How to design a PCB for high frequency?

I.Introduction

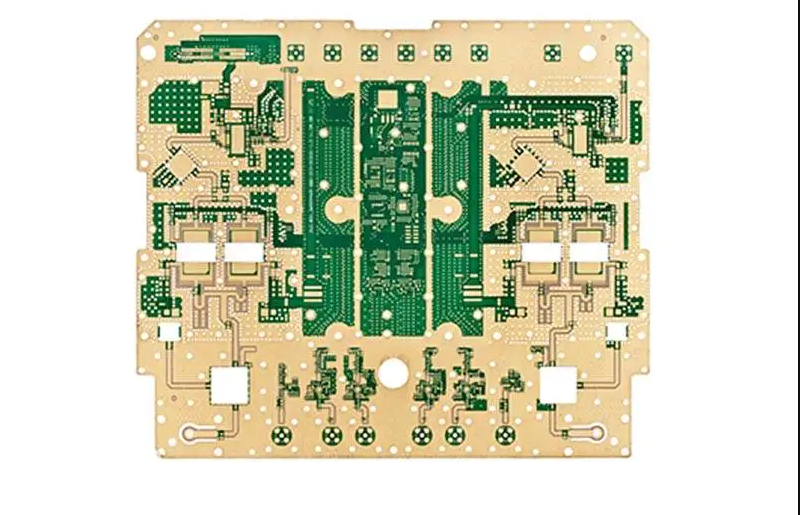

High-frequency PCBs, often called R.F. (Radio Frequency), are a specialized category of printed circuit boards designed to handle signals with frequencies in the gigahertz range. These boards are critical in various applications, from wireless communication devices to radar systems and medical equipment. In this article, we will delve into the intricacies of high-frequency PCB design, highlighting the significance of proper design techniques and providing a comprehensive overview of the topics we will cover.

High-frequency PCBs are engineered to accommodate signals that operate at significantly higher frequencies than standard PCBs. These frequencies typically fall in the range of 1 GHz (gigahertz) and above. Due to their unique characteristics and the demands of high-frequency applications, these PCBs differ in design and material selection compared to their lower-frequency counterparts.

Designing a high-frequency PCB correctly is of paramount importance for several reasons:

1. Signal Integrity

High-frequency signals are susceptible to various forms of interference and degradation. Proper PCB design minimizes signal losses, reflections, and electromagnetic interference (EMI), ensuring reliable signal transmission.

2. Impedance Matching

Impedance matching is crucial in high-frequency circuits to prevent signal reflections. A well-designed PCB maintains consistent impedance across traces and components.

3. Minimized Crosstalk

Crosstalk between traces can lead to signal distortion. Careful design techniques help minimize Crosstalk, preserving signal quality.

4. EMI/EMC Compliance

High-frequency devices must adhere to electromagnetic interference (EMI) and electromagnetic compatibility (EMC) regulations. Correct PCB design aids in achieving compliance.

5. Heat Dissipation

High-frequency components generate heat. Effective thermal management is necessary to prevent overheating and ensure long-term reliability.

In the following sections, we will delve deeper into the intricacies of high-frequency PCB design. We will explore critical aspects such as selecting suitable materials, designing the layer stack up, component placement, grounding strategies, impedance matching techniques, signal integrity analysis, and considerations for electromagnetic compatibility (EMC) and electromagnetic interference (EMI). Additionally, we will discuss the importance of testing and validation in high-frequency PCB design.

II.Understanding High-Frequency Signals

High frequency is distinctive in printed circuit board (PCB) design, particularly in applications where signals traverse the gigahertz range.

A.Definition of High Frequency in PCB Context

High frequency in PCB design typically refers to signals that operate at frequencies starting from 1 GHz (gigahertz) and extend into the multi-gigahertz range. These frequencies are characteristic of wireless communication, satellite systems, radar technology, and high-speed data transmission applications.

In the context of high-frequency PCBs, signal wavelengths become increasingly critical. If not managed appropriately, the signal's wavelength becomes shorter at higher frequencies, leading to signal degradation and interference.

B.Challenges Posed by High-Frequency Signals

Designing PCBs for high-frequency signals introduces several notable challenges:

1. Skin Effect: At high frequencies, the skin effect becomes more pronounced. This phenomenon causes current to concentrate near the surface of conductors, leading to increased resistance and losses.

2. Dielectric Loss: Dielectric materials exhibit frequency-dependent characteristics. High-frequency signals can result in dielectric losses, affecting signal quality.

