronic systems redefine industry standards and transform our lives and work.