a fully-flexible solution-processed autonomous glucose indicator

by:Rocket PCB

2019-10-29

For the first time, we showed a completeflexible, self-

Electric glucose indicator system with two flexible electronic technology synergies: a flexible self

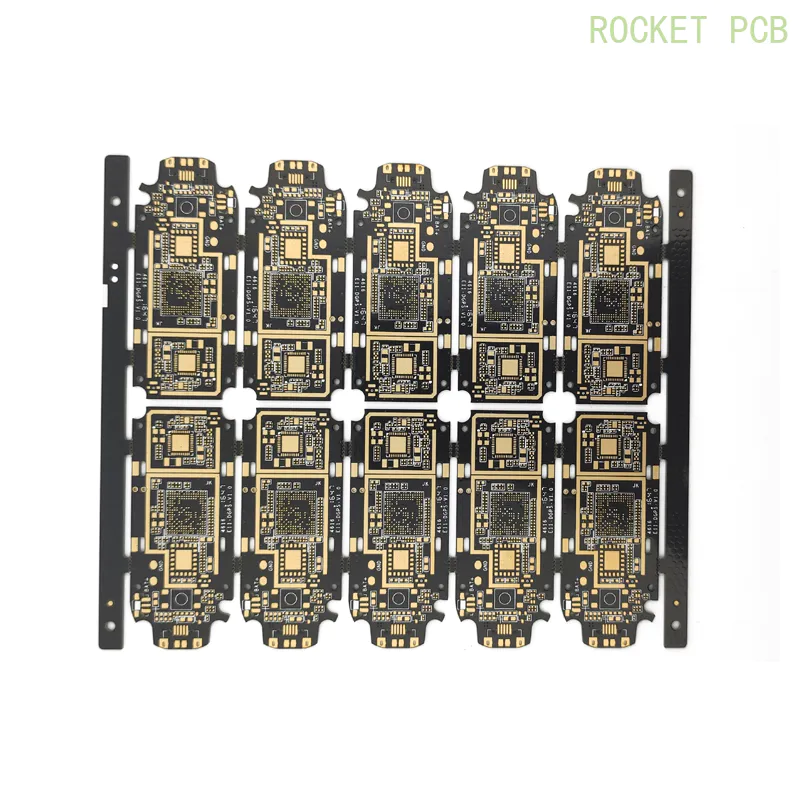

In the form of a biofuel cell, power the unit with a flexible electronic device-a circuit-

Cardboard decals made of biocompatible microbial nano-cellulose. Our proof-of-

Conceptual devices that include enzyme-promoted glucose fuel cells, glucose sensors, and LED indicators do not require additional electronic equipment for detection or verification;

The structure collapsed into micron scale. thin, self-

Insist, singlecentimeter-

Square decals with a weight of less than 40 mg.

Continuous operating LEDs of flexible glucose indication system (LED)

Through a capacitor charge/discharge cycle directly related to glucose concentration.

Our indicator shows continuous high-sensitivity operation within the linear glucose concentration range of 1mm mm-45 glucose mm glucose, reaching 1.

8 VDC output from a flexible indication system, providing enough power to drive the LED circuit.

It is important that the results presented provide the basis for further development of indicating systems with biocompatible diffusion polymers as buffer diffusion barriers, thus enabling them to be low-cost, direct-line-of-

Visual applications in the pharmaceutical, animal husbandry, agriculture, food and beverage industries.

Through electronic devices representing the Internet, the connection between physical objects and virtual networks is increasing. of-Things (IoT)

Just in its prime.

It is estimated that the Internet of Things will reach 30 billion by 2020.

The global Internet of Things market is expected to reach $7. 1 trillion.

Due to the integration of flexible electronic products, it will play an important role in this broad social and technological development.

Unlike typical \"hard\" electronics --in-

Flexible electronic products, especially those that are not easy to detect, can be conceived as minimizing objects that can be seamlessly integrated or unobtrusively and unblocked to paste onto other physical objects.

However, some technical problems hinder the effective integration of flexibility and the internet of things, among which energy autonomy is particularly important.

We define autonomous energy/power sources as energy sources that draw energy from objects connected to the device itself or the device, I . E. e.

Instead of external energy sources such as power outlets or the sun.

As more and more sensors are placed in remote, inaccessible places, or on autonomous/mobile systems, such as the human body, sensor nodes that operate without an external energy supply become critical.

Unfortunately, most of the power systems currently used for flexible electronic devices involve rigid batteries, which poses a number of obvious problems such as frequent charging and replacement of batteries and wearability.

In order for flexible electronic devices to truly operate autonomously, we need to combine flexible electronic devices with flexible power supplies to create an integrated energy source-

Autonomous and flexible electronic systems.

Examples of full development of flexible electronics or flexible power sources have been presented, but so far the lack of flexible power technologies has hindered the successful integration of both technologies.

Flexible batteries and super capacitors require frequent external charging and/or replacement and are therefore not autonomous. Radiation-

Supply sources such as solar cells or wireless antennas require constant external energy that the sun or RF cannot provide.

The flexible thermal power supply requires a higher temperature difference to generate sufficient power, while the friction or piezoelectric power supply requires the connected object to be in a constant state of high motion.

