Can mobile handsets biz better Modi\'s \'Make in India\' plan?

by:Rocket PCB

2019-09-17

Ndians is the second largest buyer after China, and all mobile phones are imported.

Why not make these phones in India?

In other product categories, producers are hampered by weak demand.

Here, there is strong demand for mobile phones with huge growth.

So in this year\'s budget, Finance Minister Arun Jaitley imposed a 12-cent countervailing duty on mobile phones, a 1 cent consumption tax on mobile phones that do not have a Cenvat credit for imported parts is tax free.

Since then, many companies have announced plans to make mobile phones in India.

In fact, many people have begun to act.

But there is one problem: most of them import halfknocked-

Put down the kit or SKDs and assemble them here.

This is more or less equivalent to turning on the phone and repackaging the phone on the table.

The value added is only one or two percentage points.

Obviously, the investment required to start such a business is very low ---

Not enough to give any meaningful impetus to manufacturing.

Like Samsung, only a few companies choose to import phones that are completely eliminated --

The Assembly of the Down kit (CKDs) increased the value by 8 to 9 percentage points ---

Higher than SKDs but not very good.

There\'s a rule of thumb, 70-

The value of the phone is hardware, and the rest is contributed by the process.

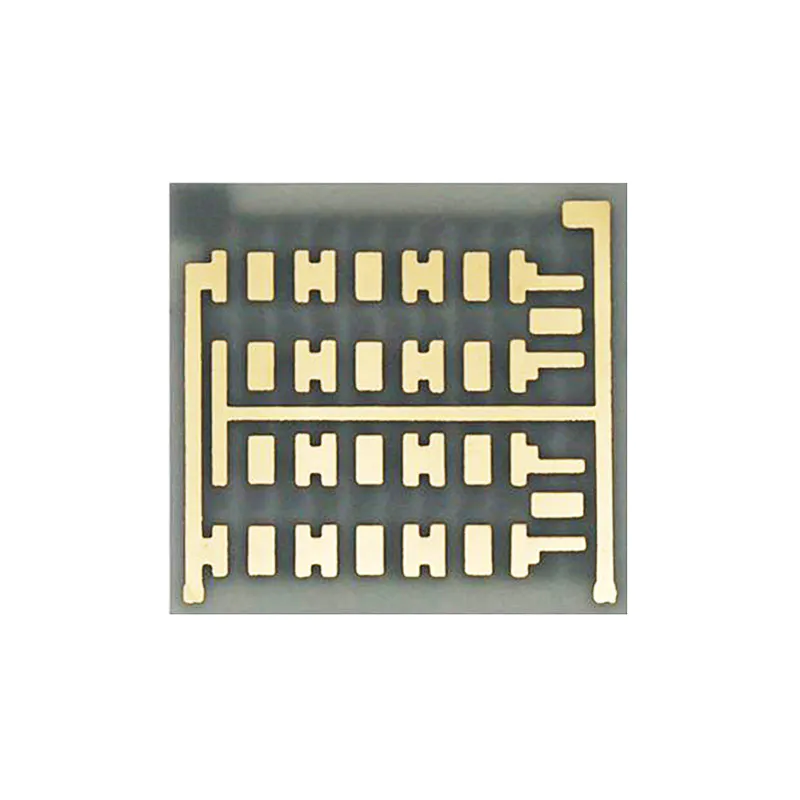

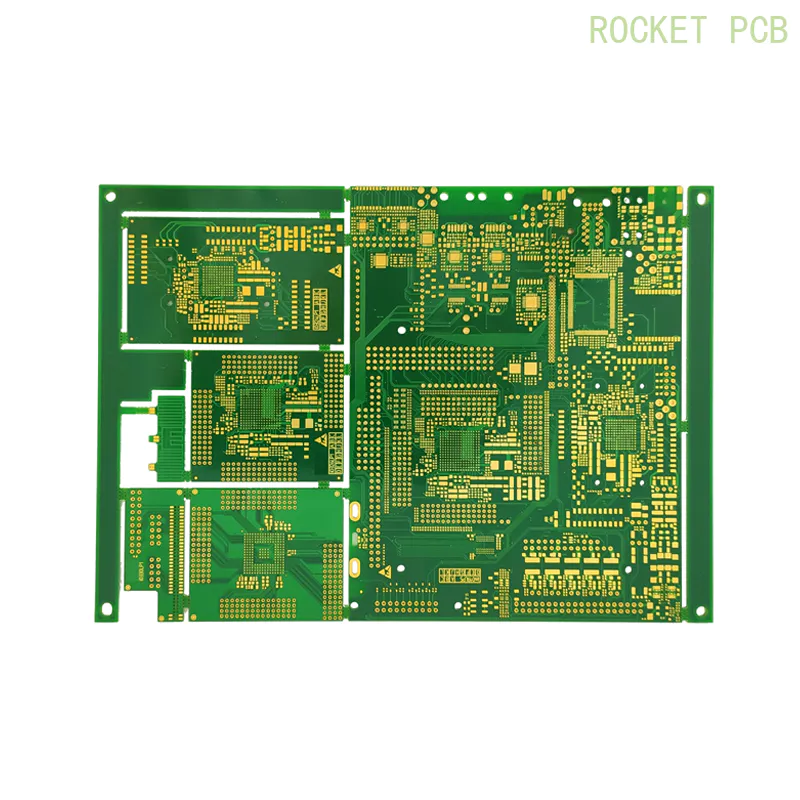

In these processes, the filling and installation of printed circuit boards is the biggest factor.

When importing the phone in SKDs, the printed circuit board is fully populated and installed.

India has no value added.

As a first step, the government should consider how to encourage handset makers to move from SKDs to CKDs.

One suggestion that seems to be popular is to impose a 12 cent countervailing duty on printed circuit boards, which will encourage manufacturers to produce and install in India.

Advocates for this step say there may be another benefit for the government in this regard: higher income.

More CKDs will lead to the design of printed circuit boards in India.

