china in charge: the 2014 ranking of the largest board fabricators reveals quiet but steady growth by domestic chinese companies.

by:Rocket PCB

2019-09-11

Among all PCB manufacturers in 2014, the winner of revenue growth was the manufacturer of flexible circuits made for Apple\'s iphone, in addition to profits.

Despite the slowdown in smartphone shipments, they continued to perform well in 2015.

The loser is the South Korean flex manufacturer that serves Samsung Electronics.

In terms of the number of entries, China became the first

The world\'s largest manufacturers are more than 100 in Taiwan and Japan.

In terms of total output, Taiwan remains in the lead position and will continue to be in the lead over the next few years.

Overall, 99 printed circuit board manufacturers generated at least $100 million in revenue from the calendar uein 2014.

2015 will see different pictures. The TTM-

From May 31, 2015, the merger of Viasystems will push the new TTM ranking up.

Amphenol purchased Invotec and will be on the list on 2015.

Several Chinese manufacturers are poised to emerge. We shall see.

Every year, data collection becomes more challenging, and this year is no exception because many companies from China will be NTI-100.

The data from CPCA is very helpful but also flawed.

Although the author knows written Chinese, many Chinese manufacturers have multiple manufacturing locations under different names, which requires in-depth investigation.

In order to determine the revenue of a manufacturer, it takes a few days, sometimes a few days of in-depth investigation.

Despite these efforts, the author is not entirely satisfied with the results.

However, a perfect list is not possible because there are too many factors affecting the outcome.

The final judgment is left to the reader.

As usual, the author is fully responsible for any errors that may exist.

Thank you very much for your comments.

He thanked pcbfabric, TPCA and CPCA for their valuable help.

As in the past, several points should be observed when collecting data. 1.

The exchange rate of major currencies.

Except for the yen, the exchange rate changed very little from 2013 to 2014.

The yen traded at an average of 107 yen/dollar against the dollar, down to 1 million yen/USDin 2013.

The yen appears to have further depreciated to 120 to 125 yen/USD 2015.

Exchange rate is one of the variance factors.

For example, 57-58% of \"Taiwan\" production occurred in China.

PCB manufacturers convert their production in China to NT dollars to come up with \"integrated\" production, which the authors then convert to US dollars.

This is true for all companies that produce pcb overseas.

Readers are advised to explain the data accordingly.

In order to see the growth rate of each manufacturer, the exchange rate of 2013 is used to convert the income of 2014 into US dollars.

Therefore, the revenue figures of individual companies listed in NTI this year

The ranking of 100 will be slightly different from that of 2013. Beware.

Japanese manufacturing output fell 7%in US dollars)

Due to exchange rate fluctuations, the conversion at 2014. 2.

As we all know, the flexible circuit sales of Apple 100% are assembled circuit boards.

As a result, sales to Apple by large FPC manufacturers include considerable assembly value.

Separating assembly value from total revenue often results in errors and sometimes larger ones.

Therefore, the author did not attempt to separate the assembly from the total revenue.

In addition, more rigid board manufacturers are participating in the assembly, including Compeq, Shennan Circuit, Multek, TTM technology (

Back panel components), Viasystems (system-levelassembly), etc.

When the value of the rigid board assembly is clearly indicated, these revenues will be subtracted from the total amount.

Otherwise, Assembly values are part of the data.

Therefore, unfortunately, the income is more likely to be \"apple and orange \".

The author will be happy to answer any questions. 3.

The comments in the form are written based on the author\'s knowledge of the manufacturer, but there may also be errors.

No offense to the manufacturer on the list. 4.

Several Chinese manufacturers have earned nearly $100 million in revenue in 2014 years.

Some of them may be on the list for next year;

Therefore, it is expected that the number of Chinese companies entering the next few years will increase.

Manufacturers with previously unknown revenues of more than $100 million may also have \'discovered \".

Please let him know if you know.

As mentioned earlier, Amphenol will be on the list in the future.

France\'s Elvia is close to $100 million.

Analysis Table 1 shows NTI-100 list.

Table 2 is a summary of the contents of table 3.

Despite the declining domestic production in Japan, the number of top manufacturers registered was 25.

Growth in 2014 was 6%, mainly for flexible manufacturers supplying Apple, mainly overseas growth. Thefour-time No.

Japanese company Mektron produces 85% of its overseas products.

Sumitomo Denko printing circuit production in China exceeds 50%.

Fujikura\'s production in Thailand and Vietnam is close to 90%.

Taiwan\'s production in China accounts for 57-58% of Taiwan\'s total output.

Thailand has made a few percent.