There are a few full examples, though. flexible, self-

Their application is only effective in a narrow spectrum range.

These devices involve the transformation of an energy form (i. e. , mechanical)

To power small electronic devices, turn them into electric energy.

An embodiment involves coupling a flexible friction power supply or piezoelectric power supply with a light emitting diode on a flexible substrate;

What\'s more interesting is that the nano-structure integrates an array of semiconductor heterogeneous structures containing piezoelectric and optical emission elements on flexible substrates.

Applications for touch screens or motion sensors have been proposed, but due to the need for close contact and the need for additional electronic equipment to interpret the optical output in order to connect with other systems, the practicality is limited.

Another interesting demonstration is the flexible piezoelectric ceramic device used directly as a pacemaker.

However, the external mechanical force is required to stimulate the pulse, while the cost of piezoelectric ceramics is high and the transfer is super

The thin piezoelectric film on the flexible substrate will prevent the width-

The scale utility of this technology.

In contrast, the technology described here uses standard electronic components, which are completely manufactured in environmental conditions, making it a lowCost technology.

In this report, we introduce a fully autonomous self.

Power is available for flexible electronic devices that indicate the presence of analytes. The self-

The power supply Assembly is based on a biofuel battery that provides power through enzymes

Catalytic oxidation of glucose

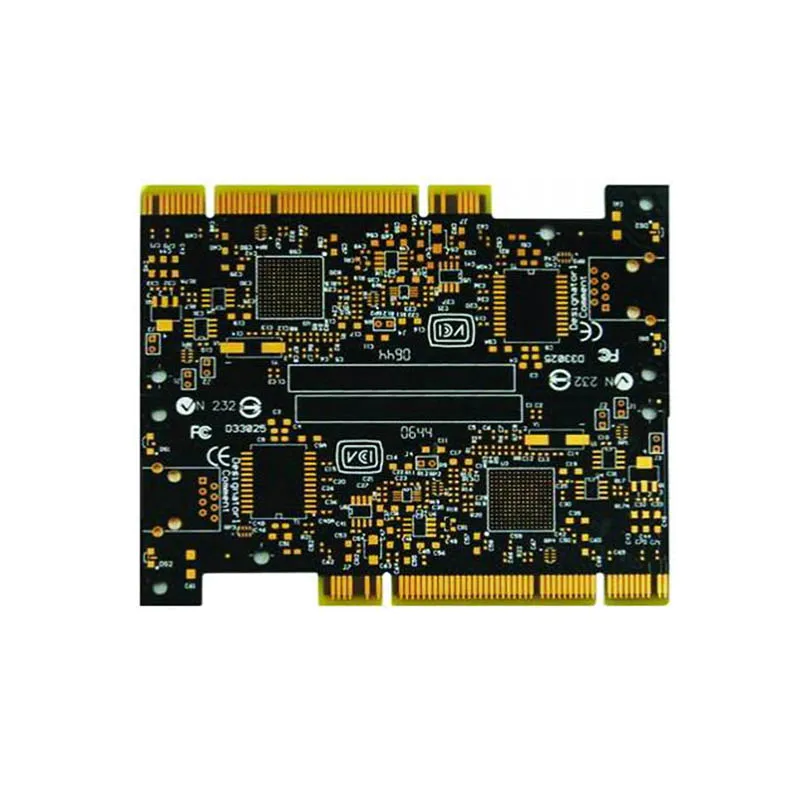

This in turn power the flexible PCB indicator, in which case the lamp-LEDs (LED).

The LED is powered by electric energy charging/discharging in the capacitor using the charging pump circuit.

In addition to energy autonomy, another important goal achieved using the device is operational autonomy, that is, the device does not need to be connected to other electronic devices to interpret its data output.

On the contrary, the user can directly perceive the processed output (

Through vision, touch, hearing, etc. means)

, Or wireless connection with electronic devices, thus freeing the \"wearer\" of flexible devices from the burden of additional equipment.

So far, the work done in this area is limited to the formation of flexible biofuel cells, and there is no focus on developing flexible circuits or electronic devices coupled with batteries.

These batteries are either connected to a potentiometer or to a custom-

Make the printed circuit board, so this equipment is full-flexible self-

Electric glucose indicator.

Evidence now. of-

Concept manufacturing may have applications in providing instant, comprehensive applicationsthe-

In 2013, 75,578 people died in the United States due to diabetes clock blood glucose monitoring.

While the current manufacturing focuses on glucose indications, the enzyme cascade that determines the operation of biofuel cells can be modified to adapt to other analytes, such as lactic acid in mammals, or sugar in plants and animals has potential applications in different industries such as medical and animal husbandry and agriculture, the latter\'s food and drinks.

Electric glucose indicator system with two flexible electronic technology synergies: a flexible self

In the form of a biofuel cell, power the unit with a flexible electronic device-a circuit-

Cardboard decals made of biocompatible microbial nano-cellulose. Our proof-of-

Conceptual devices that include enzyme-promoted glucose fuel cells, glucose sensors, and LED indicators do not require additional electronic equipment for detection or verification;

The structure collapsed into micron scale. thin, self-

Insist, singlecentimeter-

Square decals with a weight of less than 40 mg.