At present, when mobile phones are imported as SKDs, royalties on all intellectual property rights are paid outside India;

If paid from India, the government will be able to impose a withholding tax when the chip is designed locally.

Only in the next stage can the government fully consider

Mobile phone manufacturing--the real stuff.

This will happen when there is a complete ecosystem: a large number of companies produce all the components that go into the phone.

Some handset manufacturers have started purchasing components locally, such as chargers and battery packs, at least one Lava has developed the software itself-

But they still have a way to go.

The most important part of the phone is the printed circuit board, which accounts for at least 40 of the total value, half of which are semiconductor chips.

These chips are not made in India.

China has announced plans to make chips more than once, but with little success.

In 2006, a joint venture named SemIndia proposed to set up a department in Hyderabad.

But the plan was put on hold in the ensuing financial crisis.

Then, on 2013, it was announced that Jaiprakash Associates and Hindustan Semiconductor Manufacturing will set up a unit in danoida and gandinana respectively.

Although Jaiprakash Associates said it would work with IBM and Tower Jazz to participate in the project, Hindustan Semiconductor Manufacturing has established contacts with ST Microelectronics and Silterra.

Since then, there has been little knowledge of these proposed projects.

Jaiprakash Associates is part of the Jaypee group, which is facing financial difficulties: its debt burden is huge and cash flow from real estate projects is getting smaller and smaller.

In fact, there is little hope that the chip factory will rush.

It could cost more than $5 billion, how much business groups in India or foreign countries

Have, have the funds to make such investments, when the business is difficult ---

Competitors in Taiwan and South Korea can ship them to India with zero tariffs. However, in smartphones, liquid crystal displays are the second most valuable component after printed circuit boards and can be produced in India in the near future.

Anil Agarwal\'s dual-StaR technology has shown interest in the country\'s LCD display equipment.