As a result, its domestic output is about 40%.

The poor performance of most South Korean manufacturers stems from the reduction in Samsung orders in 2014.

Flex, in particular, was hit hard.

Several South Korean flex manufacturers are said to have defaulted.

However, 2015 of the situation seems to be improving.

In terms of the number of entries, China is very strong, with 29 out of a total of 99 companies leading Taiwan and Japan, although the total revenue share of these 29 companies is far less than the largest manufacturers in Taiwan and Japan ---yet.

It is estimated that the world total PCB production in 2014 was $60 billion. Taiwan is 31 years old.

3% share, followed by 22% in Japan and 14 in South Korea. 6%.

These percentages are consistent with the \"highest share\" percentage (by country)shown.

There are about 2,400 PCB manufacturers in the world, operating about 2,700 to 2,800 factories.

There are about 1,200 manufacturers and about 1,600 factories in China.

The top 99 manufacturers account for 4% of the total (99/2,400)

Accounting for 85% of the world\'s total production (

$51. 365 trillion/$60. 03 billion)(FIGURE 1).

The author is very positive if we consider 240 manufacturers (10% of the total)

Their output accounts for 95% of the total output.

The usual 20: 80 rule does not apply in the pcb industry.

As mentioned earlier, the flex manufacturer that provides Apple with the assembly of tablets has received the greatest benefit, with one exception being MFlex.

MFlex seems to reduce its reliance on Apple.

Mektron in Japan, Sumitomo Denko and fujikura in Japan, flexding Technology in Taiwan, Flexium and career are considered to be Apple\'s main flex suppliers.

They have grown far more than the total.

NTI has achieved 66%100.

2015 will be a repetition of this pattern.

In the past few years, Japan\'s Mektron has been very dependent on Apple.

Apple orders are driving its growth.

While Apple still serves Apple well, it seems the company is trying to diversify.

These efforts were reflected in the booth at the JPCA show by niponmektron.

$0. 195 billion investment in niponmektron (

Exchange rate is 107 yen/USD)infiscal 2014.

The current fiscalyear is expected to cost $0. 22 billion, a significant portion of which is said to be for domestic upgrades.

Its production of 2015 is likely to reach $3.

8 billion yen/USD, about $107.

4 billion yen/USD, 120.

Most likely, the Japanese Mektron will keep No.

1 position in 2015. SEMCO (

Samsung Electric Machinery Co. , Ltd. )

According to rumors, it is expected that SEMCO will close the IC substrate operation of its Chochuwon plant and transfer production to Busan, South Korea, which may become a central part of the operation of the semco ic substrate.

Rigid HDI microvia board includedflex boards (

Rigid more than 90%

Flexible plate with micro-guide structure)

It is possible to transfer to Kunshan, China and build a factory in Vietnam.

The author made these comments in speculation. Take heed. ZDT (

Technology)

It may be Apple\'s second-largest flexsupplier supplier after Japan\'s Mektron.

In response to the order that Apple added to the next iPhone model using the forced touch panel (iPhone6S)

ZDT and Flexium technologies are said to be investing in a massive expansion of sumstoward\'s capacity.

It is reported that the market capacity of Flexium has tripled in fiscal 2016.

Wus completed the Kunshan factory built in 1993 (

The land was absorbed by the Kunshan government)

Also at the newQingsong factory in Kunshan, actually right next door to the Nanya PCB, along the old canal leading to the center of Beijing.

Wus group has a factory in Kaohsiung, Taiwan, and two factories in Kunshan (

An old one for automotive PCB)

There is a factory in Huangxi

Yongbang group consists of four PCB manufacturing subsidiaries of Korea circuit, Telani, Interflex and Yongbang electronics.

Interflex and type did not perform well in 2014.

The South Korean tour and Terranix did not perform badly.

Samsung Electronics is their main customer, the same as most large manufacturers in South Korea.

Ibiden had a problem getting orders from Apple\'s new Malaysian factory.

But it did get new orders at the end of the year, and the profit was not that bad. Its flip-

The chip substrate business forMPU continues to be flat or even down due to poor performance and increasingly fierce price competition in the PC sector.

However, revenue in the industry has been driven by flip-

Chip CSPs for wireless devices.

Investing $0. 37 billion will boost Ibiden\'s revenue as it appears to have taken orders from Apple in Malaysia.

Investment in fiscal 2015 is expected to be around $0. 215 billion.

Total investment in PCBs by major Japanese companies in the current fiscal year is estimated at about $1. 2billion to $1.

3 billion, mainly for their overseas factories.

The hottest topic of the year may be the merger of TTM technology and the Viasystems Group.

