How does the selection of substrate materials impact the performance and reliability of PCBs during fabrication?

Introduction

In the world of electronic devices, ensuring signal integrity is paramount. As technology advances and devices become more complex, the need for robust and reliable PCB prototypes has never been greater. This article aims to shed light on the significance of signal integrity in PCB prototypes and address the challenges users face in optimizing it.

The Importance of Signal Integrity in PCB Prototypes

Signal integrity refers to the ability of a PCB to transmit electrical signals without distortion or loss. A well-designed PCB with excellent signal integrity ensures reliable communication between components and minimizes the risk of data corruption or performance degradation. Whether it's a high-speed communication system, a power distribution network, or an analogue signal path, maintaining signal integrity is crucial for the overall functionality and performance of the device.

Challenges in Optimizing Signal Integrity

PCB fabrication and assembly users often encounter challenges in achieving optimal signal integrity. These challenges arise due to various factors, including the complexity of circuit layouts, high-frequency operation, and noise sources. Let's explore some of the common challenges:

1. Routing and Layout Design

Efficient PCB fabrication and assembly rely heavily on proper routing and layout design. Signal integrity issues can emerge from inadequate trace spacing, incorrect layer stacking, or improper termination. Achieving optimal signal paths, minimizing crosstalk, and ensuring controlled impedance are critical considerations that require expertise in PCB fabrication and layout design.

2. High-Speed Signaling

With the growing demand for high-speed data transfer, signal integrity challenges have become even more pronounced. High-speed signals are susceptible to signal degradation, such as reflections, ringing, and skew. Designing PCBs with controlled impedance, matched trace lengths, and carefully placed decoupling capacitors is crucial for mitigating these issues.

3. Power Integrity

Reliable power delivery to various components on a PCB is essential for overall system performance. Inadequate power distribution can lead to voltage drops, ground bounce, or excessive noise, affecting the functionality and stability of the device. Proper power plane design, decoupling capacitors, and effective grounding strategies are vital for maintaining power integrity.

Signal integrity plays a vital role in PCB fabrication and assembly success. It ensures reliable communication, optimal performance, and overall system functionality. Users can optimize signal integrity in their PCB prototypes by addressing the challenges associated with routing and layout design, high-speed signalling, and power integrity.

II.Understanding Signal Integrity

In PCB fabrication and assembly, signal integrity is a crucial aspect that directly impacts the performance and reliability of PCB prototypes.

A.Defining Signal Integrity and Its Significance in PCB Prototypes

Signal integrity refers to the ability of a PCB to transmit electrical signals accurately and reliably from the source to the destination. It encompasses various factors, including signal quality, distortion, noise immunity, and timing. Achieving and maintaining signal integrity is vital for adequately functioning electronic devices.

In the context of PCB prototypes, signal integrity is of utmost importance during the development and testing stages. During these phases, designers and engineers assess the PCB's performance and functionality, ensuring signals propagate as intended. Any deviations from the desired signal characteristics can lead to compromised system performance and potential failures.

B.Impact of Signal Integrity on Overall System Performance

Signal integrity directly influences the system's overall performance in which the PCB is integrated. Here are vital aspects highlighting its impact:

1. Data Integrity: Signal integrity ensures the transmitted data remains intact and accurate. Without proper signal integrity, data corruption can occur, leading to errors, packet loss, or even complete system failure. PCB fabrication and assembly processes should focus on maintaining signal integrity to preserve data integrity.

2. Timing and Synchronization: Proper signal integrity is crucial for maintaining precise timing and synchronization within a system. Timing errors, such as skew or jitter, can cause timing violations, resulting in functional errors and decreased system reliability. PCB prototype fabrication services should prioritize signal integrity for accurate timing and synchronization.

3. Noise Immunity: Signal integrity plays a critical role in mitigating the effects of external noise sources. PCBs exposed to electromagnetic interference (EMI) or radio frequency interference (RFI) may suffer from signal degradation and increased error rates. By optimizing signal integrity, PCB fabrication and assembly can enhance the system's immunity to noise, ensuring reliable operation in various environments.

C.Common Signal Integrity Issues and Their Consequences

Several signal integrity issues can arise during PCB fabrication and assembly, potentially leading to adverse consequences:

1. Reflections: Improper impedance matching or signal termination can cause signal reflections, resulting in signal distortions, ringing, and increased noise. These reflections can lead to errors, degraded signal quality, and reduced system performance.

2. Crosstalk: Inadequate spacing between traces or improper routing can cause crosstalk, where signals interfere. Crosstalk can introduce noise and distortion, affecting signal integrity and leading to errors in data transmission.

3. Signal Loss: Insufficient transmission line quality or excessive trace length can result in signal attenuation or loss. Signal loss can cause weakened signals and reduced noise margins, ultimately impacting the system's performance and reliability.

Addressing these signal integrity issues through careful PCB design, proper layout, controlled impedance, and signal integrity analysis tools is crucial for achieving high-quality PCB prototypes.

