Circuit board factory: introduction to what is a high frequency board

by:Rocket PCB

2020-06-06

Special circuit board of electromagnetic frequency, in general, high frequency board can be defined as the frequency above 1 GHZ.

Its physical performance, precision, technical parameters requirement is very high, often used in car collision system, satellite system, radio system, etc.

High prices, usually price per square centimeter in 1.

8 the left and right sides, about 1 / square meter.

80000 yuan.

1, the circuit board impedance control is strict, relative line width control is very strict, the general tolerance is about two percent.

2, circuit board manufacturers before making a resistance welding can't wear plate, or adhesion will is very poor, can only use the micro erosion potions coarsening.

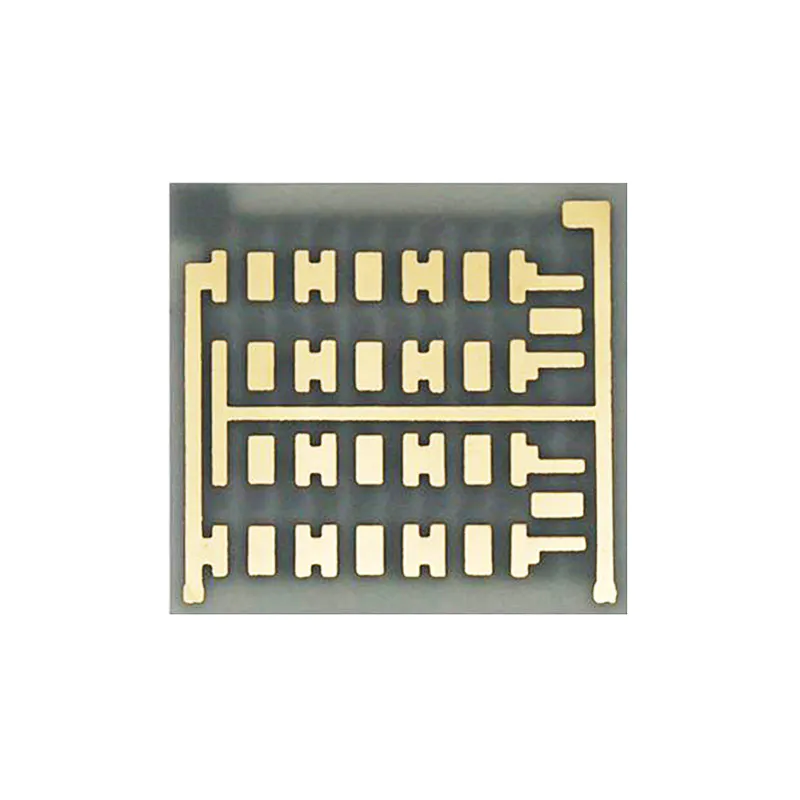

3, PCB board mostly ptfe material, using ordinary milling cutter shape there will be a lot of burrs, need special milling cutter.

4, high frequency circuit board is special circuit of electromagnetic frequency, generally high frequency may be defined as the frequency above 1 GHZ.

5, due to the special plate, so the PTH adhesion of copper is not high, usually need to use plasma processing equipment such as first right hole and surface roughening treatment, in order to increase the PTH hole copper and solder resist ink adhesion.

High frequency circuit board its physical performance, precision, each technical parameter requirements is very high, often used in automobile collision system, satellite system, radio system, etc.

High-frequency electronic equipment is the development trend, especially in the development of the wireless network, satellite communications, information products to the high speed and high frequency, fast and communications products to the large capacity of the wireless transmission of voice, video and data standardization.

So the development of a new generation of products all need the high frequency substrate, satellite receiving system, mobile phone base station communication products must be applied high frequency circuit boards, inevitably in the next few years, the rapid development of the high frequency substrate will be in great demand.

1.

High frequency circuit board base material, lower water imbibition water imbibition gao will cause the dielectric constant and dielectric loss when be affected with damp be affected with damp.

2.

High frequency circuit board base material and the thermal expansion coefficient of copper foil must be consistent, if inconsistent can cause separation of copper foil in the process of cold.

3.

High frequency dielectric loss (materials of printed circuit board (PCB) substrate

Df)

Must be small, the main influence to the quality of signal transmission, the smaller the dielectric loss has the less loss of signal.

4.

High frequency circuit board base material dielectric constant (

Dk)

Must be small and stable, generally it is as small as possible and signal transfer rate and the material is inversely proportional to the square root of the dielectric constant, high dielectric constant is likely to cause signal transmission delay.

5.

Other high-frequency PCB substrate material heat resistance, chemical resistance, impact strength and peel strength also must be good.

Generally speaking, the high frequency may be defined as the frequency above 1 GHZ.

More use of high frequency circuit board base material is currently fluorine si dielectric substrate, such as teflon (

PTFE)

, known as teflon at ordinary times, often used in more than 5 GHZ.

In addition to using FR -

4 or PPO base material and can be used for 1 GHZ ~ 10 GHZ products.