3. Signal Loss: High-frequency signals are prone to attenuation or loss as they traverse traces and components. Minimizing these losses is critical for signal integrity.

4. Crosstalk: Crosstalk between adjacent traces becomes more problematic at high frequencies. Proper trace spacing and shielding are essential to mitigate Crosstalk.

C.Importance of Signal Integrity and Impedance Matching

Signal Integrity:

Maintaining signal integrity is paramount in high-frequency PCB design. Signal integrity refers to preserving the signal's quality as it travels through the PCB. Key factors affecting signal integrity include:

· Reflections: High-frequency signals can reflect impedance mismatches, leading to signal degradation. Minimizing these reflections is crucial.

· Rise Time: High-frequency signals have fast rise times, making them susceptible to distortion. Signal integrity measures aim to maintain signal shapes.

Impedance Matching:

Impedance matching ensures that the characteristic impedance of the transmission lines (traces) matches the impedance of the source and load components. In high-frequency circuits, impedance matching is essential for the following reasons:

· Reflection Reduction: Impedance matching minimizes signal reflections at transitions, ensuring signals are efficiently transmitted and received.

· Power Transfer: Proper impedance matching maximizes power transfer between components, enhancing overall circuit performance.

· Minimized Losses: Impedance mismatches can lead to signal losses, which must be minimized to maintain signal quality.

Comprehending high-frequency signals in PCB design is foundational to success in high-frequency applications. It involves recognizing the unique characteristics and challenges of high-frequency signals and the critical roles played by signal integrity preservation and impedance matching. In the subsequent sections, we will explore strategies and techniques to address these challenges effectively.

III.Selecting the Right Materials for High-Frequency PCBs

When designing high-frequency PCBs, one of the foundational decisions you'll face is selecting the suitable materials.

A.Overview of PCB Material Options

PCBs can be fabricated using various materials, each with its characteristics. Here are some standard options:

1.FR-4 (Fire-Resistant 4):

· FR-4 is a widely used PCB material due to its affordability and versatility.

· It is suitable for low to moderate-frequency applications but may not be ideal for high-frequency PCBs due to its limitations in terms of dielectric properties.

2. Rogers Corporation Materials:

· Rogers Corporation produces a range of high-frequency PCB materials, such as the RO4000 series and RO3000 series.

· These materials are engineered specifically for high-frequency applications, offering low dielectric loss and consistent performance.

3. PTFE (Polytetrafluoroethylene):

· PTFE-based materials like Teflon are known for their excellent electrical properties and low loss characteristics.

· They are well-suited for high-frequency PCBs, particularly in applications where signal integrity is critical.

4. Isola Materials:

· Isola manufactures materials like IS620 and IS680 for high-speed and high-frequency applications.

· These materials provide low loss and stable dielectric constants.

B.Properties of Materials Suitable for High-Frequency PCBs

Materials suitable for high-frequency PCBs share several essential properties:

1. Low Dielectric Constant (Dk):

· Low Dk materials minimize the propagation delay of high-frequency signals.

· This property ensures that signals travel at the desired speed, reducing the risk of signal distortion.

2. Low Dissipation Factor (Df):

· A low Df indicates a minimal dielectric loss.

· High-frequency PCBs demand materials with low Df to minimize signal attenuation.

3. Consistency and Stability:

· Materials used in high-frequency PCBs must exhibit consistent electrical properties over various frequencies and environmental conditions.

· Stability is essential to maintain signal integrity.

C.How dielectric Constant and Loss Tangent Impact Material Selection

Dielectric Constant (Dk):

A material's dielectric constant (Dk) determines the speed at which electromagnetic signals travel through it. When selecting materials for high-frequency PCBs, you'll want to choose those with a low Dk. This ensures signals propagate at the desired velocity, minimizing signal delay and distortion.

Loss Tangent (Dissipation Factor, Df):

A material's loss tangent (Df) represents its ability to dissipate electrical energy as heat. Low-loss materials with a low Df are preferred for high-frequency applications. Materials with a high Df can cause significant signal attenuation and reduced signal quality.

Selecting suitable materials for high-frequency PCBs is crucial for achieving optimal performance. Materials like PTFE-based substrates, Rogers Corporation materials, and Isola materials offer the properties necessary for high-frequency applications. Consider the dielectric constant and loss tangent carefully, as they directly impact signal speed and quality. In the subsequent sections, we will explore leveraging these materials to design high-performance, high-frequency PCBs.

