Circuit boards & quot; Printing & quot;

by:Rocket PCB

2020-06-19

Movable type printing was one of the four great inventions in ancient China,.

First developed mud type used in the northern song dynasty.

Modern electronics as the core of printed circuit boards are named for 'printing' two words.

Between the ancient and modern invention of two what is the origin?

Used thought, wood carving, stone carving and printing is not very convenient at the time, then consider for each word moulding, movable type printing.

Because the mud type like pottery and porcelain is fragile, which greatly limits its application.

China's four great inventions of Mongolian cavalry later turn spread to Europe.

As a result, a German Gutenberg in the 15th century, developed the type printing.

Soon, the germans find themselves faced with a difficult problem, how to print picture?

Different from the Chinese preference for the wood and stone, the germans chose the copper plate.

Sculpture art, want to use the copperplate etching technique, which involves a series of fine chemical reaction.

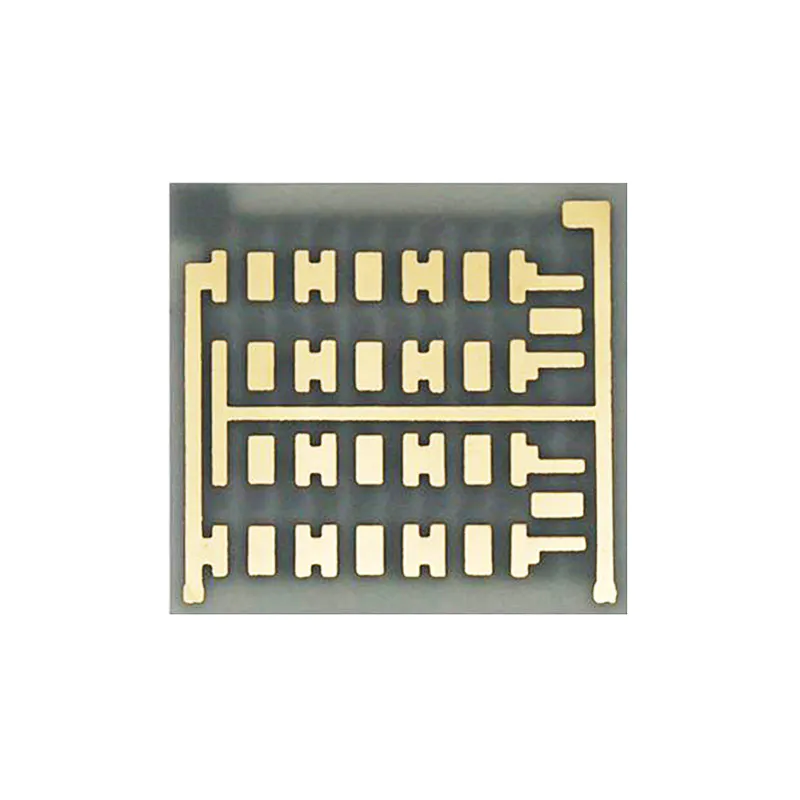

The first is made of photosensitive polymer film.

It was found that water soluble polymer materials such as animal glue, resin and dichromate solution mixed colloid have such properties of mixture, exposure partly soluble in water, not part of the exposure is not soluble in water.

This is because, dichromate is a kind of photosensitive material, after the glare, hexavalent chromium ion precipitation become soluble in water of trivalent chromium ions, so that the polymer and the material of chromate acid precipitation, after exposure is soluble in water.

Then put the sensitive glue under the condition of weak light coating on copper plate, drying, and the original film covering, to the sun.

So, on the copper plate surface is complex with a layer of good protective layer is designed according to the original.

Finally, the copper plate corrosion ferric chloride solution soak into the shadows.

Using copper and ferric iron ions is the principle of oxidation-reduction reaction, copper plate on exposure after slow corrosion by ferric chloride solution without cover part of the 'eat'.

One or two days later, remove the copper plate, dry cleaning, get the fine strokes, and mother of printing edition.

