Eight kinds of surface treatment technology of PCB manufacturer

As for the human living environment asks is ceaseless rise, the PCB manufacturer is in manufacturing process involves the environmental problem is particularly prominent.

About lead and bromine is one of the hottest, utilizing and halide will influence the development of PCB circuit boards in many ways.

Although for now, the surface of PCB process changes and is not very big, still more distant things like, but should notice: long-term slow change will result in great changes.

In the case of environmental protection calls for more and more high, the surface of the PCB proofing process changes will happen in the future.

Surface treatment is to ensure that the basic purpose of good weldability or performance.

Due to the nature of copper in air tend to exist in the form of oxide, is unlikely to keep to the original copper for a long time, so you need to other copper processing.

While in the later assembly, strong flux can be used to remove most of the copper oxide, but strong flux itself is not easy to remove, so the industry generally don't use strong flux.

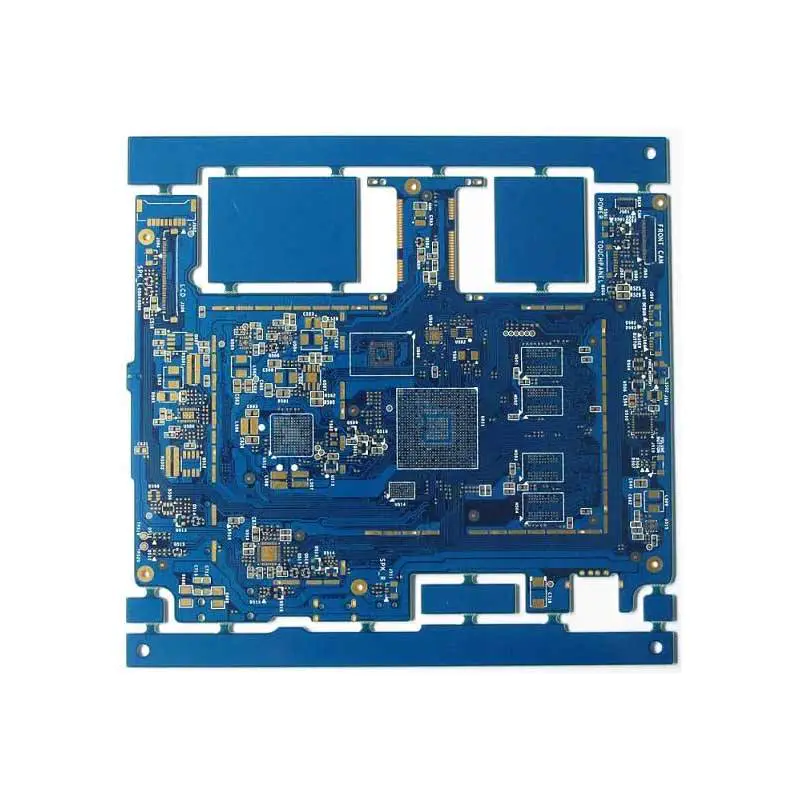

PCB manufacturers now have a lot of PCB surface treatment technology, the common is hot air leveling, organic coating, electroless nickel/immersion gold, immersion silver and tin the five kinds of craft, the following will introduce one by one.

1, hot air leveling (

Tin)

Hot air leveling and hot air solder leveling (

Commonly known as spray tin)

In PCB, which is coated on the surface of molten tin (

Lead)

Solder and heat of compressed air (

Blow)

Flat technology, make its form a layer of copper oxidation resistance, and can provide good weldability of the coating layer.

Hot the usual solder and copper in the junction between the copper and tin compounds.

PCB for hot blast the usual sinking in the molten solder;

The wind flat knife before solder solidification liquid solder;

Air knife can minimize the meniscus shape of the solder copper surface and prevent the solder bridge.

2, organic solderability protectants (

OSP)

OSP is printed circuit board (

PCB)