V.Component Placement and Routing for High Frequency PCBs

Efficient component placement and precise trace routing are paramount in high frequency PCB design. In this section, we'll explore best practices for component placement, delve into trace routing techniques tailored to high frequency applications, and discuss strategies for minimizing parasitic capacitance and inductance to ensure optimal performance.

A.Best Practices for Component Placement

1.Signal Integrity-Centric Placement:

· Place high-speed and critical components as close to each other as possible to reduce trace lengths.

· Minimize the number of vias and avoid long, meandering traces.

2.Thermal Considerations:

· Strategically position heat-generating components to ensure efficient heat dissipation.

· Use ground and power planes for thermal relief and spreading.

3.Signal Isolation:

· Keep analog and digital components separated to minimize interference.

· Use guard traces or isolation techniques to maintain signal integrity.

4.Connector Placement:

· Plan for connectors early in the design phase and allocate sufficient space for them.

· Ensure connectors have adequate ground shielding to prevent EMI.

B.Trace Routing Techniques for High Frequency PCBs

1.Controlled Impedance Routing:

· Maintain controlled impedance by adhering to specified trace widths and layer stackup.

· Use impedance calculators and simulation tools to verify trace parameters.

2.Differential Pair Routing:

· Route high-speed signals as differential pairs to improve noise immunity.

· Ensure consistent trace lengths to maintain signal balance.

3.Minimize Crossings:

· Avoid traces crossing over each other, as this can lead to coupling and interference.

· Implement proper signal layer changes using vias to reduce Crosstalk.

4.Avoid Right Angles:

· Right-angle bends can cause signal reflections and impedance mismatches.

· Use curved traces or chamfered corners for smoother signal paths.

C.Minimizing Parasitic Capacitance and Inductance

1.Ground Plane Usage:

· Employ a solid ground plane on adjacent layers to minimize parasitic capacitance and inductance.

· Maintain a uniform ground plane, avoiding splits or cuts that can disrupt signal return paths.

2.Via Design:

· Minimize via stubs by using blind or buried vias for signal transitions between layers.

· Place ground vias nearby to provide low-inductance return paths.

3.Component Selection:

· Choose components with minimized parasitic effects, such as surface mount devices (SMDs) over through-hole components.

· Opt for capacitors with low equivalent series resistance (ESR) and inductance (ESL).

Component placement and routing are critical aspects of high frequency PCB design. A focus on signal integrity, thermal considerations, and adherence to best practices can help ensure the successful implementation of high-speed designs. Additionally, strategies for minimizing parasitic capacitance and inductance play a pivotal role in achieving optimal high-frequency performance.

VI.Grounding and Decoupling in High Frequency PCBs

Grounding and decoupling are vital aspects of high-frequency PCB design that directly impact signal integrity, noise reduction, and overall circuit performance. In this section, we will explore strategies for effective grounding in high frequency PCBs, the essential role of decoupling capacitors, and guidelines for their placement and selection.

A.Strategies for Effective Grounding in High Frequency PCBs

Grounding is foundational to high-frequency PCB design, and effective grounding strategies are crucial. Here are some key considerations:

1.Single-Point Grounding:

· Implement a single-point ground to minimize ground loops and reduce noise.

· Connect all ground references at a single designated point to ensure a common ground potential.

2.Ground Plane:

· Utilize dedicated ground planes on inner layers to provide a low-inductance return path for high-frequency signals.

· Ensure the ground plane is continuous, avoiding splits or cuts that could disrupt signal return paths.

3.Separation of Analog and Digital Grounds:

· Maintain separate ground planes for analog and digital sections to minimize interference.

· Use ferrite beads or inductors for isolation between ground planes if necessary.

4.Via Stitching:

· Employ via stitching to connect ground planes on different layers, reducing loop area and improving high-frequency performance.

B.Role of Decoupling Capacitors

Decoupling capacitors are essential components that help stabilize power distribution and minimize voltage fluctuations in high frequency circuits:

1.Noise Filtering:

· Decoupling capacitors act as a low-pass filter, attenuating high-frequency noise on the power supply lines.

· They prevent noise from propagating to sensitive components.

2.Energy Storage:

· Decoupling capacitors store energy that can be quickly released when needed, ensuring a stable and reliable power supply to I.C.s during high-frequency operation.

3.Reduction of Voltage Ripple:

· Decoupling capacitors reduce voltage ripple on the power rails caused by rapid changes in current demand.

