How do impedance matching techniques influence signal propagation in high-frequency PCBs?

I.Introduction

In the world of advanced electronics, high-frequency PCBs have emerged as a critical component enabling the seamless transmission of signals in applications such as 5G communication, aerospace, radar systems, and more. These specialized circuit boards are designed to handle calls with frequencies ranging from hundreds of megahertz to gigahertz, catering to the demands of modern high-speed data transmission and communication systems.

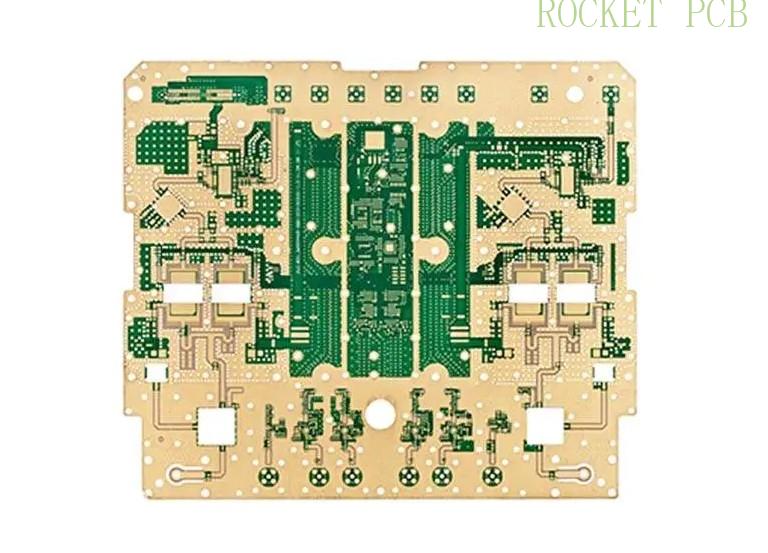

High-frequency PCBs, or RF (Radio Frequency), are engineered to maintain signal integrity and minimize signal losses when dealing with high-frequency electronic signals. Unlike traditional PCBs, these boards exhibit unique design considerations and incorporate specialized materials to meet the stringent requirements of high-frequency applications.

The applications of high-frequency PCBs span various industries, including telecommunications, aerospace, medical devices, automotive radar systems, and wireless technology. These boards enable high-performance and reliable signal transmission, making them indispensable in the modern digital age.

Signal integrity is a paramount concern when dealing with high-frequency electronic circuits. As frequencies increase, the behavior of signals becomes more sensitive to impedance discontinuities and parasitic effects. Any degradation or distortion in signal quality can lead to data errors, reduced communication range, and compromised system performance.

To mitigate signal integrity challenges, high-frequency PCBs are carefully engineered with meticulous attention to layout design, controlled impedance traces, and selecting appropriate dielectric materials. Ensuring signal integrity is not just a matter of clear transmission but is also crucial in preventing electromagnetic interference (EMI) that could interfere with other nearby circuits.

Impedance matching is a fundamental principle in high-frequency PCB design that directly influences signal propagation. In simple terms, impedance matching refers to designing the PCB's transmission lines to match the characteristic impedance of the connected components, such as microprocessors, amplifiers, or antennas.

By achieving impedance matching, maximum power transfer occurs between the source and the load, preventing signal reflections that could cause data loss or noise. Properly matched impedance ensures minimal signal distortion, reduced EMI emissions, and enhanced overall signal integrity.

In the context of high-frequency PCBs, the significance of impedance matching is further magnified due to the vulnerability of signals at such frequencies. Therefore, a deep understanding of the impedance characteristics and techniques to achieve matching is essential for designers and users.

As the demand for high-frequency PCBs continues to rise, selecting the right high-frequency PCB supplier becomes crucial to ensure the highest quality and performance. When seeking high-frequency PCB for sale, choosing a supplier with expertise in impedance matching techniques and a proven track record in delivering reliable high-frequency PCBs is imperative.

High-frequency PCBs represent the cutting edge of signal transmission technology, enabling seamless data communication in various critical applications. These specialized circuit boards play a pivotal role in shaping the future of high-speed and high-performance electronics by focusing on signal integrity through impedance matching.

