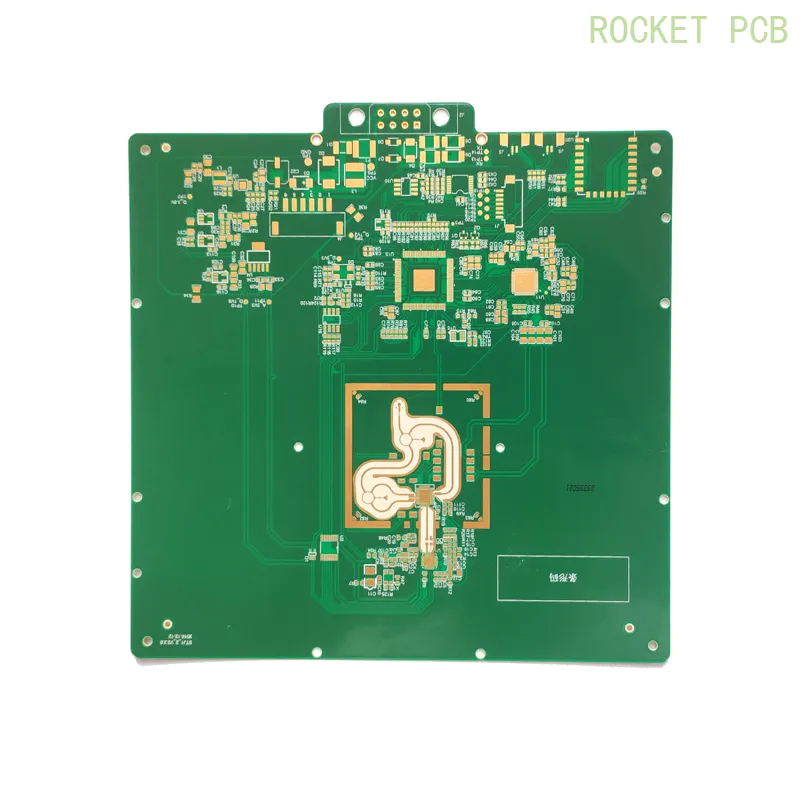

A common fault analysis circuit board

by:Rocket PCB

2020-06-11

Stand or fall of various electrical fault probably includes the following several ways: a, poor contact: PCB board and slot when poor contact, the cable is broken inside the impassability, spark plug and terminal blocks, welding contact is bad, components, etc are such.

A solution to this kind of failure is a careful examination of suspected connectors, see if there are any obvious oxidation or contact undesirable phenomenon, scraping file, oxidation of the metal contact dial to adjust the position of contact point, after processing to dial test contact are in good condition.

Signal interference: for digital circuits, in the case of a certain I drunk to sleep under, failure to be present.

May interfere with too big impact control system does make its error, also have a circuit board component parameters or individual overall performance parameters changed, make the anti-interference ability toward a tipping point, thus fault occurs.

This kind of failure on check grounding device is good, use test pencil check whether the equipment enclosure is charged, or to communicate in the table is used to measure the shell of the earth if there is a high voltage equipment, generally below 1 v, if more than 10 v will doubt whether good grounding.

/ PCB PCB circuit boards, circuit boards such as moisture, dust, moisture and dust will be conductive, the resistance effect, but also in the process of heat bilges cold shrink, the resistance will also change, the resistance value in conjunction with other components associated with the effect, the effect is stronger when can change the circuit parameters, make failure.

This kind of failure can be solved through the circuit board to clean.

Recommend the use of washing water cleaning circuit board, or directly use clean water, use hair dryer to dry thoroughly again.

Don't recommend the use of alcohol, because alcohol after cleaning is very easy to leave some white stuff on the plate.

Four bad thermal stability, components: from a lot of maintenance practice, most notably the thermal stability of the electrolytic capacitor is bad, followed by other capacitor, transistor, diode, IC, resistance, etc.

1, thermal stability failure belongs to the soft failure, repair is not easy to directly determine the fault detection element, but can be used to artificially suspect components of heating or cooling way to narrow the scope of inspection.

Can use hair dryer or electric gun to doubt heating element, use cotton swabs dipped in alcohol to doubt element cooling temperature.