· They maintain the voltage within acceptable limits, preventing disruptions.

C.Placement and Selection of Decoupling Components

Effective placement and selection of decoupling components are crucial for their proper operation:

1.Proximity to I.C.s:

· Place decoupling capacitors as close as possible to the power pins of I.C.s they are intended to support.

· Short traces reduce inductance and maximize their effectiveness.

2.Multiple Capacitor Values:

· Use a combination of decoupling capacitors with different capacitance values (e.g., 0.1 µF and 10 µF).

· Smaller capacitors handle higher-frequency noise, while larger ones provide energy storage.

3.Low Equivalent Series Resistance (ESR):

· Choose capacitors with low ESR to ensure effective noise filtering.

· Ceramic capacitors, such as MLCCs (Multi-Layer Ceramic Capacitors), are often preferred for high-frequency decoupling.

Grounding and decoupling are fundamental aspects of high-frequency PCB design. Effective grounding strategies, dedicated ground planes, and proper decoupling capacitor placement and selection are essential for maintaining signal integrity, reducing noise, and ensuring reliable circuit performance in high-frequency applications.

VII.Impedance Matching in High Frequency Circuits

Impedance matching is a fundamental concept in high frequency PCB design that plays a crucial role in ensuring signal integrity and optimal performance. In this section, we will provide an explanation of impedance matching in high-frequency circuits, discuss techniques for achieving impedance matching, and introduce tools and calculators that facilitate this critical aspect of PCB design.

A.Explanation of Impedance Matching in High Frequency Circuits

Impedance matching is the process of adjusting the electrical impedance of a component or transmission line to match the impedance of the source and load. In high-frequency circuits, impedance matching is essential for several reasons:

· Signal Reflection Reduction: Impedance mismatches can cause signal reflections at the interfaces between components or transmission lines. These reflections lead to signal degradation, signal loss, and potential interference.

· Maximizing Power Transfer: Proper impedance matching ensures maximum power transfer between components, optimizing the efficiency and performance of the circuit.

· Minimizing Voltage Standing Wave Ratio (VSWR): Impedance matching helps minimize VSWR, which is a measure of how well a transmission line is matched to the source and load impedances. Lower VSWR indicates better impedance matching and less signal loss.

B.Techniques for Achieving Impedance Matching

Achieving impedance matching in high-frequency circuits involves the following techniques:

1.Component Selection:

· Select components with specific impedance values that match the desired impedance of the circuit.

· Use components like resistors, capacitors, and inductors with the appropriate values to achieve matching.

2.Transmission Line Design:

· Design transmission lines, such as microstrip or stripline traces, with precise dimensions to achieve the desired impedance.

· Control the trace width, dielectric thickness, and separation between the signal and ground planes to achieve matching.

3.Baluns and Transformers:

· Utilize baluns and transformers to match impedances between different parts of the circuit.

· These passive devices can be used to transform impedance from one value to another.

4.Smith Chart Analysis:

· Employ the Smith chart, a graphical tool for analyzing and designing impedance matching networks.

· It helps visualize impedance transformations and aids in selecting appropriate components.

C.Tools and Calculators for Impedance Matching

Impedance matching can be a complex task, and several tools and calculators are available to assist in the process:

1.Online Impedance Calculators:

· Various online calculators are available to determine trace dimensions, component values, and impedance values for different transmission lines.

2.Simulation Software:

· PCB design software, such as Altium Designer and Cadence Allegro, often includes impedance matching simulation tools.

· These tools allow you to model and analyze impedance-matching networks within your PCB layout.

3.Vector Network Analyzers (VNAs):

· VNAs are laboratory instruments used for precise impedance measurement and characterization.

· They are invaluable for validating and fine-tuning impedance matching in high-frequency circuits.

Impedance matching is a critical aspect of high-frequency PCB design, essential for minimizing signal reflections, optimizing power transfer, and ensuring the overall performance of high-frequency circuits. Understanding the principles of impedance matching, employing appropriate techniques, and utilizing available tools and calculators are essential to successful high-frequency PCB design.

VIII.Signal Integrity Analysis in High-Frequency PCBs

Signal integrity analysis is a critical aspect of high-frequency PCB design, ensuring that signals maintain their quality and Integrity throughout the circuit.

A.Importance of Signal Integrity Analysis

The importance of signal integrity analysis in high frequency PCBs must be considered. Here's why it's crucial:

1. Preservation of Signal Quality:

· High-frequency signals are vulnerable to distortion, reflections, and noise. Signal integrity analysis helps preserve the quality of these signals, ensuring they meet performance criteria.