II.Understanding Impedance Matching in High-Frequency PCBs

A.Impedance and its Significance in Signal Transmission

Impedance is a fundamental electrical property crucial in transmitting signals within high-frequency PCBs. An electrical circuit offers a complex measure of opposition to alternating current (AC) flow. Impedance is represented by a combination of resistance (R) and reactance (X), where reactance accounts for the effects of capacitance and inductance in the circuit.

In the context of high-frequency PCBs, impedance becomes particularly significant due to the rapid switching of signals and the inherent capacitive and inductive effects of the PCB traces and components. Controlling impedance becomes essential to ensure signals propagate through the PCB without significant attenuation or distortion.

B.The Concept of Impedance Matching and its Purpose

Impedance matching is designing the transmission lines on the high-frequency PCB to have the same characteristic impedance as the connected devices or components. The characteristic impedance is the value at which the transmission line appears resistive to the AC signal, with no reflections occurring at the transitions.

Impedance matching aims to maximize power transfer efficiency between the signal source and the circuit's load (connected component). When the transmission line's characteristic impedance matches the load's impedance, the AC signal can travel along the tube without any reflections. As a result, signal integrity is maintained, and the risk of signal loss, distortion, or EMI generation is significantly reduced.

C.Reflections and Signal Distortion in the Absence of Impedance Matching

Without impedance matching, high-frequency PCBs can suffer from signal reflections at points of impedance discontinuity. When the transmission line's characteristic impedance differs from the connected component, part of the signal energy gets reflected toward the source.

Signal reflections can lead to a phenomenon known as standing waves, where the original signal and its reflected waves interfere with each other. This interference causes signal distortion, resulting in signal degradation and potential data errors in the system.

Moreover, reflections also contribute to signal ringing and overshooting, leading to undesirable noise and jitter in the circuit. The accumulation of these signal integrity issues can severely impact the performance of high-frequency PCBs and compromise the overall functionality of the electronic system.

Understanding impedance and impedance matching is paramount in high-frequency PCB design. Proper impedance matching ensures efficient signal transmission, minimizes reflections, and maintains signal integrity. When seeking high-frequency PCB for sale, users should look for reputable high-frequency PCB suppliers with expertise in impedance control to ensure their electronic applications' highest performance and reliability.

III.Factors Affecting Impedance Matching in High-Frequency PCBs

A.Trace Geometry and its Impact on Characteristic Impedance

The geometry of traces, including their width, thickness, and separation, significantly influences the characteristic impedance of transmission lines on high-frequency PCBs. As signals propagate through the PCB traces, their geometry determines the distribution of electric and magnetic fields, affecting the line's impedance.

1. Trace Width: Wider traces result in lower impedance, while narrower paths lead to higher impedance. Therefore, controlling the trace width is crucial in achieving the desired characteristic impedance for the specific application.

2. Trace Thickness: The thickness of the conductive layer affects the trace's resistance, which, in turn, influences the overall impedance. In high-frequency PCBs, thinner conductive layers are preferred to minimize signal losses.

3. Trace Separation: The distance between adjacent traces, known as trace separation or spacing, affects the capacitance and crosstalk between traces. Proper spacing is essential to avoid unwanted coupling and maintain signal integrity.

4. Trace Length: Although not directly related to impedance, the trace length can introduce transmission line effects that impact signal propagation and may require impedance matching at specific points.

Accurate control of trace geometry is essential for maintaining consistent characteristic impedance along the entire signal path and ensuring efficient impedance matching.

B.Influence of Dielectric Material Properties on Impedance

The dielectric material used in high-frequency PCBs substantially impacts the characteristic impedance of the transmission lines. Dielectric constant (εr) and loss tangent (tan δ) define the material's electrical properties.

1. Dielectric Constant (εr): This parameter represents the material's ability to store electric energy relative to free space (vacuum). PCB materials with higher dielectric constants result in higher characteristic impedances, while lower dielectric constants lead to lower impedances.

