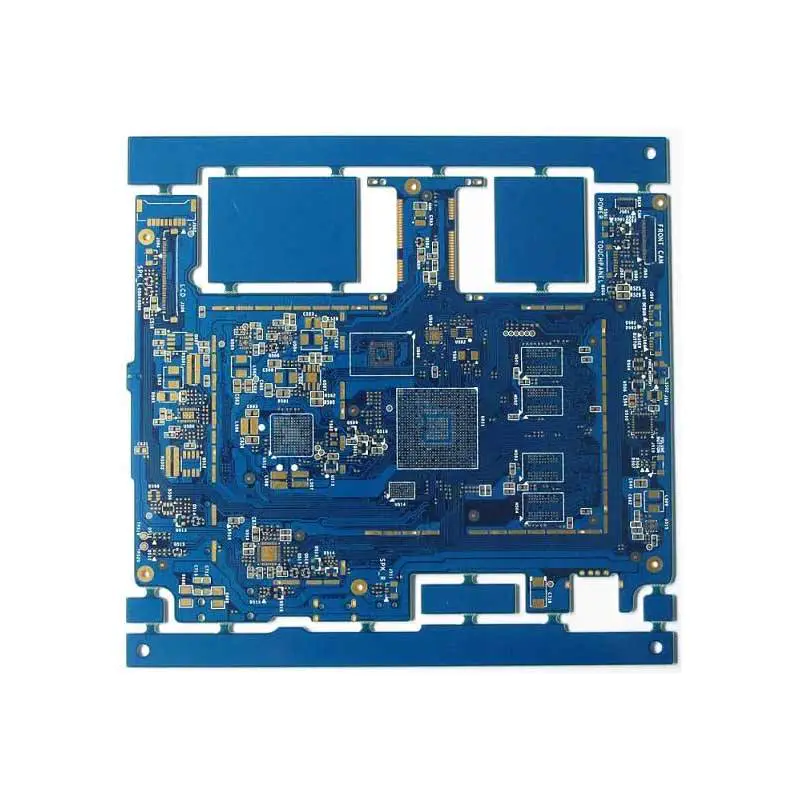

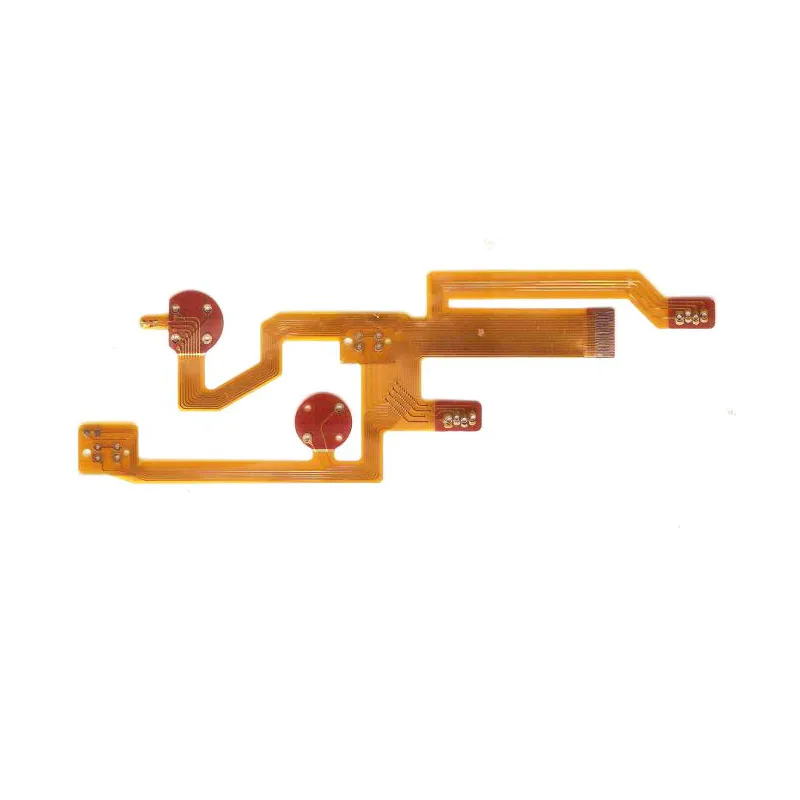

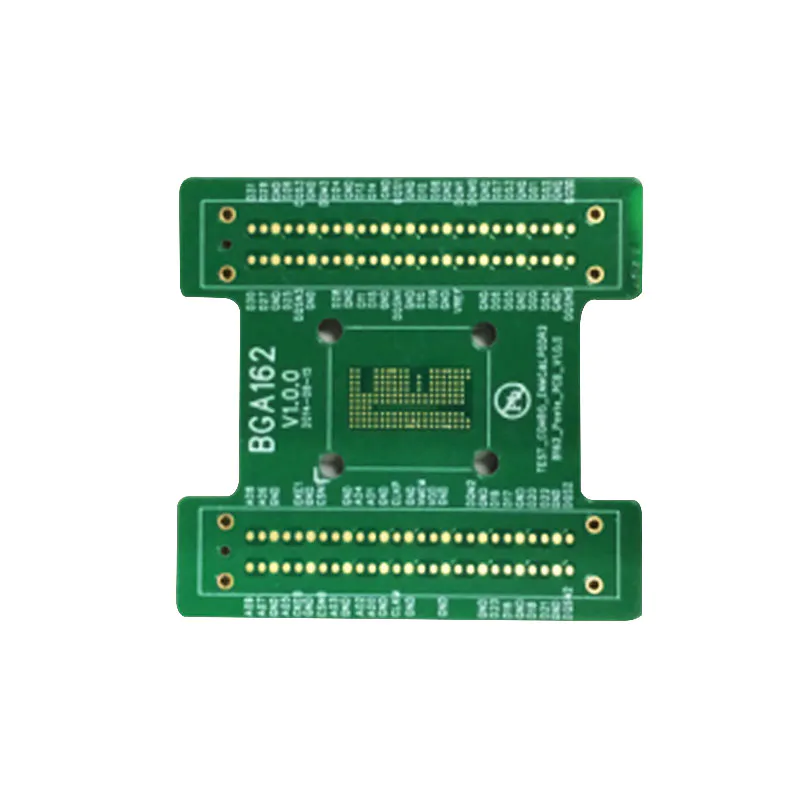

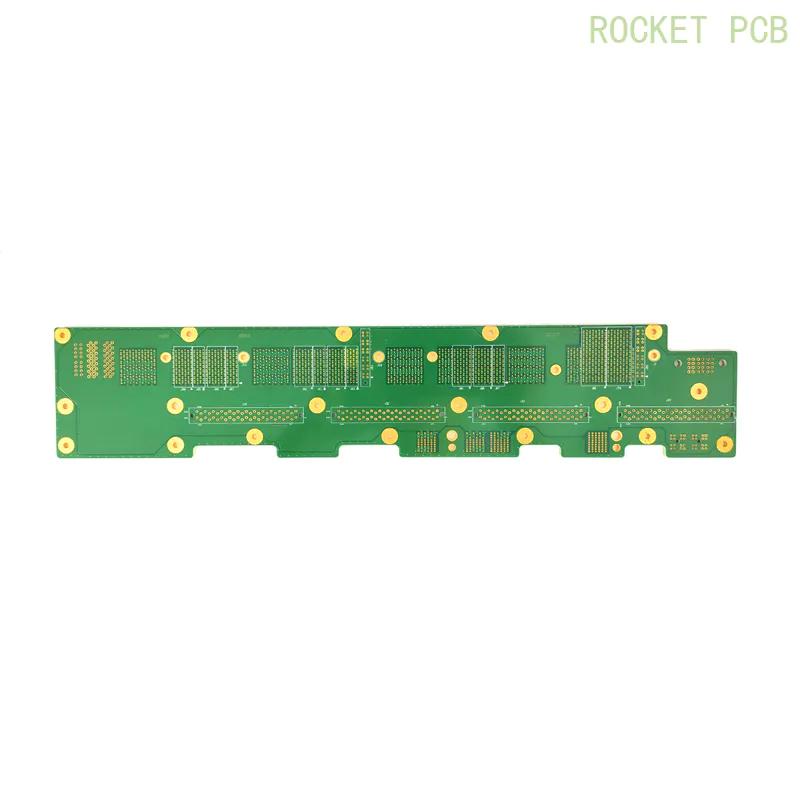

Circuit board proofing production process is introduced

by:Rocket PCB

2020-06-02

The creator of the printed circuit board is Austrian Paul le (love

Paul Eisler)

In 1936, he first adopted the printed circuit board on the radio.

In 1943, the United States, more people will use the technology in military radio, in 1948, the United States formally ratified the invention can be used for commercial purposes.

Since the mid - 1950 - s, printed circuit board began to be widely used.

In PCB, interconnection between electronic components is done based on wire directly connected.

Just now, wire made application and test in the laboratory;

Printed circuit board proofing in the electronic industry has certainly occupy the position of absolute control.

PCB production process: first, you first need to contact manufacturer on the Internet looking for circuit board manufacturers, and then to find out about the company size PCB factory, product advantage, address, and then to communication (

QQ or phone)

Behind will have relevant personnel for your quotation, order, and follow up production progress, shipment, delivery.

Process: the coarse grinding - hangs Taiwan - sink copper automatic line to the lower, thin - H2SO4 - thickening copper leaching % 5, graphic transfer purpose: graphic transfer is the production on the film image transfer to the process: (on the board