2.Minimization of Signal Degradation:

· The analysis identifies potential issues like impedance mismatches, Crosstalk, and reflections, allowing for corrective measures before fabrication.

3. Compliance with Standards:

· Many high-frequency applications must adhere to stringent signal quality standards. Signal integrity analysis helps verify compliance with these standards.

4. Cost Savings:

· Identifying and rectifying signal integrity issues during the design phase is far more cost-effective than addressing them post-production.

B.Tools and Simulations for Analyzing Signal Integrity

Several tools and simulations are available to analyze signal integrity in high-frequency PCBs:

1. SPICE (Simulation Program with Integrated Circuit Emphasis):

· SPICE simulators are widely used for electrical circuit analysis.

· They can analyze high-frequency behavior, transient responses, and noise in PCB designs.

2. E.M. Field Simulators:

· Tools like CST Studio Suite and ANSYS HFSS simulate electromagnetic fields and analyze their impact on high-frequency signals.

· They are invaluable for predicting EMI and signal propagation.

3.IBIS Models:

· IBIS (Input/Output Buffer Information Specification) models describe the electrical behavior of semiconductor devices.

· These models are essential for simulating the interaction between I.C.s and PCBs in high-frequency designs.

4.Time-Domain Reflectometry (TDR):

· TDR instruments send pulses into a transmission line and analyze the reflections.

· They are useful for identifying impedance mismatches and trace discontinuities.

C.Mitigating Signal Integrity Issues

To mitigate signal integrity issues identified through analysis, consider the following strategies:

1.Impedance Matching:

· Adjust trace widths and stackup configurations to achieve impedance matching.

· Use series terminations or resistors for controlled impedance routing.

2.Crosstalk Mitigation:

· Increase trace spacing and use guard traces to reduce Crosstalk.

· Employ differential signaling for critical high-speed signals.

3.Termination Techniques:

· Implement termination techniques like parallel termination (e.g., resistors) to minimize signal reflections.

· Use A.C. coupling capacitors for D.C. isolation in certain applications.

4.Grounding Strategies:

· Ensure solid ground planes, minimizing ground loop and noise.

· Employ split ground planes for analog and digital sections, if necessary.

Signal integrity analysis is indispensable in high-frequency PCB design to maintain signal quality, minimize degradation, and ensure compliance with standards. Utilizing the appropriate tools and simulations helps identify and rectify potential issues, while strategic design choices and mitigation techniques are key to achieving reliable signal integrity in high-frequency applications.

IX.EMC/EMI Considerations in High Frequency PCBs

Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) are critical concerns in high-frequency PCB design. In this section, we will explore the significance of addressing EMC/EMI, discuss shielding techniques tailored to high frequency PCBs, and emphasize the importance of compliance with regulatory standards.

A.Addressing Electromagnetic Compatibility and Interference

1.Significance of EMC/EMI:

· High frequency PCBs often generate and are susceptible to electromagnetic interference (EMI).

· EMC ensures that electronic systems can operate in proximity to each other without causing or experiencing interference.

2.Potential Issues:

· Without proper EMC/EMI measures, high frequency PCBs can disrupt nearby electronic devices, leading to malfunctions or data corruption.

· They can also be vulnerable to external interference, affecting their own performance.

3.EMC/EMI Analysis:

· Conduct EMC/EMI analysis to identify potential sources of interference and vulnerabilities in the design.

· This analysis helps in implementing effective mitigation strategies.

B.Shielding Techniques for High Frequency PCBs

Effective shielding is essential to prevent EMI in high frequency PCBs:

1.Grounded Metal Enclosures:

· Enclose high-frequency PCBs within grounded metal enclosures to contain electromagnetic emissions.

· Ensure good electrical contact between the enclosure and the PCB's ground plane.

2. Shielded Cable Routing:

· Use shielded cables for high-frequency connections to prevent radiation and susceptibility to external interference.

· Properly terminate and ground shielded cables at both ends.

3. Ferrite Beads and Chokes:

· Place ferrite beads or chokes on signal and power lines to suppress high-frequency noise.

· These components provide a high impedance to high-frequency noise, reducing its impact.

4.Slot and Gap Considerations:

· Avoid large slots and gaps in PCB traces and ground planes, as they can act as antennas and radiate EMI.

· Minimize trace loops to reduce inductive coupling.