2. Loss Tangent (tan δ): Loss tangent quantifies the dielectric material's dissipation factor or how much energy is lost as heat during signal transmission. Low-loss materials with a low tan δ are preferred for high-frequency PCBs to minimize signal attenuation and distortion.

Selecting the appropriate dielectric material with the desired electrical properties is critical for achieving the target characteristic impedance and ensuring effective impedance matching in high-frequency applications.

C.Parasitic Elements and their Effects on Impedance Matching

Parasitic elements refer to unintended components in the PCB layout that can impact impedance matching. These parasitics arise due to the inherent properties of the conductive traces, vias, and component pads.

1. Capacitance: The proximity of traces and the PCB's conductive layers create parasitic capacitance, affecting the overall impedance of the transmission lines. Uncontrolled capacitance can lead to impedance variations and signal distortions.

2. Inductance: Parasitic inductance in the PCB traces can cause impedance deviations and signal reflections, particularly at high frequencies. Minimizing inductance is crucial for maintaining impedance consistency.

3. Via Effects: Although necessary for interconnecting PCB layers, Vias introduce additional impedance discontinuities. Proper design and placement are essential to minimize their impact on impedance matching.

4. Pad Effects: The size and shape of component pads can influence the effective characteristic impedance of the connected transmission lines. Careful consideration of pad design helps avoid impedance deviations.

Addressing and mitigating parasitic elements through careful layout design and optimized PCB manufacturing processes are essential for accurate and reliable impedance matching in high-frequency PCBs.

In high-frequency PCB designs, a thorough understanding of these factors is indispensable for achieving precise impedance control and successful signal propagation. When sourcing high-frequency PCBs from suppliers, users must ensure that the selected high-frequency PCB supplier possesses expertise in managing these factors to deliver high-quality PCBs suitable for the intended high-frequency applications.

IV.Common Impedance Matching Techniques for High-Frequency PCBs

A.Series and Parallel Resistor Networks

Series and parallel resistor networks are simple yet effective techniques used for impedance matching in high-frequency PCBs.

1. Series Resistor Network: Placing a series resistor in the signal path can effectively increase the impedance of the transmission line. By carefully selecting the resistor value, the transmission line's characteristic impedance can be adjusted to match the impedance of the connected component.

2. Parallel Resistor Network: In contrast, adding a parallel resistor network across the load can decrease the effective impedance seen by the signal. This approach is practical when the transmission line impedance needs to be lowered to match the load impedance.

Series and parallel resistor networks are commonly employed for relatively low-frequency applications and can be straightforward. However, they may introduce signal attenuation and are less suitable for ultra-high-frequency designs due to the parasitic effects of resistors.

B.The Use of Transmission Lines and Microstrips for Impedance Control

Transmission lines, such as microstrips, are fundamental building blocks for controlled impedance in high-frequency PCBs. Microstrips consist of a conductive trace placed on one layer of the PCB, separated from the ground plane by a dielectric material.

1. Microstrip Transmission Line: By carefully designing the width and thickness of the microstrip trace, as well as selecting the appropriate dielectric material, designers can precisely control the characteristic impedance. Microstrips are commonly used for single-ended signal transmission in high-frequency PCBs.

2. Stripline Transmission Line: Stripline transmission lines are similar to microstrips but are sandwiched between two dielectric layers with ground planes on both sides. This configuration provides better isolation and reduced EMI, making it suitable for high-frequency differential signal transmission.

The controlled impedance of transmission lines ensures minimal signal reflections and distortion, contributing to superior signal integrity in high-frequency PCB designs. These techniques are widely used in RF and microwave applications, where precise impedance control is essential.

C.Tuning Stubs and their Applications in Impedance Matching

Tuning stubs, known as stub matching, are passive components that achieve impedance matching in high-frequency PCBs.

1. Open-End Stub: An open-circuited stub is a short transmission line section left open at one end. When placed strategically along the main transmission line, it acts as a capacitive load, effectively increasing the line's characteristic impedance.

2. Short-End Stub: Conversely, a short-circuited stub is a short section of a transmission line that is shorted at one end. This stub behaves as an inductive load, reducing the effective impedance of the main transmission line.