By simply increasing the revenue of the two companies will be close to $2.

63 billion, of which about $2.

An estimated 4 billion are sold on bare metal.

Given the great value of lex assembly in Japan Mektron and ZDT, \"new\" TTM will not.

Ranked first in the world in bare metal sales.

From 1996 to today, the progress of TTM is remarkable.

In 2000, sanmina became the world\'s largest manufacturer for $1.

Revenue was $55 billion and Viasystems ranked second at $1. 25 billion.

Daeduck Group by Daeduck Electronics (high-layer-

MLBand count for IC substrate)

And Daeduck GDS (FPC, rigid-

Flexible and HDI microviaboards).

Despite the decline in income, profits are still good.

Daeduck is very cautious about the new investment.

South Asia PCB did a good job in 2014.

The author speculated that Nanya PCB performed well on the IC substrate.

Compeq completed the first phase of its Chongqing plant in July2014 and continued to expand the first phase before starting the second phase of construction.

The revenue contribution of the Dongqing factory in 2014 is small, but it will upgrade Compeq in 2015.

PSA PCB Group (

Passive System Alliance)

The drawing board is set up by Hanyu color crystal, and the Great Bauhinia Xun Xian. (

The two are the same presidents. )

HannStar Board has a plantin Taiwan and six in the \"Jiangyin campus\" in northern Wuxi, China.

There are four factories in GBM: GBM Arts (Shenzhen), CMK-GBM(Dongguang)Yuangmao, sage of Great Bauhinia (Kunshan)

Chongqing Chuangyi and GBM (Chongqing).

Hanxing\'s board of directors accounts for about 70% of total revenue. KG PCB Group (

Gold Board chemical PCB)

By Elec & Eltek (

Kaiping, Nanjing, Yangzhou, great city, Thailand, Guangzhou),Techwise (

Huiyang, Foshan)

Jiangmen glory faith (Jiangmen)

, TopFaith, Evertek (Kunshan)

And fast circuit (

Changshu, Dongguang, Qingyuan).

More than 50% of revenue seems to come from Elec & Eltek.

KB chemical owns a stake in some other PCB manufacturers in China, but it is not large enough to integrate.

AT&T continues to do a good job.

Its HDI microvia plant in Shanghai contributed 55% of its revenue.

The new Chongqing plant is undergoing a qualification review and is expected to begin delivery of ic substrates in early 2016.

Income of $1 billion may not be realized.

Meizi\'s revenue growth is good, but because of the high manufacturing cost, the profit has not increased, compared with the Chinese factory, its contribution in Vietnam is very small.

US high is expanding its business in Vietnam this year (

Part of the problem was the fire in 2013)

Do your best to reduce the manufacturing cost of all factories.

There is no panqin industry.

Became a Automotive PCB manufacturer in 2014, followed by CMK, Meiko, Viasystems, Nippon Mektron and KCE Electronics in Thailand.

Pan Qin, through his subsidiaries (

Consolidated Report of delaco PCB not part of Pan Chin)

KCE has completed a large number of PCB factories for automotive PCB manufacturing in Thailand.

In 2014, the automotive PCB market was about $5 billion, accounting for 8% of global PCB production.

The growth of the automotive PCB market is not as dramatic as the smartphone, but unlike the latter, its seasonality is relatively small, growing steadily by 5-6% per year.

Over the past few years, we have heard about the sharp rise in wages in China, labor shortages, stricter environmental regulations, and other adverse conditions facing manufacturing.

Nevertheless, investment in China remains strong. In 2013-

14. It is estimated to have twice the capacity.

Side panels and multi-board boards rose by about 3. 5% inChina.

This may sound small, but consider 3.

Estimated 5% [0. 2 billion]m. sup. 2](

Current capacity in China)is 7 million[m. sup. 2]

Or nearly 600,000 [m. sup. 2]per month!

Expansion continues.

We may want to know where the market is.

Taiwanese transplant and halffrom Chinese manufacturers account for half of the expansion in China: Compeq (Chongqing), GBM (Chongqing), Unimicron(Huangxi), Wus (

Kunshan, Huangxi), ZDT (

Shenzhen, Huai\'an, Yinkou, Tsinghua Road), Palwon (Suzhou), TPT (

Chengdu and Wuxi), and Tripod(Xiantao)

Several names from Taiwan.

APCB is looking for land for a second plant near Kunshan.

Unitech bought land in Nantong. (

Of course, there is more that the author does not know. )

Chinese manufacturers are not dormant.

Deep South Circuit (SCC)

A large factory consisting of four buildings was built in Wuxi, one of which was used for ICsubstrates (

Recently inaugurated).