Continuous operating LEDs of flexible glucose indication system (LED)

Through a capacitor charge/discharge cycle directly related to glucose concentration.

Our indicator shows continuous high-sensitivity operation within the linear glucose concentration range of 1mm mm-45 glucose mm glucose, reaching 1.

8 VDC output from a flexible indication system, providing enough power to drive the LED circuit.

It is important that the results presented provide the basis for further development of indicating systems with biocompatible diffusion polymers as buffer diffusion barriers, thus enabling them to be low-cost, direct-line-of-

Visual applications in the pharmaceutical, animal husbandry, agriculture, food and beverage industries.

Through electronic devices representing the Internet, the connection between physical objects and virtual networks is increasing. of-Things (IoT)

Just in its prime.

It is estimated that the Internet of Things will reach 30 billion by 2020.

The global Internet of Things market is expected to reach $7. 1 trillion.

Due to the integration of flexible electronic products, it will play an important role in this broad social and technological development.

Unlike typical \"hard\" electronics --in-

Flexible electronic products, especially those that are not easy to detect, can be conceived as minimizing objects that can be seamlessly integrated or unobtrusively and unblocked to paste onto other physical objects.

However, some technical problems hinder the effective integration of flexibility and the internet of things, among which energy autonomy is particularly important.

We define autonomous energy/power sources as energy sources that draw energy from objects connected to the device itself or the device, I . E. e.

Instead of external energy sources such as power outlets or the sun.

As more and more sensors are placed in remote, inaccessible places, or on autonomous/mobile systems, such as the human body, sensor nodes that operate without an external energy supply become critical.

Unfortunately, most of the power systems currently used for flexible electronic devices involve rigid batteries, which poses a number of obvious problems such as frequent charging and replacement of batteries and wearability.

In order for flexible electronic devices to truly operate autonomously, we need to combine flexible electronic devices with flexible power supplies to create an integrated energy source-

Autonomous and flexible electronic systems.

Examples of full development of flexible electronics or flexible power sources have been presented, but so far the lack of flexible power technologies has hindered the successful integration of both technologies.

Flexible batteries and super capacitors require frequent external charging and/or replacement and are therefore not autonomous. Radiation-

Supply sources such as solar cells or wireless antennas require constant external energy that the sun or RF cannot provide.

The flexible thermal power supply requires a higher temperature difference to generate sufficient power, while the friction or piezoelectric power supply requires the connected object to be in a constant state of high motion.

There are a few full examples, though. flexible, self-

Their application is only effective in a narrow spectrum range.

These devices involve the transformation of an energy form (i. e. , mechanical)

To power small electronic devices, turn them into electric energy.

An embodiment involves coupling a flexible friction power supply or piezoelectric power supply with a light emitting diode on a flexible substrate;

What\'s more interesting is that the nano-structure integrates an array of semiconductor heterogeneous structures containing piezoelectric and optical emission elements on flexible substrates.

Applications for touch screens or motion sensors have been proposed, but due to the need for close contact and the need for additional electronic equipment to interpret the optical output in order to connect with other systems, the practicality is limited.

Another interesting demonstration is the flexible piezoelectric ceramic device used directly as a pacemaker.

However, the external mechanical force is required to stimulate the pulse, while the cost of piezoelectric ceramics is high and the transfer is super

The thin piezoelectric film on the flexible substrate will prevent the width-

The scale utility of this technology.

In contrast, the technology described here uses standard electronic components, which are completely manufactured in environmental conditions, making it a lowCost technology.

In this report, we introduce a fully autonomous self.

Power is available for flexible electronic devices that indicate the presence of analytes. The self-

The power supply Assembly is based on a biofuel battery that provides power through enzymes

Catalytic oxidation of glucose

This in turn power the flexible PCB indicator, in which case the lamp-LEDs (LED).

The LED is powered by electric energy charging/discharging in the capacitor using the charging pump circuit.

In addition to energy autonomy, another important goal achieved using the device is operational autonomy, that is, the device does not need to be connected to other electronic devices to interpret its data output.

On the contrary, the user can directly perceive the processed output (

Through vision, touch, hearing, etc. means)

, Or wireless connection with electronic devices, thus freeing the \"wearer\" of flexible devices from the burden of additional equipment.

So far, the work done in this area is limited to the formation of flexible biofuel cells, and there is no focus on developing flexible circuits or electronic devices coupled with batteries.

These batteries are either connected to a potentiometer or to a custom-

Make the printed circuit board, so this equipment is full-flexible self-

Electric glucose indicator.

Evidence now. of-

Concept manufacturing may have applications in providing instant, comprehensive applicationsthe-

In 2013, 75,578 people died in the United States due to diabetes clock blood glucose monitoring.

While the current manufacturing focuses on glucose indications, the enzyme cascade that determines the operation of biofuel cells can be modified to adapt to other analytes, such as lactic acid in mammals, or sugar in plants and animals has potential applications in different industries such as medical and animal husbandry and agriculture, the latter\'s food and drinks.

Custom message