Tuning stubs are versatile and can be easily adjusted by altering their physical length to match the required impedance. They find applications in various high-frequency PCB designs, mainly with narrowband applications or specific frequency ranges.

Impedance matching is a critical aspect of high-frequency PCB design, ensuring efficient signal transmission and integrity. Series and parallel resistor networks offer straightforward solutions for low-frequency applications, while transmission lines and microstrips provide precise impedance control in RF and microwave designs.

Additionally, tuning stubs offer flexibility and ease of adjustment for impedance matching in specialized high-frequency applications. When seeking high-frequency PCB for sale, users should consider the impedance matching techniques the high-frequency PCB supplier uses to ensure optimal performance in their electronic systems.

V.Impedance Matching Considerations for Different High-Frequency Signals

A.Digital Signals and their Impedance Requirements

In high-frequency PCB designs, digital signals are characterized by rapid transitions between logic levels, necessitating careful impedance matching to maintain signal integrity.

1. Edge Rates and Signal Integrity: Digital signals with fast edge rates are more susceptible to signal reflections and ringing. Proper impedance matching ensures that these reflections are minimized, reducing the risk of data errors and ensuring reliable signal propagation.

2. Termination Techniques: Termination resistors, such as series or parallel termination, are commonly used to minimize signal reflections in digital designs. The value of these resistors is selected to match the transmission line's characteristic impedance, effectively absorbing the reflected energy.

3. Clock Distribution Networks: In high-frequency digital systems, clock distribution networks must be designed with precise impedance control to ensure synchronized and jitter-free clock signals across the PCB.

Achieving accurate impedance matching for digital signals is essential to avoid distortion and maximize the system's data transmission performance.

B.RF Signals and their Unique Impedance Challenges

Radio Frequency (RF) signals operate at much higher frequencies than digital signals, bringing about specific impedance challenges that demand careful consideration.

1. 50-Ohm Standard: The 50-ohm characteristic impedance is a common standard for transmission lines and connectors in RF systems. Maintaining a consistent 50-ohm impedance throughout the RF circuitry is crucial for optimal signal transmission.

2. VSWR and Return Loss: Voltage Standing Wave Ratio (VSWR) and Return Loss are essential metrics in RF designs, indicating the efficiency of impedance matching. Low VSWR and high Return Loss show minimal signal reflections and good impedance matching.

3. Microstrip and Stripline Designs: RF signals are often routed using microstrip or stripline transmission lines to achieve controlled impedance and minimize signal losses and interference.

4. Balanced and Unbalanced Signals: RF systems may use flat (differential) or unbalanced (single-ended) signal configurations. Proper impedance matching is necessary for both cases, with additional considerations for common-mode rejection in differential signals.

Achieving precise impedance matching in RF designs is crucial for maintaining signal purity, maximizing power transfer, and avoiding losses due to reflections.

C.Differential Signals and their Impact on Impedance Matching

Differential signaling is a common technique to improve noise immunity and signal integrity in high-frequency PCB designs.

1. Balanced Transmission Lines: Differential signals consist of two traces with equal but opposite signal voltages. Maintaining consistent characteristic impedance for both traces is essential to achieve balanced transmission.

2. Common-Mode Rejection: Impedance mismatch in differential pairs can lead to common-mode noise, interfering with the signal. Proper impedance matching minimizes common-mode noise, enhancing noise immunity.

3. Single-Ended to Differential Conversion: At interfaces where single-ended signals are converted to differential signals (e.g., at connectors), impedance continuity must be ensured to avoid signal reflections.

Differential signaling offers superior noise rejection capabilities, but achieving proper impedance matching is crucial to harness these benefits fully.

Different high-frequency signals present unique impedance-matching challenges. Digital signals require careful termination and edge rate considerations, while RF signals demand adherence to specific characteristic impedance standards. Differential signals require balanced impedance for optimal performance. High-frequency PCB designers must be aware of these considerations and employ appropriate impedance-matching techniques to ensure reliable signal transmission and robust performance in their electronic systems. When seeking high-frequency PCB for sale, users should collaborate with experienced PCB suppliers with expertise in addressing the impedance matching requirements for diverse high-frequency signals.

VI.Practical Design Guidelines for Impedance Matching

A.Calculating Characteristic Impedance Based on PCB Stack-up

1. PCB Layer Stack-up: Understanding the layer stack-up of the PCB is essential for accurately calculating the characteristic impedance of transmission lines. The number and arrangement of signal layers, ground planes, and power planes influence the propagation of electromagnetic fields and affect the characteristic impedance.

2. Dielectric Material Properties: Gather each dielectric layer's dielectric constant (εr) and thickness in the stack-up. These parameters directly impact the propagation speed of signals and, consequently, the characteristic impedance.

3. Trace Dimensions: Note the width and thickness of the traces used for signal routing. These dimensions, along with the dielectric properties, determine the characteristic impedance of the transmission lines.

4. Online Calculators and Formulas: Utilize online impedance calculators or formulas based on the geometry and dielectric parameters to compute the characteristic impedance for different transmission line configurations within the stack-up.

Correctly calculating the characteristic impedance based on the PCB stack-up is foundational for achieving precise impedance matching in high-frequency PCB designs.

B.Selecting Appropriate Transmission Line Widths for Impedance Control

1. Design Requirements: Determine the required characteristic impedance based on the specific high-frequency signals used in the PCB design. The design requirements and desired impedance value will dictate the transmission line widths.

2. Trace Thickness Considerations: A thinner trace reduces the characteristic impedance in microstrip transmission lines, while a thicker hint increases it. Adjust the trace thickness according to the desired impedance and other signal integrity considerations.

3. Crosstalk and Spacing: Remember the impact of trace spacing on impedance and crosstalk. Properly spaced traces help maintain impedance and minimize undesired signal coupling.

4. Manufacturing Tolerances: Account for manufacturing tolerances when selecting trace widths. Variations in PCB fabrication processes can affect the final impedance values.

5. Differential Pairs: For differential signals, ensure both traces have equal dimensions to maintain balanced impedance.

Careful selection of transmission line widths is crucial for achieving the desired characteristic impedance and ensuring efficient signal transmission in high-frequency PCBs.

C.Using Impedance Calculators and Simulation Tools for Accurate Matching

1. Commercial Software: Employ specialized PCB design software that includes impedance calculators and simulation tools. These tools can accurately model the transmission lines and predict their impedance under different conditions.

2. EM Simulation: Electromagnetic (EM) simulation tools provide a more comprehensive analysis of signal behavior, considering the effects of parasitics and field distribution. They offer accurate impedance predictions for complex PCB structures.

3. S-parameters and Reflection Coefficients: Utilize S-parameters and reflection coefficients obtained from simulations to assess the performance of impedance-matching networks and adjust component values if necessary.

4. Iterative Approach: Adopt an iterative design approach, adjusting trace widths and component values based on simulation results until the desired impedance matching is achieved.

By leveraging impedance calculators and simulation tools, designers can validate impedance matching decisions, fine-tune their designs, and anticipate potential signal integrity issues before prototyping.

Practical design guidelines for impedance matching in high-frequency PCBs are critical for achieving optimal signal integrity and performance. Calculating characteristic impedance based on the PCB stack-up, selecting appropriate transmission line widths, and employing impedance calculators and simulation tools empower designers to achieve accurate impedance matching. By following these guidelines, high-frequency PCB designers can deliver reliable and efficient electronic systems that meet the stringent requirements of modern high-speed applications.

Collaborating with experienced high-frequency PCB suppliers is also beneficial, as they can provide valuable insights and support throughout the design and manufacturing process.

VII.Measuring and Validating Impedance Matching

A.Non-Destructive Testing Methods for Impedance Verification

1. Time-Domain Reflectometry (TDR): TDR is a widely used non-destructive method for impedance verification. A TDR instrument sends a fast pulse down the transmission line and measures the reflections caused by impedance variations. The reflected waveforms help identify impedance discrepancies and assess signal integrity.

2. Vector Network Analyzer (VNA): VNAs are versatile instruments used to measure the S-parameters of transmission lines. They provide valuable information on characteristic impedance, return, and insertion loss, enabling comprehensive impedance validation.

3. Frequency Domain Reflectometry (FDR): FDR is a variant of TDR that analyzes the frequency domain response of the transmission line to evaluate impedance matching. It offers insights into the impedance behavior across different frequencies.

4. Smith Chart Analysis: These are graphical tools for visualizing impedance matching and reflection coefficients. They aid in identifying the optimal impedance matching points on the chart.

Non-destructive testing methods provide a non-intrusive way to evaluate impedance matching without damaging the PCB or altering its performance.

B.Impact of Test Equipment and Measurement Accuracy on Results

1. Calibration and Accuracy: Proper calibration of test equipment, especially VNAs, is crucial for accurate impedance measurements. Calibration standards ensure that the measurements are referenced correctly, minimizing measurement errors.

2. Connector Effects: The choice and quality of connectors used during testing can impact measurement accuracy. High-quality connectors with low insertion loss and impedance consistency are essential for reliable measurements.

3. Frequency Range: The frequency range of the test equipment should align with the operating frequencies of the high-frequency PCB to ensure accurate impedance measurements across the desired bandwidth.

4. Grounding and Shielding: Adequate grounding and shielding of the test setup are vital to reduce interference and ensure reliable measurements in high-frequency applications.

Understanding the limitations and sources of potential errors in impedance measurements is essential for obtaining reliable and meaningful results.

C.Case Studies and Examples of Impedance Matching Validation

1. Case Study 1: Microstrip Transmission Line: A high-frequency PCB for a 5G communication system underwent impedance matching validation using a VNA. The S-parameters were measured, and the Smith chart analysis confirmed precise impedance matching at 50 ohms, ensuring efficient signal propagation and low return loss.

2. Case Study 2: Differential Signal Integrity: A TDR was employed in a high-speed data communication application to verify impedance matching in differential signal pairs. The TDR measurements indicated a balanced impedance of 100 ohms, mitigating common-mode noise and achieving high-speed data transmission without signal distortions.

3. Example: RF Filter Design: An RF filter design on a high-frequency PCB was optimized using FDR. The frequency response analysis showed excellent impedance matching within the passband, resulting in minimal insertion loss and superior filter performance.

Case studies and examples are practical demonstrations of successful impedance matching validation, showcasing the effectiveness of non-destructive testing methods and the importance of accurate measurements in high-frequency PCB designs.

Measuring and validating impedance matching ensures optimal signal integrity and performance in high-frequency PCBs. Non-destructive testing methods like TDR and VNAs offer valuable insights into impedance behavior, while proper calibration and equipment selection enhance measurement accuracy. Real-world case studies and examples further highlight the significance of impedance validation in achieving reliable high-frequency electronic systems. Collaborating with experienced high-frequency PCB suppliers with expertise in impedance testing and verification ensures the delivery of high-quality PCBs that meet the stringent requirements of modern high-speed applications.

IX.Conclusion

Impedance matching is paramount in high-frequency PCB design, and Rocket-PCB, as a leading brand in the industry, understands its significance in delivering top-notch electronic solutions. With a firm grasp of impedance control techniques, Rocket-PCB ensures seamless signal transmission, optimal signal integrity, and reliable performance in high-frequency applications.

For users seeking to purchase high-frequency PCBs, Rocket-PCB offers vital takeaways to ensure a successful partnership. By working with Rocket-PCB's experienced team, users can expect tailored solutions that meet specific impedance requirements, rigorous validation processes to guarantee optimal performance and continuous dedication to minimizing manufacturing tolerances and process variations.

Rocket-PCB remains at the forefront of impedance-matching technology as the industry advances. With an eye on future trends, Rocket-PCB embraces cutting-edge advancements, including higher frequencies, integration of AI and automation, utilization of advanced materials, and the pursuit of miniaturization and 3D integration.

Rocket-PCB's commitment to impedance matching excellence solidifies its position as a trusted and innovative brand in the high-frequency PCB domain. Whether powering the next-generation communication networks, elevating aerospace capabilities, enhancing consumer electronics, or advancing memory technologies, Rocket-PCB's impedance matching prowess continues to drive progress in high-frequency electronic systems.