Shenzhen Suntech built the first large building in its Jiangmen campus and started work the next day. (

There will be three buildings in total. )

Olympic plans to build the fourth building opposite Heshan\'s existing factory.

Shenzhen Express India has built a huge factory in Yixing, south of Wuxi.

SZ Fast Print purchased eXeptionCircuits in the UK and Multitest, a former port electronics, in San Jose.

Shenzhen Boming electronics has set up a large factory in Dafeng, north of Suzhou.

After setting up a large factory in Jiangxi, Jin Wang is growing rapidly.

The red board expands the factory in Jiangxi.

KDS in Beijing has built a new factory in Wuhan.

These are the tip of the iceberg.

India and Brazil have always been the lips of PCB manufacturers, but as far as the authors know, there is no significant foreign investment.

Southeast Asia is definitely the next place after China, but joint investment in Southeast Asia is negligible compared with China.

In response to rising wages and labor shortages, China\'s PCB factories are automating.

The author has seen many robots for autonomous driving.

Plated racks and AOI.

AVI is replacing carriers.

Whether successful or not, China will dominate PCB manufacturing in the foreseeable future.

Figure 2 is interesting.

Taiwan\'s production in China continues to increase, but its share is falling, although only a small part.

A few years ago, the author predicted that Taiwan\'s share of China would exceed 50%.

He does not know that Chinese manufacturers are quietly rising.

Some Chinese manufacturers have the same level of technology as Taiwan, Japan and the West.

By the way, readers may want to know the Million Group Holdings (89), 3Win Group (90)

And Ji an mankun (97).

The author knows nothing about these.

He learned about them by chance.

Million Group Holdings (

Chinese name spelling [:

Text that cannot be copied in ASCII])

Consists of four entities :(

Xiongyu Electronic Technology), (

Tai \'an electronic Tai Ya Wan electronic), (

Huang Yu Huaguang), and (

Da Ya Ba Xiongyu technology.

It was not until an old acquaintance sent an email containing therevenue that the author knew about the companies.

The author happened to understand Chinese characters and was able to conduct an investigation. 3Win Group (

Tongyin Technology Group)

It consists of nearly half of its subsidiaries.

From the name of the subsidiary that is spelled Chinese, there seems to be four or five PCB factories.

Under the guidance of the author\'s FPC factory (

Flexible circuit board)

It is located in Doumen, Zhuhai, between Meike TEC Longshan factory and Fangzheng technology.

Other business units listed include Shenzhen Tongyin industry, Shenzhen Tongxin circuit electronics, Zhuhai Tongyin electronics, Jiangsu Tongxin electronic technology, etc.

The organization also seems to have aluminum-acid plants in Jiangxi province.

Ji \'an mankun has four PCB divisions: Shenzhen mankun electronics Ji \'an mankun technology mankun electronics (Huizhou)and HTD Group (Hong Kong)Ltd.

There are more such Chinese manufacturers.

Now you can understand why there are 1,200 PCB manufacturers operating 600 factories in China.

Dealing with fab stores in China is becoming more challenging every year. DR.

Zhongyuan Hao Yao is president of the state. T. Information; nakanti@yahoo. com.