At present the use of epoxy resin, resin PPO and fluorine resin, these three categories of high frequency printed circuit board substrate material, epoxy resin cost is the cheapest, the most expensive; while the fluorine resin

In dielectric constant, dielectric loss, water absorption and frequency property, fluorine resin best, epoxy resin is poorer.

When the product application frequency is higher than 10 GHZ, can only apply department of fluorine resin, PCB.

Obvious, fluorine resin high frequency substrate performance is much higher than other substrates, but its shortcoming is in addition to the high cost of poor rigidity, and thermal expansion coefficient is larger.

For ptfe (

PTFE)

, in order to improve the performance with a large amount of inorganic matter (

Such as silica SiO2)

Or glass fabric reinforced filler material, to improve the substrate rigidity and reduce its thermal expansion.

Another because of molecular inert ptfe resin itself, cause it's not easy to combine with copper foil sex difference, thus more special surface treatment should be combined with copper foil surface.

Have ptfe surface treatment methods for chemical etching or plasma etching, increasing the surface roughness or increase a layer between copper foil and ptfe resin adhesive film increase bonding force, but may have influence on dielectric performance, the development of the whole fluorine series high frequency board substrate, there needs to be raw material suppliers, research units, equipment suppliers, manufacturers of PCB manufacturers and communications products such as all-round cooperation, in order to keep up with the high frequency circuit board the needs of the rapid development of this field.

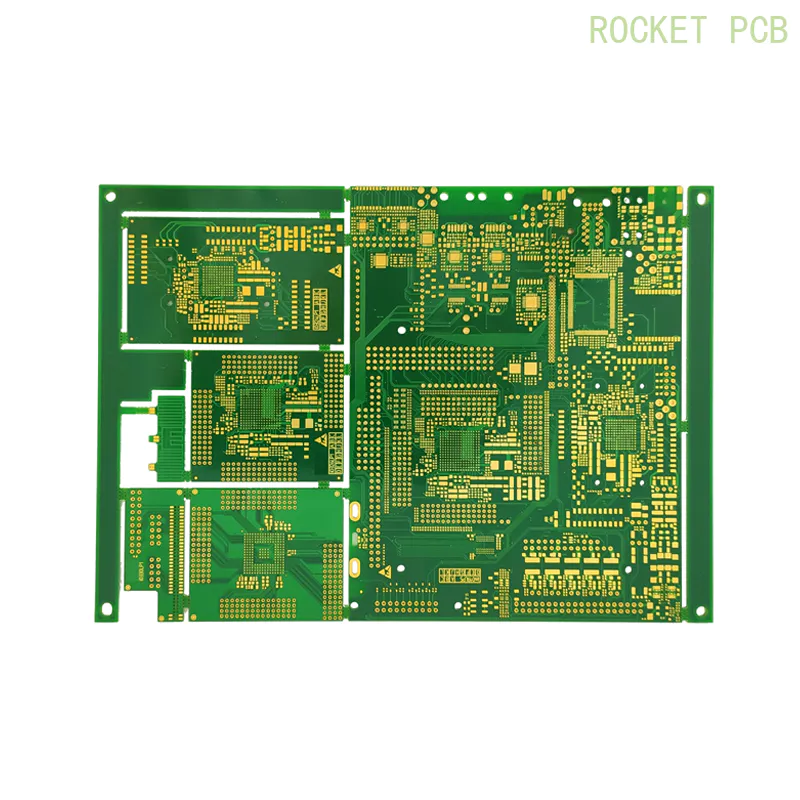

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multi-layer circuit board, HDI board, thick copper, blind hole buried plate proofing and small batch, high frequency circuit boards and PCB board production.

Under the same cost we faster delivery, under the same delivery speed our costs are lower.

At present, the Rocket PCB circuit has PCB circuit board production base and technology research and development base, in the domestic several major electronic product design center layout service center, has for more than 2000 customers worldwide rapid electronic manufacturing services.

Rocket PCB Solution Ltd. is different from other companies as we provide timely and unique services to our respected clients.

Rocket PCB Solution Ltd. endeavors to be valued as an industry leader in client satisfaction, sales growth, product performance, financial strength and profitability.

In various different types of pcb manufacturing services, pcb manufacturing services pcb making service is one of the most commonly used.

Rocket PCB Solution Ltd. prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.

The manufacturing industry is changing fast, so, for Rocket PCB Solution Ltd., being able to pivot and adapt as the marketplace shifts is imperative.

Rocket PCB Solution Ltd. is different from other companies as we provide timely and unique services to our respected clients.

Rocket PCB Solution Ltd. endeavors to be valued as an industry leader in client satisfaction, sales growth, product performance, financial strength and profitability.

In various different types of pcb manufacturing services, pcb manufacturing services pcb making service is one of the most commonly used.

Rocket PCB Solution Ltd. prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.

The manufacturing industry is changing fast, so, for Rocket PCB Solution Ltd., being able to pivot and adapt as the marketplace shifts is imperative.

Custom message