C.Compliance with Regulatory Standards

1.Regulatory Standards:

· Familiarize yourself with regional and industry-specific regulatory standards governing EMC/EMI.

· Common standards include FCC (Federal Communications Commission) regulations in the U.S. and C.E. (Conformité Européenne) standards in Europe.

2.Pre-Compliance Testing:

· Conduct pre-compliance testing to identify and rectify EMC/EMI issues before seeking formal certification.

· This reduces the risk of costly design modifications after production.

3. Certification:

· Engage with accredited testing laboratories to obtain EMC/EMI certifications.

· Ensure your high-frequency PCB design meets all applicable standards to market and sell your product legally.

Addressing EMC/EMI considerations is essential in high-frequency PCB design to ensure the reliable operation of electronic systems and compliance with regulatory standards. Effective shielding techniques, grounded enclosures, and adherence to best practices in PCB layout are crucial in mitigating EMI. Compliance with regional and industry standards is vital for market access and customer confidence.

X.Testing and Validation in High-Frequency PCB Design

Testing and validation are integral steps in high-frequency PCB design, ensuring the finished PCB meets performance specifications and functions as intended. In this section, we will underscore the importance of testing high-frequency PCB designs, discuss the types of tests and measurements involved, and provide guidance on interpreting test results and making necessary adjustments.

A.Importance of Testing High-Frequency PCB Designs

Testing serves several critical purposes in high-frequency PCB design:

1. Verification of Performance:

· Testing validates that the PCB design meets the specified high-frequency performance criteria.

· It ensures that the PCB functions correctly and reliably in its intended application.

2. Identification of Issues:

· Testing can uncover signal integrity issues, impedance mismatches, and EMI problems that may not be apparent during the design phase.

· Identifying these issues early allows for adjustments and improvements.

3. Compliance with Standards:

· Testing is necessary to confirm that the PCB design complies with regulatory and industry standards, particularly regarding EMC/EMI.

4. Quality Assurance:

· Testing is a fundamental aspect of quality assurance, helping to identify and rectify defects or manufacturing issues.

B.Types of Tests and Measurements

Several tests and measurements are pertinent to high-frequency PCB design:

1. Signal Integrity Testing:

· This includes measuring signal integrity parameters like rise time, fall time, overshoot, and jitter.

· Tests ensure that high-frequency signals propagate correctly without distortion.

2. Impedance Testing:

· Impedance tests verify that the PCB traces and components have the desired impedance values.

· Techniques like Time-Domain Reflectometry (TDR) and Vector Network Analysis (VNA) are used.

3. EMC/EMI Testing:

· Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) tests assess the PCB's susceptibility to interference and its emissions.

· Compliance with regulatory standards is essential.

4.Power Integrity Testing:

· Power integrity tests ensure that the power distribution network delivers clean and stable power to components.

· They verify that voltage levels and noise levels are within acceptable limits.

5. Functional Testing:

· Functional tests confirm that the PCB performs its intended functions correctly.

· They involve verifying the operation of components and interfaces.

C.Interpreting Test Results and Making Adjustments

1. Data Analysis:

· Analyze test data meticulously, comparing the results with design specifications and performance requirements.

· Look for deviations, anomalies, or areas where the PCB may fall short.

2. Iterative Process:

· Testing is often an iterative process. If issues are identified, make necessary adjustments to the PCB design.

· Re-test the modified design to ensure that improvements have been achieved.

3. Simulation Validation:

· Compare test results with simulation predictions to validate the accuracy of the design simulations.

· Use simulation tools to fine-tune the design based on real-world test data.

4. Documentation:

· Thoroughly document test results, adjustments, and any changes made to the PCB design.

· Documentation is crucial for traceability and future reference.

Testing and validation are indispensable in high-frequency PCB design to confirm performance, identify issues, and ensure compliance with standards. A systematic approach to testing, careful data analysis, and iterative adjustments contribute to the successful development of high-frequency PCBs that meet their design objectives.

XI.Conclusion

In the world of high-frequency PCB design, achieving success requires a combination of expertise, precision, and attention to detail.

High-frequency PCB design is a dynamic field that continuously evolves with technology. Rocket-PCB encourages you to stay updated with the latest advancements, materials, and design techniques in the high-frequency domain. Expertise is built through experience and continuous learning, and Rocket-PCB is your trusted partner in this journey.

If you require professional PCB design services or consultation, or if you have any further questions, Rocket-PCB is here to assist you: