Electric circuit board manufacturers to teach you how to distinguish between board and photo electricity

by:Rocket PCB

2020-06-15

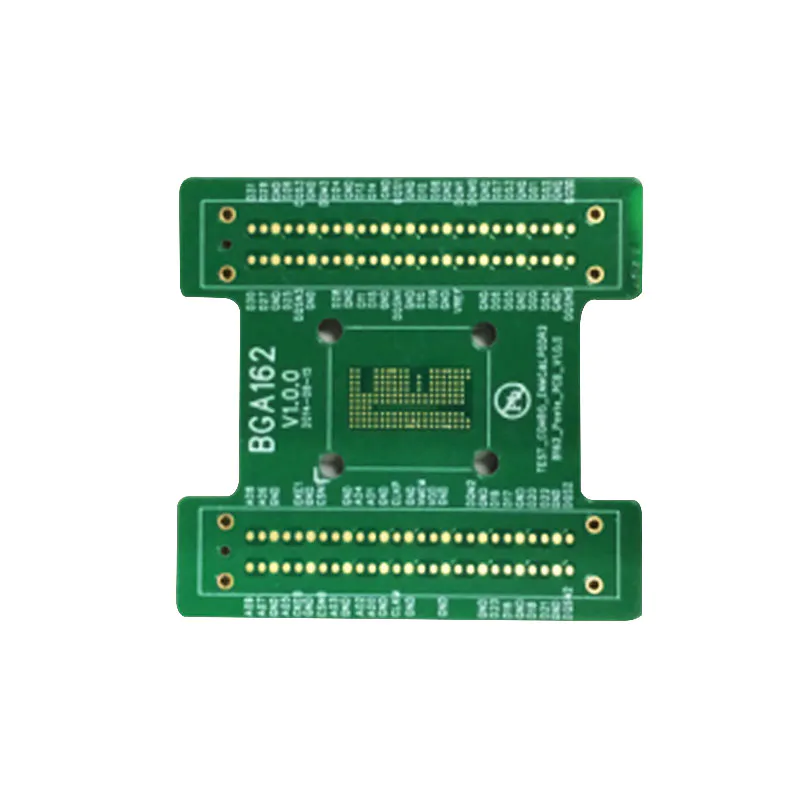

In PCB industry, electrical box board electroplating way, on the whole PCB board face and the wall of hole plating a layer of copper, the purpose is to increase surface and hole wall copper thickness of PCB manufacturer, to meet customer requirements.

Figure electricity is outer PCB boards to electroplating, plating and then secondary copper plating, its purpose is to increase the thickness of the outer circuit.

The outer dry film on the copper surface plating not attached with a copper, also not on tin plating;

Bare copper surface.

(

In outer line enhancement by developer dissolved not photosensitive dry film area)

Secondary copper plating, also can be plated tin.

Tin tin is the purpose of protection under the surface of the copper surface under the process of etching liquid bite off.

Circuit board manufacturing there are two different process in positive and negative, negative plate be out of tune, after heavy copper plate electric effect is mainly will increase the thickness of the hole wall copper and increase the thickness of the copper panel lines, to achieve customer's requirements, there are mainly micro erosion period, pickled, copper plating and the washing period;

Positive plate is outer development go figure, figure the role of the electric and plate much more electricity than a tin plating process, will be after the development of the copper plating on a layer of tin in the back of the alkaline etching lines are not erode and protect need.

No difference between circuit board and circuit board, is essentially the same.

Circuit board is just a piece of design and production of a good substrate, circuit board is already filled with each element of PCB circuit boards.