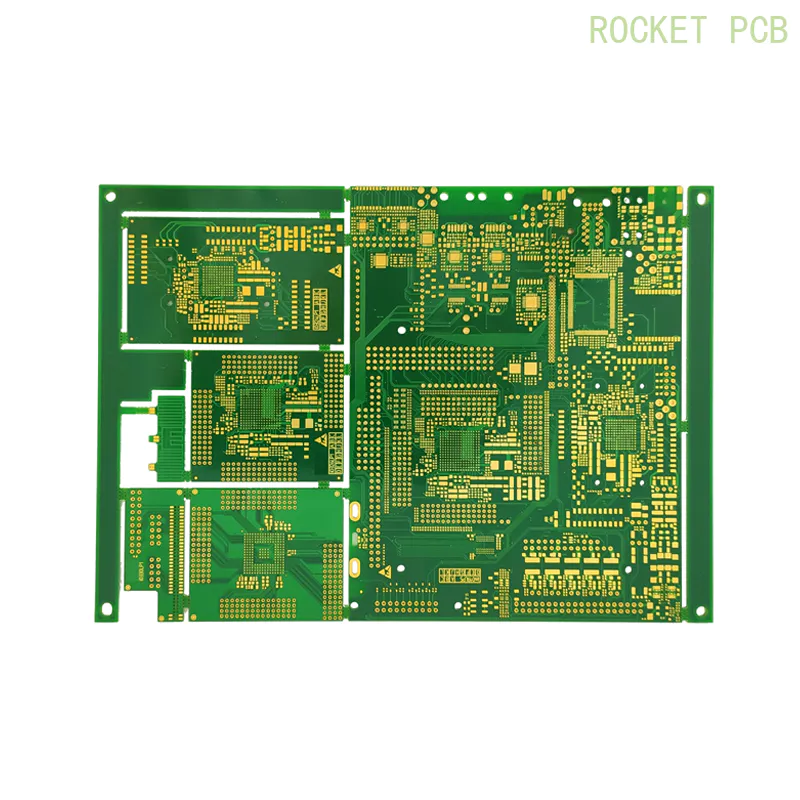

Engraving technique is so successful, and the corrosion of the modern printed circuit board production also have adopted similar corrosion technology, namely on the insulating substrate, apply the metal coating, coated with light-sensitive materials, according to the wiring diagram plate burning, corrosion, and then coated with a layer of protective film, finally to cut holes in the circuit board, is used for welding electronic components.

This circuit board, fine structure, high reliability, convenient for mass production.

With the progress of technology, printed circuit boards usually have now can do eight layer structure, fully automatic welding of drilling hole.

Between layer and layer of multilayer structure of hole have played an important role in connecting the electronic circuit, and so on the small board can achieve very complicated circuit.

Because until the end of the qing dynasty in our country is still popular wood and stone carving printing, although after the introduction of type printing and handwritten ink printing method, but soon directly into the laser typesetting era, there is no enough copperplate printing experience.

Copperplate printing was printed circuit board technology chip manufacturing technology of precursor, even in the field of electronics industry in our country, also should strive to forge ahead.

If you are looking for an effective and safe way to take care of pcb manufacturing services, then pcb making service pcb manufacturing services are the best bet.

Rocket PCB Solution Ltd. are dedicated to providing excellent underwriting and loss control advice up front, and to ensuring superior customer service through the life of the policy.

By investing in an ethical supply chain, Rocket PCB Solution Ltd. position ourselves to engage with a driven, engaged customer base.

If you are looking for an effective and safe way to take care of pcb manufacturing services, then pcb making service pcb manufacturing services are the best bet.

Rocket PCB Solution Ltd. are dedicated to providing excellent underwriting and loss control advice up front, and to ensuring superior customer service through the life of the policy.

By investing in an ethical supply chain, Rocket PCB Solution Ltd. position ourselves to engage with a driven, engaged customer base.

Custom message