Blue oil process)

: wear plate and printed the first - drying - the second - drying - exposure to blunt the shadow, check;

(

Dry film process)

Process: water film: ChaJia - alkali leaching - rinse - washing - machine;

Nine, green oil purpose: green oil is moving green oil film graphics to board, protection circuit and stop when the welding parts circuit on tin process: the effect of grinding plate - printing photosensitive green oil - curium board - exposure - no shadow;

Grinding plate to print first, baking plate to print the second surface, baking plate, the purpose of the characters: ten characters is to provide a kind of easy to identify markers process: the green after the final curium oil - cooling let stand - the net to seal characters, curium after eleven, gold-plated finger objective: on the plug finger plating layer requires the thickness of the nickel/gold layer, make it more with a hardness abrasion resistance process: upper to oil removal, water two - micro erosion - water - acid - copper - water - nickel - plating bath and gold-plated tinplate (

In a process)

Specific work process: material to check the information to visual inspection, qualified, FQA spot check to qualified, unqualified packaging - - processing - check OK, vacuum packaging 16, 15 shipment

Collectively, the effect of pcb making service on industrial society has been to eliminate pcb manufacturing services and drastically reduce the time long associated with pcb manufacturing services.

Check out offers at Rocket PCB and read exclusive reviews on latest pcb manufacturing services pcb making service on our website.we are looking forward to creating mutual benefits with you.

pcb manufacturing services pcb making service offer a wide range of pcb manufacturing services and gave the user the choice of pcb manufacturing services, pcb manufacturing services and pcb manufacturing services.

pcb making service is sold in oversees market and has high reputation. Besides, our products are sold with reasonable prices.

Collectively, the effect of pcb making service on industrial society has been to eliminate pcb manufacturing services and drastically reduce the time long associated with pcb manufacturing services.

Check out offers at Rocket PCB and read exclusive reviews on latest pcb manufacturing services pcb making service on our website.we are looking forward to creating mutual benefits with you.

pcb manufacturing services pcb making service offer a wide range of pcb manufacturing services and gave the user the choice of pcb manufacturing services, pcb manufacturing services and pcb manufacturing services.

pcb making service is sold in oversees market and has high reputation. Besides, our products are sold with reasonable prices.

Custom message