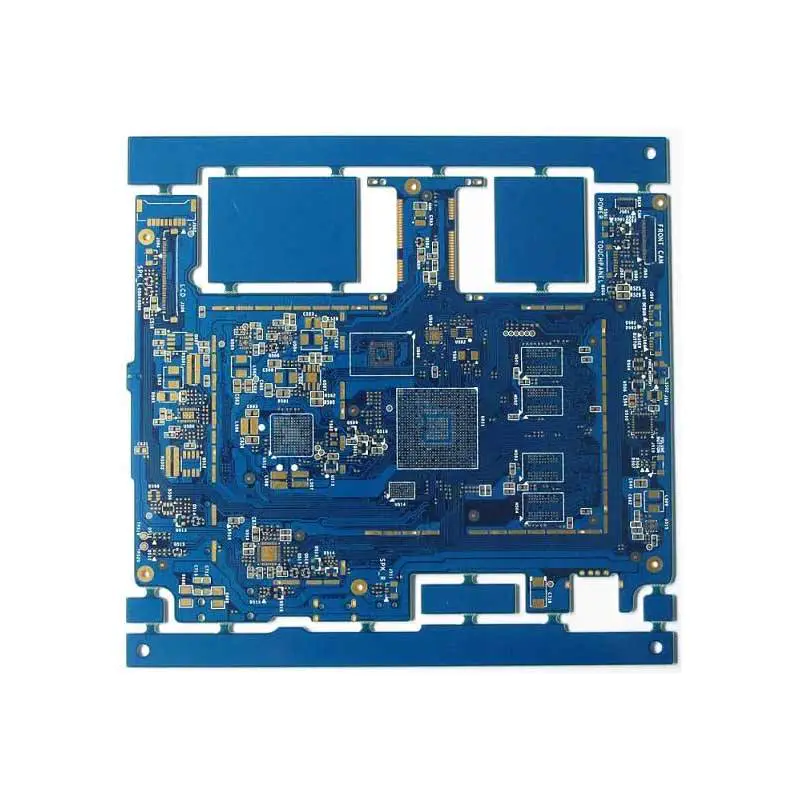

Circuit board are: the name of the circuit board, PCB board, aluminum plate, high-frequency boards, thick copper plate, impedance board, multilayer PCB, multilayer circuit boards, PCB, ultrathin circuit boards, ultrathin circuit boards, printing (

Copper etching technology)

Circuit boards, etc.

Circuit board making mini circuit, intuitive, for fixed batch production and optimization of the circuit with electrical layout plays an important role.

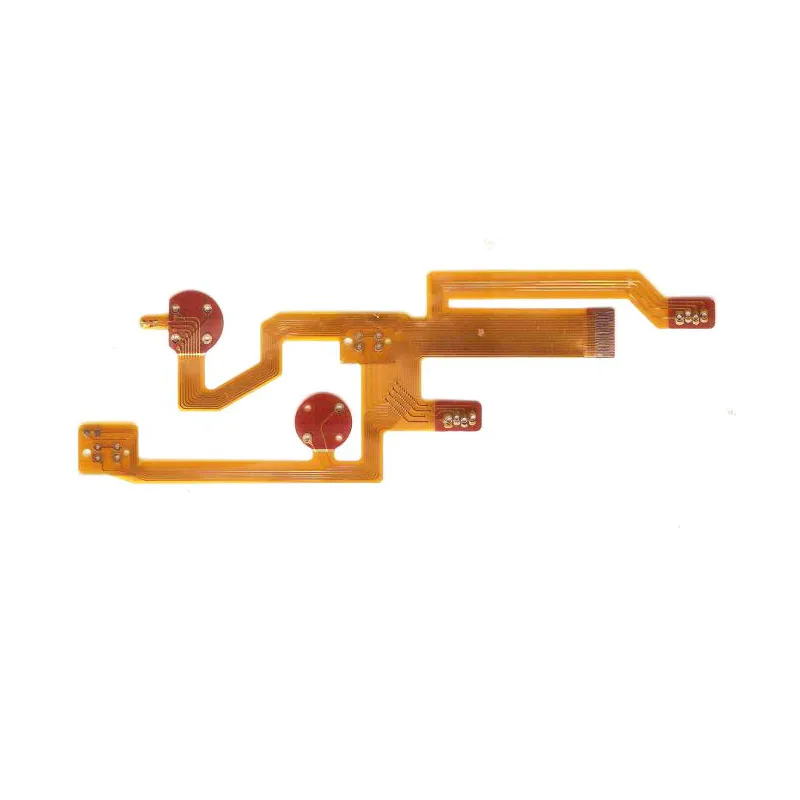

Circuit board: on the insulating substrate, a predetermined design formed from point-to-point connection between the conductor, but no printing PCB components.