III.Key Considerations for Optimizing Signal Integrity in PCB Prototypes

A.Component Placement and Routing

Effective component placement and routing are crucial for optimizing signal integrity in PCB prototypes. Consider the following key considerations:

1. Impact of Component Placement: How does the placement of components on a PCB affect signal integrity in the PCB prototypes during fabrication and assembly?

2. Routing Techniques: What routing techniques can be employed to minimize signal interference and crosstalk in PCB prototypes? How can these techniques be implemented during the PCB fabrication and assembly process?

3. Importance of Controlled Impedance Routing: Why is controlled impedance routing important for optimizing signal integrity in PCB prototypes? How can handled impedance routing be achieved during the PCB fabrication and assembly?

B.Power and Ground Planes

Power and ground planes play a crucial role in maintaining signal integrity. Consider the following considerations:

1. Role of Power and Ground Planes: What is the significance of power and ground planes in signal integrity optimization during PCB fabrication and assembly? How do power and ground planes reduce noise and enhance signal integrity?

2. Proper Power and Ground Plane Design: What are the key factors when designing power and ground planes in PCB prototypes? How can adequate power and ground plane design ensure good signal integrity during the PCB fabrication and assembly?

3. Significance of Decoupling Capacitors: Why are decoupling capacitors important for signal integrity optimization in PCB prototypes? How should decoupling capacitors be placed and selected to effectively suppress voltage fluctuations and improve power integrity during the PCB fabrication and assembly?

C.Signal Integrity Analysis and Simulation

Signal integrity analysis and simulation are essential tools for optimizing PCB prototypes. Consider the following aspects:

1. Signal Integrity Analysis Tools: What are the commonly used signal integrity analysis tools and techniques? How can these tools help identify and address signal integrity issues during PCB fabrication and assembly?

2. Pre-layout and Post-layout Simulations: What are the benefits of performing pre-layout and post-layout simulations for signal integrity optimization in PCB prototypes? How do these simulations aid in identifying potential issues and improving overall signal integrity?

3. Importance of Analyzing Reflections, Signal Integrity Metrics, and Eye Diagrams: Why is it essential to analyze reflections, signal integrity metrics, and eye diagrams during the PCB fabrication and assembly process? How do these analyses provide insights into signal quality and aid in optimizing signal integrity?

D.High-Speed Design Considerations

High-speed signals require specific considerations to maintain signal integrity in PCB prototypes. Consider the following aspects:

1. Impact of High-Speed Signals: How do high-speed signals impact signal integrity in PCB prototypes? What are the challenges associated with high-speed designs during the PCB fabrication and assembly process?

2. Controlled Impedance: Why is maintaining controlled impedance crucial for high-speed signals in PCB prototypes? How can controlled impedance be achieved and maintained during the PCB fabrication and assembly?

3. Termination and Skew Management: What are the techniques and best practices for proper termination and skew management in high-speed designs? How can these techniques be implemented to minimize signal reflections and ensure optimal signal integrity in PCB prototypes during the fabrication and assembly process?

IV.PCB Prototype Testing and Validation

A.Significance of Testing and Validation in Optimizing Signal Integrity

Testing and validation are critical in optimizing signal integrity in PCB prototypes during the PCB fabrication and assembly process. The following aspects highlight their significance:

· Ensuring Signal Integrity: Testing and validation help verify the integrity of signals transmitted through the PCB. Conducting thorough testing can identify and address potential issues affecting signal quality, ensuring optimal performance.

· Detecting Design Flaws: Testing allows for detecting design flaws that may negatively impact signal integrity. By identifying these flaws early on, necessary modifications can be made during the PCB fabrication and assembly process, minimizing the risk of signal degradation.

· Enhancing Reliability: Rigorous testing and validation improve the PCB prototypes' overall reliability. Potential failures or errors can be identified and rectified by evaluating signal integrity, leading to a more robust and reliable PCB design.

B.Various Testing Methods

Several testing methods are employed to assess signal integrity in PCB prototypes during the PCB fabrication and assembly process. The following techniques are commonly utilized:

· Time-Domain Reflectometry (TDR): TDR measures the impedance and detects anomalies in transmission lines by sending a pulse and analyzing the reflected signal. This method helps identify impedance mismatches, signal reflections, and other discontinuities affecting signal integrity.

· Network Analyzers: Network analyzers are versatile tools for characterizing and analyzing electrical networks. They measure vital parameters such as impedance, S-parameters, and frequency response, providing valuable insights into signal integrity.

· Signal Integrity Simulations: Simulation tools enable virtual testing of PCB prototypes, predicting the behaviour of signals under different conditions. Simulations help identify potential signal integrity issues, allowing for premature optimization and refinement during the PCB fabrication and assembly process.