And the stand or fall of capacitor using the VI curve test is easy to distinguish.

2, the fault will typically associated with machine boot time and appear or disappear, essence is fault changes over a fault element temperature.

Electrolytic capacitor ageing caused by fault, for example, are usually just electricity failure, and electricity fault disappeared after a period of time, namely the cold machine has fault, trouble-free and engine.

The essence of which is: aging of electrolytic capacitor capacitance with temperature changes, the low temperature capacity small, filtering harmful, circuit board can't work normally, and with the current time, director of the people of electrolytic capacitor temperature rise, capacity increases, filtering conditions, thus fault and vanished.

Five, the software is also one factor: using software to adjust the circuits of many parameters, some parameters of margin adjusted too low, in the critical range, when the machine operation comply with software fault reason, then the alarm will appear.

This kind of failure can be solved by adjusting the related parameters.

Such as frequency converter, deceleration time, if the Settings, run time, could be seen through the load alarm;

CNC machining parameter Settings, processing product may not conform to the requirements, encounter these situations, the first time to doubt parameter setting problem, rule out the possibility of parameter Settings wrong to doubt after the equipment itself.

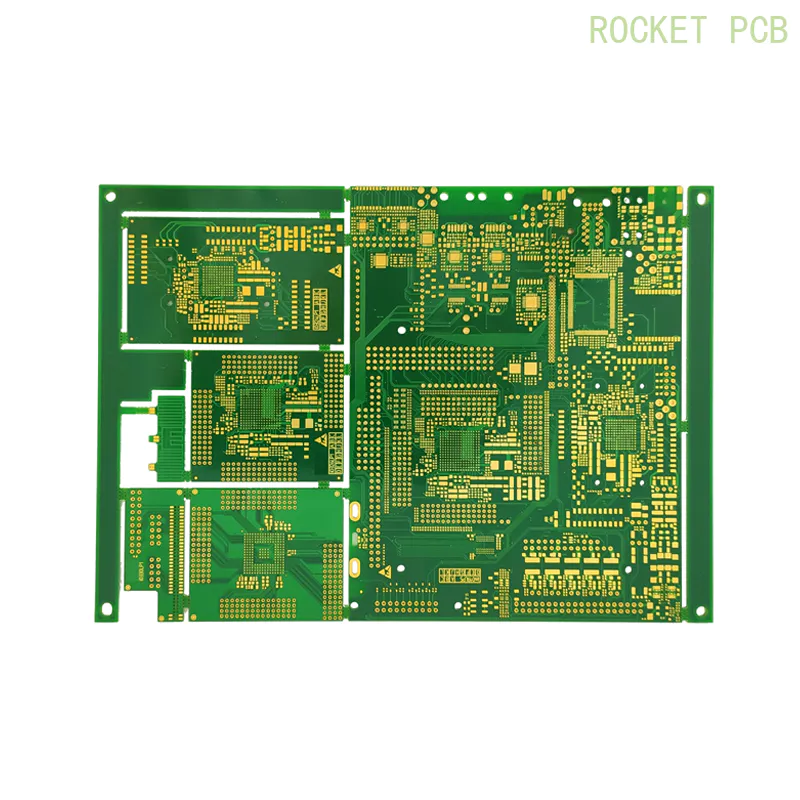

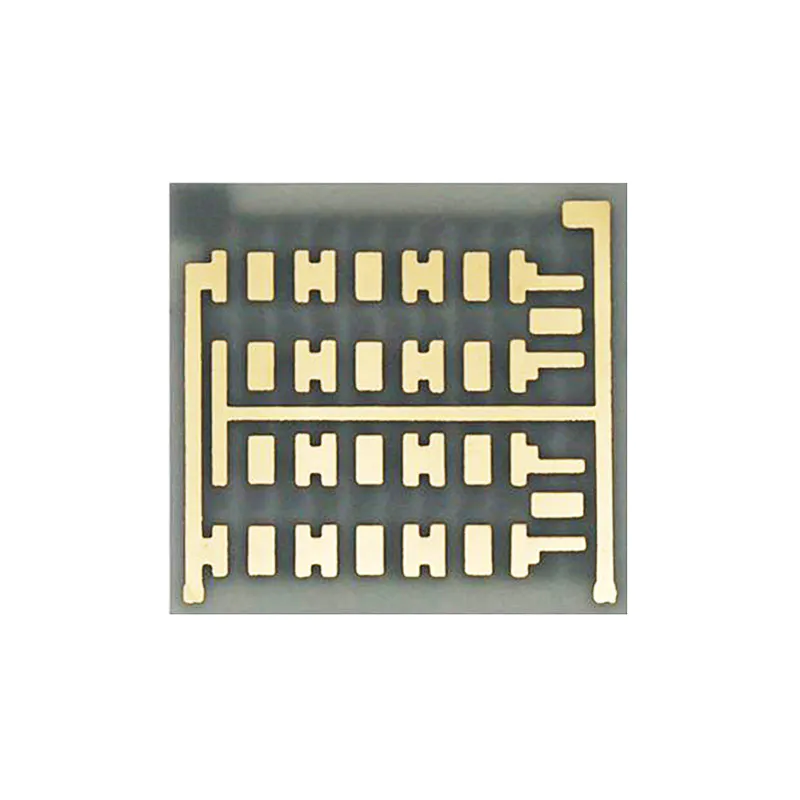

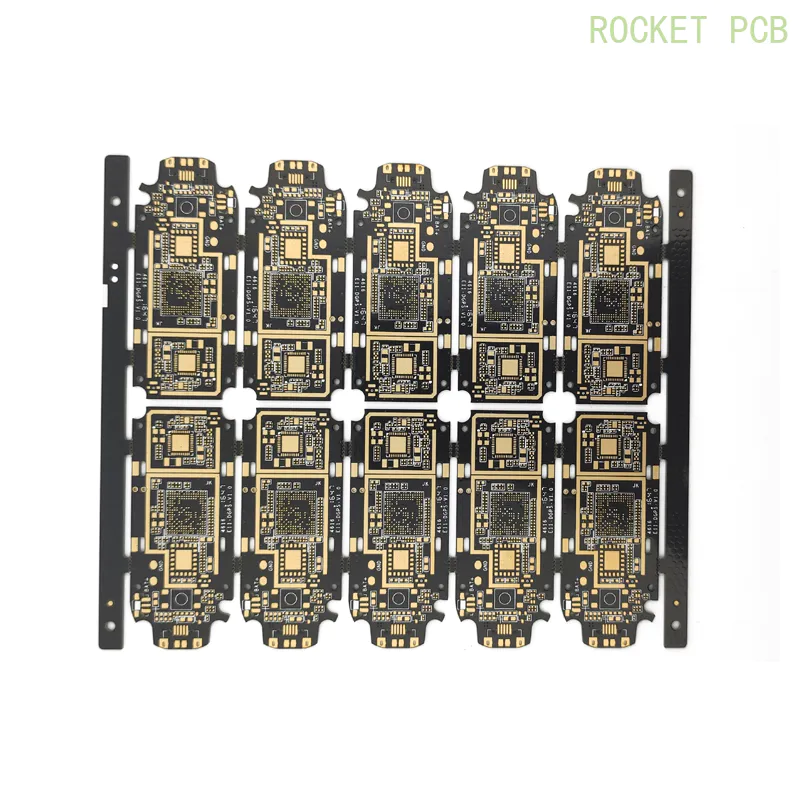

Rocket PCB Solution Ltd. is dedicated to servicing our customers with a wide array of high-quality service and products.

Review Rocket PCB Solution Ltd.'s progress at regular intervals, so we can continue with the strategies that work well and change or eliminate the ones that don't give the results we are looking for.

Basically, you cannot have a pcb manufacturing services without having the right pcb making service. Since you are going to use it regularly, be sure to invest in one that has a high quality.

Rocket PCB Solution Ltd. is dedicated to servicing our customers with a wide array of high-quality service and products.

Review Rocket PCB Solution Ltd.'s progress at regular intervals, so we can continue with the strategies that work well and change or eliminate the ones that don't give the results we are looking for.

Basically, you cannot have a pcb manufacturing services without having the right pcb making service. Since you are going to use it regularly, be sure to invest in one that has a high quality.

Custom message