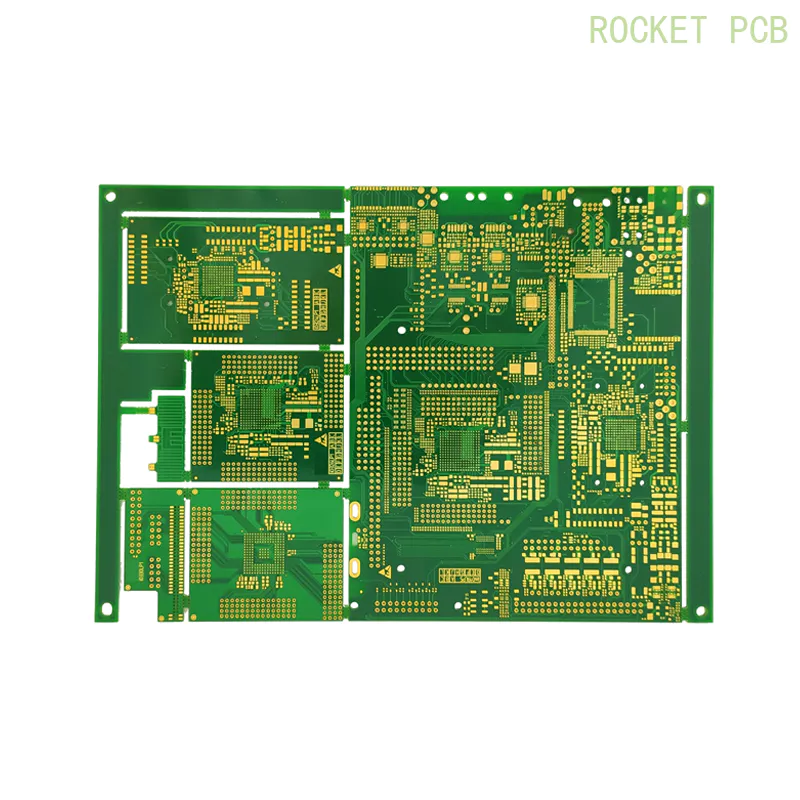

When you find yourself in need of printed circuit board company , you may not know where to begin. And that's OK! Search out Rocket PCB Solution Ltd. to handle your pcb pool needs.

The best for is one that works best for your needs and what you can support in your home. Among Rocket PCB Solution Ltd.'s diversified list of products at different price ranges, you will surely find your one with high quality. make your choice at Rocket PCB Solution!

The lower cost of single sided printed circuit board, compared to other product, and Rocket PCB Solution Ltd.’s services provide may well suit the needs for customers.

Despite the slowdown in smartphone shipments, they continued to perform well in 2015.

The loser is the South Korean flex manufacturer that serves Samsung Electronics.

In terms of the number of entries, China became the first

The world\'s largest manufacturers are more than 100 in Taiwan and Japan.

In terms of total output, Taiwan remains in the lead position and will continue to be in the lead over the next few years.

Overall, 99 printed circuit board manufacturers generated at least $100 million in revenue from the calendar uein 2014.

2015 will see different pictures. The TTM-

From May 31, 2015, the merger of Viasystems will push the new TTM ranking up.

Amphenol purchased Invotec and will be on the list on 2015.

Several Chinese manufacturers are poised to emerge. We shall see.

Every year, data collection becomes more challenging, and this year is no exception because many companies from China will be NTI-100.

The data from CPCA is very helpful but also flawed.

Although the author knows written Chinese, many Chinese manufacturers have multiple manufacturing locations under different names, which requires in-depth investigation.

In order to determine the revenue of a manufacturer, it takes a few days, sometimes a few days of in-depth investigation.

Despite these efforts, the author is not entirely satisfied with the results.

However, a perfect list is not possible because there are too many factors affecting the outcome.

The final judgment is left to the reader.

As usual, the author is fully responsible for any errors that may exist.

Thank you very much for your comments.

He thanked pcbfabric, TPCA and CPCA for their valuable help.

As in the past, several points should be observed when collecting data. 1.

The exchange rate of major currencies.

Except for the yen, the exchange rate changed very little from 2013 to 2014.

The yen traded at an average of 107 yen/dollar against the dollar, down to 1 million yen/USDin 2013.

The yen appears to have further depreciated to 120 to 125 yen/USD 2015.

Exchange rate is one of the variance factors.

For example, 57-58% of \"Taiwan\" production occurred in China.

PCB manufacturers convert their production in China to NT dollars to come up with \"integrated\" production, which the authors then convert to US dollars.

This is true for all companies that produce pcb overseas.

Readers are advised to explain the data accordingly.

In order to see the growth rate of each manufacturer, the exchange rate of 2013 is used to convert the income of 2014 into US dollars.

Therefore, the revenue figures of individual companies listed in NTI this year

The ranking of 100 will be slightly different from that of 2013. Beware.

Japanese manufacturing output fell 7%in US dollars)

Due to exchange rate fluctuations, the conversion at 2014. 2.

As we all know, the flexible circuit sales of Apple 100% are assembled circuit boards.

As a result, sales to Apple by large FPC manufacturers include considerable assembly value.

Separating assembly value from total revenue often results in errors and sometimes larger ones.

Therefore, the author did not attempt to separate the assembly from the total revenue.

In addition, more rigid board manufacturers are participating in the assembly, including Compeq, Shennan Circuit, Multek, TTM technology (

Back panel components), Viasystems (system-levelassembly), etc.

When the value of the rigid board assembly is clearly indicated, these revenues will be subtracted from the total amount.

Otherwise, Assembly values are part of the data.

Therefore, unfortunately, the income is more likely to be \"apple and orange \".

The author will be happy to answer any questions. 3.

The comments in the form are written based on the author\'s knowledge of the manufacturer, but there may also be errors.

No offense to the manufacturer on the list. 4.

Several Chinese manufacturers have earned nearly $100 million in revenue in 2014 years.