According to a report on September, the company, together with Taiwan Youda optoelectronic company, is eager to build a facility in Noida with an investment of 6,000 rupees (60 billion rupees.

Some industry insiders believe that the huge investment in liquid crystal display is coming ---

It may start in the next two months.

Currently, the move from SKDs to CKDs should be good enough.

Why not make these phones in India?

In other product categories, producers are hampered by weak demand.

Here, there is strong demand for mobile phones with huge growth.

So in this year\'s budget, Finance Minister Arun Jaitley imposed a 12-cent countervailing duty on mobile phones, a 1 cent consumption tax on mobile phones that do not have a Cenvat credit for imported parts is tax free.

Since then, many companies have announced plans to make mobile phones in India.

In fact, many people have begun to act.

But there is one problem: most of them import halfknocked-

Put down the kit or SKDs and assemble them here.

This is more or less equivalent to turning on the phone and repackaging the phone on the table.

The value added is only one or two percentage points.

Obviously, the investment required to start such a business is very low ---

Not enough to give any meaningful impetus to manufacturing.

Like Samsung, only a few companies choose to import phones that are completely eliminated --

The Assembly of the Down kit (CKDs) increased the value by 8 to 9 percentage points ---

Higher than SKDs but not very good.

There\'s a rule of thumb, 70-

The value of the phone is hardware, and the rest is contributed by the process.

In these processes, the filling and installation of printed circuit boards is the biggest factor.

When importing the phone in SKDs, the printed circuit board is fully populated and installed.

India has no value added.

As a first step, the government should consider how to encourage handset makers to move from SKDs to CKDs.

One suggestion that seems to be popular is to impose a 12 cent countervailing duty on printed circuit boards, which will encourage manufacturers to produce and install in India.

Advocates for this step say there may be another benefit for the government in this regard: higher income.

More CKDs will lead to the design of printed circuit boards in India.

At present, when mobile phones are imported as SKDs, royalties on all intellectual property rights are paid outside India;

If paid from India, the government will be able to impose a withholding tax when the chip is designed locally.

Only in the next stage can the government fully consider

Mobile phone manufacturing--the real stuff.

This will happen when there is a complete ecosystem: a large number of companies produce all the components that go into the phone.

Some handset manufacturers have started purchasing components locally, such as chargers and battery packs, at least one Lava has developed the software itself-

But they still have a way to go.

The most important part of the phone is the printed circuit board, which accounts for at least 40 of the total value, half of which are semiconductor chips.

These chips are not made in India.

China has announced plans to make chips more than once, but with little success.

In 2006, a joint venture named SemIndia proposed to set up a department in Hyderabad.

But the plan was put on hold in the ensuing financial crisis.

Then, on 2013, it was announced that Jaiprakash Associates and Hindustan Semiconductor Manufacturing will set up a unit in danoida and gandinana respectively.

Although Jaiprakash Associates said it would work with IBM and Tower Jazz to participate in the project, Hindustan Semiconductor Manufacturing has established contacts with ST Microelectronics and Silterra.

Since then, there has been little knowledge of these proposed projects.

Jaiprakash Associates is part of the Jaypee group, which is facing financial difficulties: its debt burden is huge and cash flow from real estate projects is getting smaller and smaller.

In fact, there is little hope that the chip factory will rush.

It could cost more than $5 billion, how much business groups in India or foreign countries

Have, have the funds to make such investments, when the business is difficult ---

Competitors in Taiwan and South Korea can ship them to India with zero tariffs. However, in smartphones, liquid crystal displays are the second most valuable component after printed circuit boards and can be produced in India in the near future.

Anil Agarwal\'s dual-StaR technology has shown interest in the country\'s LCD display equipment.

According to a report on September, the company, together with Taiwan Youda optoelectronic company, is eager to build a facility in Noida with an investment of 6,000 rupees (60 billion rupees.

Some industry insiders believe that the huge investment in liquid crystal display is coming ---

It may start in the next two months.

Currently, the move from SKDs to CKDs should be good enough.

Custom message