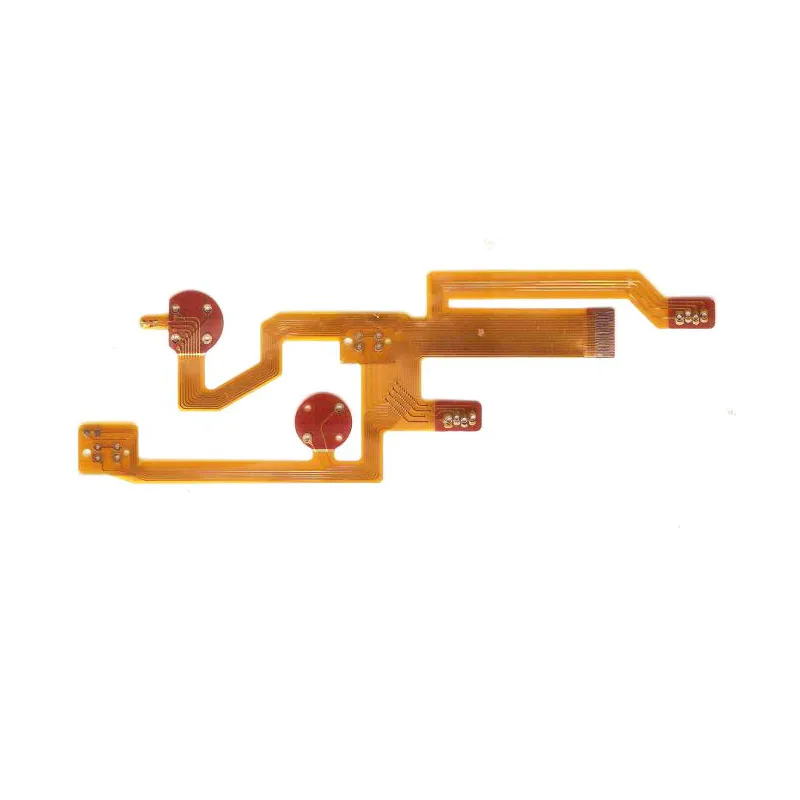

Copper foil surface treatment of a kind of technology to meet the requirements of RoHS directive.

Short for OSP is Organic Solderability Preservatives, translated into Organic shielded welding membrane, also called copper agent, English also called Preflux.

In a nutshell, OSP is on clean bare copper surface, a layer of organic chemical method to skin membrane.

Impact the membrane oxidation resistant, heat resistant, moisture resistant, to protect the copper surface in normal environment does not continue to rust,

Oxide or sulfide, etc. )

;

But in the subsequent welding heat, the protective film and must be quickly removed by flux easily, so just can make clean copper surface of the show is in a very short period of time with molten solder immediately become a solid solder joints.

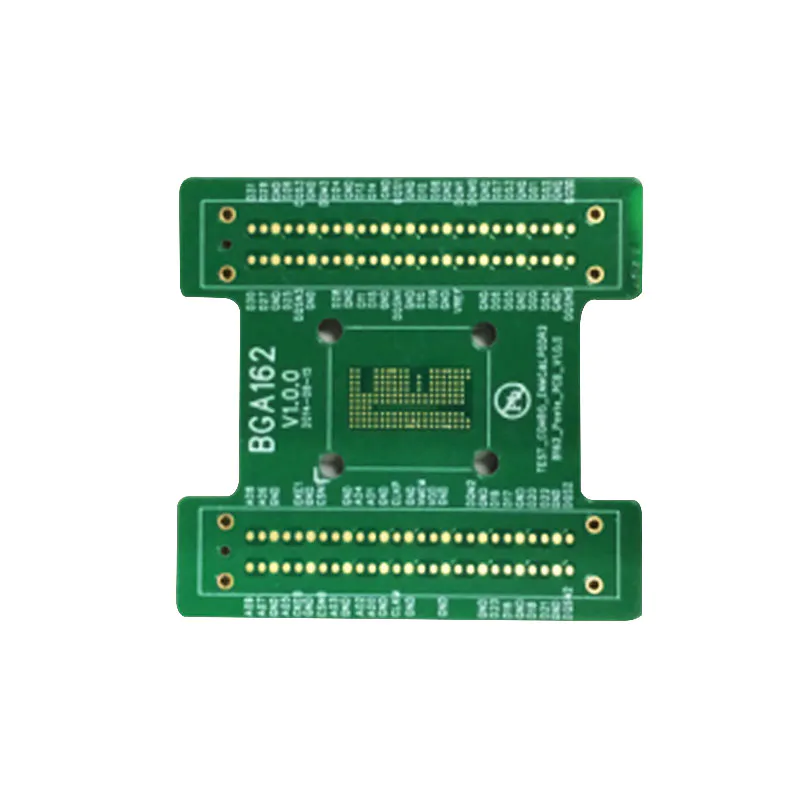

3, the whole plate nickel plating gold PCB plating nickel and gold is on the PCB surface conductor plating first again after a layer of nickel plated with a layer of gold and nickel plating is mainly to prevent the spread between the gold and copper.