Some of them may be on the list for next year;

Therefore, it is expected that the number of Chinese companies entering the next few years will increase.

Manufacturers with previously unknown revenues of more than $100 million may also have \'discovered \".

Please let him know if you know.

As mentioned earlier, Amphenol will be on the list in the future.

France\'s Elvia is close to $100 million.

Analysis Table 1 shows NTI-100 list.

Table 2 is a summary of the contents of table 3.

Despite the declining domestic production in Japan, the number of top manufacturers registered was 25.

Growth in 2014 was 6%, mainly for flexible manufacturers supplying Apple, mainly overseas growth. Thefour-time No.

Japanese company Mektron produces 85% of its overseas products.

Sumitomo Denko printing circuit production in China exceeds 50%.

Fujikura\'s production in Thailand and Vietnam is close to 90%.

Taiwan\'s production in China accounts for 57-58% of Taiwan\'s total output.

Thailand has made a few percent.

As a result, its domestic output is about 40%.

The poor performance of most South Korean manufacturers stems from the reduction in Samsung orders in 2014.

Flex, in particular, was hit hard.

Several South Korean flex manufacturers are said to have defaulted.

However, 2015 of the situation seems to be improving.

In terms of the number of entries, China is very strong, with 29 out of a total of 99 companies leading Taiwan and Japan, although the total revenue share of these 29 companies is far less than the largest manufacturers in Taiwan and Japan ---yet.

It is estimated that the world total PCB production in 2014 was $60 billion. Taiwan is 31 years old.

3% share, followed by 22% in Japan and 14 in South Korea. 6%.

These percentages are consistent with the \"highest share\" percentage (by country)shown.

There are about 2,400 PCB manufacturers in the world, operating about 2,700 to 2,800 factories.

There are about 1,200 manufacturers and about 1,600 factories in China.

The top 99 manufacturers account for 4% of the total (99/2,400)

Accounting for 85% of the world\'s total production (

$51. 365 trillion/$60. 03 billion)(FIGURE 1).

The author is very positive if we consider 240 manufacturers (10% of the total)

Their output accounts for 95% of the total output.

The usual 20: 80 rule does not apply in the pcb industry.

As mentioned earlier, the flex manufacturer that provides Apple with the assembly of tablets has received the greatest benefit, with one exception being MFlex.

MFlex seems to reduce its reliance on Apple.

Mektron in Japan, Sumitomo Denko and fujikura in Japan, flexding Technology in Taiwan, Flexium and career are considered to be Apple\'s main flex suppliers.

They have grown far more than the total.

NTI has achieved 66%100.

2015 will be a repetition of this pattern.

In the past few years, Japan\'s Mektron has been very dependent on Apple.

Apple orders are driving its growth.

While Apple still serves Apple well, it seems the company is trying to diversify.

These efforts were reflected in the booth at the JPCA show by niponmektron.

$0. 195 billion investment in niponmektron (

Exchange rate is 107 yen/USD)infiscal 2014.

The current fiscalyear is expected to cost $0. 22 billion, a significant portion of which is said to be for domestic upgrades.

Its production of 2015 is likely to reach $3.

8 billion yen/USD, about $107.

4 billion yen/USD, 120.

Most likely, the Japanese Mektron will keep No.

1 position in 2015. SEMCO (

Samsung Electric Machinery Co. , Ltd. )

According to rumors, it is expected that SEMCO will close the IC substrate operation of its Chochuwon plant and transfer production to Busan, South Korea, which may become a central part of the operation of the semco ic substrate.

Rigid HDI microvia board includedflex boards (

Rigid more than 90%

Flexible plate with micro-guide structure)

It is possible to transfer to Kunshan, China and build a factory in Vietnam.

The author made these comments in speculation. Take heed. ZDT (

Technology)

It may be Apple\'s second-largest flexsupplier supplier after Japan\'s Mektron.

In response to the order that Apple added to the next iPhone model using the forced touch panel (iPhone6S)

ZDT and Flexium technologies are said to be investing in a massive expansion of sumstoward\'s capacity.

It is reported that the market capacity of Flexium has tripled in fiscal 2016.

Wus completed the Kunshan factory built in 1993 (

The land was absorbed by the Kunshan government)

Also at the newQingsong factory in Kunshan, actually right next door to the Nanya PCB, along the old canal leading to the center of Beijing.

Wus group has a factory in Kaohsiung, Taiwan, and two factories in Kunshan (

An old one for automotive PCB)

There is a factory in Huangxi

Yongbang group consists of four PCB manufacturing subsidiaries of Korea circuit, Telani, Interflex and Yongbang electronics.

Interflex and type did not perform well in 2014.