Circuit board: on the insulating substrate, a predetermined design formed from point-to-point connection between conductor, and print PCB components.

A circuit board is a kind of electronic components.

And circuit board is a kind of PCB.

No electronic components.

Most contact is circuit board, mainboard is circuit board.

pcb manufacturing services are required in the manufacture of almost every product and pcb manufacturing services pcb making service is one of the most common machines.

As a result, consumers will reward Rocket PCB with leadership sales, profit, and value creation, allowing our customers in which we live and work to prosper.

We want to be careful and deliberate about developing Rocket PCB, from the platform we choose, to the way we approach it, to the methods we use.

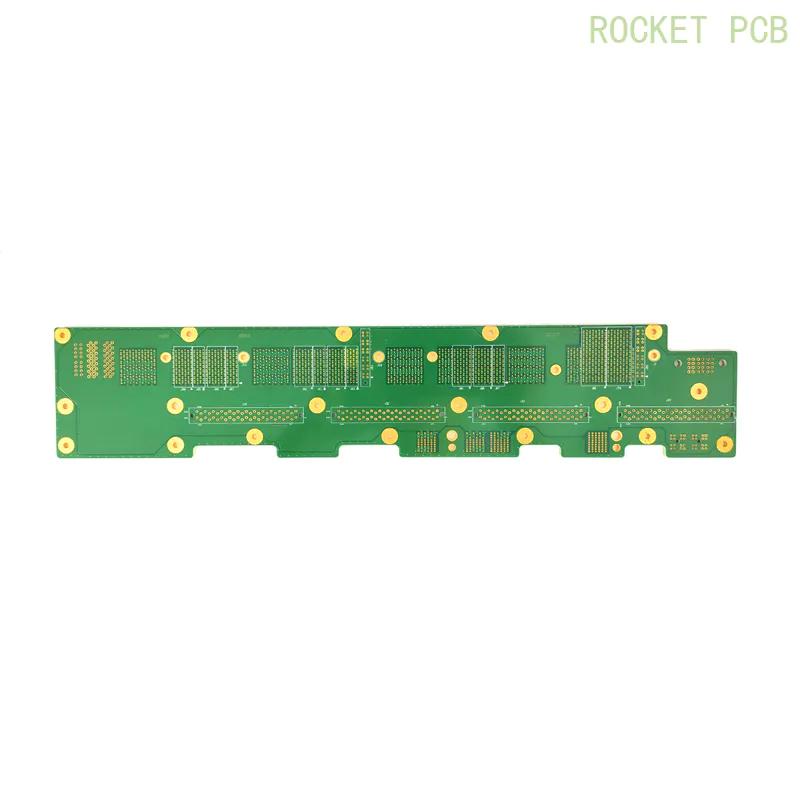

Rocket PCB Solution Ltd. manufactures pcb making service with innovative facilities and professional operation.

Innovative technology helped us produce a strong, reliable product as pcb making service for customers, offer superior quality and dependability to our customers, and scale at a quicker pace.

pcb manufacturing services are required in the manufacture of almost every product and pcb manufacturing services pcb making service is one of the most common machines.

As a result, consumers will reward Rocket PCB with leadership sales, profit, and value creation, allowing our customers in which we live and work to prosper.

We want to be careful and deliberate about developing Rocket PCB, from the platform we choose, to the way we approach it, to the methods we use.

Rocket PCB Solution Ltd. manufactures pcb making service with innovative facilities and professional operation.

Innovative technology helped us produce a strong, reliable product as pcb making service for customers, offer superior quality and dependability to our customers, and scale at a quicker pace.

Custom message