Now there are two types of electroplating nickel gold: soft gold plating (

Pure gold, gold surface looks not bright)

And hard gold plating (

Surface is smooth and hard, wear-resisting, contain other elements such as cobalt, gold looks more light)

。

Soft gold play gold wire is mainly used in chip packaging;

Hard gold is mainly used in the welding place electrical interconnection.

4, zedoary zedoary is wrapped a thick layer of, on the surface of the copper electrical good nickel and gold alloy, it can be long-term protection PCB;

It also has other surface treatment does not have the patience to the environment.

In addition turmeric can also prevent the dissolution of copper, this will be beneficial to lead-free assembly.

5, heavy tin because now all is based on tin solder, so the tin can match with any type of solder.

Tin process between flat copper tin compounds can be formed, this feature makes heavy tin has like hot air leveling of good weldability and no hot air leveling flatness of headache problem;

Heavy tin plate cannot be stored for too long, the assembly must be according to the order of tin.

6, with heavy silver and silver process between organic coating and electroless nickel/heavy gold, the process is simple, rapid,

Even if exposure to the hot, wet and pollution of the environment, silver can still maintain good solderability, but will lose its luster.

Heavy silver does not have the chemical plating nickel/heavy gold have good physical strength because there is no nickel silver layer below.

7, chemical nickel, chemical nickel, palladium and palladium zedoary is compared between nickel and gold is much more a layer of palladium and palladium can prevent displacement reaction caused by corrosion phenomenon, fully prepared for the heavy gold drive.

Gold is tightly covered on palladium, provide a good interface.

8, hard gold plating in order to improve the product wear-resisting performance, increase the number of plug and hard gold plating.

As users demand more and more high, environment is becoming more and more strict, surface treatment technology is more and more, whether to choose the sort of promising, stronger commonality of surface treatment technology, it seems like a bit dazzling, uncertain.

PCB surface treatment technology in the future will go, now also can predict.

Anyway, to meet user requirements and environmental protection must first do it!

need huge investment, so it is important to shop with caution.

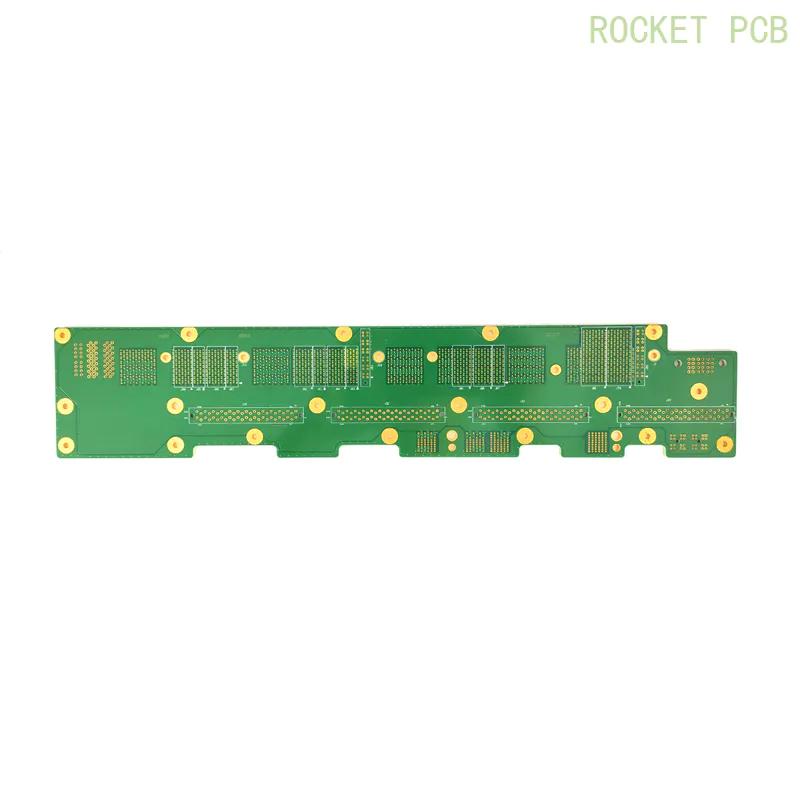

Rocket PCB Solution Ltd. is working with the best teams, aligned with international standards and practices to focus on R&D and manufacture of products, and are continuously launching new products in the market. Get to know us at Rocket PCB .

Along the way, Rocket PCB Solution Ltd. will face a wide range of challenges. The most successful will show our resolve by working through the challenges and finding ways to improve and grow.