The South Korean tour and Terranix did not perform badly.

Samsung Electronics is their main customer, the same as most large manufacturers in South Korea.

Ibiden had a problem getting orders from Apple\'s new Malaysian factory.

But it did get new orders at the end of the year, and the profit was not that bad. Its flip-

The chip substrate business forMPU continues to be flat or even down due to poor performance and increasingly fierce price competition in the PC sector.

However, revenue in the industry has been driven by flip-

Chip CSPs for wireless devices.

Investing $0. 37 billion will boost Ibiden\'s revenue as it appears to have taken orders from Apple in Malaysia.

Investment in fiscal 2015 is expected to be around $0. 215 billion.

Total investment in PCBs by major Japanese companies in the current fiscal year is estimated at about $1. 2billion to $1.

3 billion, mainly for their overseas factories.

The hottest topic of the year may be the merger of TTM technology and the Viasystems Group.

By simply increasing the revenue of the two companies will be close to $2.

63 billion, of which about $2.

An estimated 4 billion are sold on bare metal.

Given the great value of lex assembly in Japan Mektron and ZDT, \"new\" TTM will not.

Ranked first in the world in bare metal sales.

From 1996 to today, the progress of TTM is remarkable.

In 2000, sanmina became the world\'s largest manufacturer for $1.

Revenue was $55 billion and Viasystems ranked second at $1. 25 billion.

Daeduck Group by Daeduck Electronics (high-layer-

MLBand count for IC substrate)

And Daeduck GDS (FPC, rigid-

Flexible and HDI microviaboards).

Despite the decline in income, profits are still good.

Daeduck is very cautious about the new investment.

South Asia PCB did a good job in 2014.

The author speculated that Nanya PCB performed well on the IC substrate.

Compeq completed the first phase of its Chongqing plant in July2014 and continued to expand the first phase before starting the second phase of construction.

The revenue contribution of the Dongqing factory in 2014 is small, but it will upgrade Compeq in 2015.

PSA PCB Group (

Passive System Alliance)

The drawing board is set up by Hanyu color crystal, and the Great Bauhinia Xun Xian. (

The two are the same presidents. )

HannStar Board has a plantin Taiwan and six in the \"Jiangyin campus\" in northern Wuxi, China.

There are four factories in GBM: GBM Arts (Shenzhen), CMK-GBM(Dongguang)Yuangmao, sage of Great Bauhinia (Kunshan)

Chongqing Chuangyi and GBM (Chongqing).

Hanxing\'s board of directors accounts for about 70% of total revenue. KG PCB Group (

Gold Board chemical PCB)

By Elec & Eltek (

Kaiping, Nanjing, Yangzhou, great city, Thailand, Guangzhou),Techwise (

Huiyang, Foshan)

Jiangmen glory faith (Jiangmen)

, TopFaith, Evertek (Kunshan)

And fast circuit (

Changshu, Dongguang, Qingyuan).

More than 50% of revenue seems to come from Elec & Eltek.

KB chemical owns a stake in some other PCB manufacturers in China, but it is not large enough to integrate.

AT&T continues to do a good job.

Its HDI microvia plant in Shanghai contributed 55% of its revenue.

The new Chongqing plant is undergoing a qualification review and is expected to begin delivery of ic substrates in early 2016.

Income of $1 billion may not be realized.

Meizi\'s revenue growth is good, but because of the high manufacturing cost, the profit has not increased, compared with the Chinese factory, its contribution in Vietnam is very small.

US high is expanding its business in Vietnam this year (

Part of the problem was the fire in 2013)

Do your best to reduce the manufacturing cost of all factories.

There is no panqin industry.

Became a Automotive PCB manufacturer in 2014, followed by CMK, Meiko, Viasystems, Nippon Mektron and KCE Electronics in Thailand.

Pan Qin, through his subsidiaries (

Consolidated Report of delaco PCB not part of Pan Chin)

KCE has completed a large number of PCB factories for automotive PCB manufacturing in Thailand.

In 2014, the automotive PCB market was about $5 billion, accounting for 8% of global PCB production.

The growth of the automotive PCB market is not as dramatic as the smartphone, but unlike the latter, its seasonality is relatively small, growing steadily by 5-6% per year.

Over the past few years, we have heard about the sharp rise in wages in China, labor shortages, stricter environmental regulations, and other adverse conditions facing manufacturing.

Nevertheless, investment in China remains strong. In 2013-

14. It is estimated to have twice the capacity.

Side panels and multi-board boards rose by about 3. 5% inChina.

This may sound small, but consider 3.