C.Importance of Prototype Iteration and Refinement

Prototype iteration and refinement based on testing results are crucial for optimizing signal integrity during the PCB fabrication and assembly. Consider the following points:

· Identifying Areas for Improvement: Testing reveals areas where signal integrity may be compromised. By analyzing test results, designers can pinpoint specific sections or components that require refinement to enhance signal performance.

· Optimizing Layout and Design: Based on testing results, modifications can be made to the PCB layout and design. This includes adjusting trace widths, optimizing component placement, and refining routing techniques to mitigate signal interference and improve overall signal integrity.

· Validation of Design Modifications: Prototype iteration allows for the confirmation of design modifications implemented to address signal integrity issues. By retesting the modified prototype, designers can ensure that the changes have effectively improved signal integrity and meet the desired performance criteria.

Testing and validation are essential for optimising signal integrity in the PCB fabrication and assembly process. By employing various testing methods and iteratively refining the design based on test results, PCB prototype fabrication services can ensure that the final product exhibits excellent signal integrity, meeting the requirements of the intended application.

V.Conclusion

Throughout this article, we have explored critical considerations for optimizing signal integrity in PCB prototypes during the PCB fabrication and assembly process. By focusing on these considerations, users can ensure the production of high-quality PCB prototypes that meet their signal integrity requirements.

Component Placement and Routing: Careful placement of components and efficient routing techniques are crucial in minimizing signal interference and crosstalk and achieving controlled impedance routing in PCB prototypes.

Power and Ground Planes: Well-designed control, ground planes, and strategically placed decoupling capacitors help reduce noise and enhance signal integrity during PCB fabrication and assembly.

Signal Integrity Analysis and Simulation: Utilizing signal integrity analysis tools and conducting simulations allow users to identify potential issues, and analyze reflections, signal integrity metrics, and eye diagrams, resulting in improved signal performance.

High-Speed Design Considerations: High-speed signals require specific considerations such as controlled impedance, proper termination, and skew management to maintain optimal signal integrity in PCB prototypes.

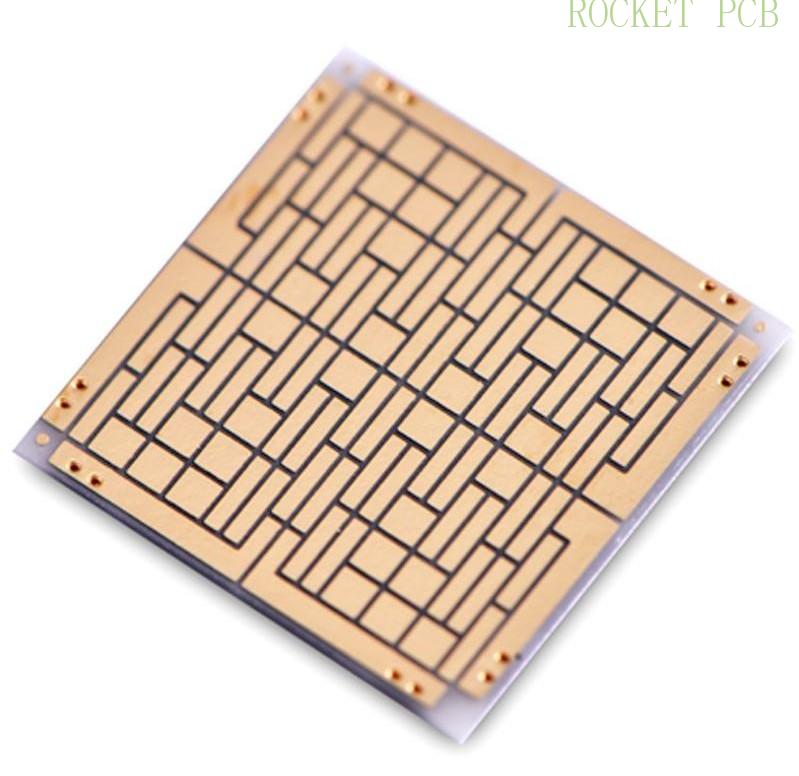

Collaboration between users and PCB manufacturers, such as Rocket-PCB, is vital to achieving the PCB prototype's best possible signal integrity. Users should provide comprehensive design specifications, requirements, and expectations to ensure a clear understanding of their signal integrity needs. With its expertise and experience, Rocket-PCB can offer guidance and recommendations throughout the PCB fabrication and assembly process, resulting in optimized signal integrity.

Rocket-PCB provides a range of services for users seeking further resources and information on signal integrity optimization, including PCB prototype fabrication. Their website and technical documentation offer valuable insights, guidelines, and recommendations for signal integrity optimization during PCB fabrication and assembly. Additionally, users can explore online communities, forums, and industry publications to stay updated on the latest advancements and best practices in signal integrity optimization.

Optimizing signal integrity in PCB prototypes is crucial for achieving reliable, high-performance electronic systems. By considering the critical considerations discussed in this article and collaborating with a reputable PCB manufacturer like Rocket-PCB, users can ensure the successful fabrication and assembly of PCB prototypes that meet their signal integrity requirements.