Estimated 5% [0. 2 billion]m. sup. 2](

Current capacity in China)is 7 million[m. sup. 2]

Or nearly 600,000 [m. sup. 2]per month!

Expansion continues.

We may want to know where the market is.

Taiwanese transplant and halffrom Chinese manufacturers account for half of the expansion in China: Compeq (Chongqing), GBM (Chongqing), Unimicron(Huangxi), Wus (

Kunshan, Huangxi), ZDT (

Shenzhen, Huai\'an, Yinkou, Tsinghua Road), Palwon (Suzhou), TPT (

Chengdu and Wuxi), and Tripod(Xiantao)

Several names from Taiwan.

APCB is looking for land for a second plant near Kunshan.

Unitech bought land in Nantong. (

Of course, there is more that the author does not know. )

Chinese manufacturers are not dormant.

Deep South Circuit (SCC)

A large factory consisting of four buildings was built in Wuxi, one of which was used for ICsubstrates (

Recently inaugurated).

Shenzhen Suntech built the first large building in its Jiangmen campus and started work the next day. (

There will be three buildings in total. )

Olympic plans to build the fourth building opposite Heshan\'s existing factory.

Shenzhen Express India has built a huge factory in Yixing, south of Wuxi.

SZ Fast Print purchased eXeptionCircuits in the UK and Multitest, a former port electronics, in San Jose.

Shenzhen Boming electronics has set up a large factory in Dafeng, north of Suzhou.

After setting up a large factory in Jiangxi, Jin Wang is growing rapidly.

The red board expands the factory in Jiangxi.

KDS in Beijing has built a new factory in Wuhan.

These are the tip of the iceberg.

India and Brazil have always been the lips of PCB manufacturers, but as far as the authors know, there is no significant foreign investment.

Southeast Asia is definitely the next place after China, but joint investment in Southeast Asia is negligible compared with China.

In response to rising wages and labor shortages, China\'s PCB factories are automating.

The author has seen many robots for autonomous driving.

Plated racks and AOI.

AVI is replacing carriers.

Whether successful or not, China will dominate PCB manufacturing in the foreseeable future.

Figure 2 is interesting.

Taiwan\'s production in China continues to increase, but its share is falling, although only a small part.

A few years ago, the author predicted that Taiwan\'s share of China would exceed 50%.

He does not know that Chinese manufacturers are quietly rising.

Some Chinese manufacturers have the same level of technology as Taiwan, Japan and the West.

By the way, readers may want to know the Million Group Holdings (89), 3Win Group (90)

And Ji an mankun (97).

The author knows nothing about these.

He learned about them by chance.

Million Group Holdings (

Chinese name spelling [:

Text that cannot be copied in ASCII])

Consists of four entities :(

Xiongyu Electronic Technology), (

Tai \'an electronic Tai Ya Wan electronic), (

Huang Yu Huaguang), and (

Da Ya Ba Xiongyu technology.

It was not until an old acquaintance sent an email containing therevenue that the author knew about the companies.

The author happened to understand Chinese characters and was able to conduct an investigation. 3Win Group (

Tongyin Technology Group)

It consists of nearly half of its subsidiaries.

From the name of the subsidiary that is spelled Chinese, there seems to be four or five PCB factories.

Under the guidance of the author\'s FPC factory (

Flexible circuit board)

It is located in Doumen, Zhuhai, between Meike TEC Longshan factory and Fangzheng technology.

Other business units listed include Shenzhen Tongyin industry, Shenzhen Tongxin circuit electronics, Zhuhai Tongyin electronics, Jiangsu Tongxin electronic technology, etc.

The organization also seems to have aluminum-acid plants in Jiangxi province.

Ji \'an mankun has four PCB divisions: Shenzhen mankun electronics Ji \'an mankun technology mankun electronics (Huizhou)and HTD Group (Hong Kong)Ltd.

There are more such Chinese manufacturers.

Now you can understand why there are 1,200 PCB manufacturers operating 600 factories in China.

Dealing with fab stores in China is becoming more challenging every year. DR.

Zhongyuan Hao Yao is president of the state. T. Information; nakanti@yahoo. com.

When you find yourself in need of printed circuit board company , you may not know where to begin. And that's OK! Search out Rocket PCB Solution Ltd. to handle your pcb pool needs.

The best for is one that works best for your needs and what you can support in your home. Among Rocket PCB Solution Ltd.'s diversified list of products at different price ranges, you will surely find your one with high quality. make your choice at Rocket PCB Solution!

The lower cost of single sided printed circuit board, compared to other product, and Rocket PCB Solution Ltd.’s services provide may well suit the needs for customers.

Custom message